Double-fluid jet nozzle for cleaning, cleaner and method for making semiconductor using same

A dual-fluid nozzle and cleaning device technology, which can be used in liquid ejection devices, semiconductor/solid-state device manufacturing, and ejection devices, etc., can solve problems such as re-attachment, easy-to-adhesion particles, and fine pattern damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

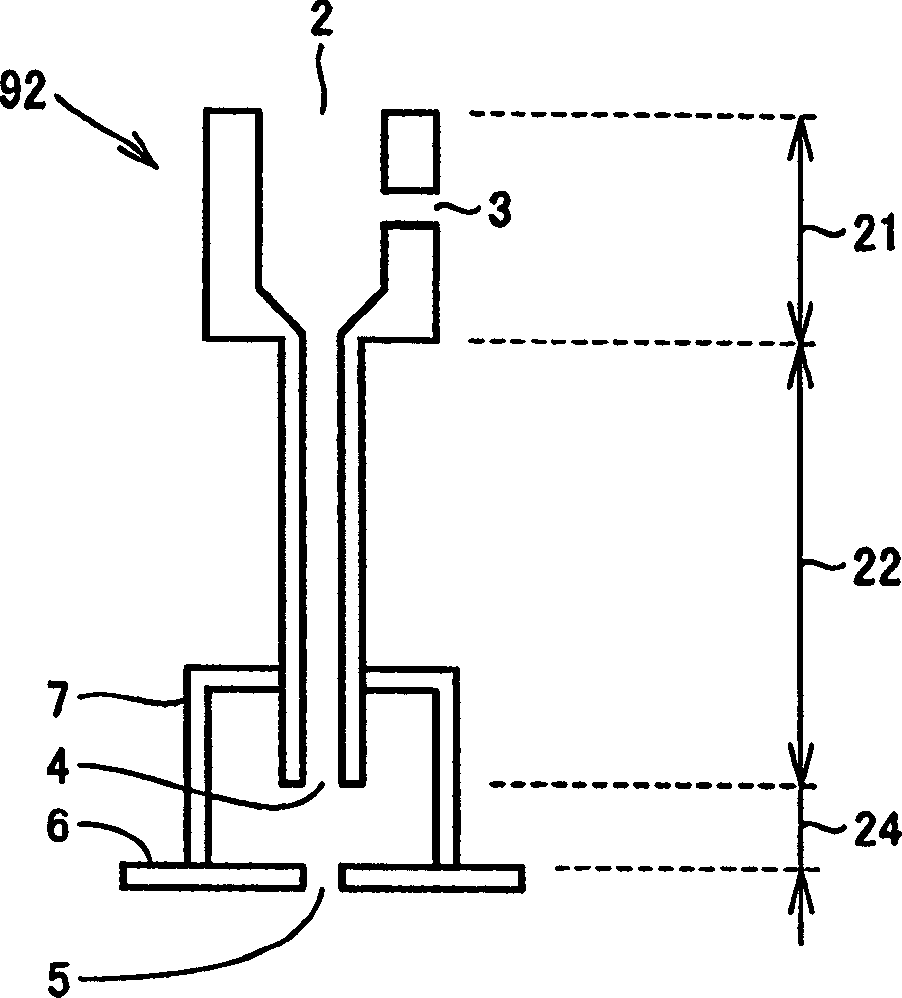

[0038] Refer below Figure 5 The cleaning two-fluid nozzle 93 according to Embodiment 3 of the present invention will be described. This two-fluid nozzle 93 for cleaning has a structure in which the gas shield 6 is connected to the two-fluid nozzle 91 for cleaning shown in the first embodiment.

[0039] In the case of the two-fluid nozzle 93 for cleaning, most of the gas is not directly blown to the target due to the double effect of the curved portion 23 described in Embodiment 1 and the effect of the baffle plate described in Embodiment 2. On the cleaning surface, it is discharged from the side surface from the gap 25 between the bent portion 23 and the gas shielding plate 6 . Therefore, adhesion of particles to the surface to be cleaned can be suppressed, and damage to fine patterns caused by the impact of particles can be prevented.

[0040] (implementation form 4)

[0041] Refer below Figure 6 A cleaning device according to Embodiment 4 of the present invention will ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com