Patents

Literature

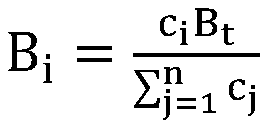

32results about How to "Eliminate alignment errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

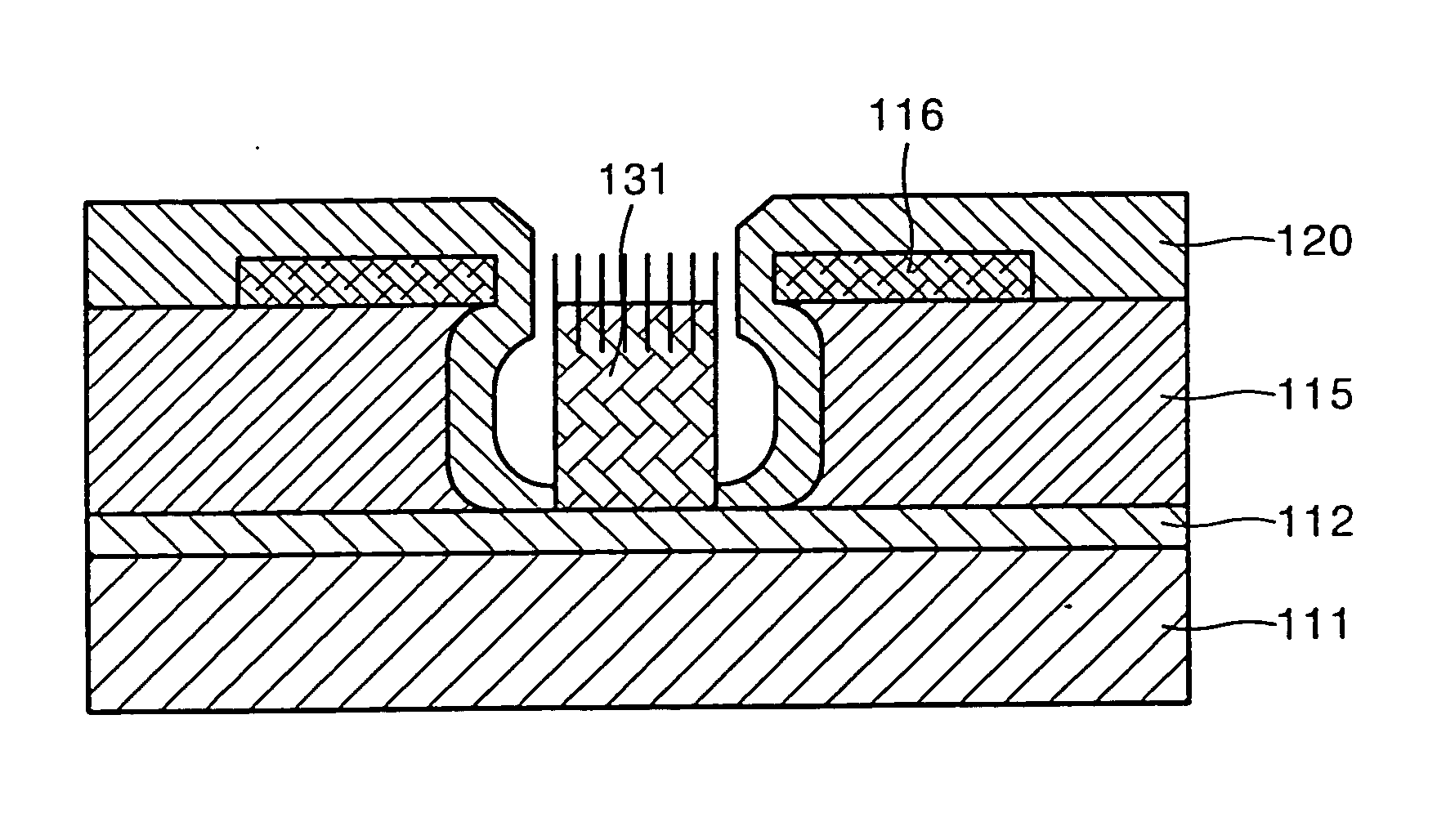

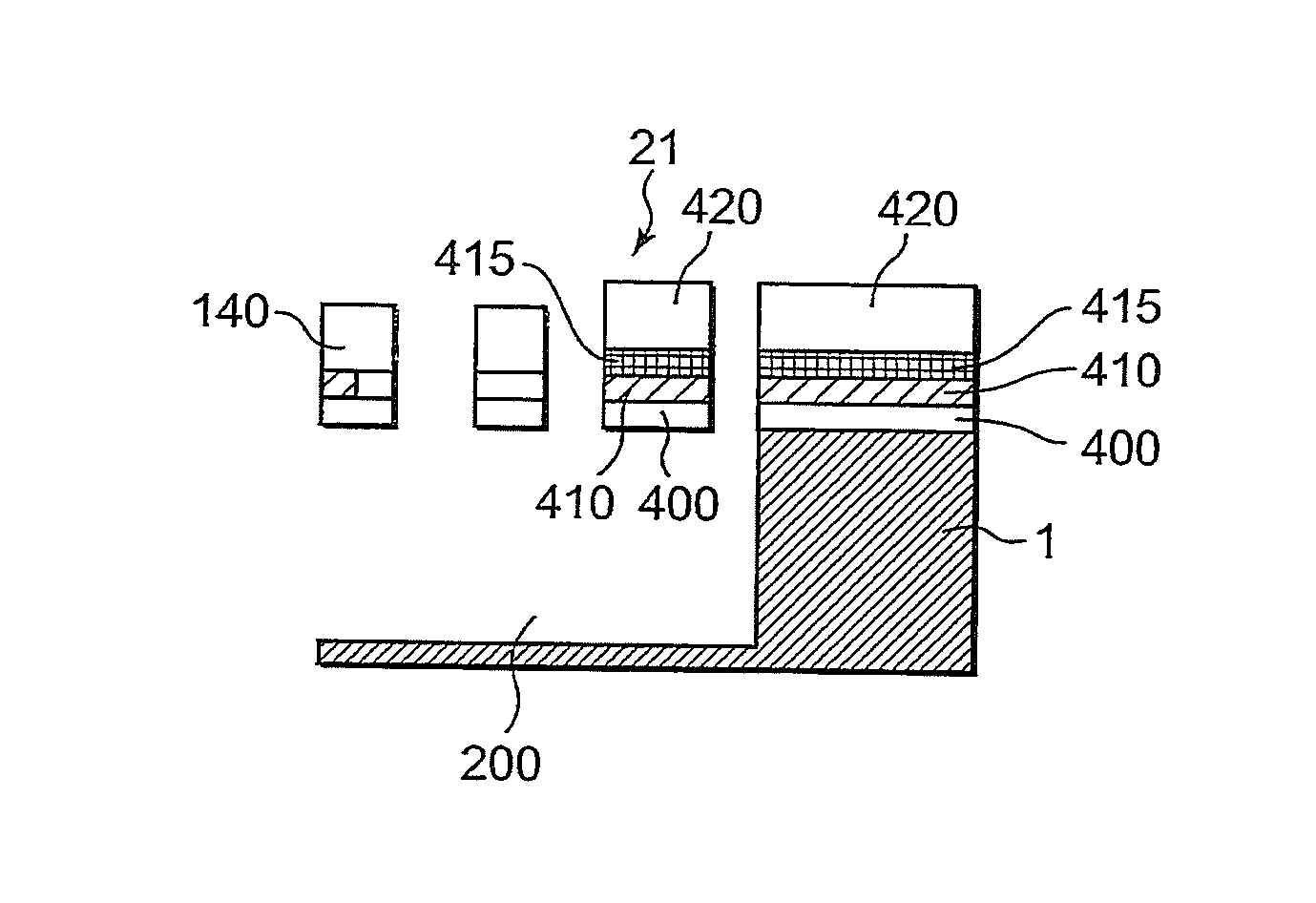

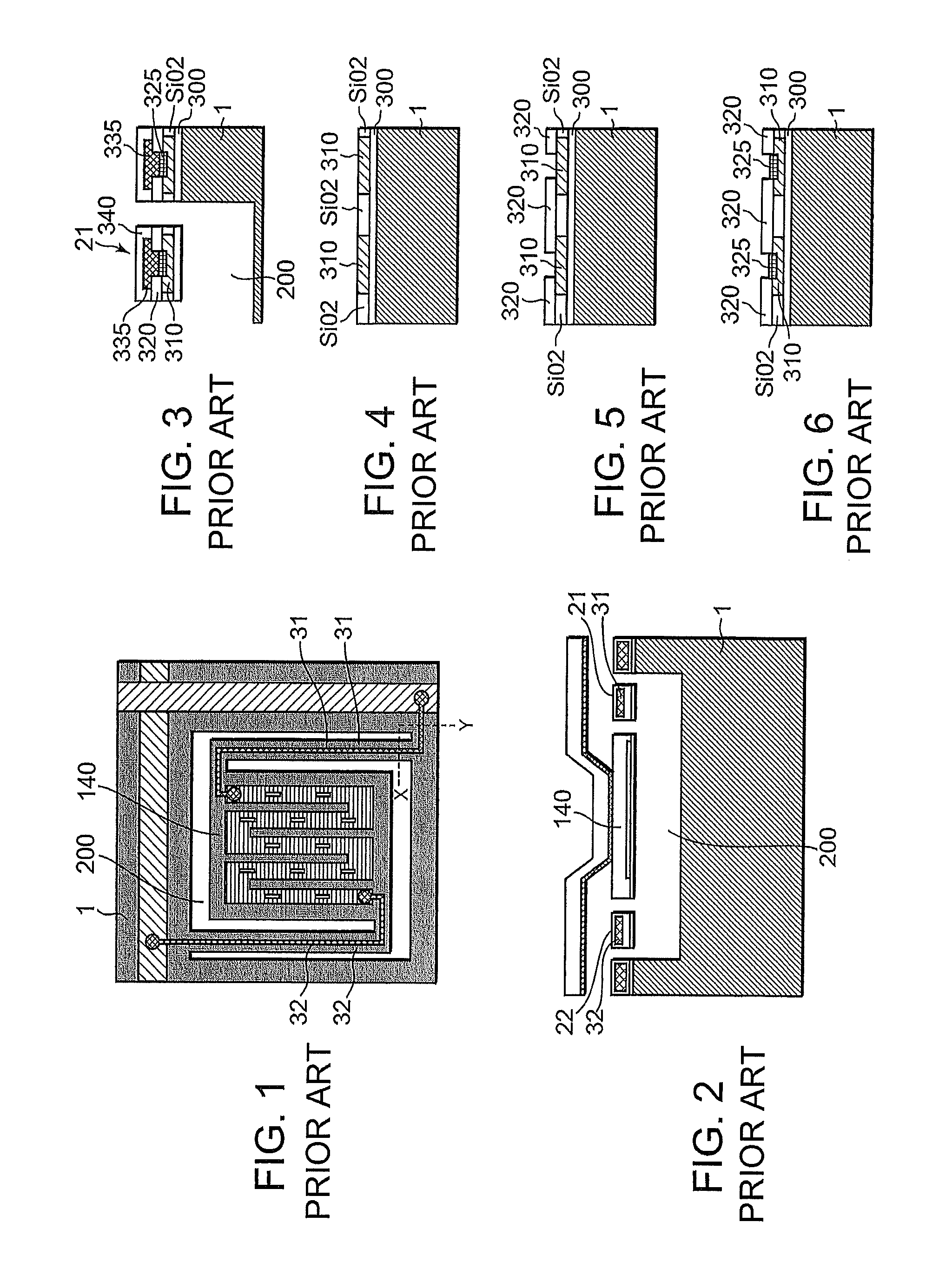

Semiconductor device comprising light-emitting element and light-receiving element, and manufacturing method therefor

InactiveUS20060065964A1Small sizeAvoid disconnectionTelevision system detailsSemiconductor/solid-state device detailsDevice materialSemiconductor chip

A semiconductor device includes a substrate for transmitting light, a wiring layer provided on the substrate, a semiconductor chip formed on the wiring layer, a columnar electrode, a sealant, and an external connection terminal electrically connected to the semiconductor chip via the wiring layer and protruding electrode. The device includes a cut surface formed by dicing and constituted by only the substrate and the sealant. Since the cut surface has a single-layer structure as a result of forming the sealant in a single step, moisture cannot infiltrate through the sealant, hence a device resistant to corrosion and operational defects is provided.

