Conductive element and liquid crystal display with said conductive element

A liquid crystal display and conductive element technology, applied in the field of liquid crystal displays, can solve the problems of increased number of parts, increased assembly steps of assembled parts, space difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

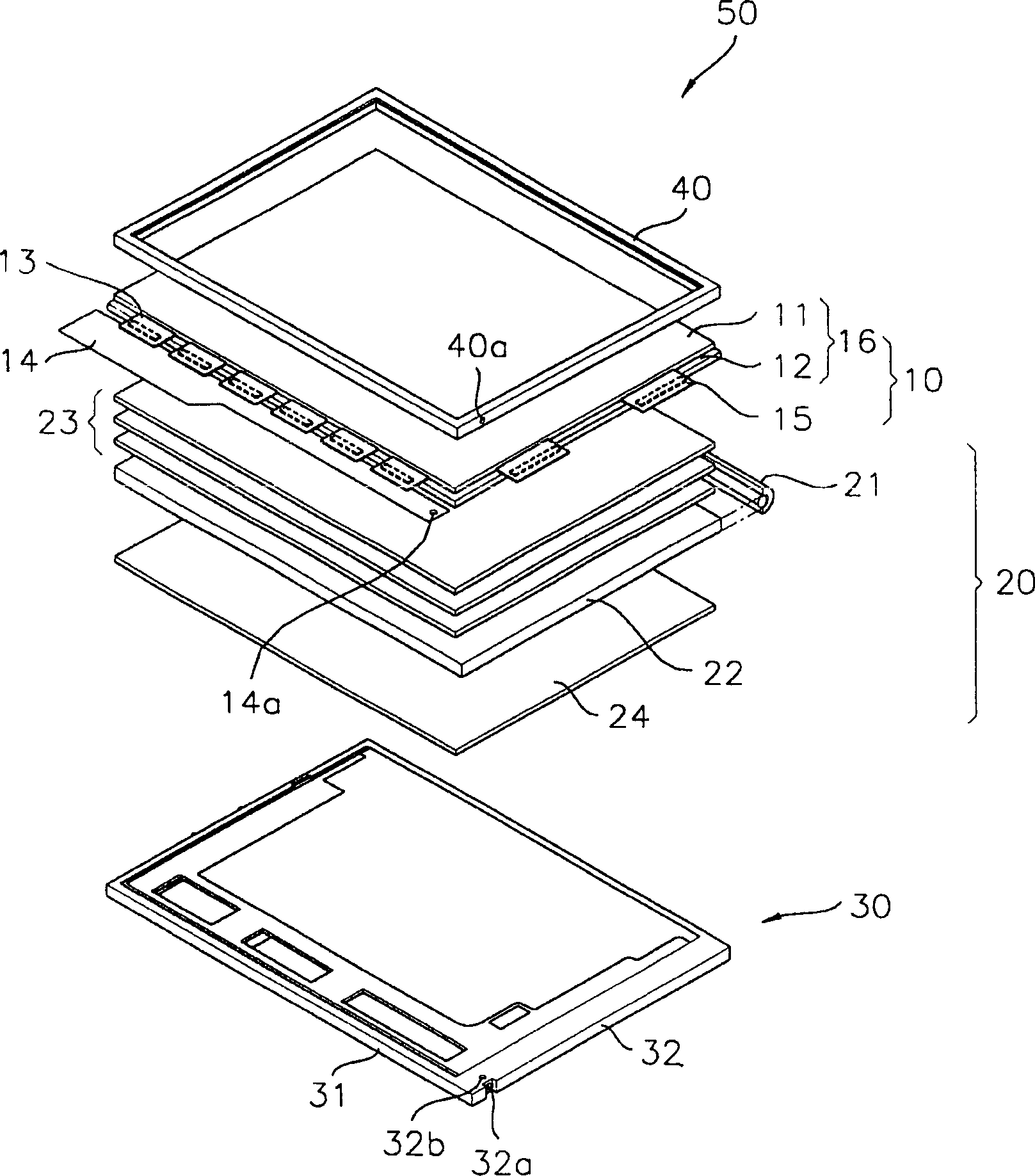

[0040] Figure 4 is an exploded perspective view of an LCD according to an embodiment of the present invention;

[0041] refer to Figure 4 , LCD500 comprises: the display unit 100 of displaying image, the backlight assembly 200 that provides light to display unit 100, the frame 300 that installs display unit 100 and backlight assembly 200, the base plate 400 that display unit 100 is fixed on the frame 300. Although not shown in the drawings, the LCD 500 is installed in front and rear cases (not shown).

[0042] The display unit 100 includes an LCD panel 160 and an integrated PCB 140 that controls the operation of the LCD panel 160 .

[0043] The LCD panel 160 has a thin film type semiconductor substrate 120, a color filter substrate 110 disposed facing the thin film type semiconductor substrate 120, and a liquid crystal layer (not shown) fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com