Circuit element assembling method

A circuit board and connecting board technology, which is applied in the direction of electrical components, electrical components, and electrical components to assemble printed circuits, etc., can solve problems such as increasing production capacity, shortening production process, and uncoordinated production capacity of semi-finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

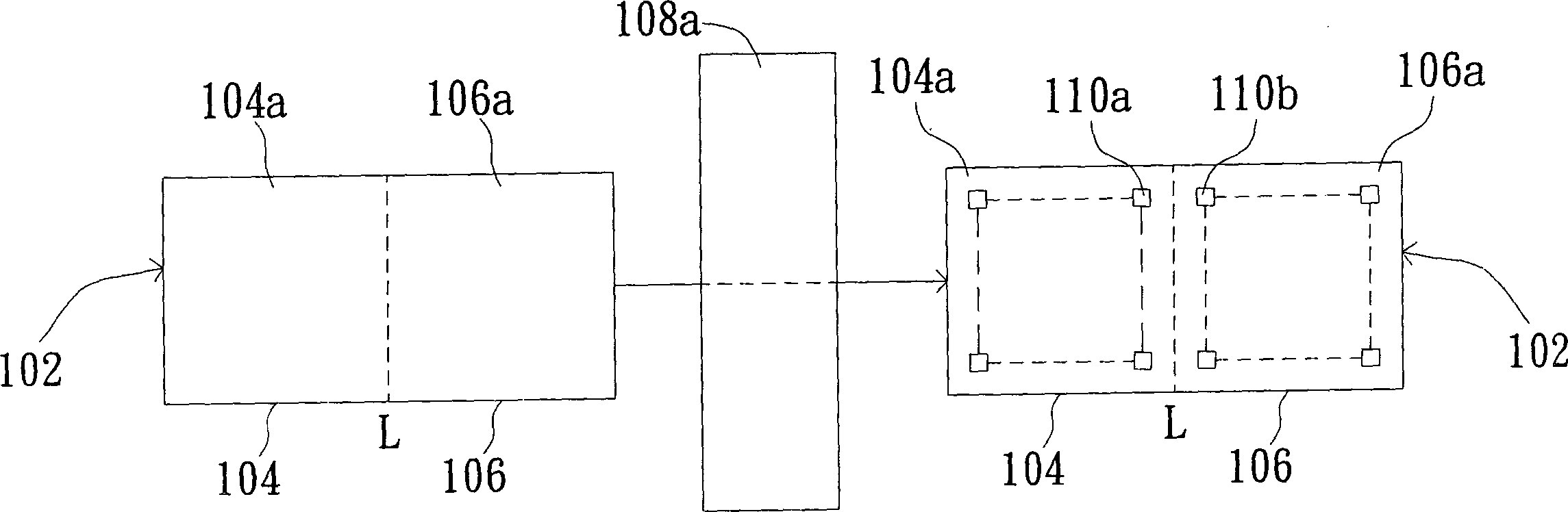

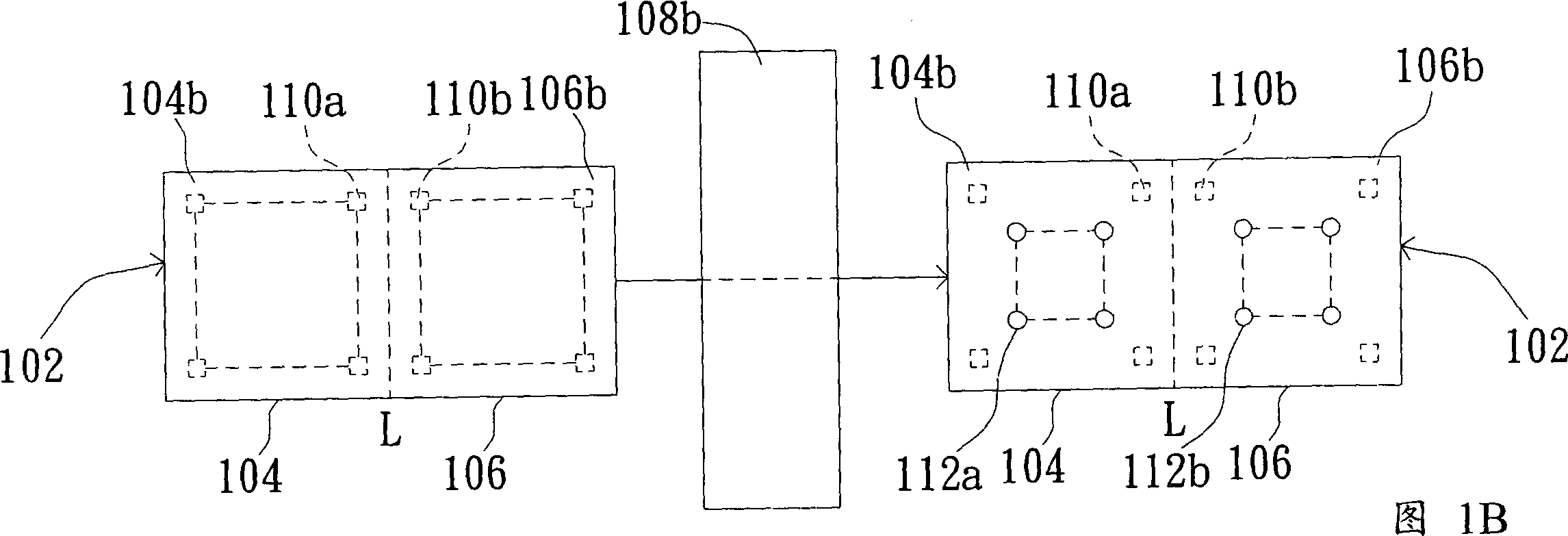

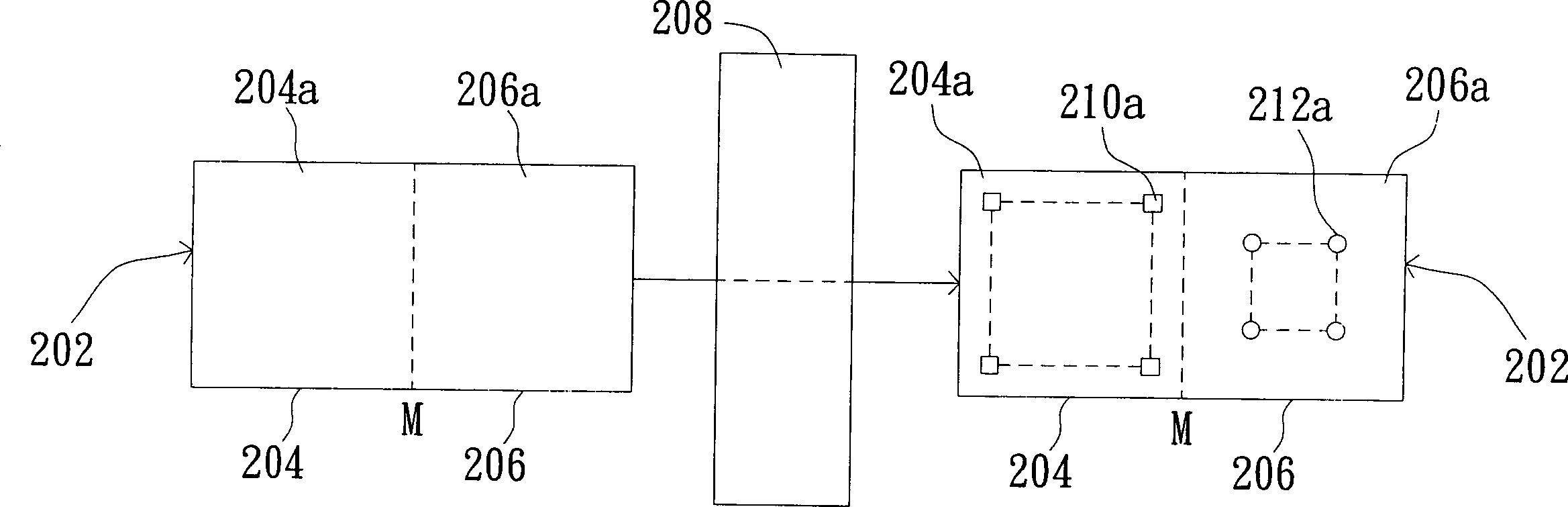

[0018] The present invention specially designs a coupling board punching method for a circuit board. At first, a coupling board with 2N substrates is provided. The value of N is a positive integer. The front side of the coupling board consists of the fronts of N substrates and N connected to the opposite side of a substrate. Then, the coupling board is sent into a punching machine for punching, and several front parts and several reverse parts are formed on the front faces of N substrates and the reverse faces of the other N substrates respectively. Then, the coupling plate is turned over, and the reverse side of the coupling plate is formed by connecting the reverse surfaces of N substrates and the front surfaces of other N substrates. Then, the coupler plate is sent into the punching machine to be punched, and another several front parts are formed on the front faces of the other N substrates, and another several reverse parts are formed on the reverse faces of the N substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com