Owner:LAPIS SEMICON CO LTD

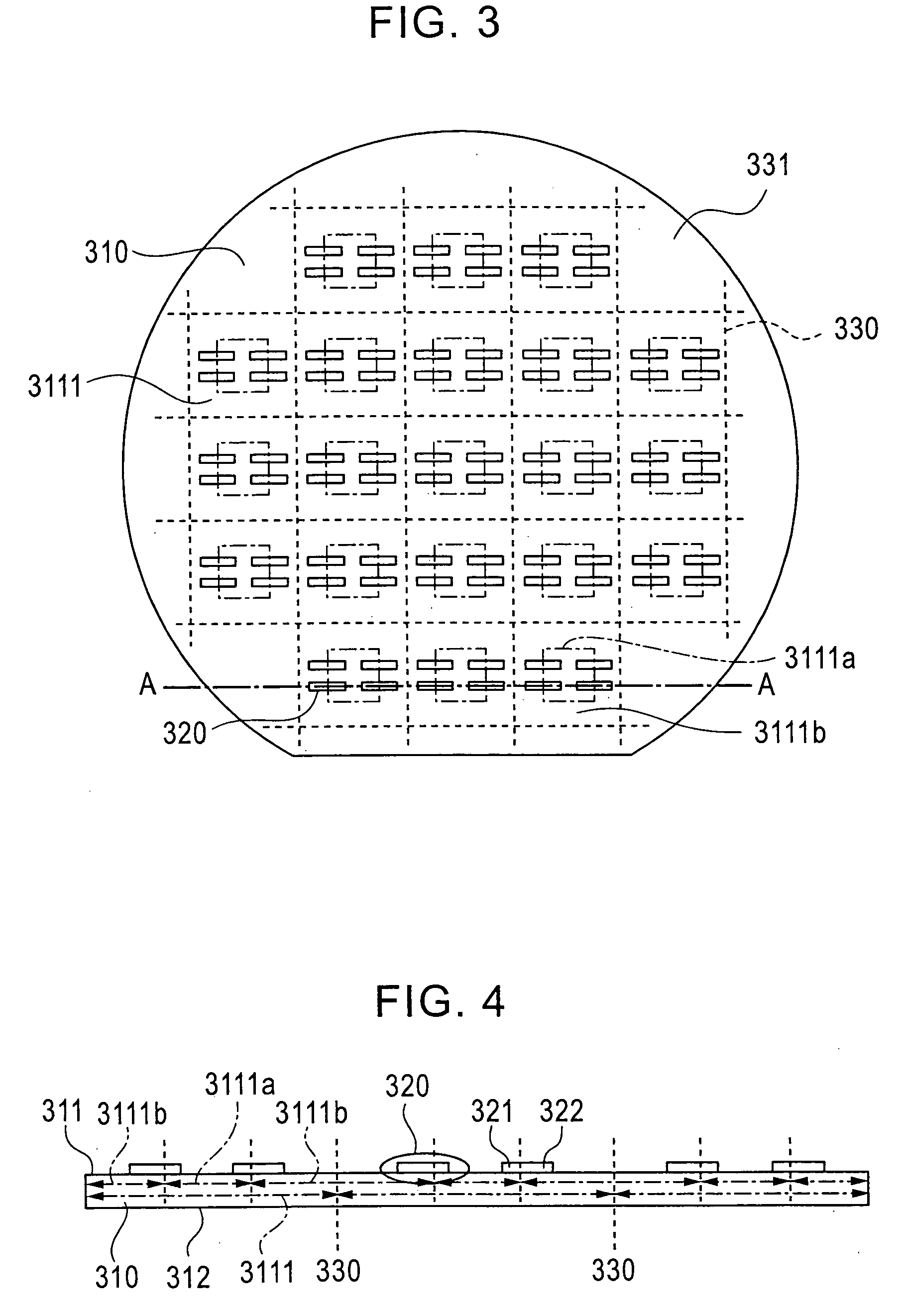

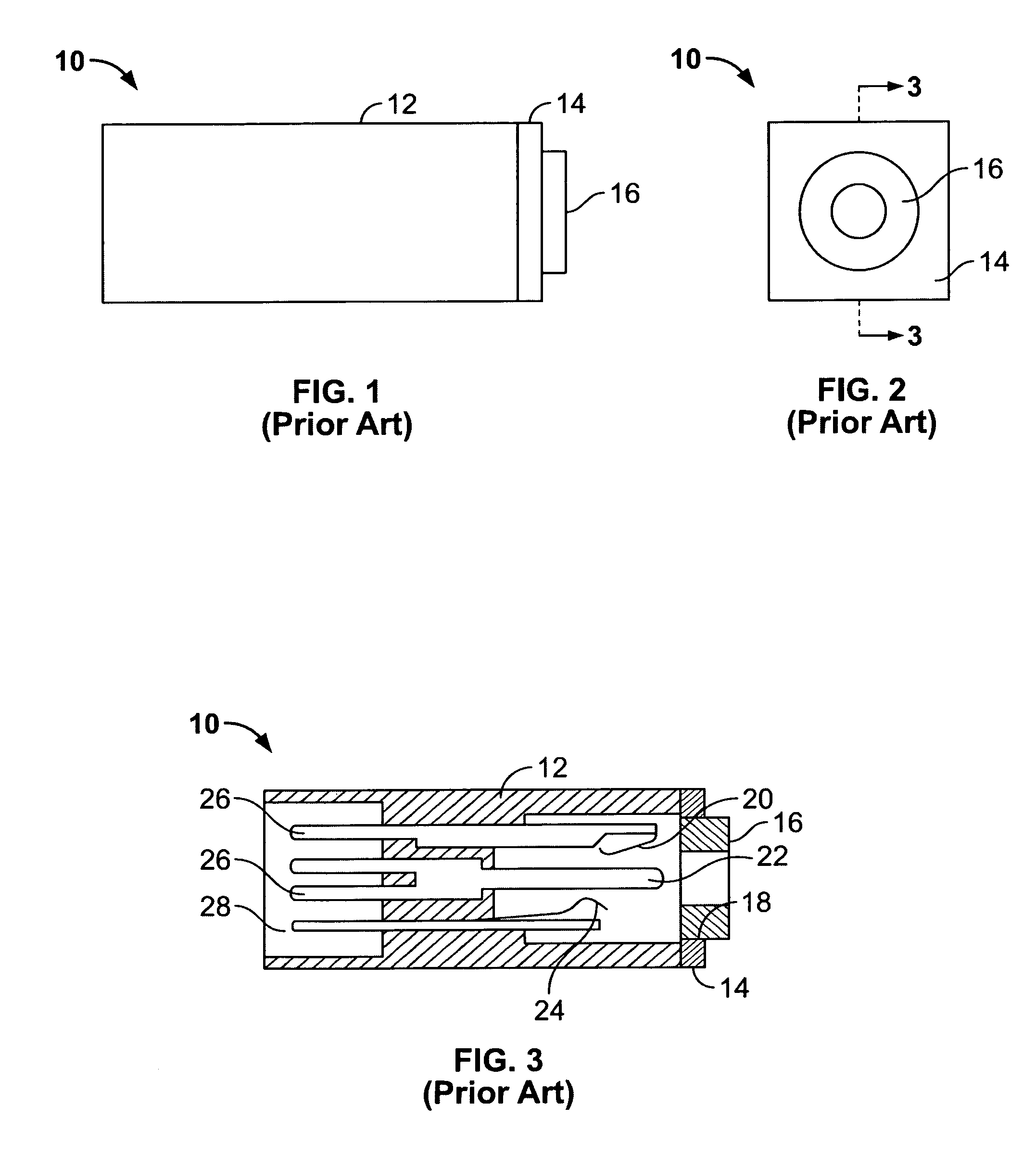

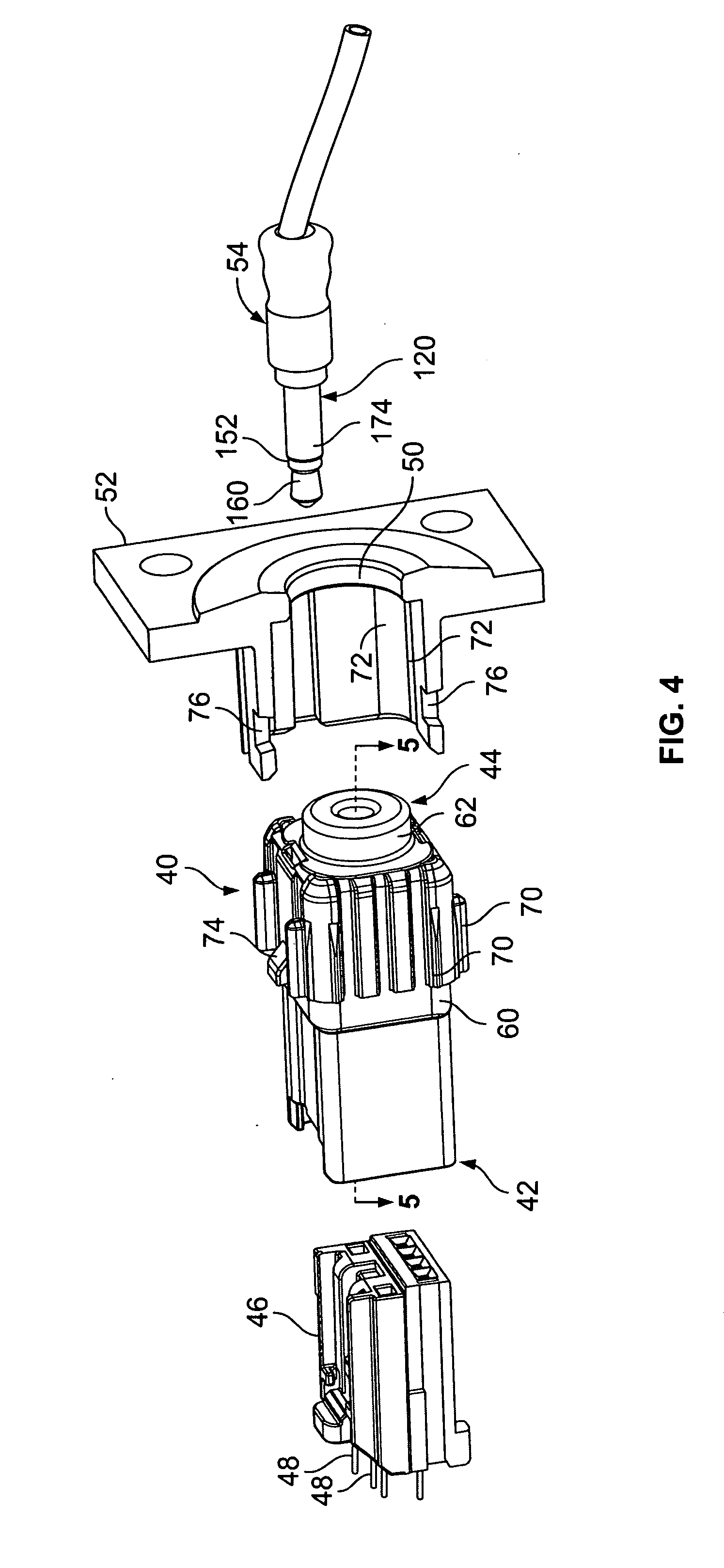

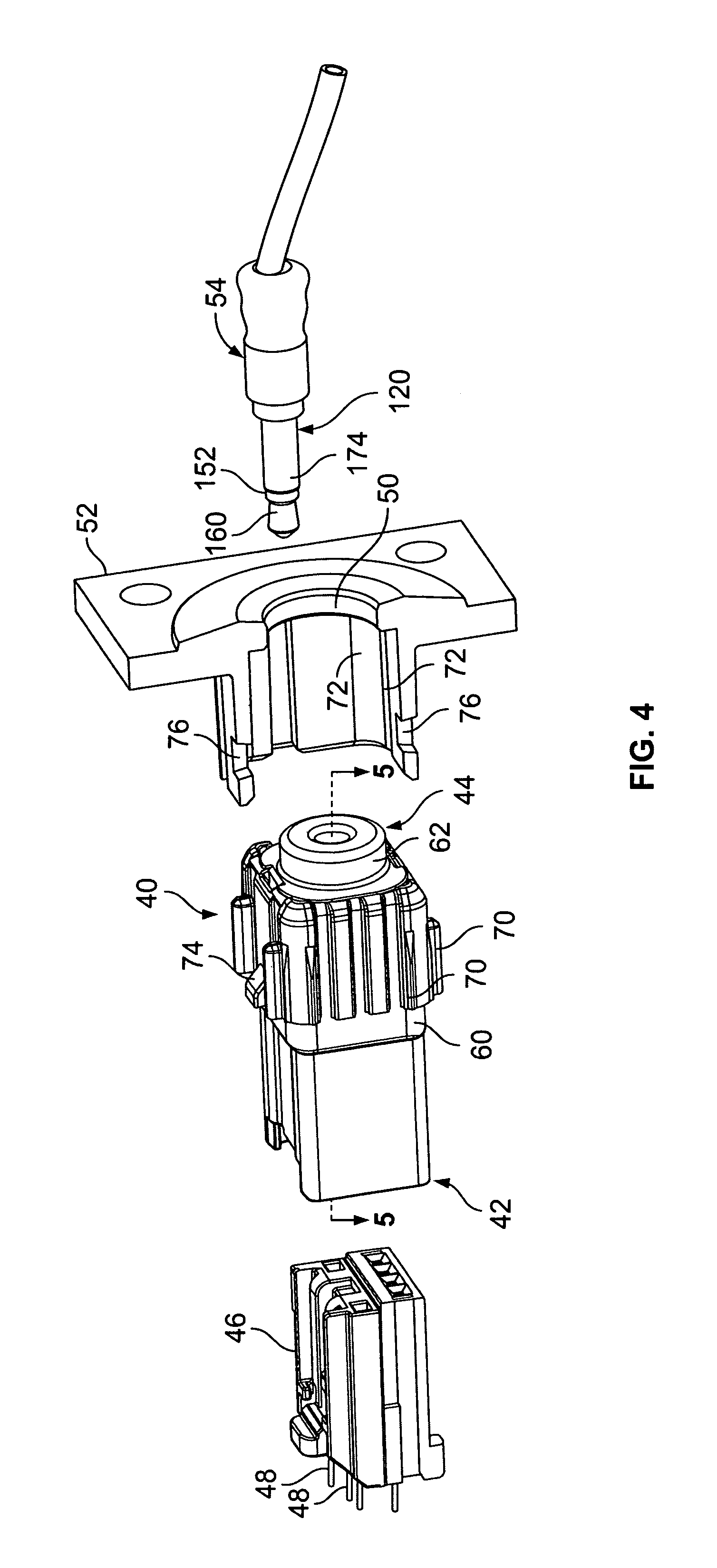

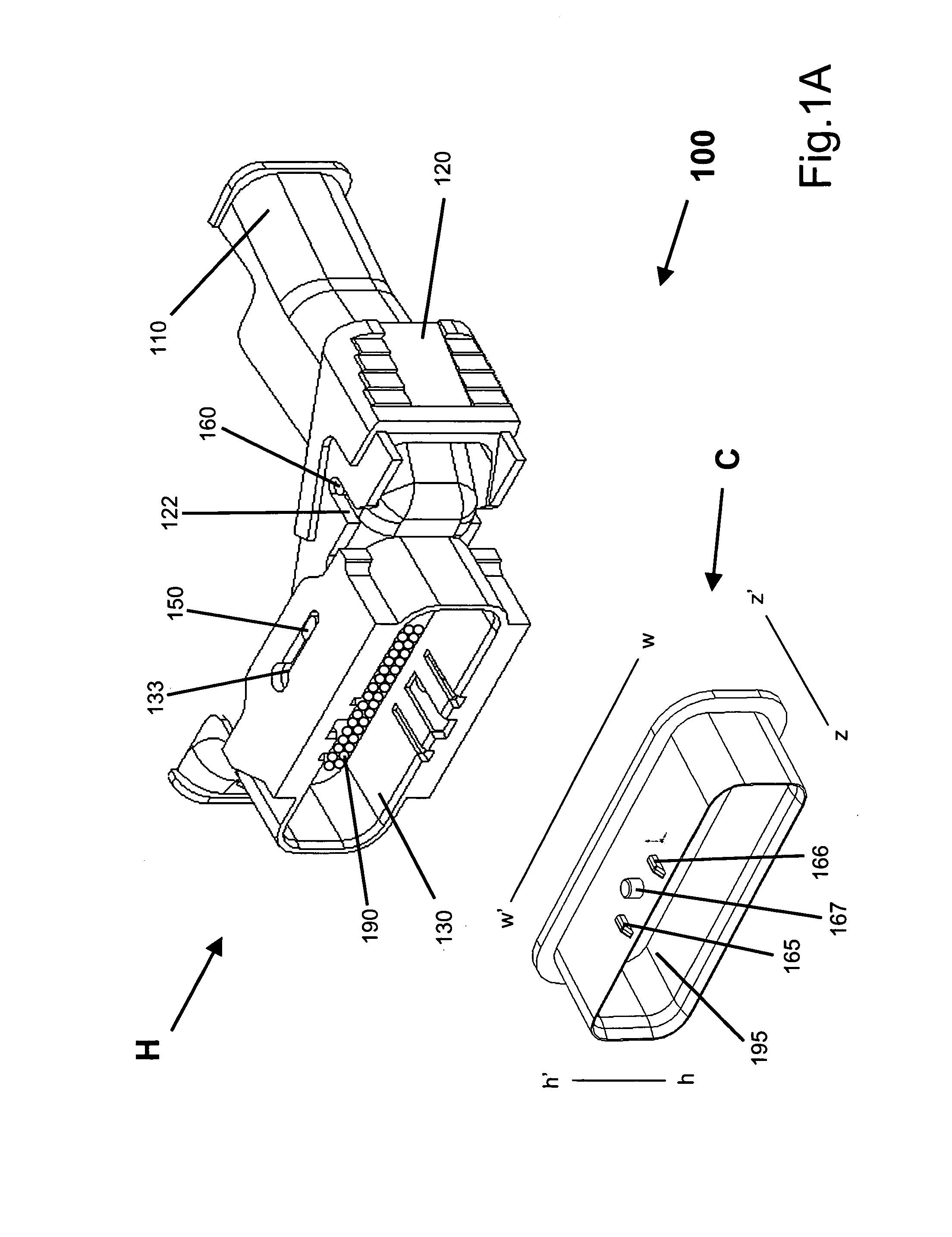

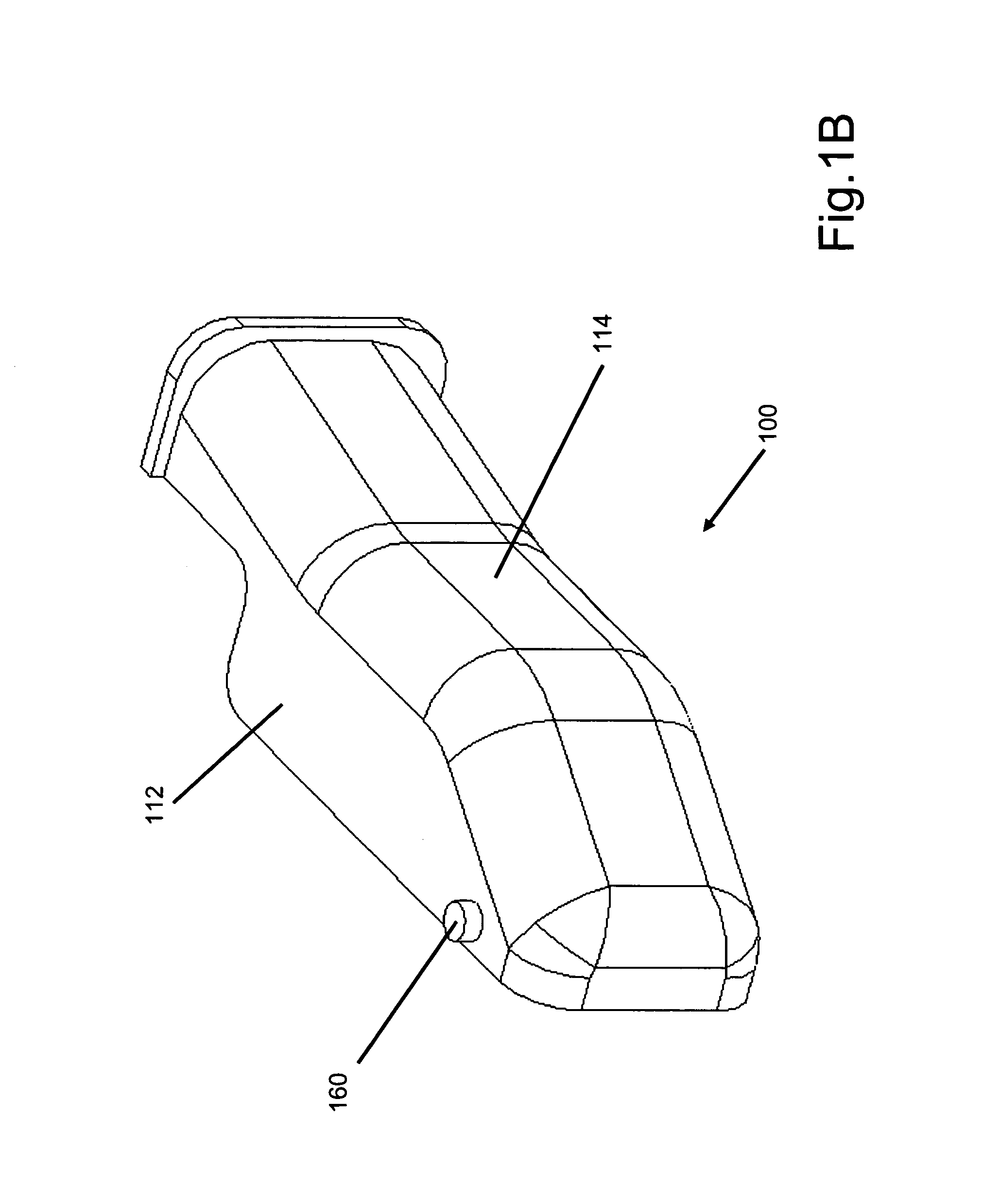

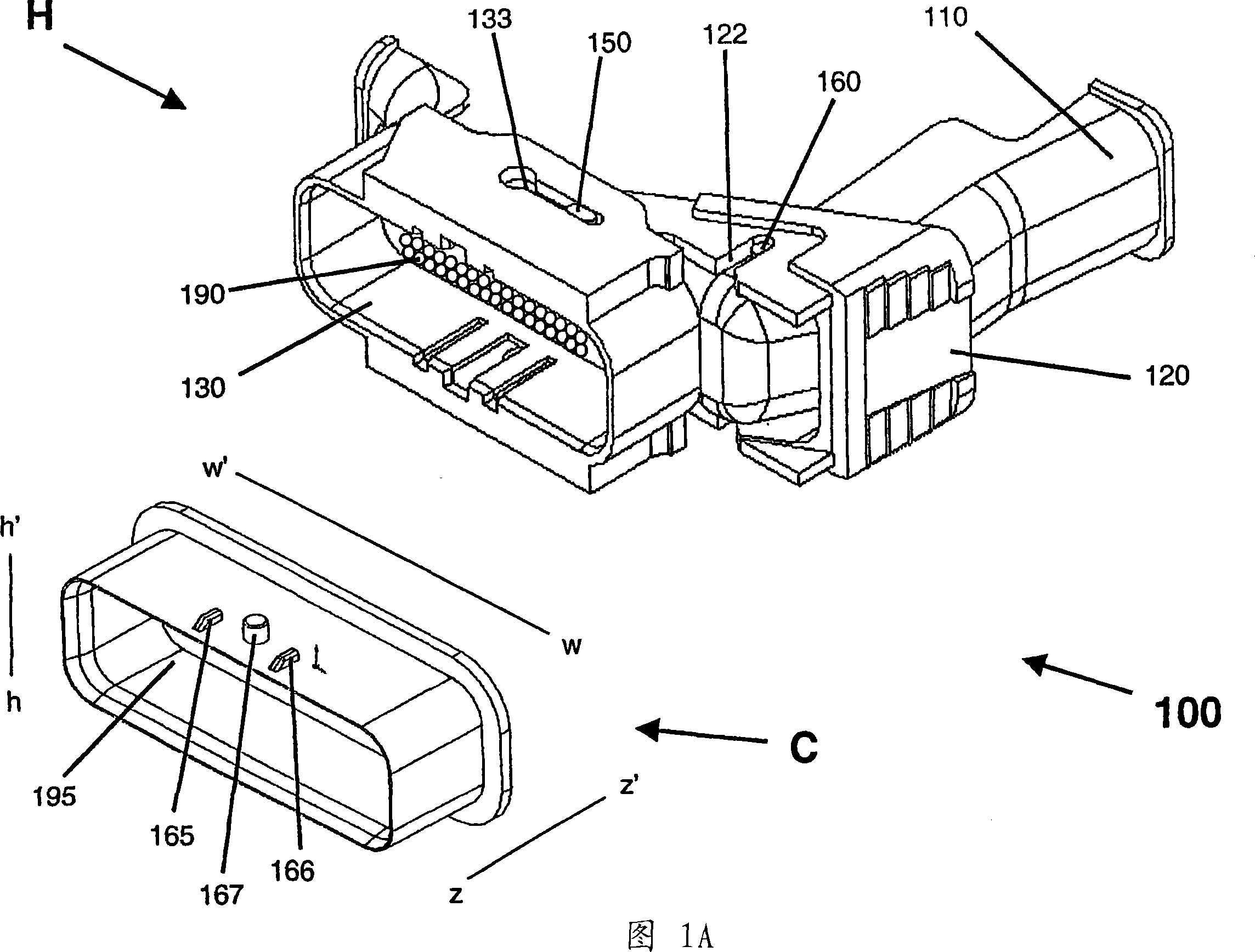

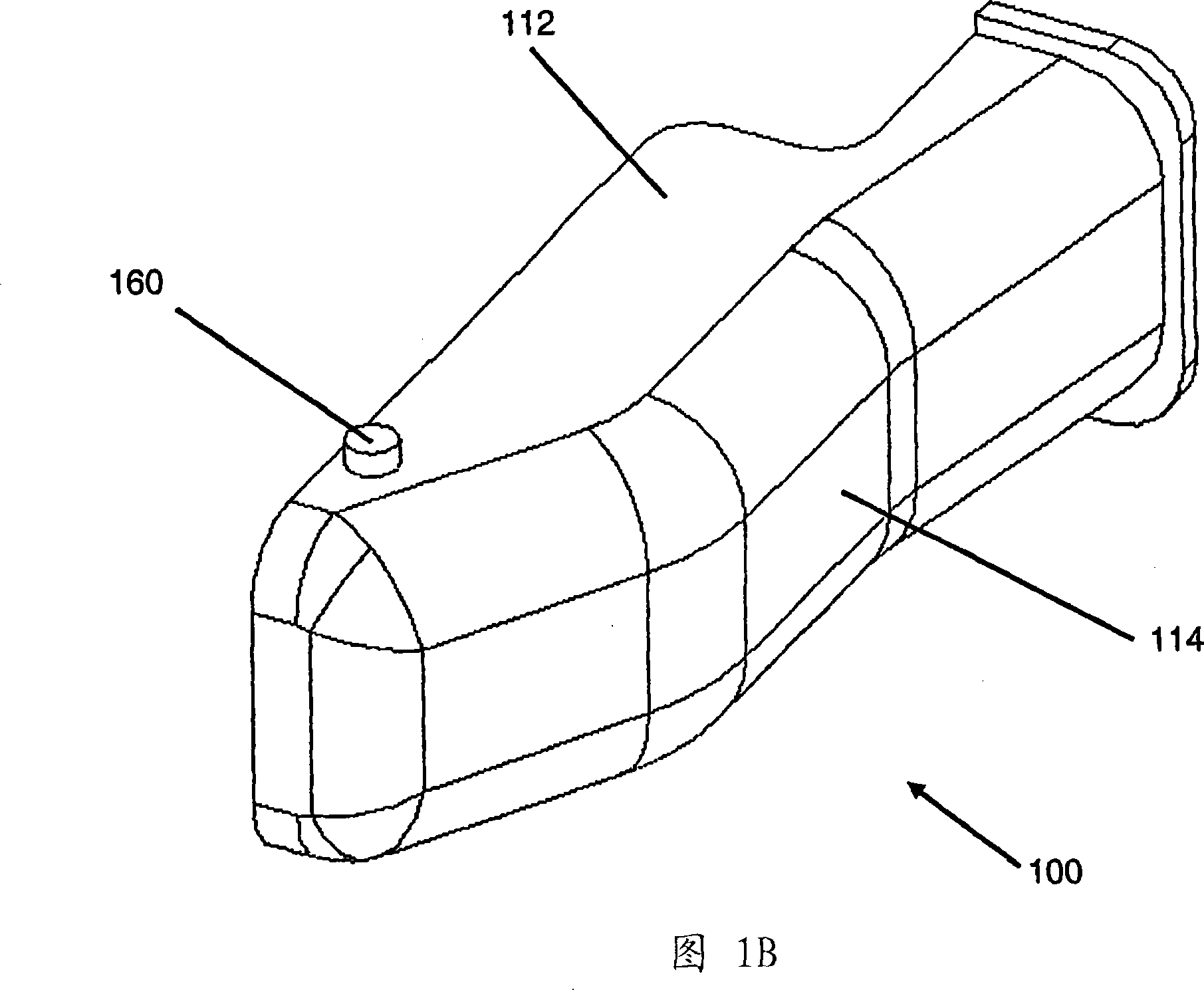

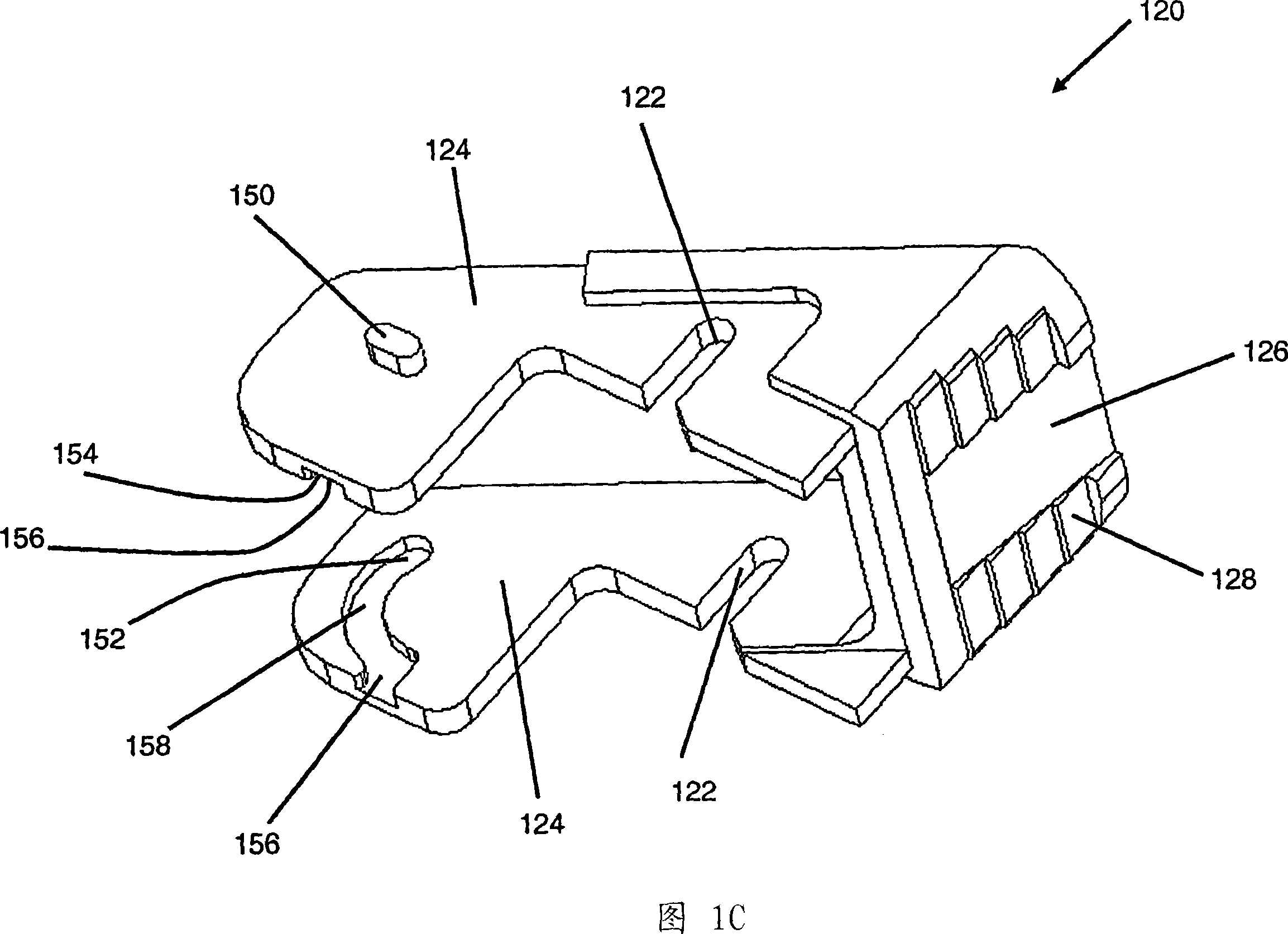

Electrical connector adapter and method for making

ActiveUS20070037452A1Assembly precisionEasy to manufactureContact member manufacturingTwo pole connectionsEngineeringCD player

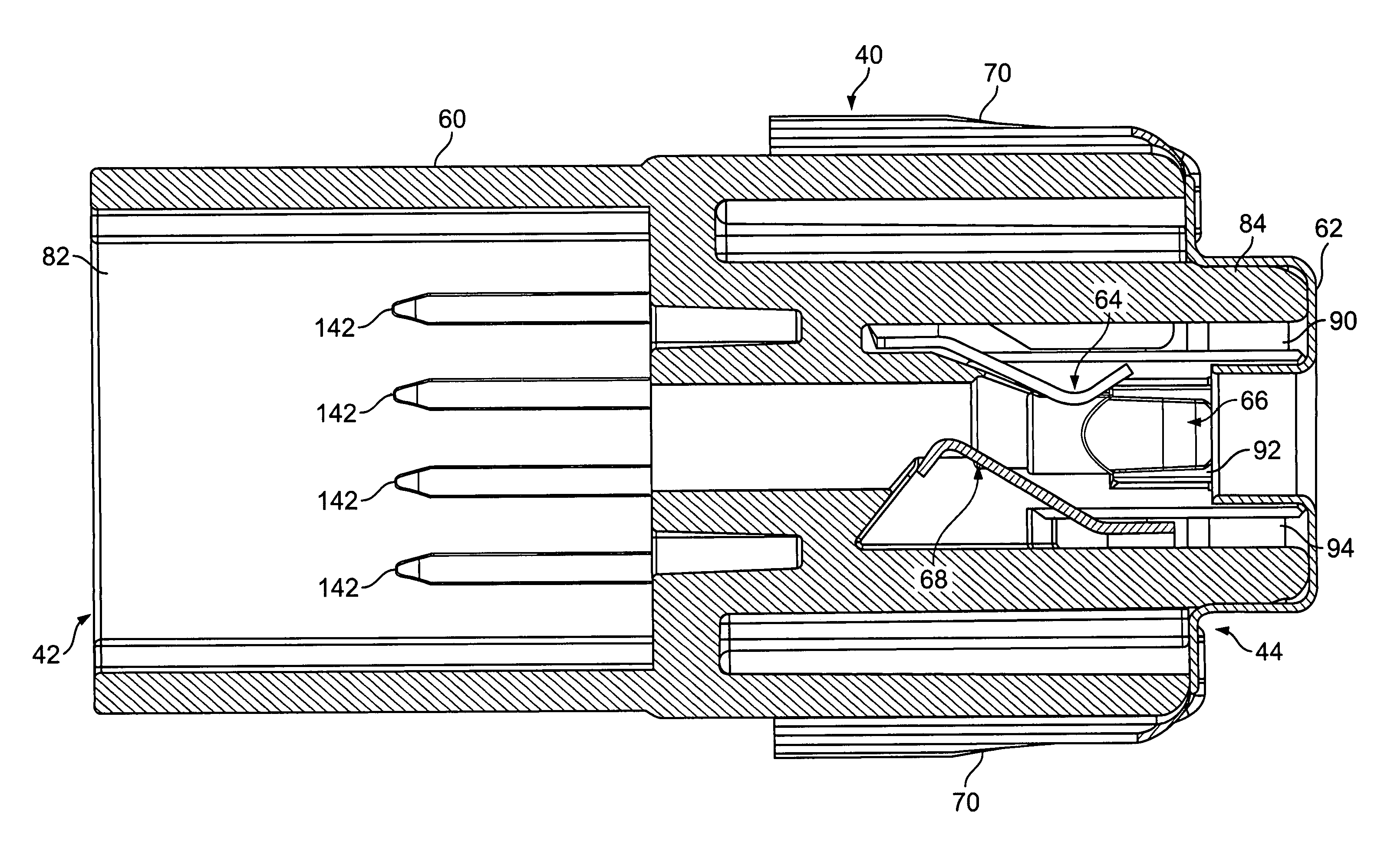

An electrical connector adapter (40) is disclosed for electrically interconnecting a portable electronic component such as an MP3 player, CD player, or other portable device with sound or other equipment in a vehicle. The adapter (40) includes a one-piece insulating housing (60) having a system mating end (42) for interconnecting to a vehicle's electrical system and a component mating end (44) for interconnecting to a portable electrical component. Three electric contacts (62, 64, 68) are retained in three openings (90, 92, 94) respectively in the housing (60) and are arranged to electrically mate with a plug (54) of a portable electrical component.

Owner:TE CONNECTIVITY CORP

Electrical connector adapter and method for making

ActiveUS7503807B2Low costReduce complexityContact member manufacturingTwo pole connectionsCD playerElectrical connector

An electrical connector adapter (40) is disclosed for electrically interconnecting a portable electronic component such as an MP3 player, CD player, or other portable device with sound or other equipment in a vehicle. The adapter (40) includes a one-piece insulating housing (60) having a system mating end (42) for interconnecting to a vehicle's electrical system and a component mating end (44) for interconnecting to a portable electrical component. Three electric contacts (62, 64, 68) are retained in three openings (90, 92, 94) respectively in the housing (60) and are arranged to electrically mate with a plug (54) of a portable electrical component.

Owner:TE CONNECTIVITY CORP

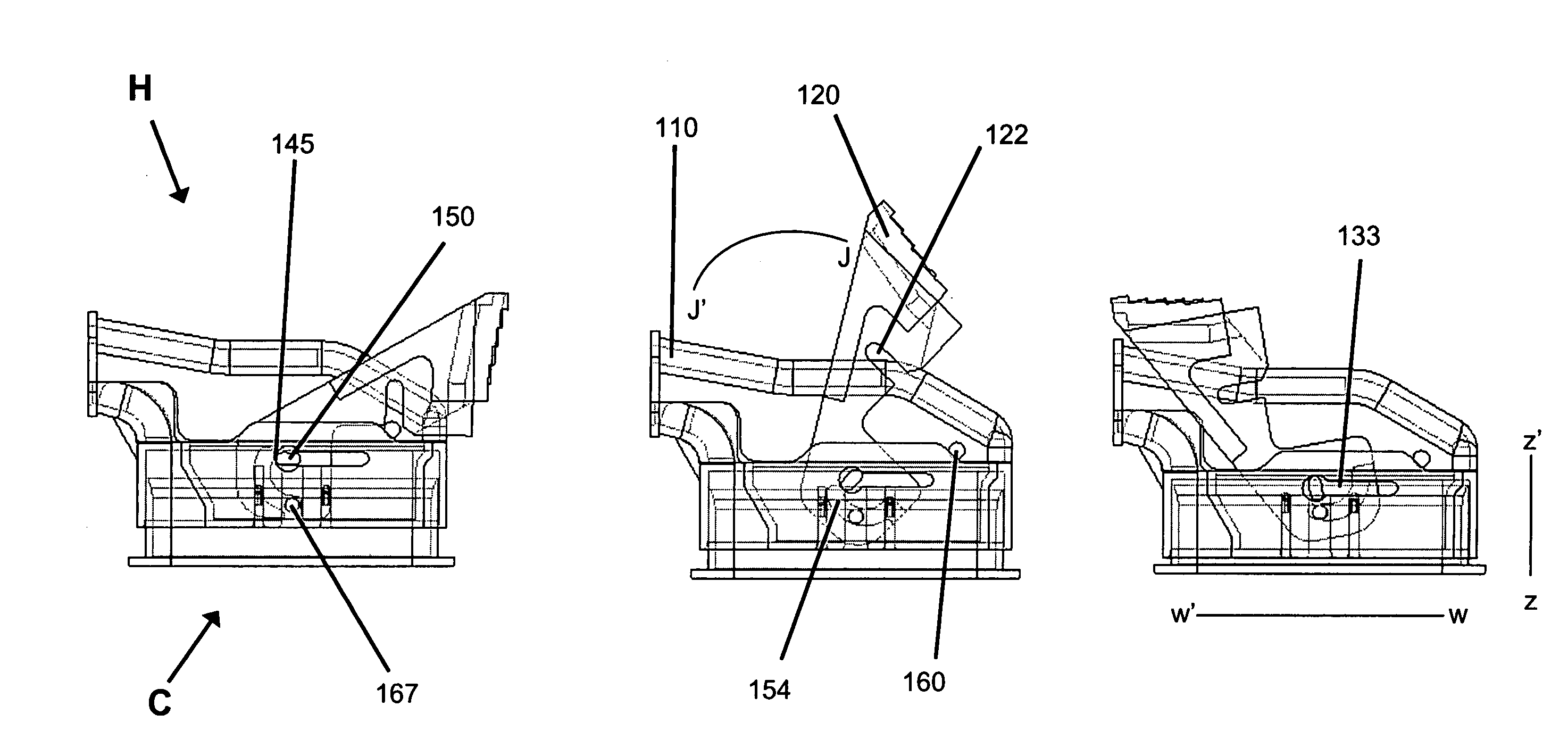

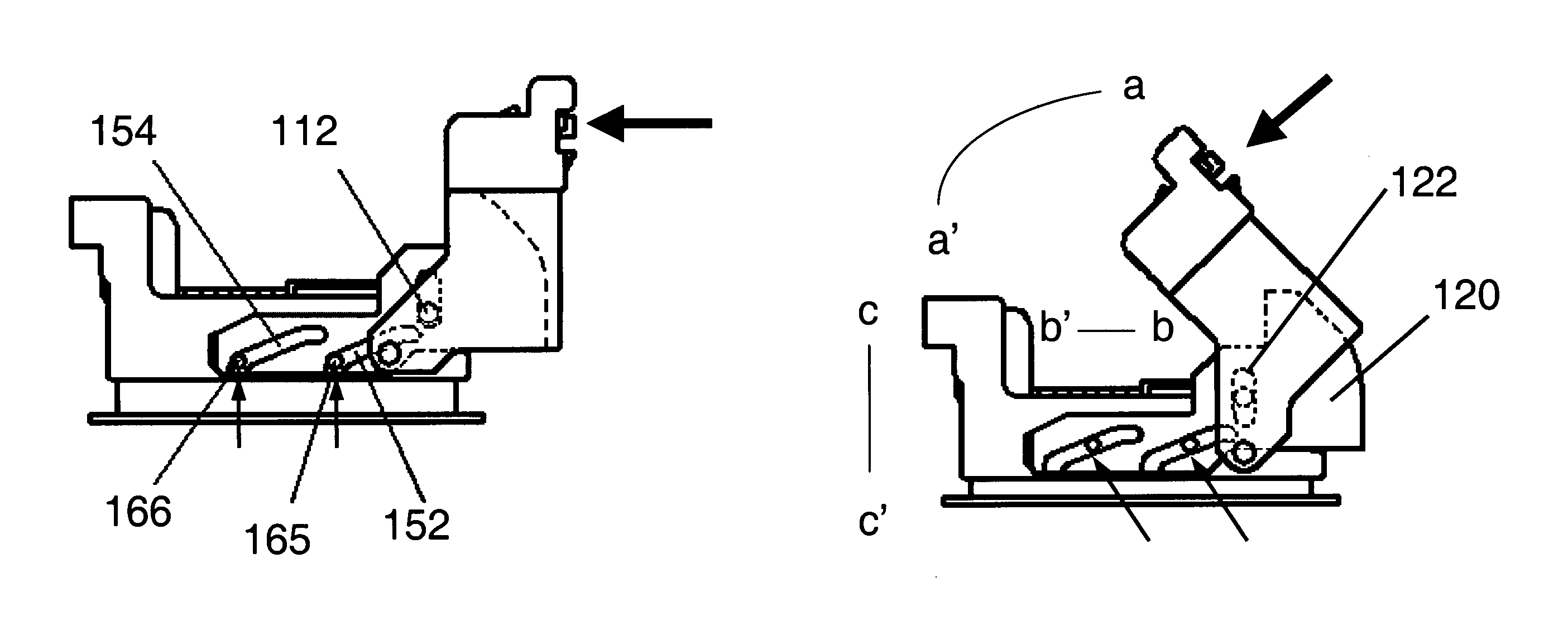

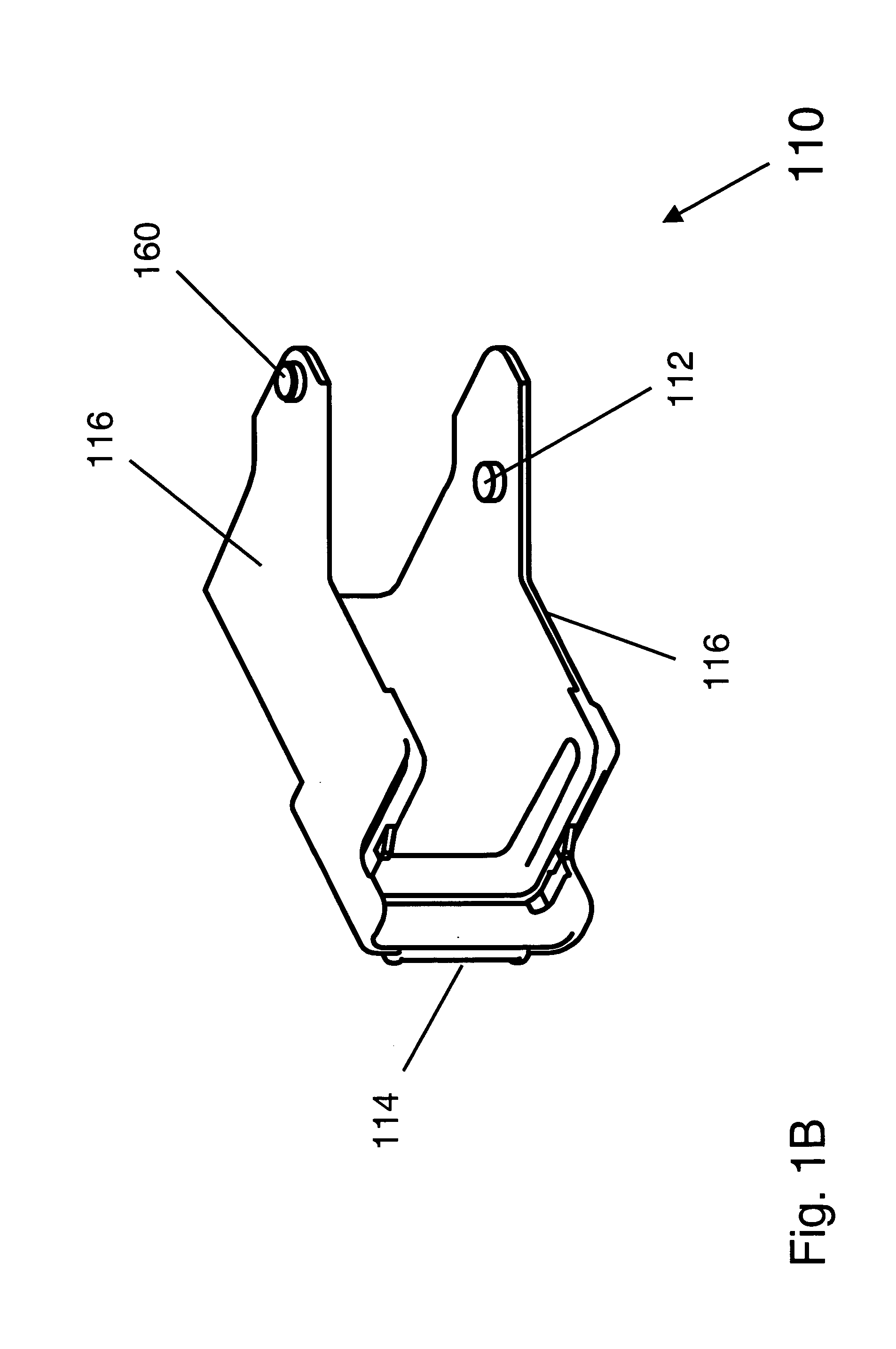

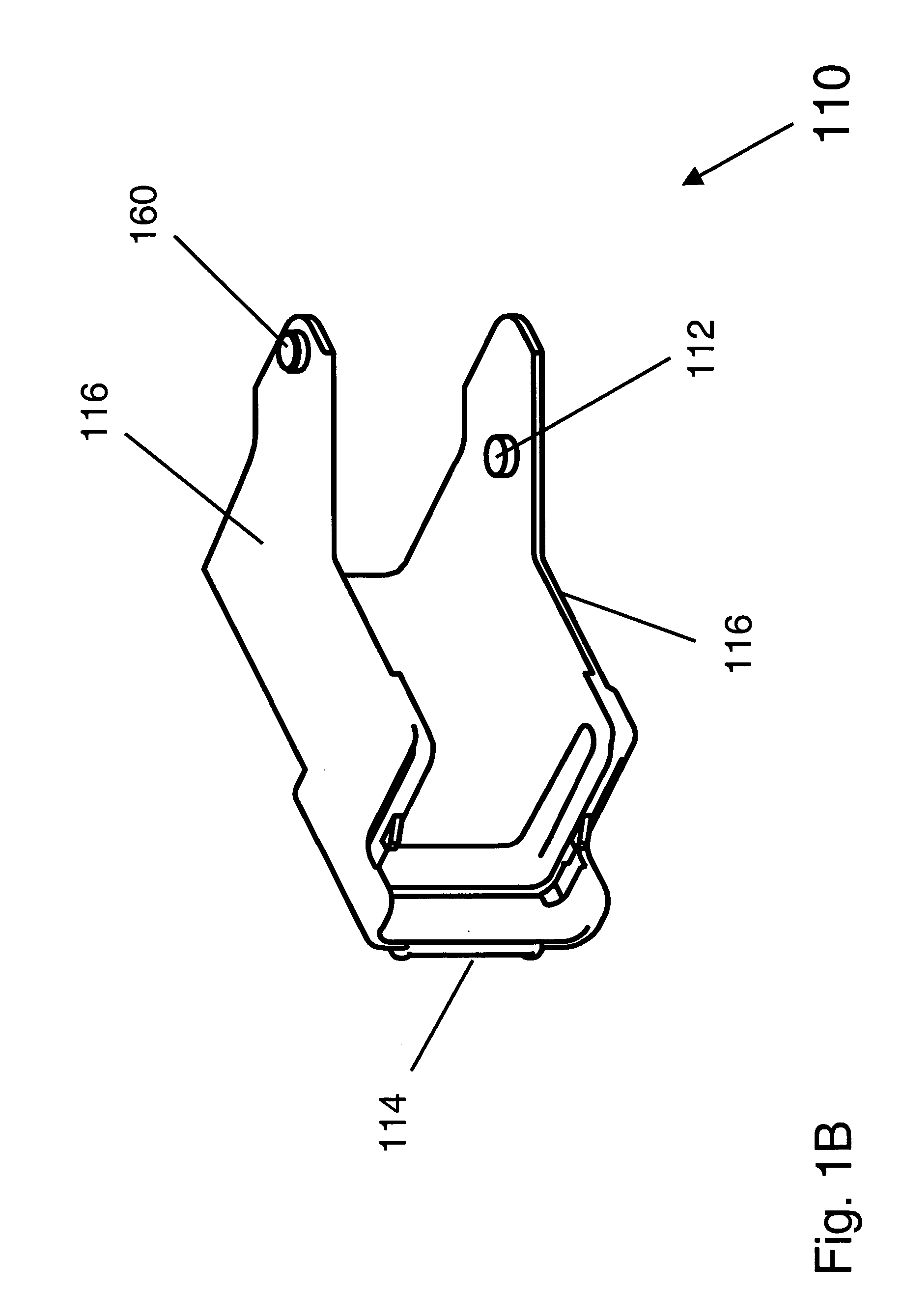

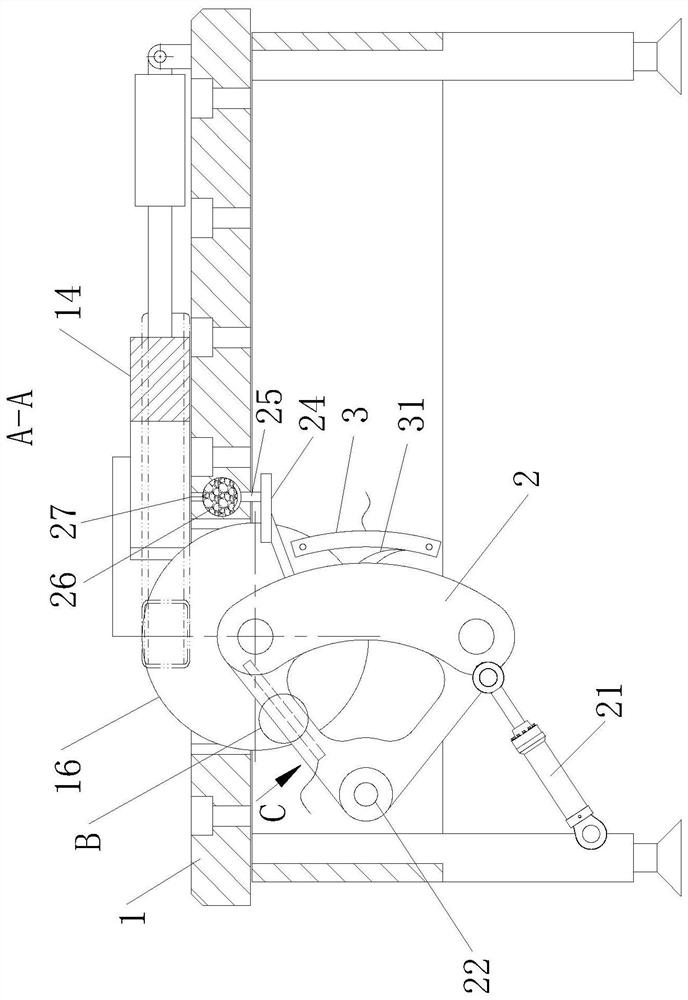

Dual action mechanical assisted connector

ActiveUS6899554B1Simple and powerfulReduce forceEngagement/disengagement of coupling partsDual actionEngineering

A lever-type electrical connector assembly reduces the connection mating forces required to mate female and male connectors. The connector assembly employs a first connector with cam follower projections, a base housing with cam grooves and a sliding guide rail, a slide lever housing including a sliding projection and a sliding guide rail, and a cover housing pivotally mounted on the base housing, the cover housing having a sliding projection. As the cover housing is rotated from an open to a closed position, it engages the sliding projection in the guide rail to permit rotation of the lever housing. This rotation engages the sliding projection in the guide rail. As the lever housing is rotated from an open to a closed position, it rotates the cam grooves to engage the cam follower projections thereby drawing the first connector into the base housing to a connected position.

Owner:J S T CORP

Dual action mechanical assisted connector

ActiveUS6971894B2Simple and powerfulReduce forceEngagement/disengagement of coupling partsRotary current collectorDual actionEngineering

A lever-type electrical connector assembly reduces the connection mating forces required to mate female and male connectors. The connector assembly employs a first connector with cam follower projections, a base housing with guide channels, a slide cam housing including cam grooves and projection guide tracks, and a cover housing pivotally mounted on the base housing, the cover housing having a cover housing projection. As the cover housing is rotated from an open to a closed position, it engages the cover housing projection in the projection guide track. This engagement moves the slide cam housing in the guide channel. As the slide cam housing is moved from an open to a closed position, it engages the cam follower projections in the cam grooves thereby drawing the first connector into the base housing to a connected position.

Owner:J S T CORP

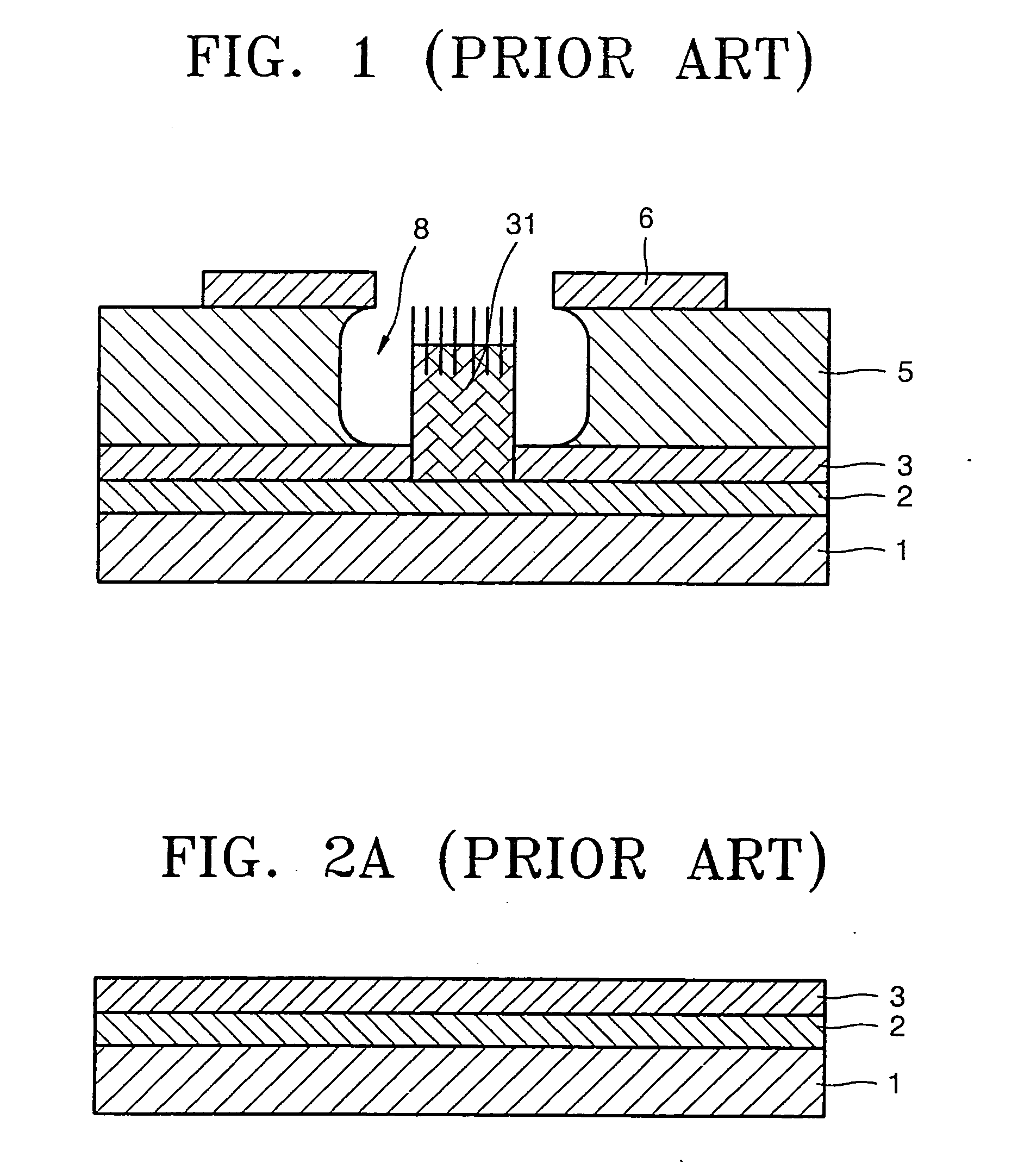

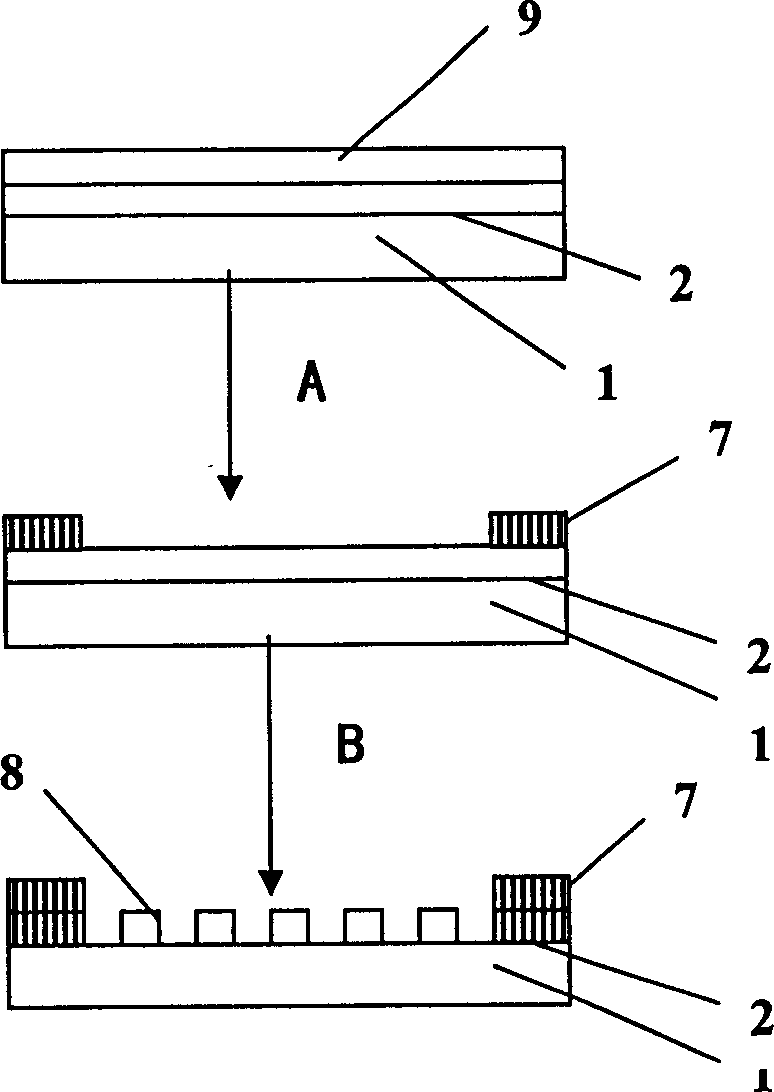

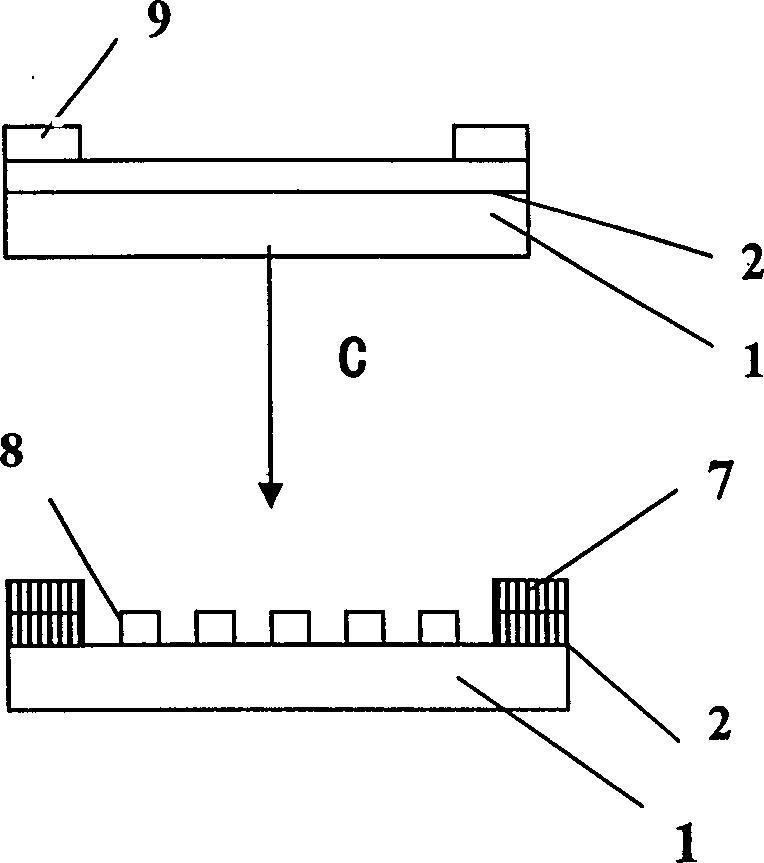

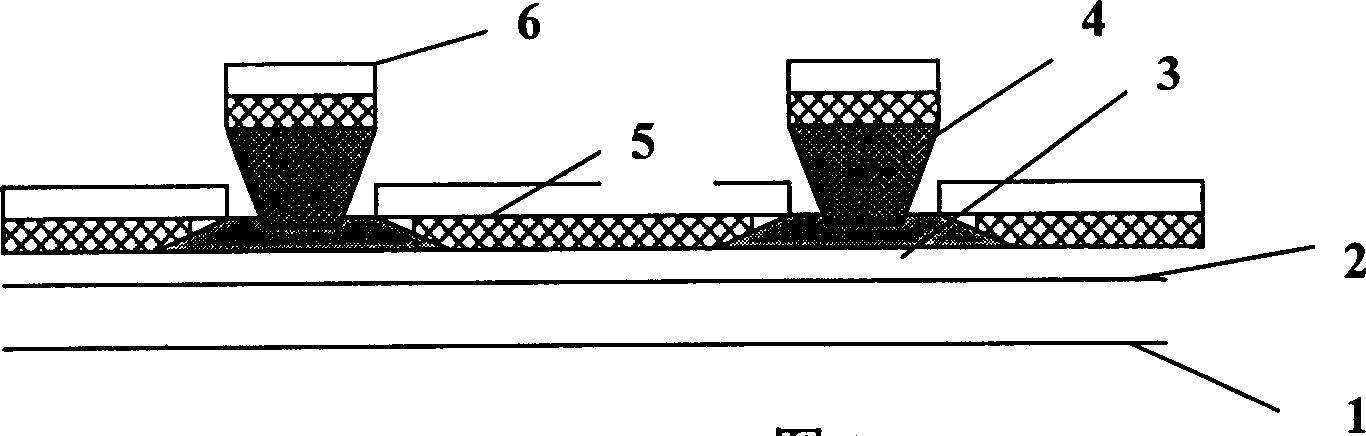

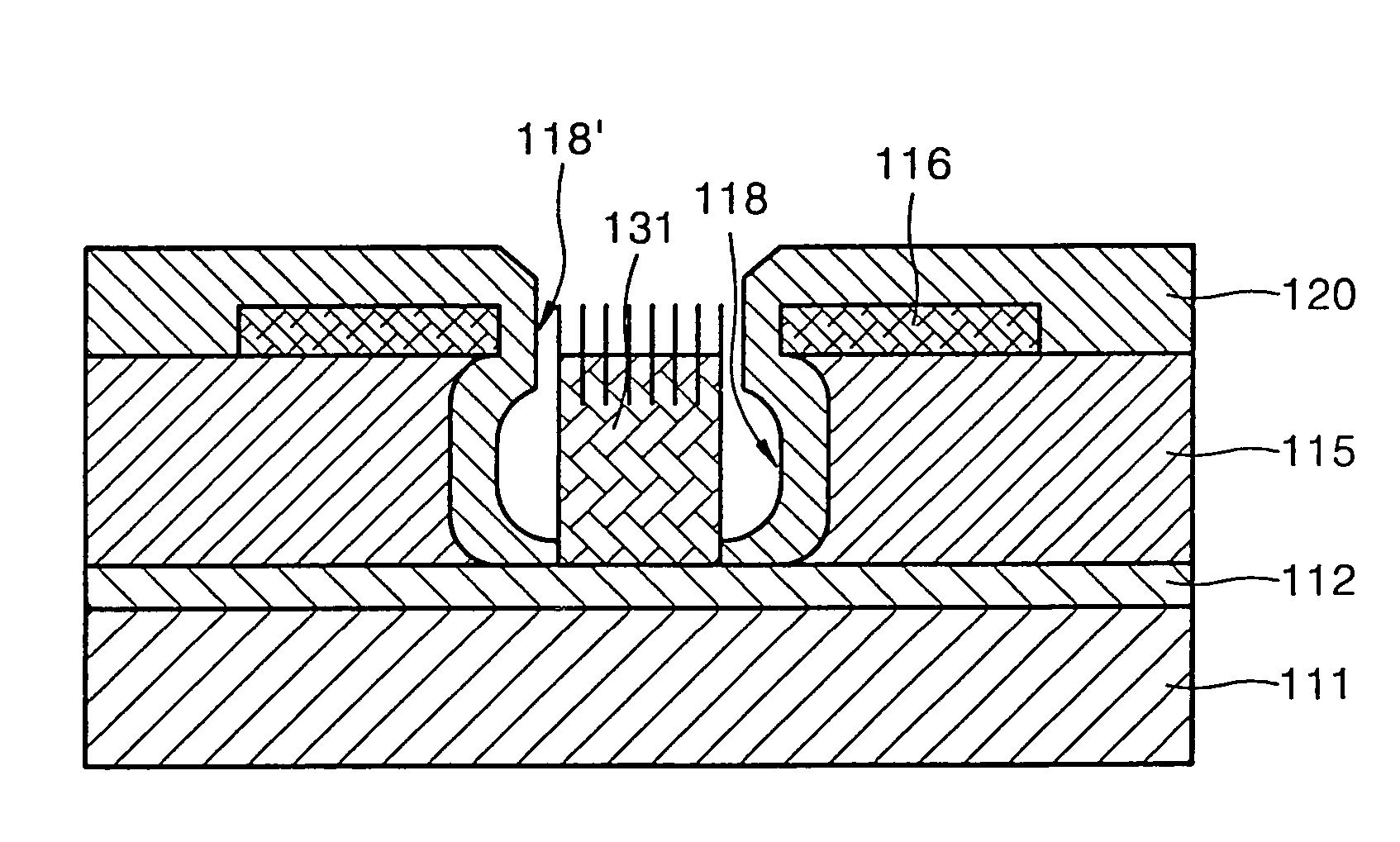

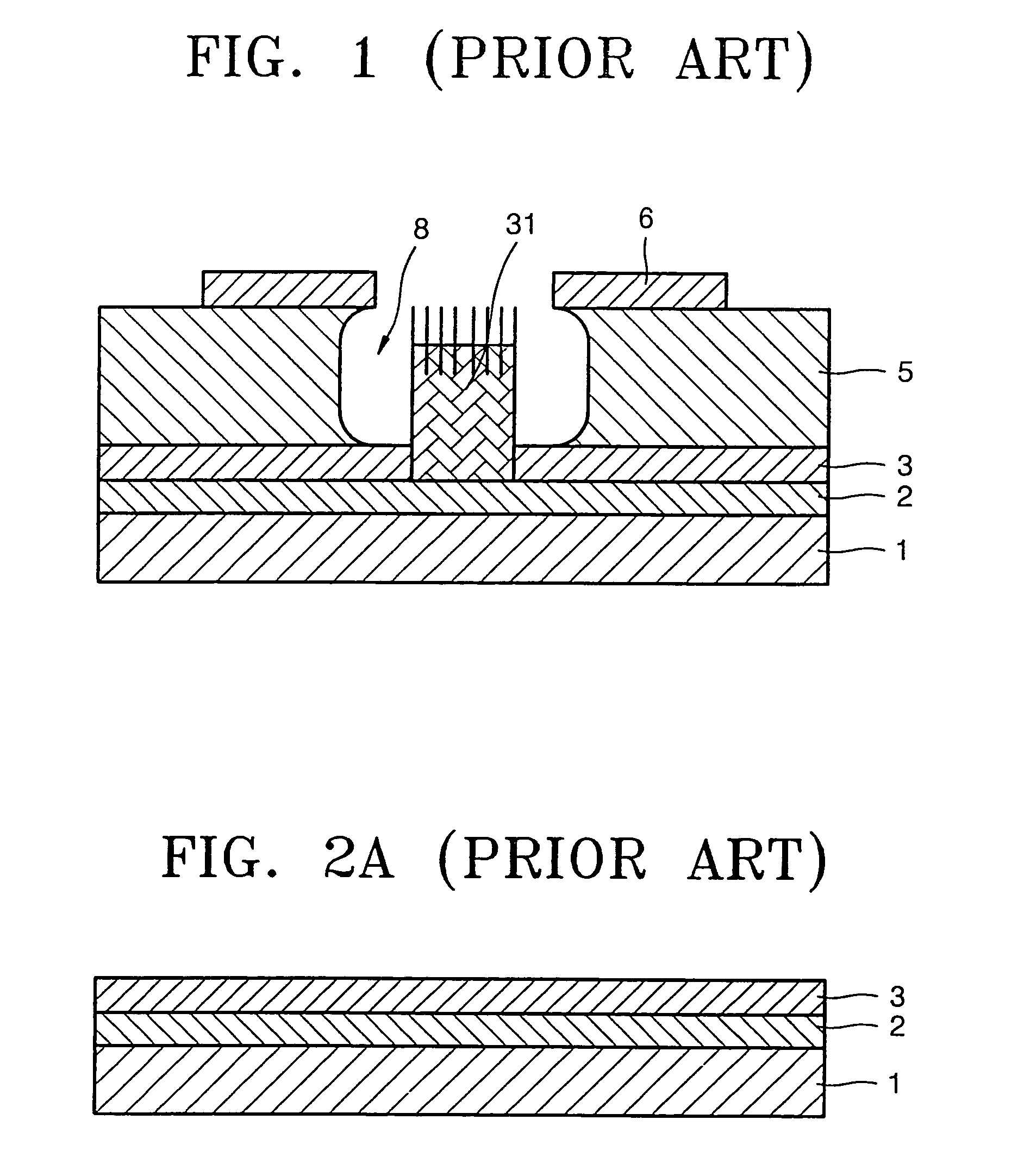

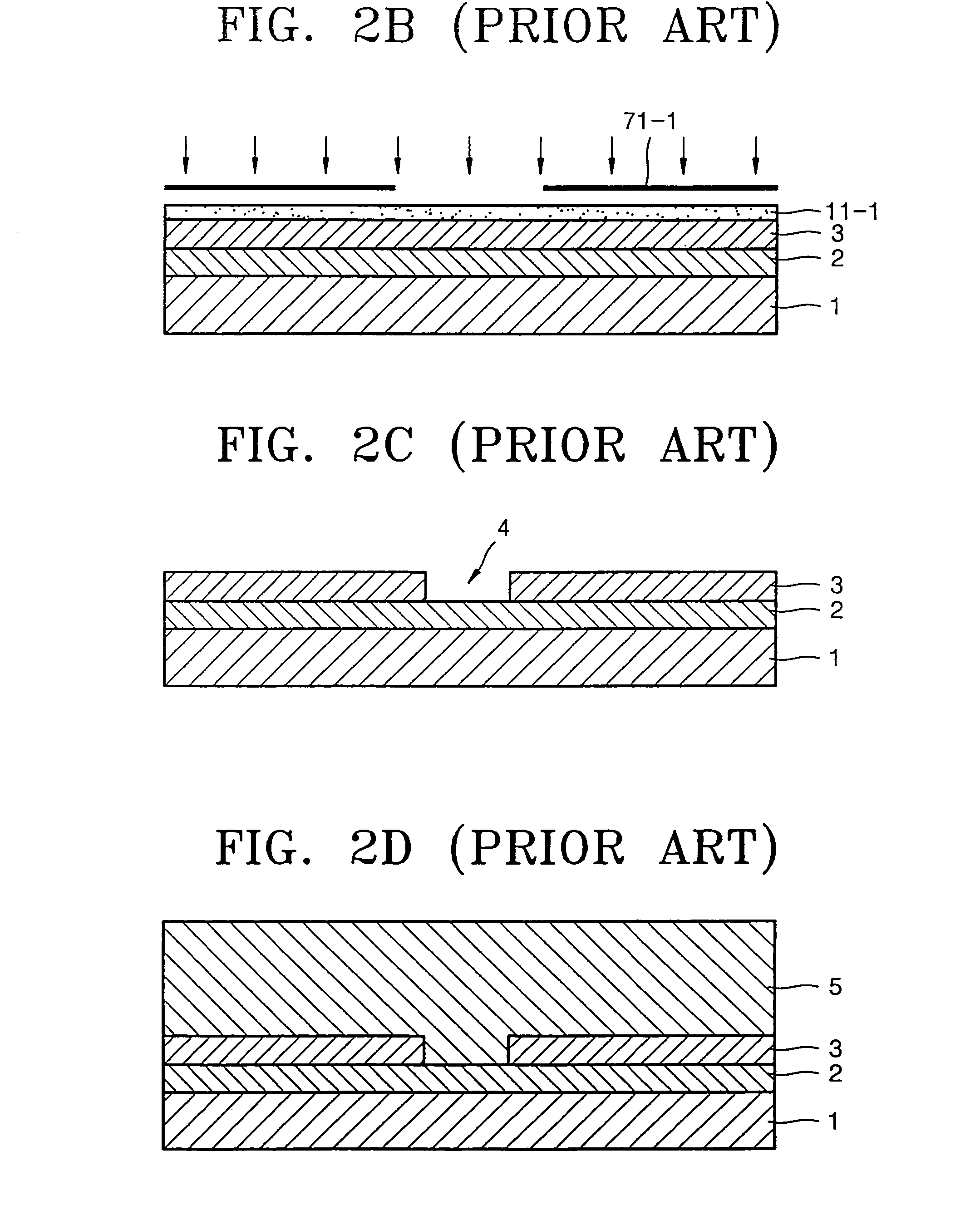

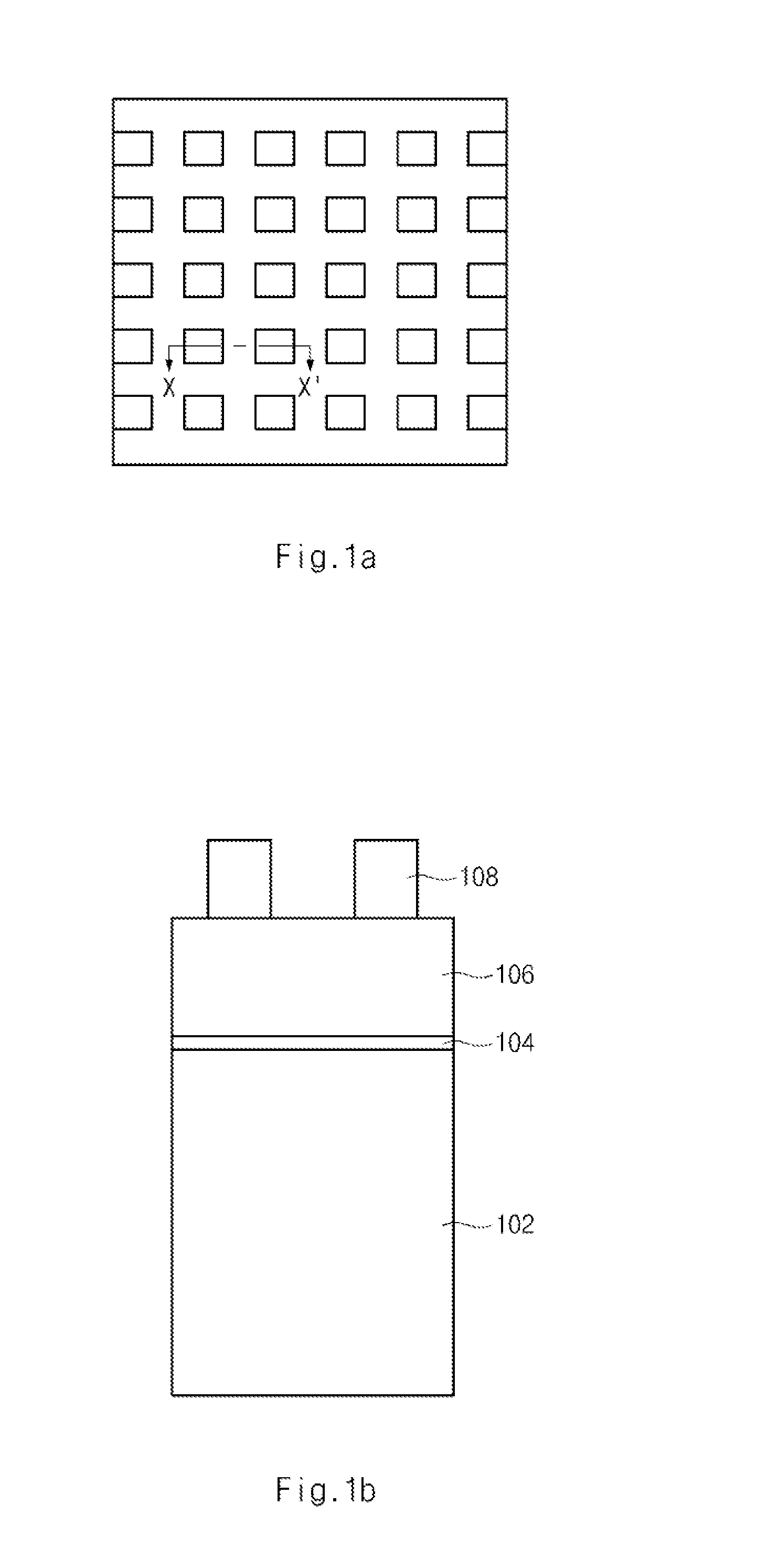

Triode structure field emission display device using carbon nanotubes and method of fabricating the same

InactiveUS20050040752A1Short circuit can be preventedBlocking may occurControl electrodesNanoinformaticsInsulation layerField emission display

A field emission display device and a method of fabricating the same are provided. The field emission display device includes a substrate, a transparent cathode layer, an insulation layer, a gate electrode, a resistance layer, and carbon nanotubes. The transparent cathode layer is deposited on the substrate. The insulation layer is formed on the cathode layer and has a well exposing the cathode layer. The gate electrode is formed on the insulation layer and has an opening corresponding to the well. The resistance layer is formed to surround the surface of the gate electrode and the inner walls of the opening and the well so as to block ultraviolet rays. The carbon nanotube field emitting source is positioned on the exposed cathode layer. An alignment error between the gate electrode and the cathode is removed, and carbon nanotube paste is prevented from remaining during development, thereby preventing current leakage and short circuit between the electrodes and diode emission. Accordingly, the performance of the field emission display device can be improved.

Owner:SAMSUNG SDI CO LTD

Dual action mechanical assisted connector

ActiveUS20050221647A1Reduces required connecting mating forceEliminate alignment errorsEngagement/disengagement of coupling partsRotary current collectorDual actionEngineering

A lever-type electrical connector assembly reduces the connection mating forces required to mate female and male connectors. The connector assembly employs a first connector with cam follower projections, a base housing with guide channels, a slide cam housing including cam grooves and projection guide tracks, and a cover housing pivotally mounted on the base housing, the cover housing having a cover housing projection. As the cover housing is rotated from an open to a closed position, it engages the cover housing projection in the projection guide track. This engagement moves the slide cam housing in the guide channel. As the slide cam housing is moved from an open to a closed position, it engages the cam follower projections in the cam grooves thereby drawing the first connector into the base housing to a connected position.

Owner:J S T CORP

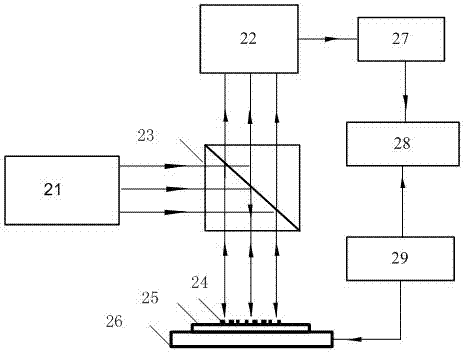

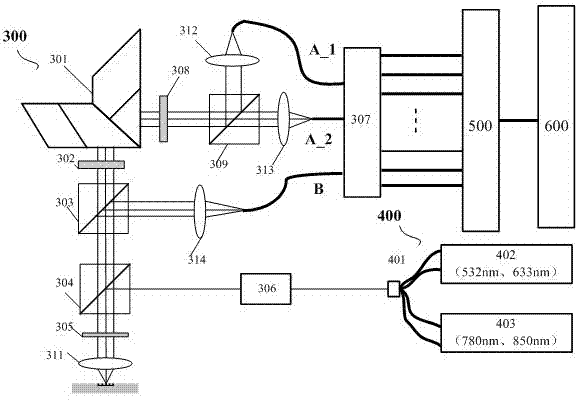

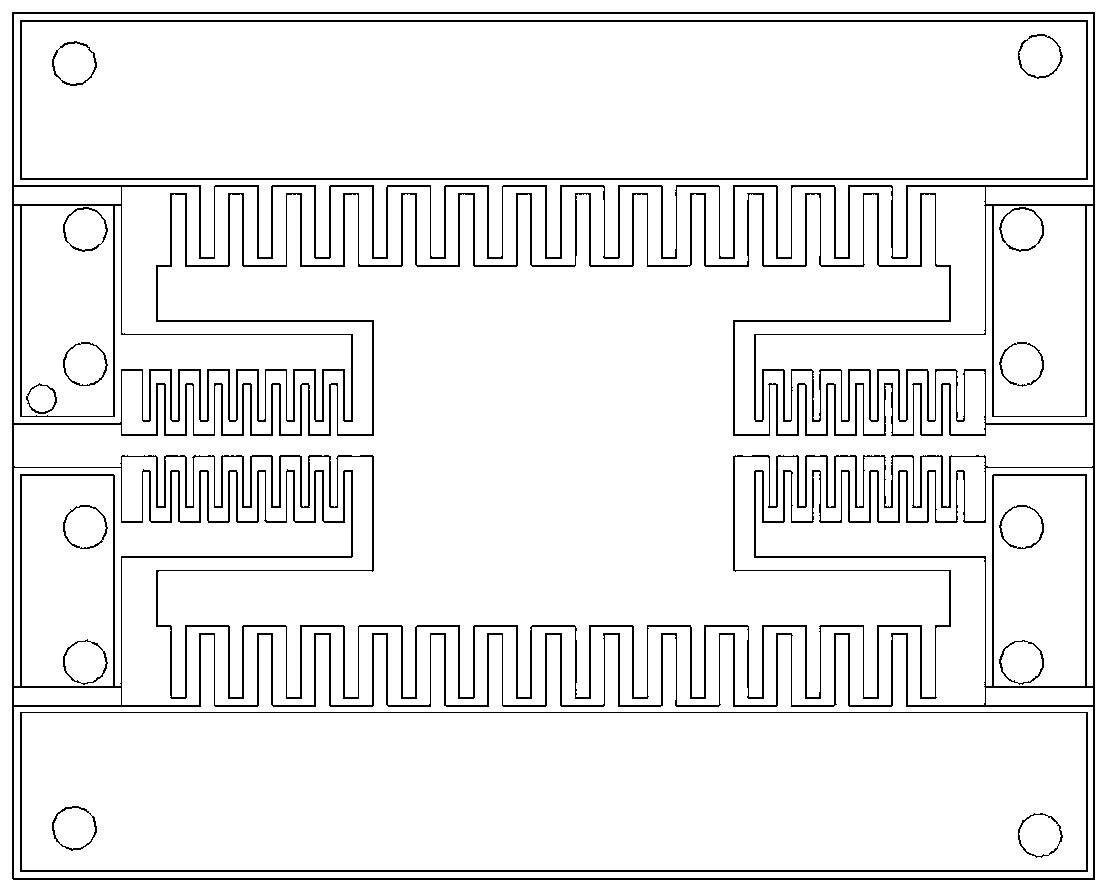

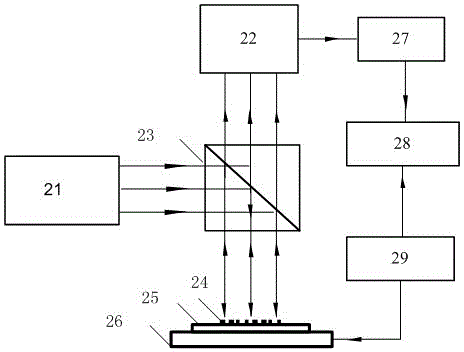

Self-reference interference alignment system for photoetching equipment

ActiveCN103365122AQuality improvementEliminate alignment errorsPhotomechanical exposure apparatusMicrolithography exposure apparatusOptical ModuleLight beam

The invention discloses a self-reference interference alignment system for photoetching equipment. The system comprises a laser light source module, an optical module, a signal acquisition module and a processing module, wherein the laser light source module is used for providing illumination beams; the optical module is used for marking the illumination beams to form a diffraction optical signal; the signal acquisition module is used for processing the optical signal to acquire a light intensity signal; the processing module is used for processing the light intensity signal to acquire an alignment position by combining position data of a workpiece table; the optical module comprises a first optical channel and a second optical channel; an optical signal in the second optical channel is processed to be used for eliminating optical noises in the first optical channel.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

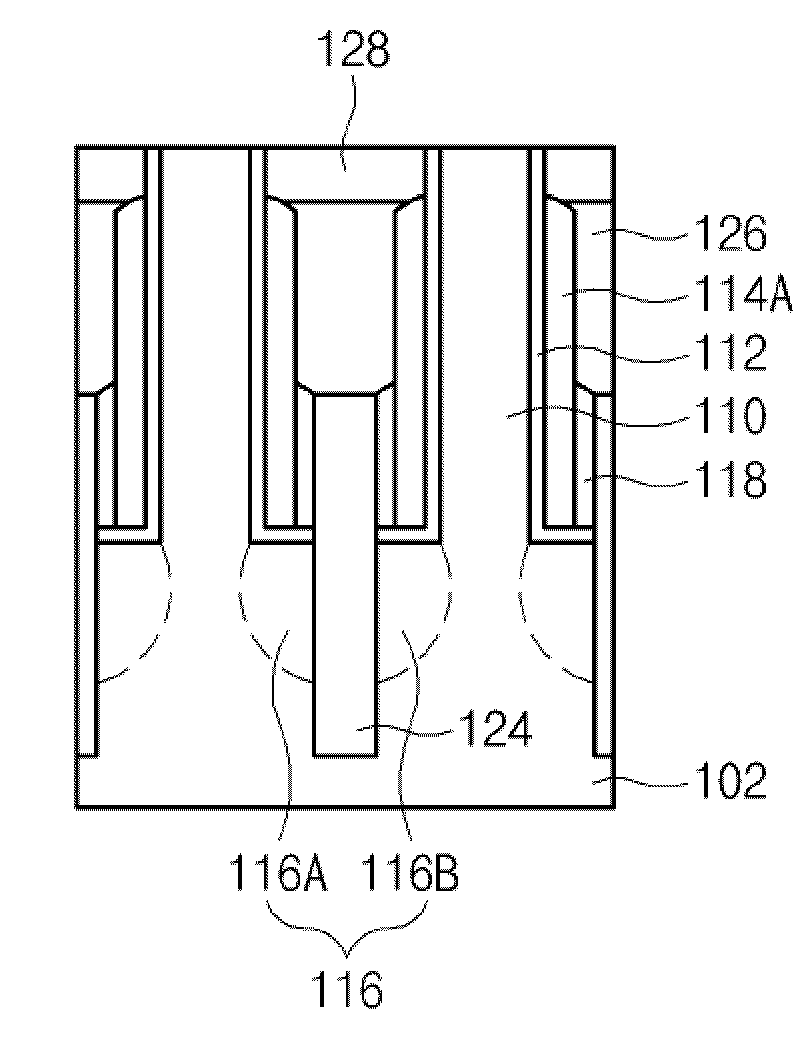

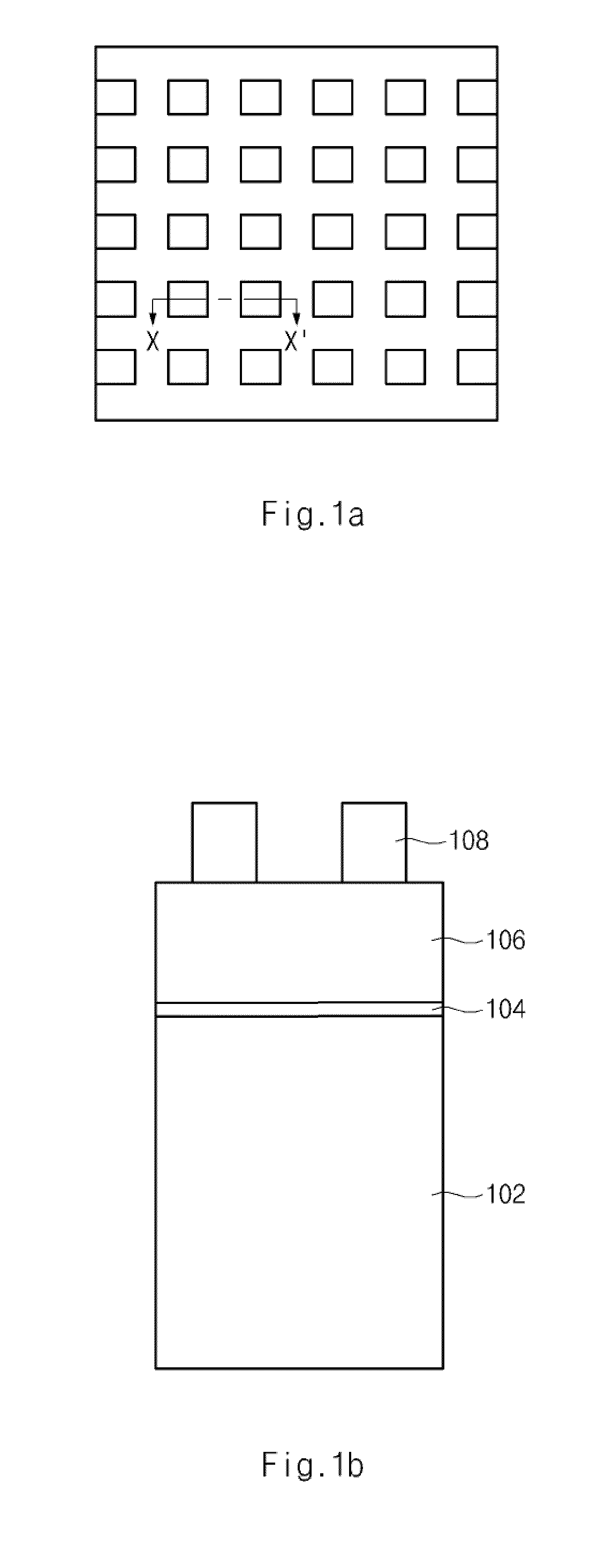

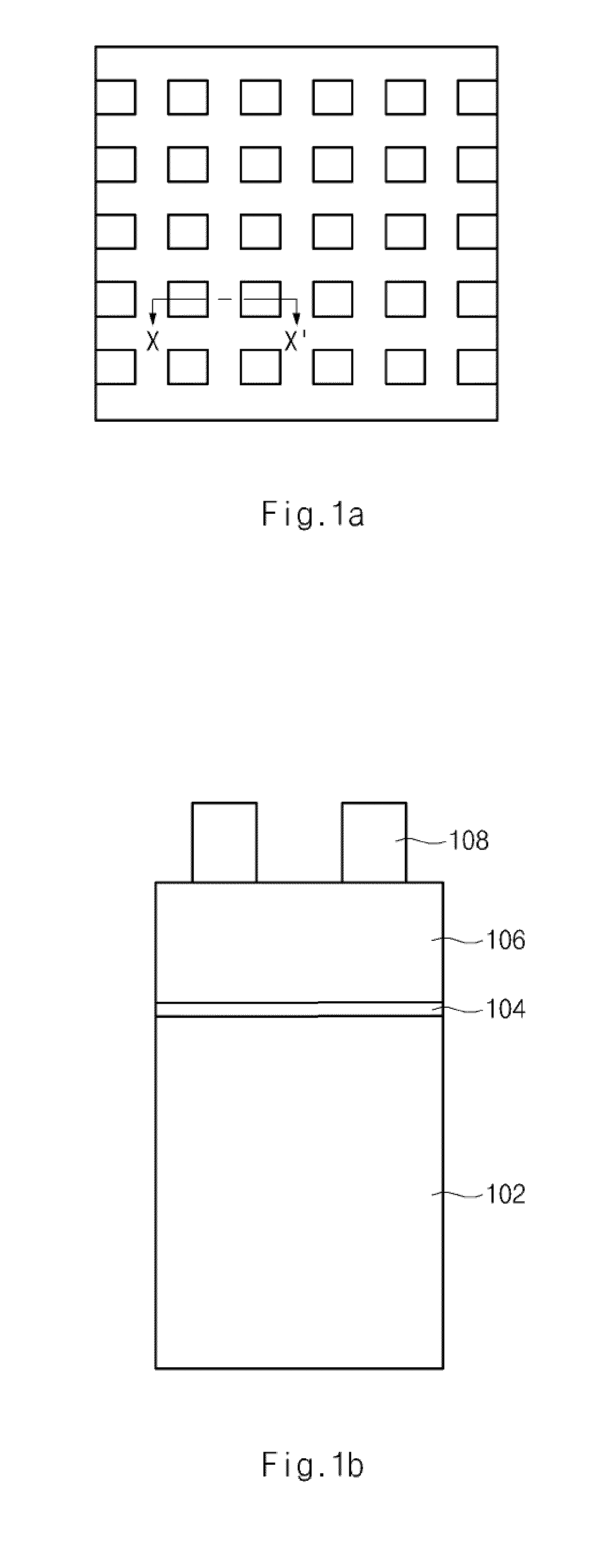

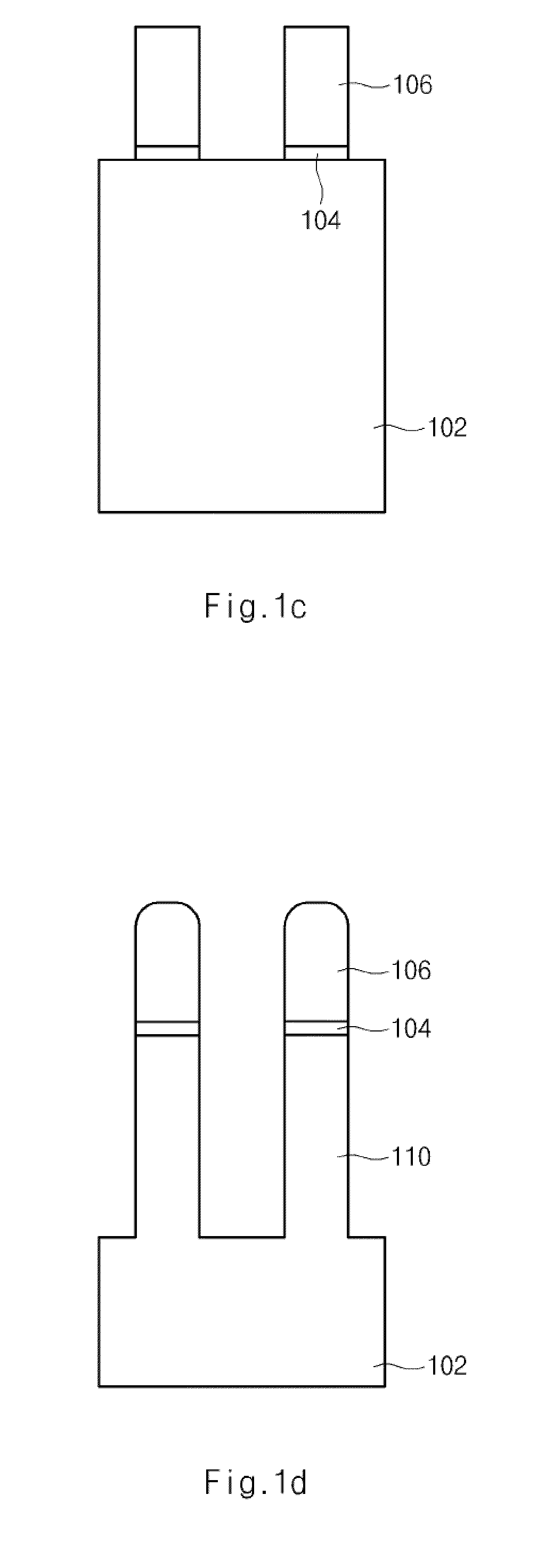

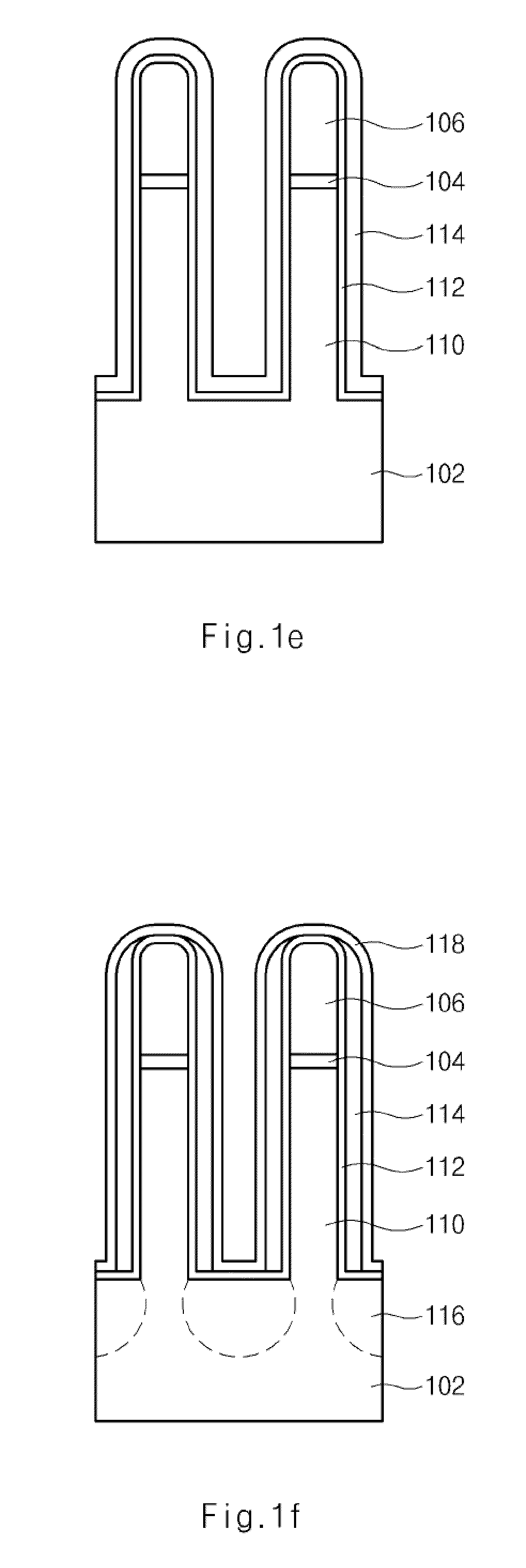

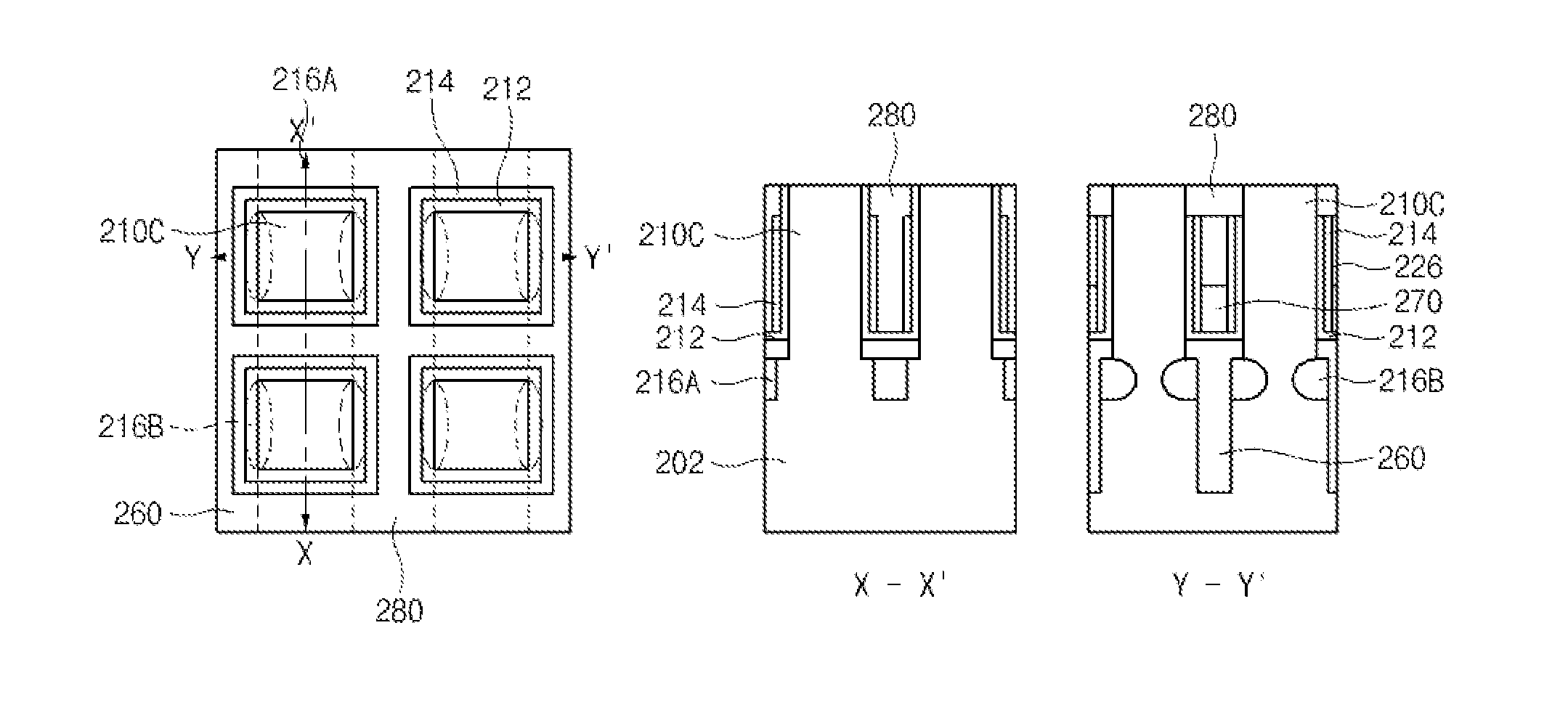

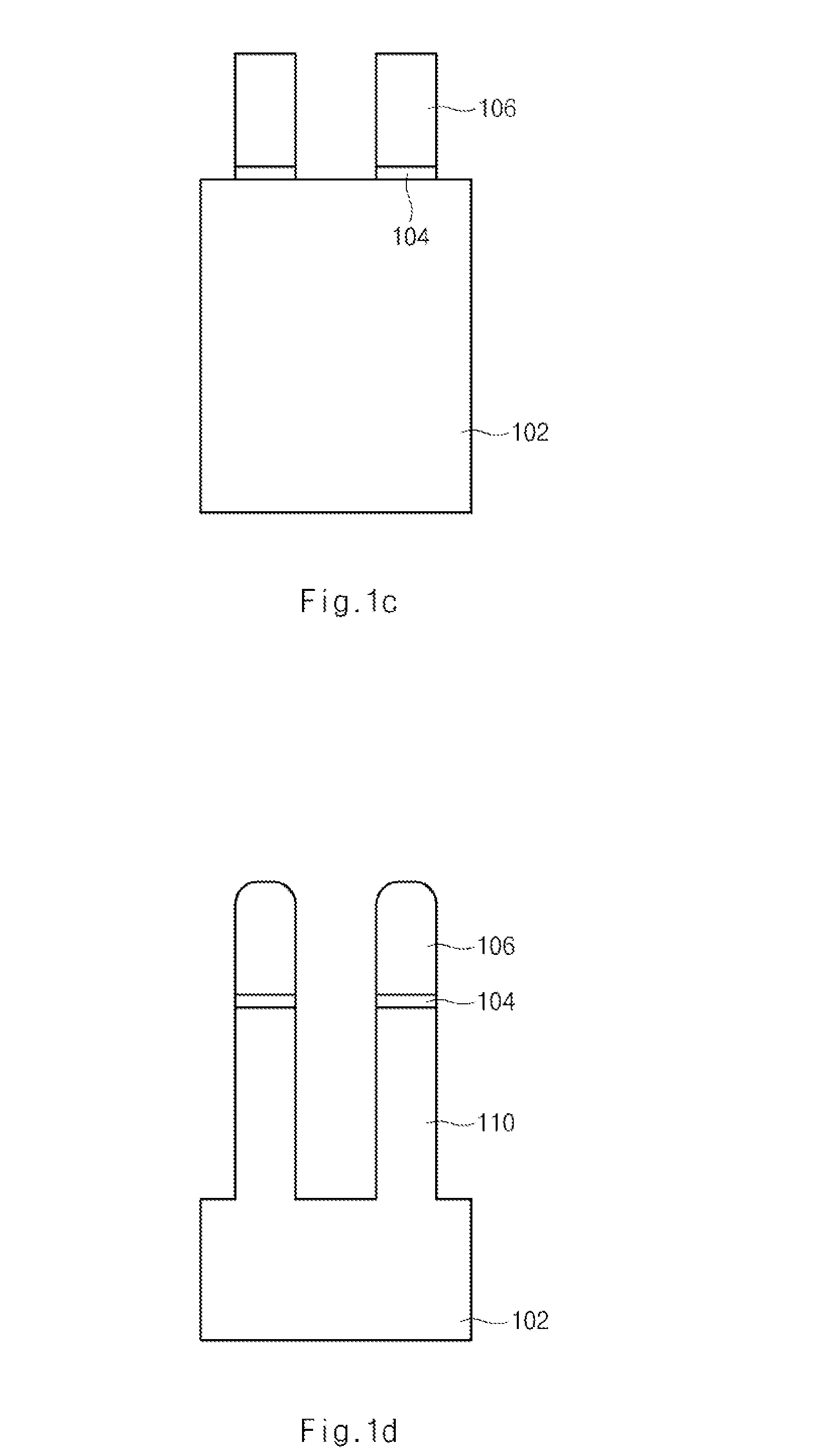

Method of manufacturing high-integrated semiconductor device and semiconductor device manufactured using the same

ActiveUS20100025758A1Excellent characteristicsHigh yieldSemiconductor/solid-state device manufacturingSemiconductor devicesBit lineSemiconductor

A semiconductor device comprises a plurality of vertical transistors each comprising barrier metal layers corresponding to source / drain regions in which a conduction region is formed under a channel region having a pillar form, and a bit line comprising a metal layer to connect the plurality of vertical transistors.

Owner:SK HYNIX INC

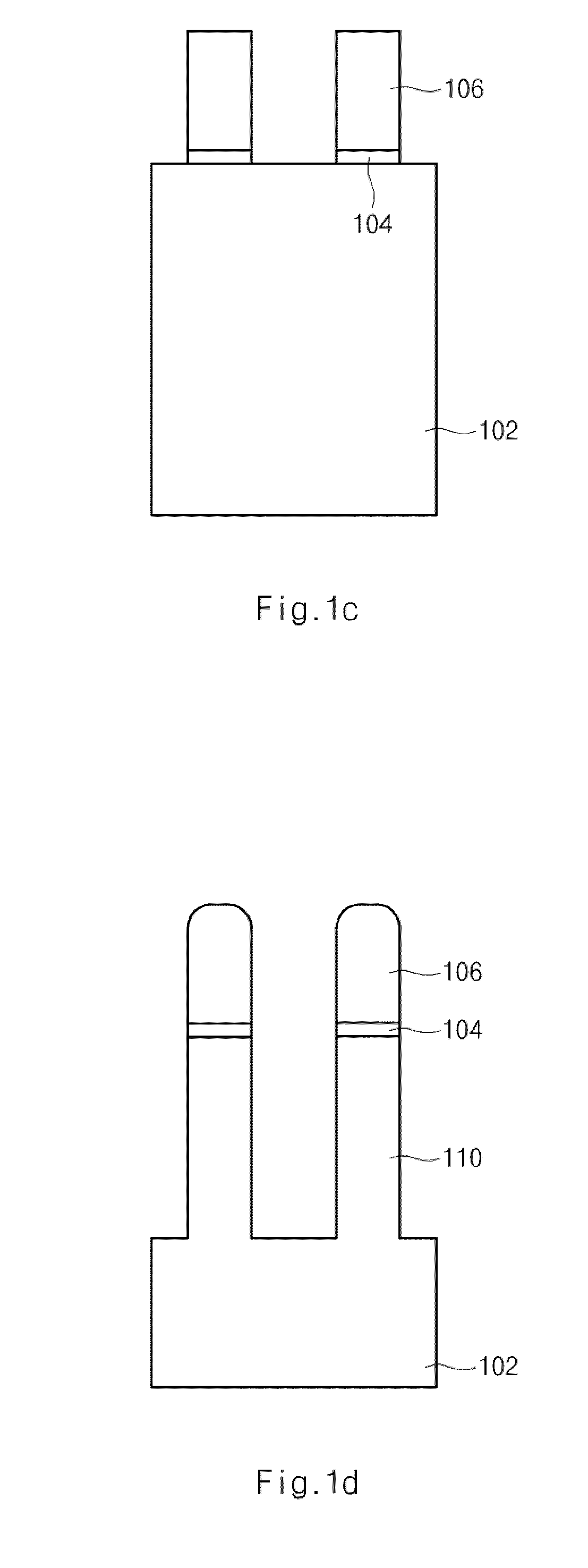

Method for manufacturing transparent anode and electrode lead wire of organic luminescent display unit

InactiveCN1791287AImprove performanceExtend your lifeElectrical apparatusElectroluminescent light sourcesSputteringOrganic electroluminescence

The invention discloses a manufacture method for transparent anode and electrode lead-out wire for organic luminous display unit, which comprises: preparing mask plate; sputtering directly need metal layer of lead-out wire with the mask plate on glass substrate with ITO transparent conductive film; spin coating positive photoresist film; exposing; developing, baking; etching Cr and ITO transparent conductive film; and releasing film. This invention just needs development and releasing-film process for one time, cuts time, and improves yield.

Owner:INESA ELECTRON

Dual action mechanical assisted connector

InactiveCN1985409AReduced connection fitEliminate alignment errorsCoupling device detailsContact members penetrating/cutting insulation/cable strandsDual actionEngineering

A lever-type electrical connector assembly reduces the connection mating forces required to mate female and male connectors. The connector assembly employs a first connector with cam follower projections, a base housing with cam grooves ans a sliding guide rail, a slide lever housing including a sliding projection and a sliding guide rail, and a cover housing pivotally mounted on the base housing, the cover housing having a sliding projection. As the cover housing is rotated from an open to a closed position, it engages the sliding projection in the guide rail to permit rotation of the lever housing. This rotation engages the sliding projection in the guide rail. As the lever housing is rotated from an open to a closed position, it rotates the cam grooves to engage the cam follower projections thereby drawing the first connector into the base housing to a connected position.

Owner:J S T CORP

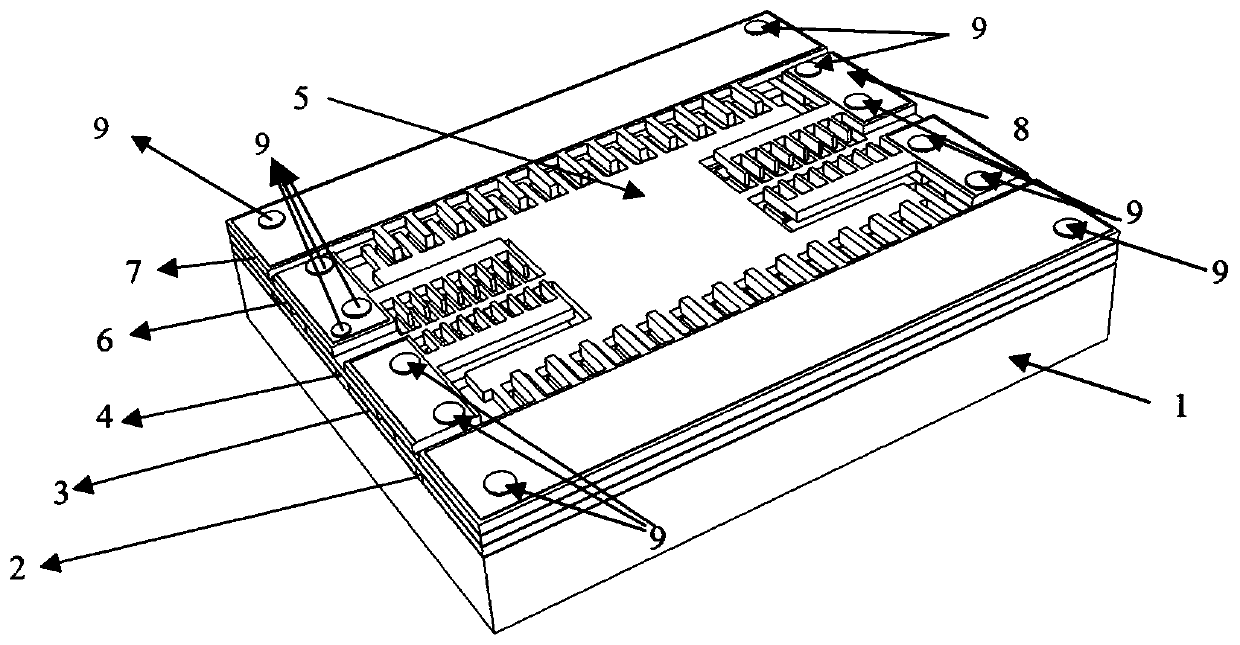

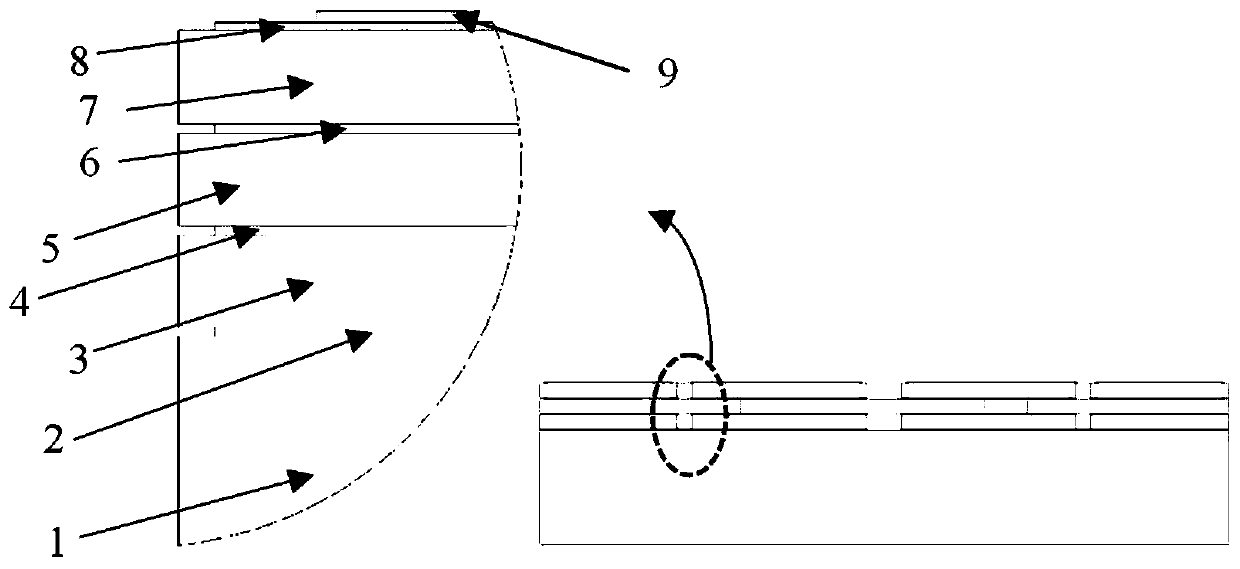

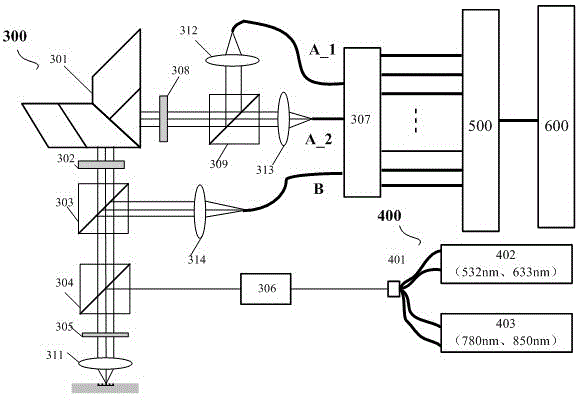

Micro-mirror with completely symmetrical differential capacitance angle feedback

ActiveCN111204701AHigh control precisionCompact structureDecorative surface effectsSolid-state devicesCapacitanceSignal processing circuits

The invention relates to the field of micro-nano optical devices, and specifically relates to a micro-mirror with completely symmetrical differential capacitance angle feedback. The micro-mirror comprises a base. A first insulating layer is arranged on the upper surface of the base. A first fixing layer is arranged on the upper surface of the first insulating layer. A second insulating layer is arranged on the upper surface of the first fixing layer, a reflecting element layer is arranged on the upper surface of the second insulating layer, a third insulating layer is arranged on the upper surface of the reflecting element layer, a second fixing layer is arranged on the upper surface of the third insulating layer, a fourth insulating layer is arranged on the upper surface of the second fixing layer, and a bonding pad is arranged on the fourth insulating layer. According to the scheme, the angle sensor is integrated in the micro-mirror, the structure is compact, power consumption is low, and process compatibility is high. The structure has vertical and planar symmetry at the same time, driving is reliable and easy, the detection signal-to-noise ratio is high, and the complexity of adetection signal processing circuit is remarkably reduced. Application requirements from low frequency to high frequency can be met.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

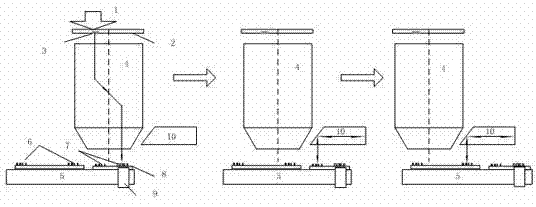

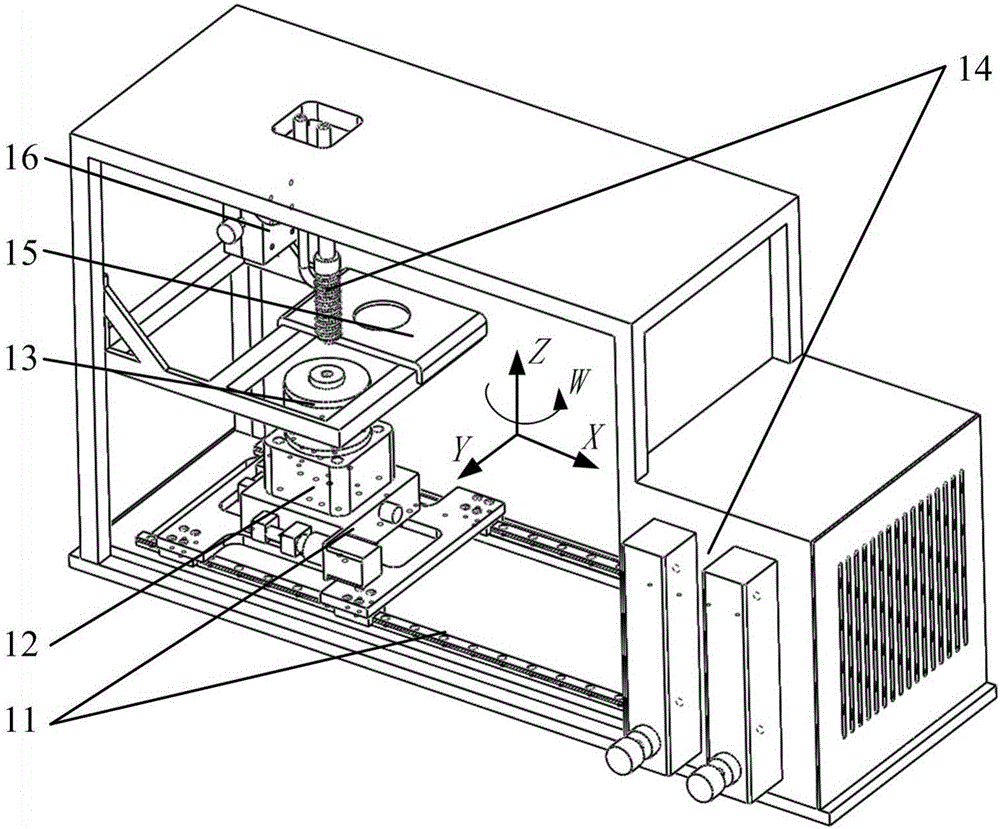

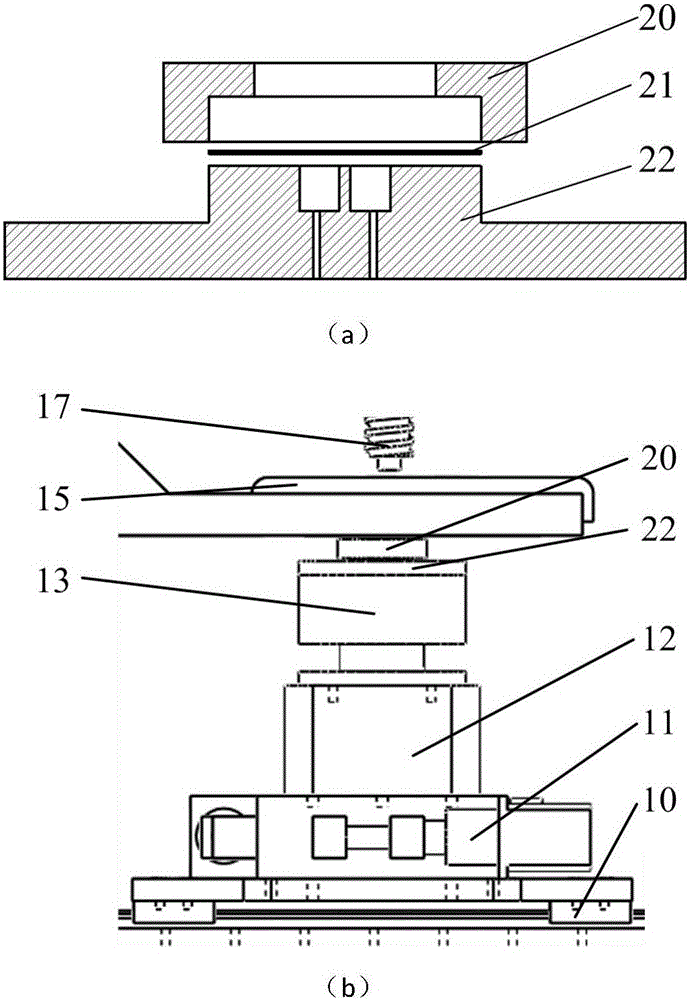

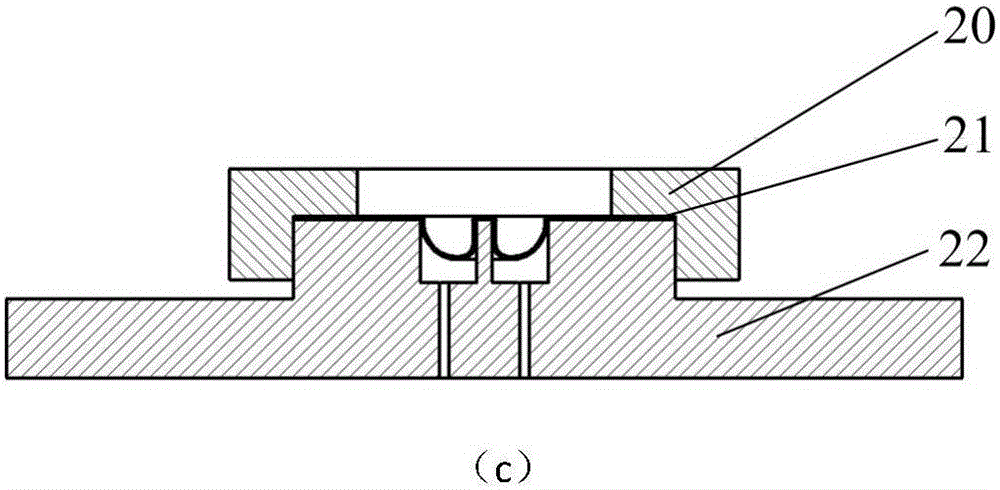

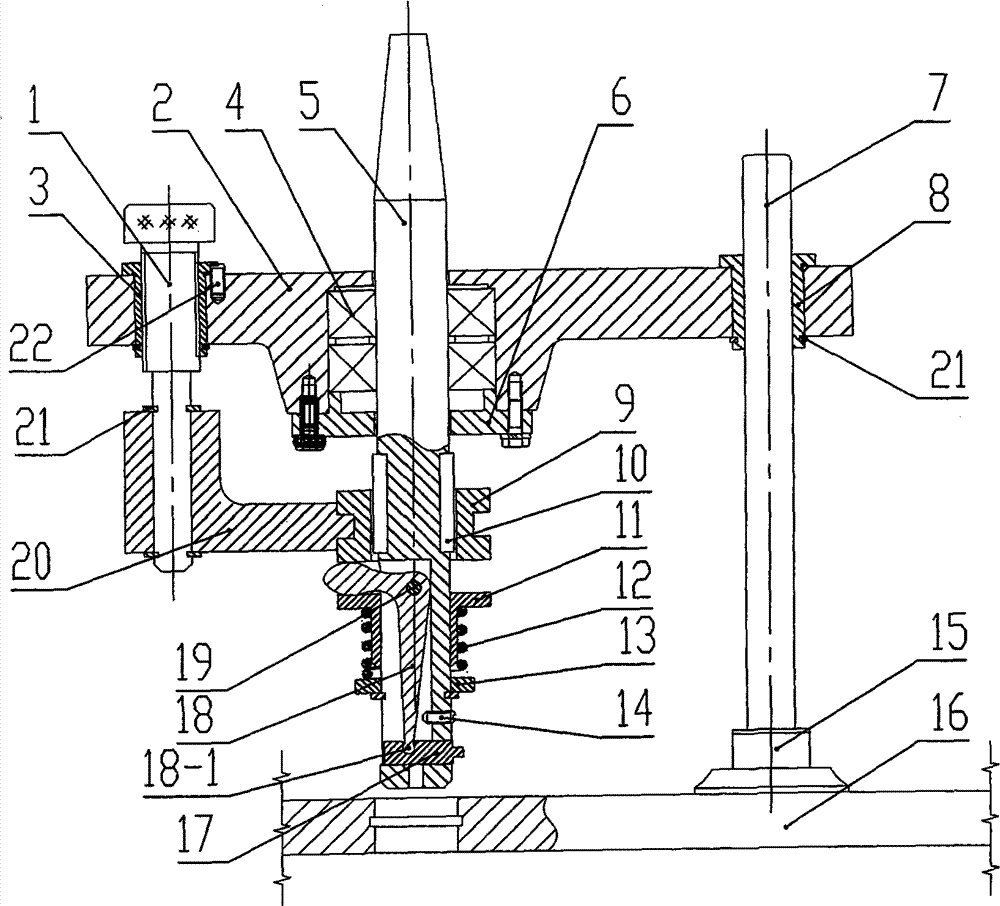

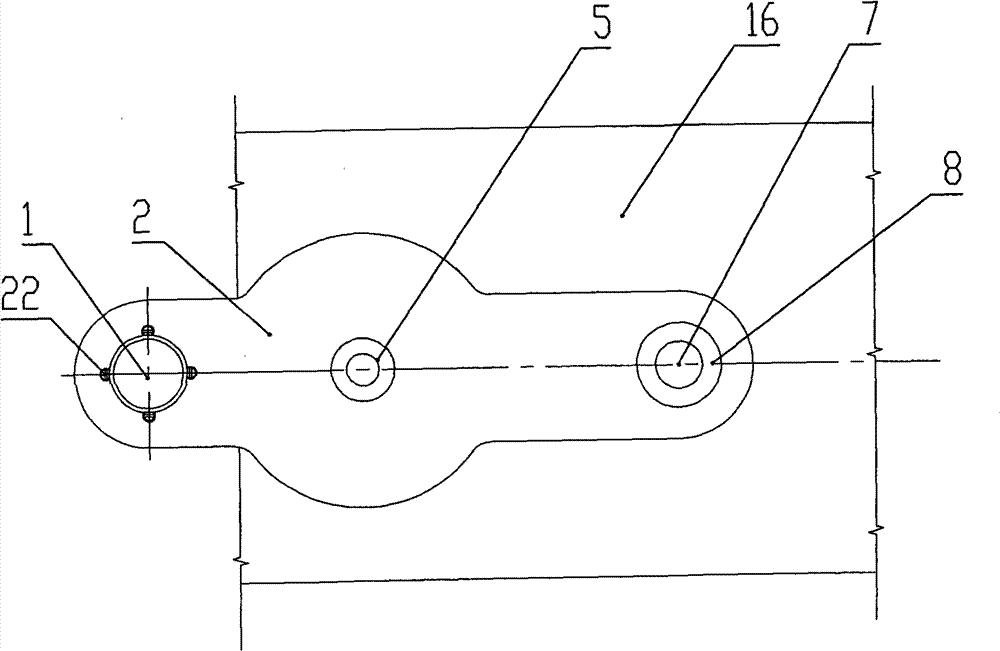

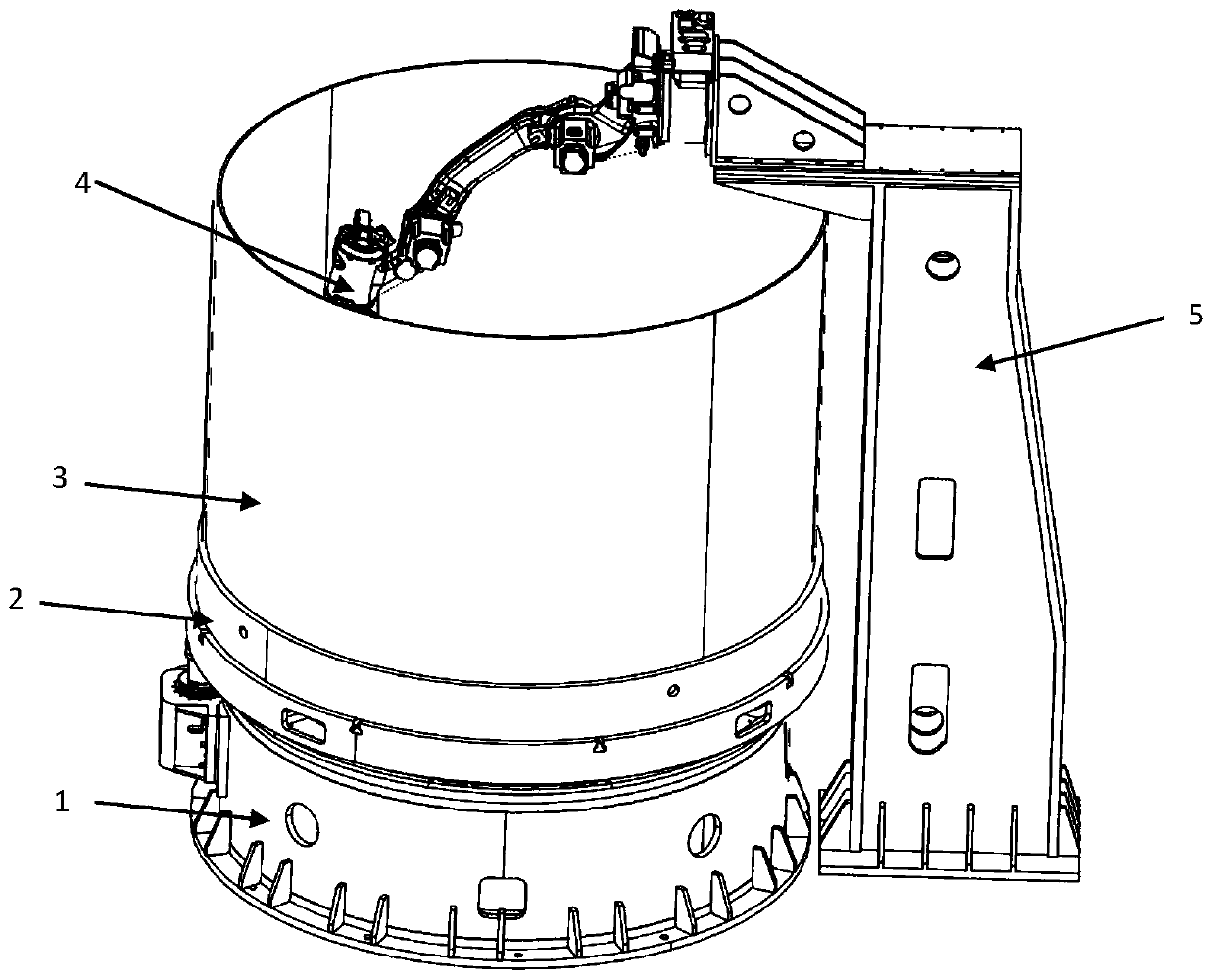

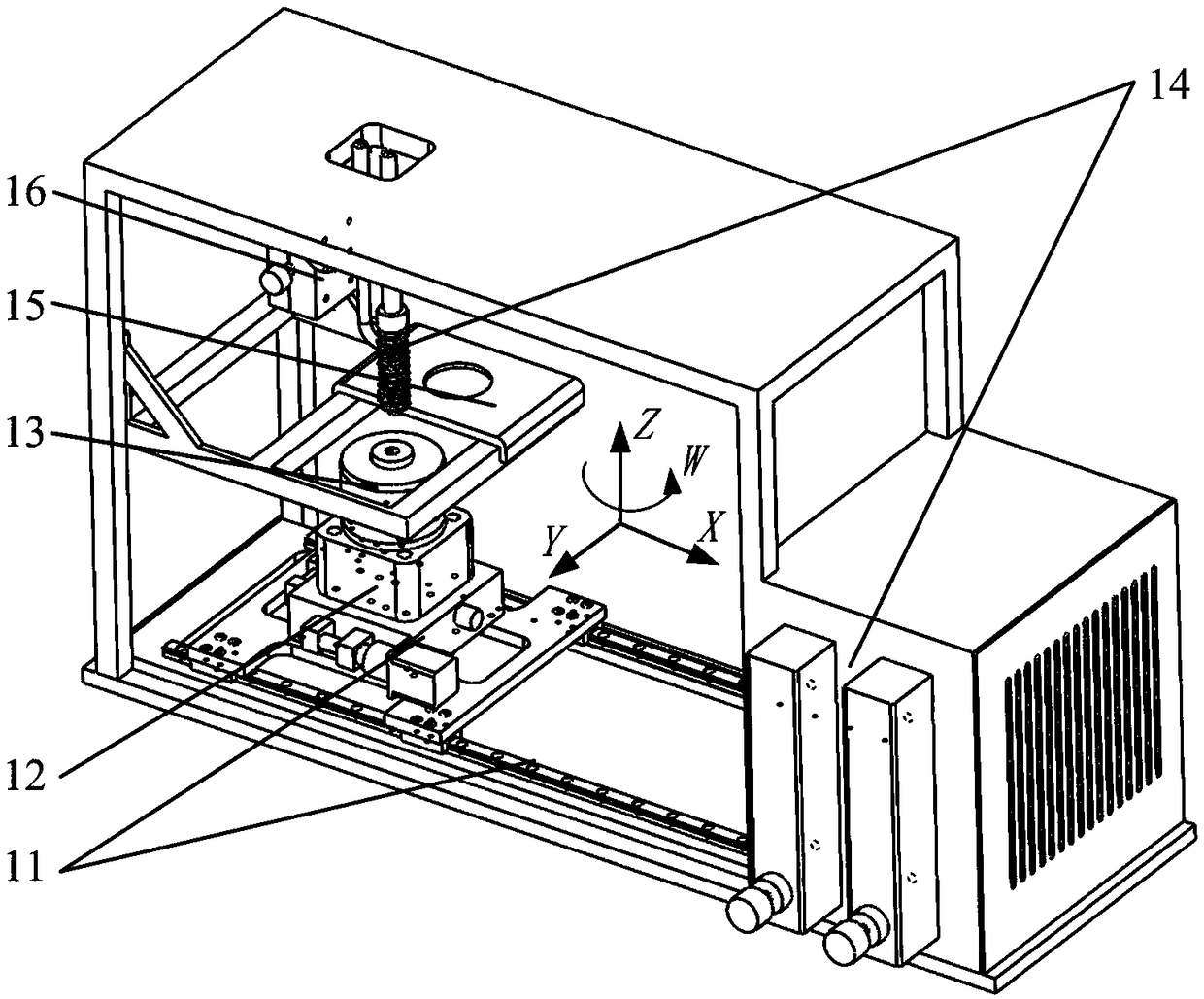

Equipment for machining high-precision fused-quartz micro shell resonant structure

ActiveCN106082602AReduce frequency crackingHigh quality factorGlass reforming apparatusControl systemEngineering

Equipment for machining a high-precision fused-quartz micro shell resonant structure comprises an XYZ three-dimensional feed mechanism, a W-direction servo rotation mechanism, a forming mold and a high-temperature flame control system; the high-temperature flame control system comprises a high-temperature flame gun, a to-be-processed quartz sheet is fixedly disposed on the forming mold, the forming mold is fixedly connected with the W-direction servo rotation mechanism, the W-direction servo rotation mechanism is capable of driving the forming mold to synchronously rotate at a high speed, the XYZ three-dimensional feed mechanism and the W-direction servo rotation mechanism are used to achieve alignment between the to-be-processed quartz sheet and high-temperature flame ejected by the high-temperature flam gun. The equipment for machining the high-precision fused-quartz micro shell resonant structure is capable of substantially improving the processing precision of a fused quartz micro shell resonant structure, substantially improves the machining efficiency, and is also applicable to machine resonant structures made from multiple materials with multiple dimension scopes.

Owner:NAT UNIV OF DEFENSE TECH

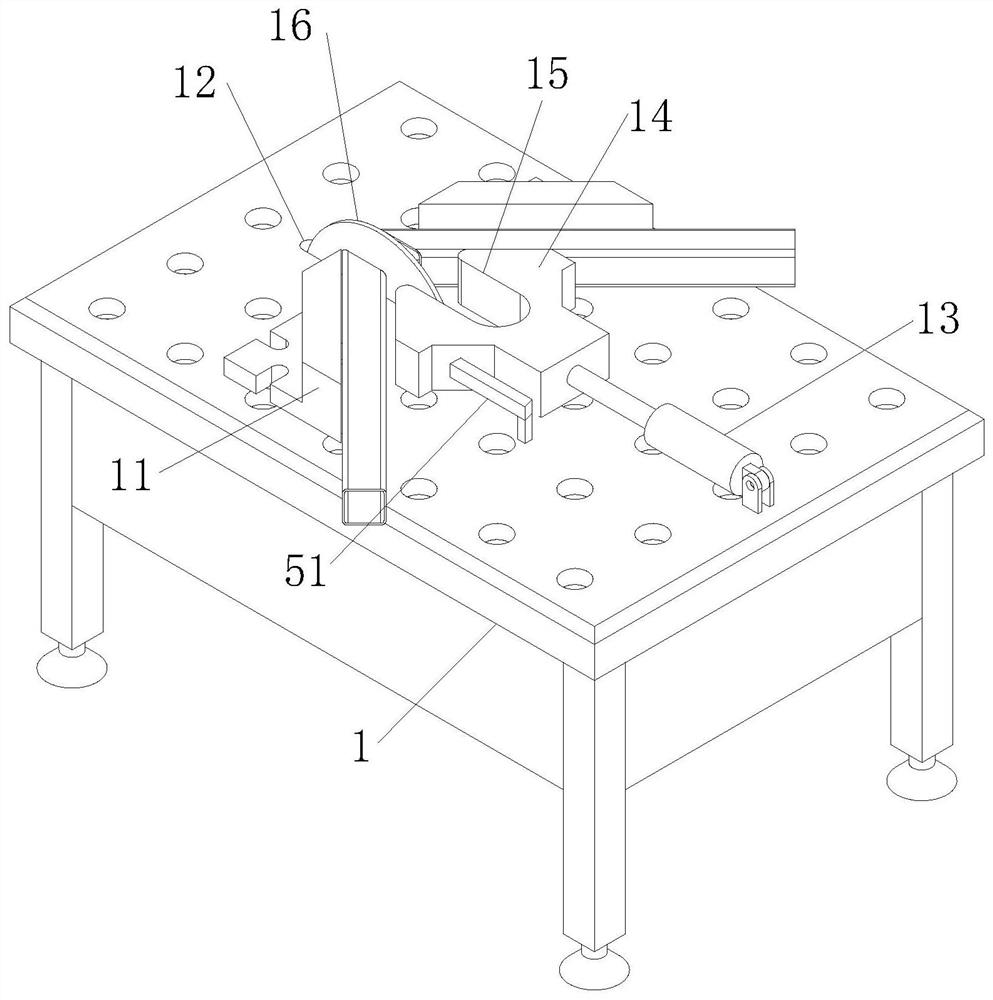

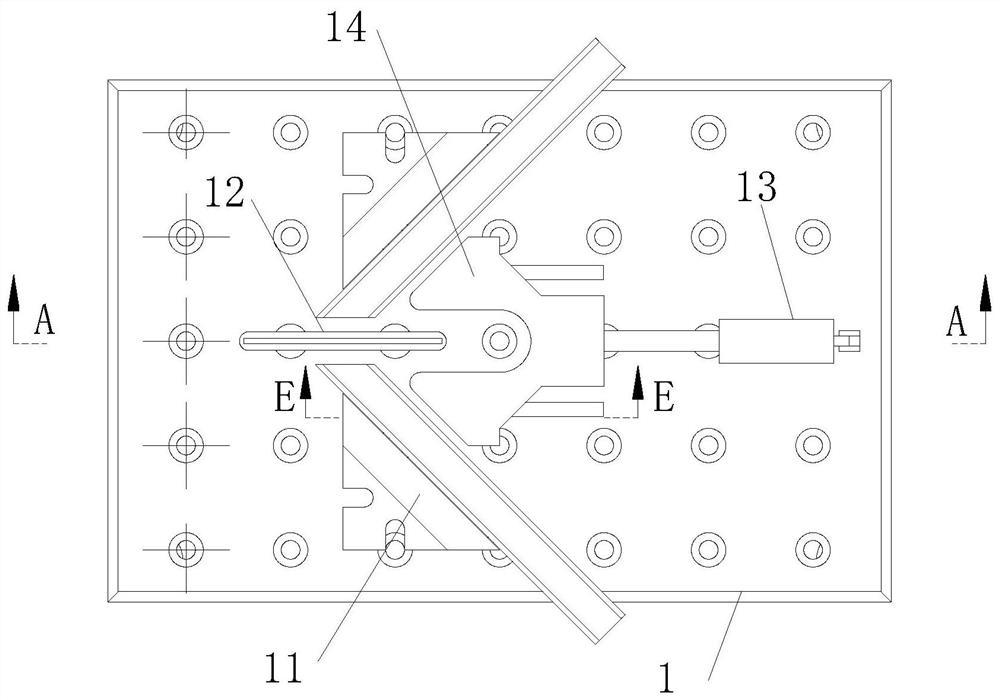

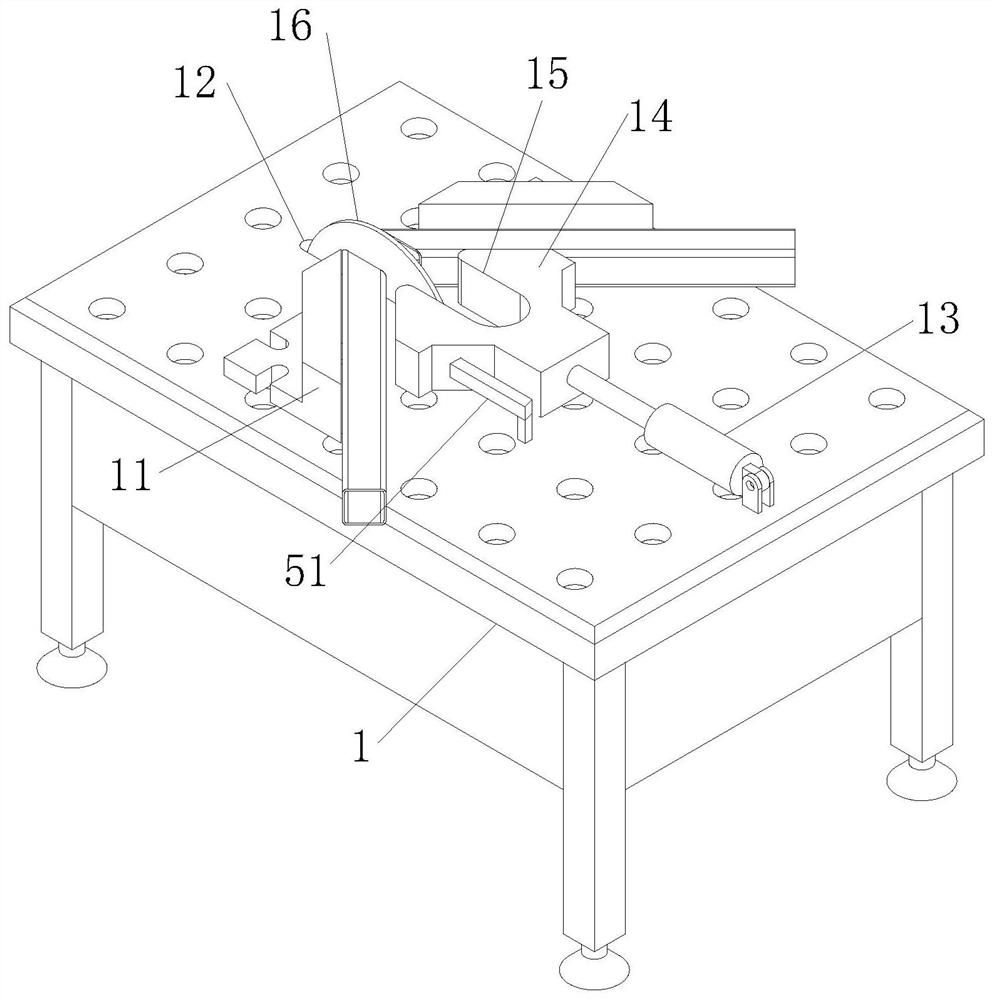

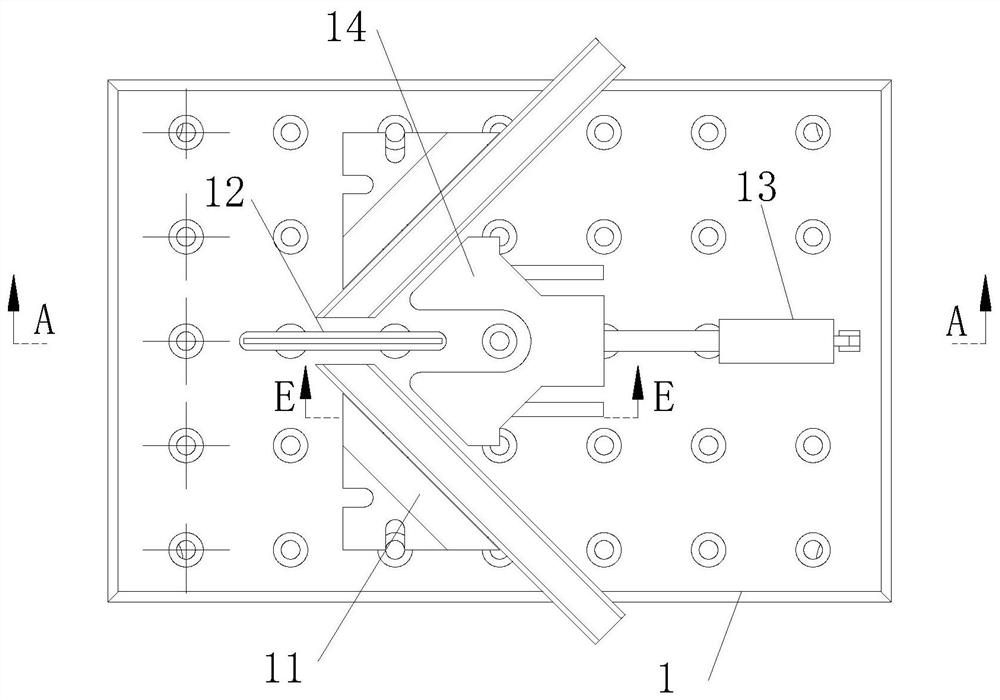

Welding tool for assembling electric tricycle

ActiveCN113369779AEliminate alignment errorsBig distanceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention belongs to the technical field of machining, and particularly relates to a welding tool for assembling an electric tricycle. The welding tool for assembling the electric tricycle comprises a tool bench body, a set of fixing holes are evenly distributed in the top of the tool bench body, and a pair of vertically-arranged limiting blocks are fixedly connected to the top of the tool bench body through bolts; a through groove is formed in the portion, between the two limiting blocks, of the top of the tool bench body, and an air cylinder is hinged to the position, corresponding to the through groove, of one side of the tool bench body; a right-angle ejector block is fixedly connected to the end of a piston rod of the air cylinder, and a U-shaped groove is formed in the side, close to the through groove, of the ejector block; and a jacking unit is arranged at the bottom of the tool bench body, a grinding disc is rotationally connected to the position, corresponding to the through groove, of the jacking unit, and the grinding disc penetrates through the through groove and extends to the top of the tool bench body. According to the welding tool for assembling the electric tricycle, the grinding disc is driven by the jacking unit to ascend to grind a notch of a steel pipe, the flatness of the notch is improved, the alignment error of the steel pipe is eliminated, and the automatic efficiency of frame welding is improved.

Owner:江苏鸿迅机车有限公司

Triode structure field emission display device using carbon nanotubes and method of fabricating the same

InactiveUS7527988B2Short circuit can be preventedBlocking may occurControl electrodesNanoinformaticsInsulation layerField emission display

A field emission display device and a method of fabricating the same are provided. The field emission display device may include a substrate, a transparent cathode layer, an insulation layer, a gate electrode, a resistance layer, and carbon nanotubes. The transparent cathode layer is deposited on the substrate. The insulation layer is formed on the cathode layer and has a well exposing the cathode layer. The gate electrode is formed on the insulation layer and has an opening corresponding to the well. The resistance layer is formed to surround the surface of the gate electrode and the inner walls of the opening and the well so as to block ultraviolet rays. The carbon nanotube field emitting source is positioned on the exposed cathode layer.

Owner:SAMSUNG SDI CO LTD

Method of manufacturing high-integrated semiconductor device and semiconductor device manufactured using the same

ActiveUS8119509B2Excellent characteristicsHigh yieldSolid-state devicesSemiconductor/solid-state device manufacturingBit lineEngineering

Owner:SK HYNIX INC

Cutting tool for boring inner hole groove

InactiveCN101780549BIncrease productivityEliminate alignment errorsTurning toolsBoring headsTool bitMechanical engineering

The invention discloses a cutting tool for boring an inner hole groove. The cutting tool can be used for directly boring the inner hole groove without taking off a workpiece after the inner hole process is performed on a drilling machine or a milling machine. The cutting tool for boring the inner hole groove comprises a cutter bar and a tool bit, wherein the tool bit is inserted in a square hole of the cutter bar in a sliding fit way; the upper end of the tool bit is connected with a cutting feed shifting fork; the cutting feed shifting fork toggles the tool bit to move axially along a boringtool bar to bore the inner hole groove; the cutting feed shifting fork is hinged with the cutter bar through a hinged shaft; the cutting feed shifting fork abuts against a sliding sleeve; the slidingsleeve is in sliding fit connection with the cutter bar; the shifting fork connected with the sliding sleeve is arranged at the lower end of a threaded rod; the threaded rod is connected with a fixedseat with nuts; the fixed seat is arranged on the cutter bar through a shaft; the lower part of the cutting feed shifting fork is provided with a spring; and a guide sleeve and a guide post are arranged on one side of the fixed seat to play an auxiliary guide role and prevent safety accidents caused by that the fixed seat rotates along with the cutter bar.

Owner:SHANGHAI DATUN ENERGY

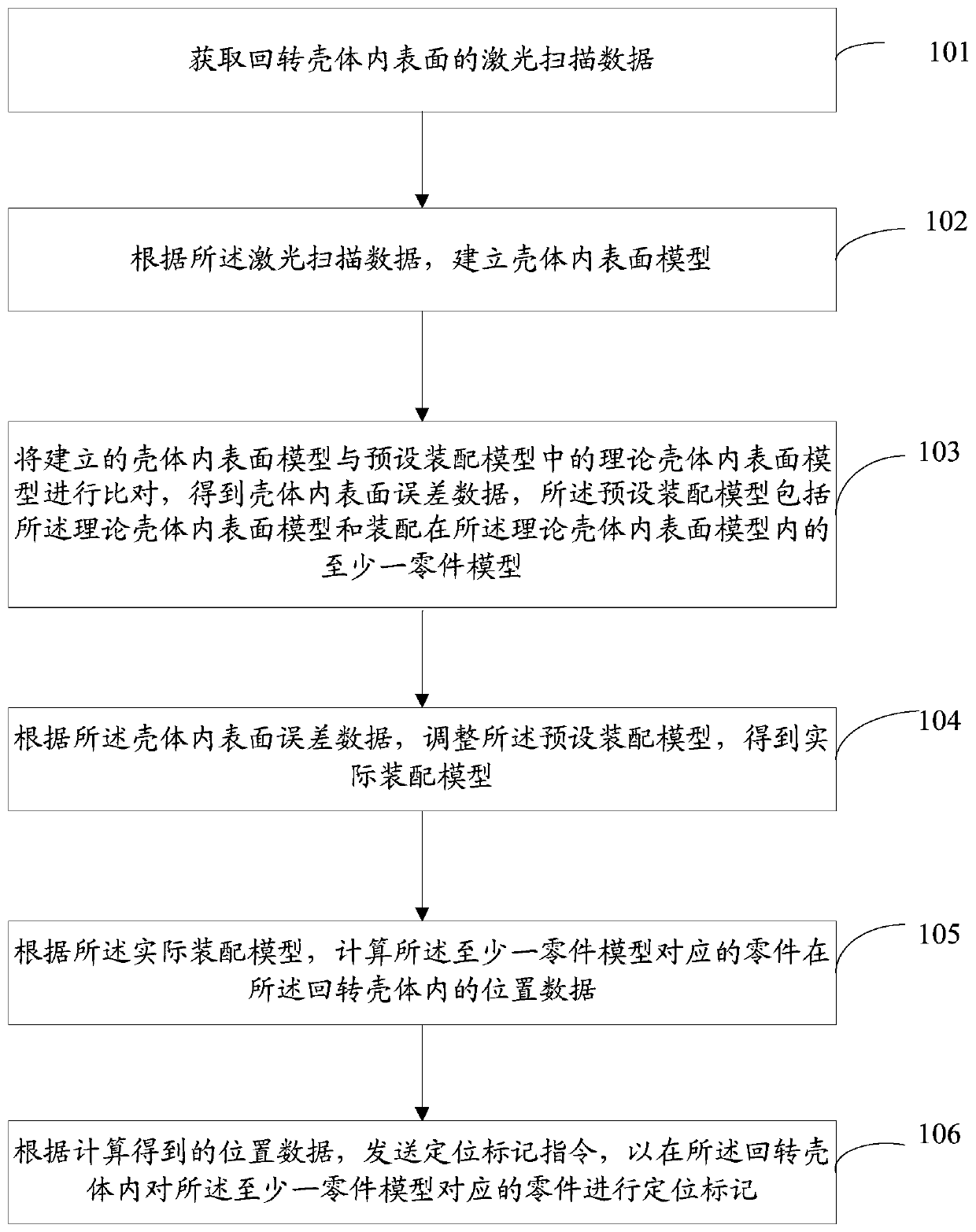

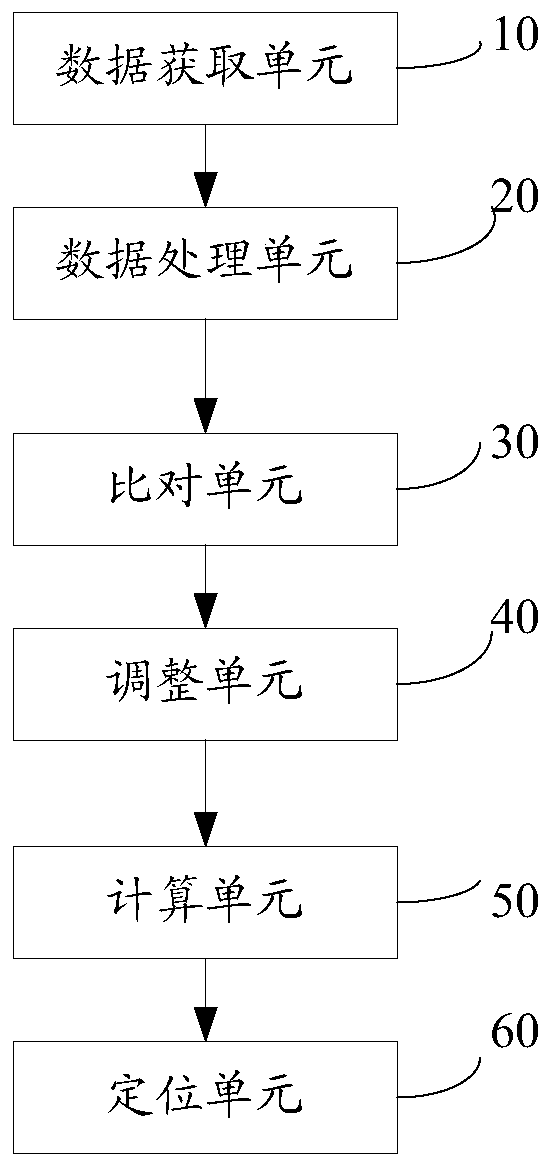

A positioning marking method, device and system for internal parts of a rotary housing

ActiveCN106903663BHigh degree of automationGuaranteed positioning accuracyOther workshop equipmentLaser scanningEngineering

The invention provides a positioning marking method, device and system of an in-built part of a rotating shell, and relates to the technical field of assembling. The positioning marking method comprises the steps that laser scanning is conducted on the inner surface of the rotating shell, so that a shell inner surface model is obtained; a preset assembling model is adjusted according to the obtained inner surface model, so that a practical assembling model is obtained; position data of the part in the rotating shell are determined according to the practical assembling model; and positioning marking is conducted on the part in the rotating shell according to the position data, so that automatic positioning marking of the part is achieved. The whole marking process is accomplished by an operator through a computer, and manual and mechanical measurement and other manual labor are not required.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

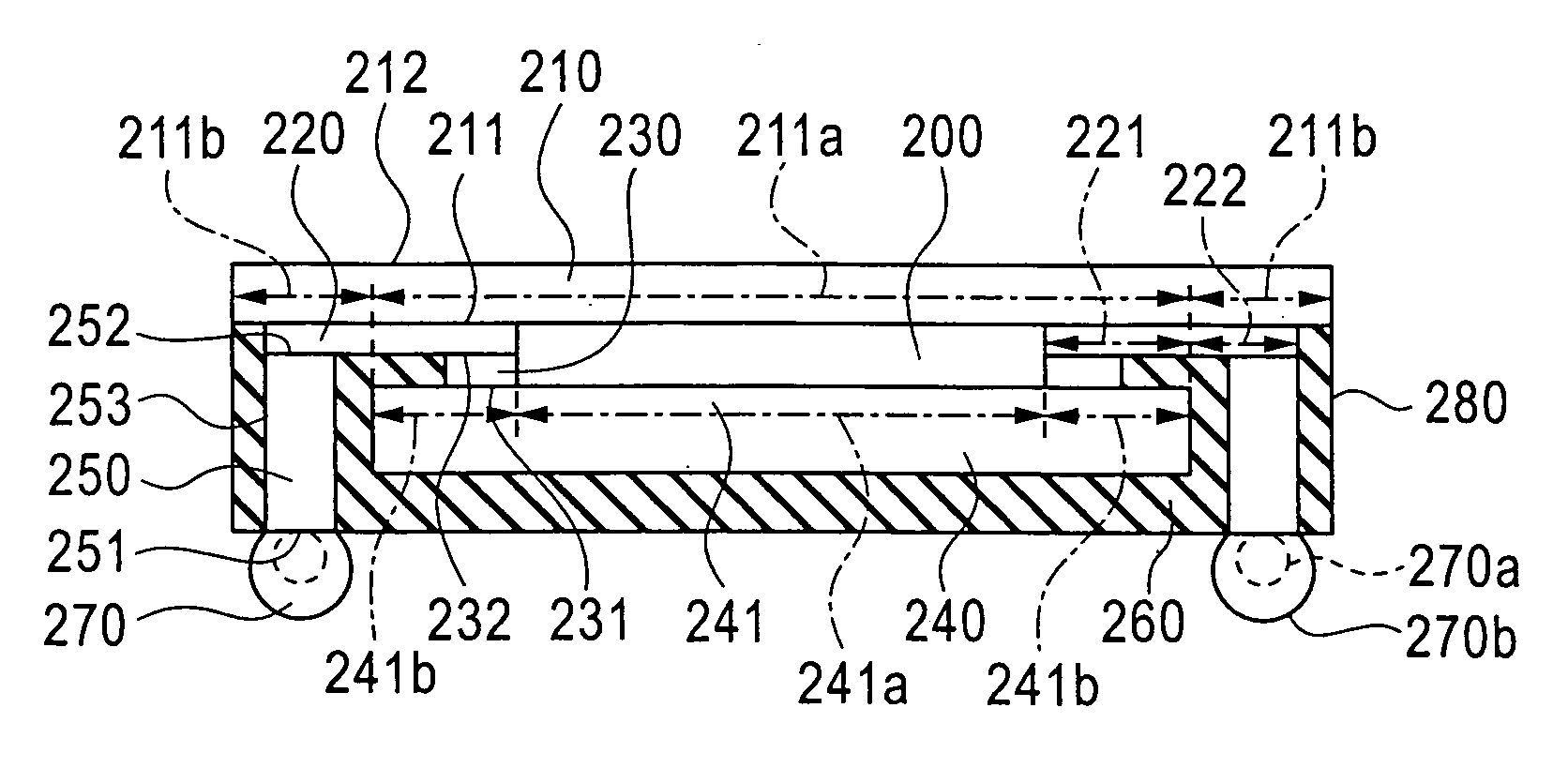

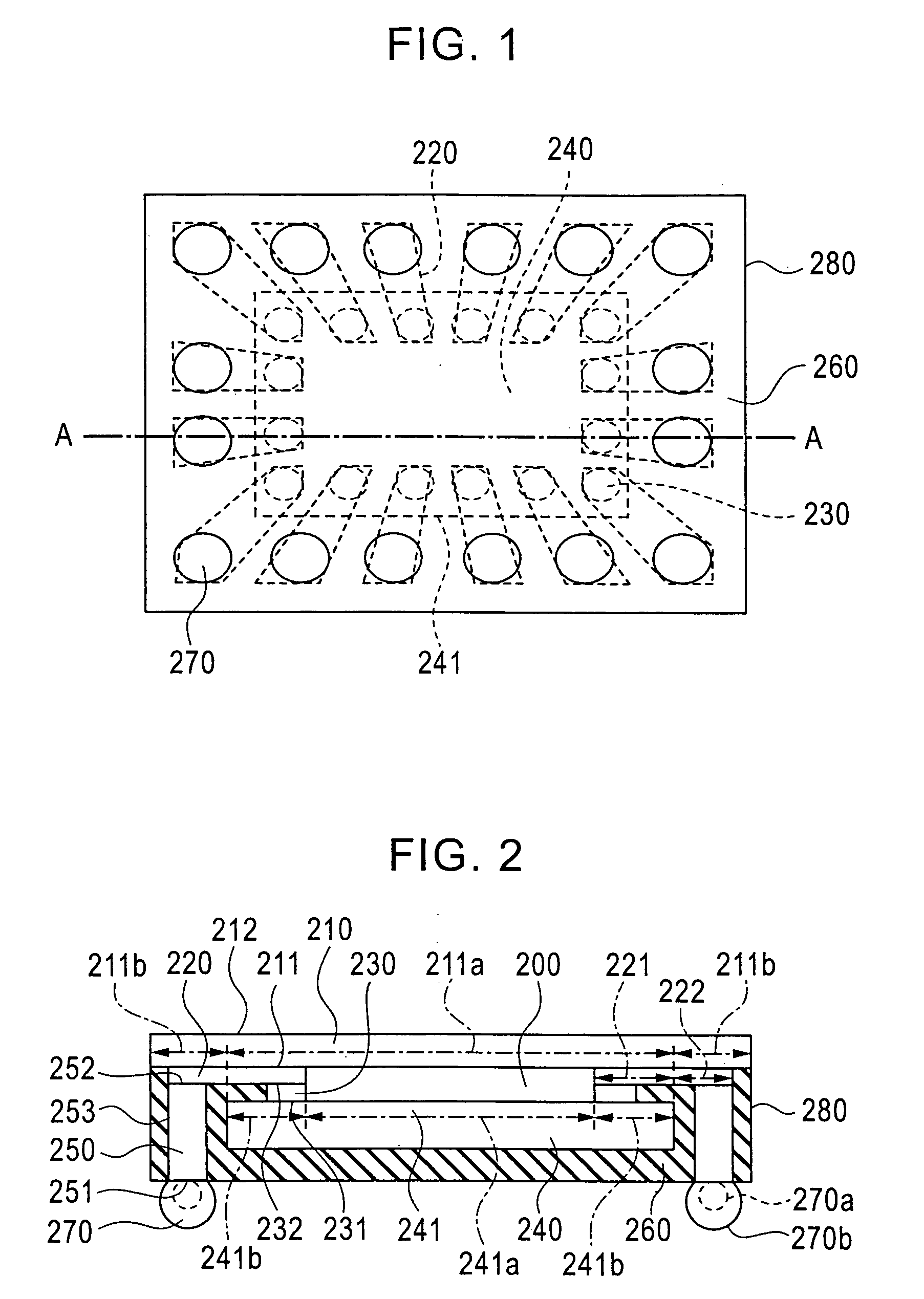

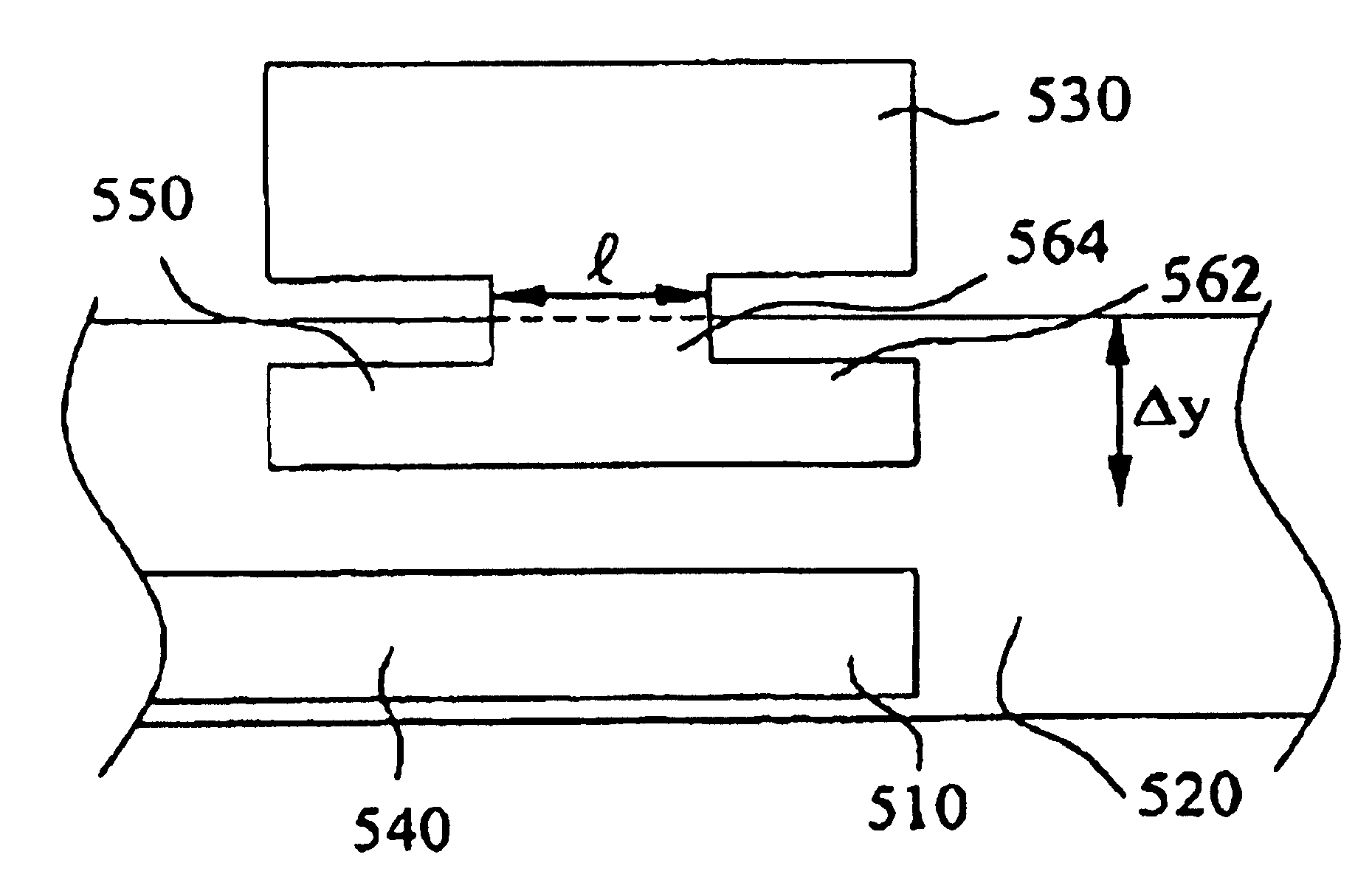

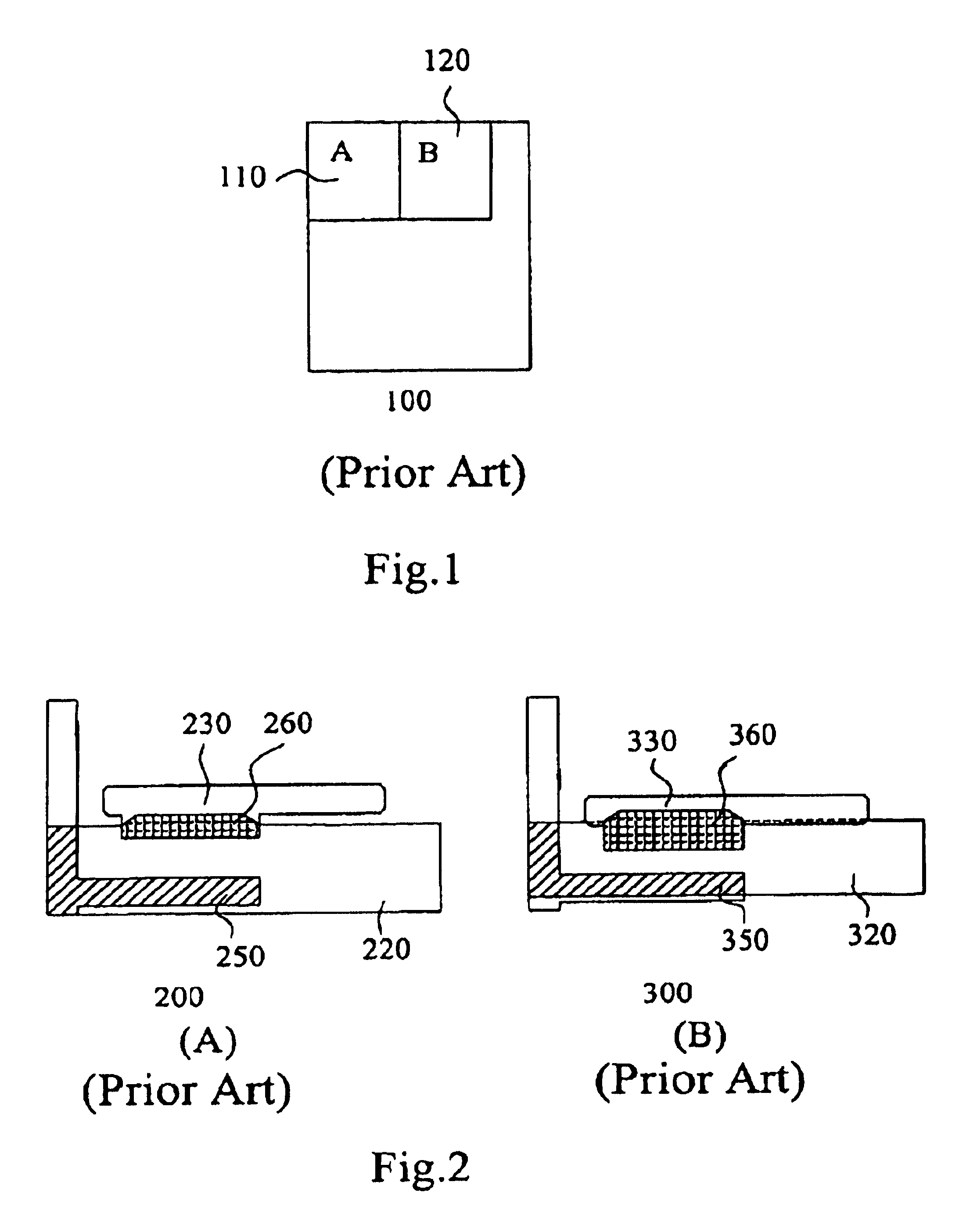

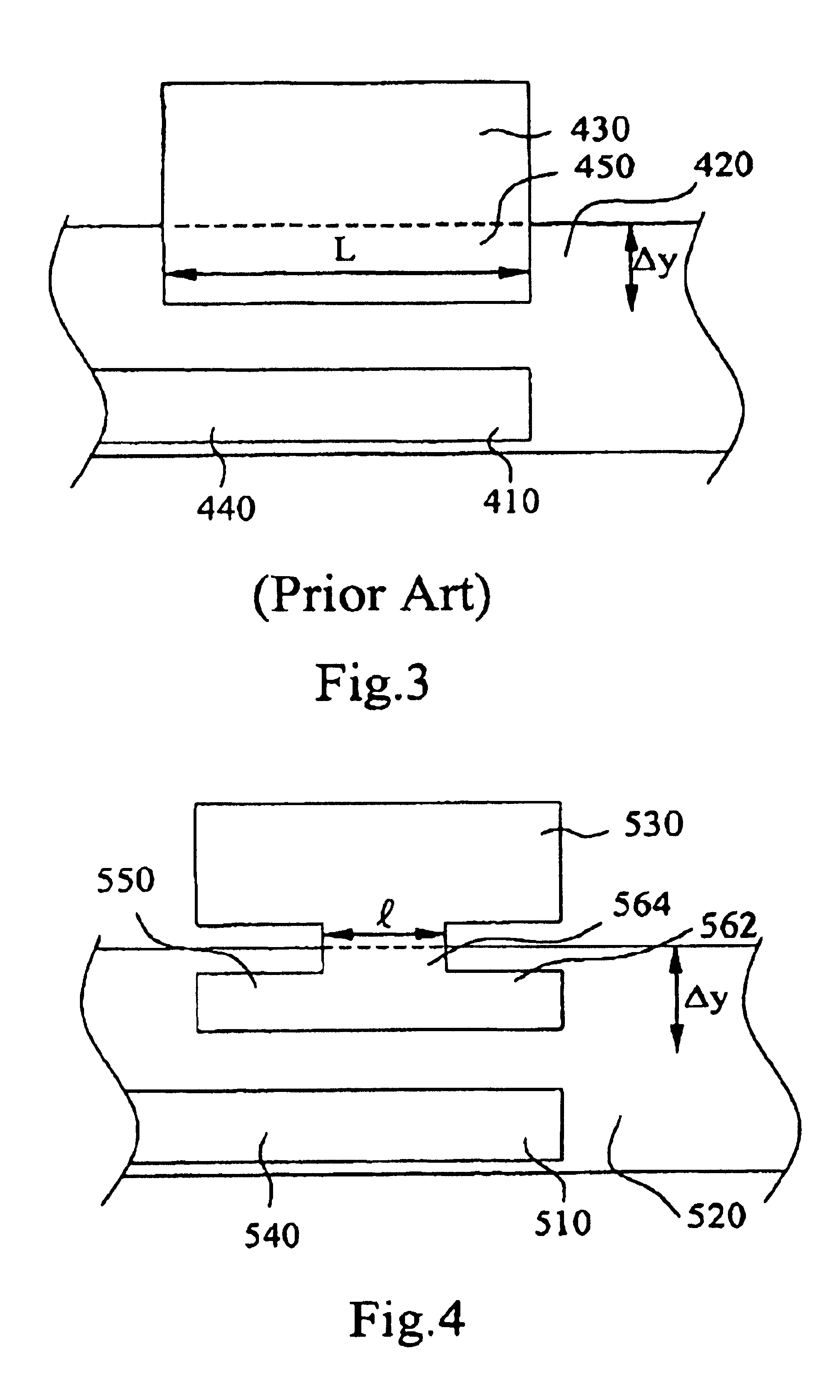

LCD and method of improving the brilliance of the same

InactiveUSRE42283E1Improve uniformityEliminate alignment errorsTransistorSolid-state devicesLiquid-crystal displayConducting zone

A TFT liquid crystal display device is disclosed, which includes two substrates and a liquid crystal layer provided in between the substrates, one substrate having a surface providing with a plurality of data signal lines, a plurality of scan lines, a plurality of pixel electrodes, and a plurality of functional components having source electrode, gate electrodes and drain electrodes. Moreover, the projection of one of the signal electrode and the drain electrode on the gate electrode having at least one bridging zone and one conducting zone. The width of the bridging zone in the direction in parallel to one side of the gate electrode is smaller than the width of the conducting zone in the direction in parallel to the side of the gate electrode.

Owner:CHUNGHWA PICTURE TUBES LTD

Magnetic resonance imaging gating system, method and magnetic resonance imaging equipment

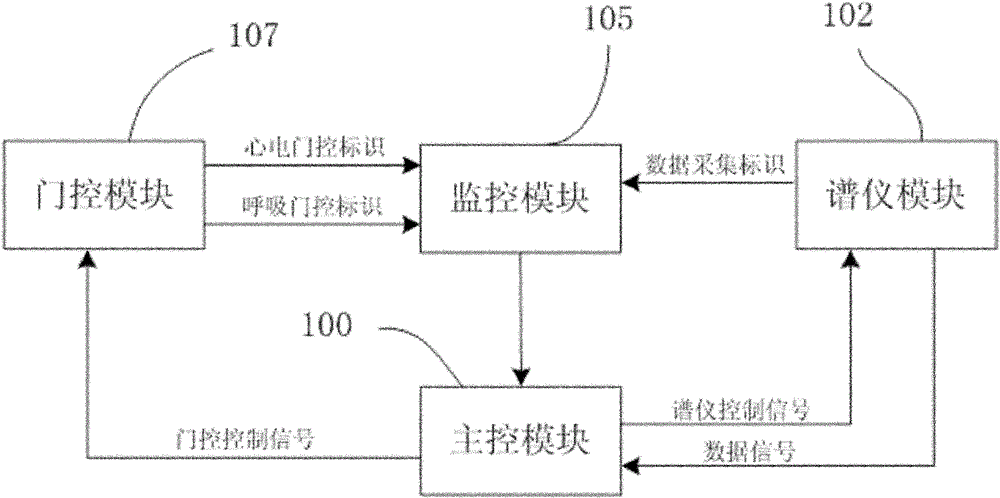

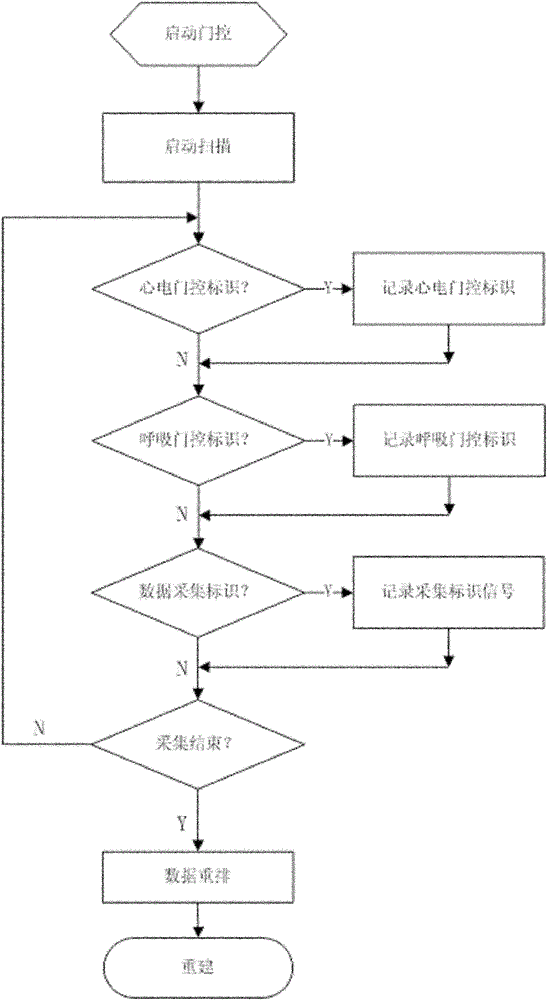

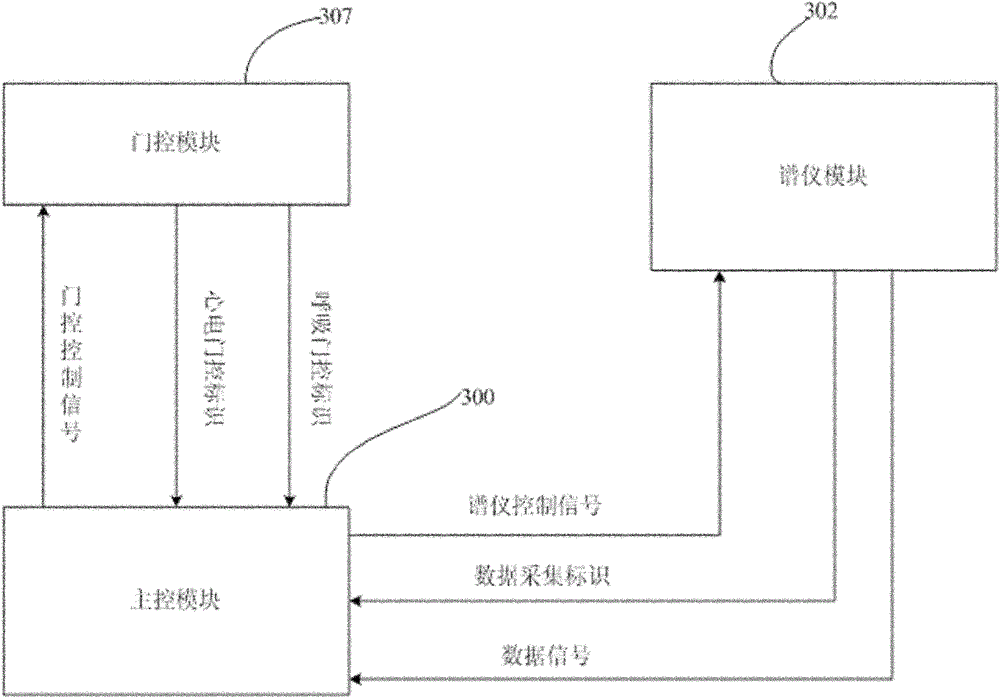

InactiveCN102525459BLow real-time requirementsAvoid interferenceDiagnostic recording/measuringSensorsData acquisitionComputer module

The invention discloses a magnetic resonance imaging device and a gate control system and method of the magnetic resonance imaging device. The magnetic resonance imaging gate control system comprises a master control module, a spectrometer module, a gate control module and a monitoring module which is independent of the spectrometer module. The gate control module is used for generating a gate control mark according to acquired gate control data; the spectrometer module is used for triggering a data acquisition mark during data acquisition; the monitoring module is used for receiving and recording the gate control mark outputted by the gate control module, generation time of the gate control mark, the data acquisition mark and triggering time of the data acquisition mark, and further outputting the same to the master control module together; the spectrometer module is used for outputting image data to the master control module; and the master control module is used for synchronously corresponding the image data with the gate control mark according to the received gate control mark, the generation time of the gate control mark, the data acquisition mark and the triggering time of the data acquisition mark, and then re-arranging the image data and the gate control mark. The magnetic resonance imaging gate control system disclosed by the invention can realize gate control through the spectrometer module with lower real-time property.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

A high-precision fused silica microshell resonant structure processing equipment

ActiveCN106082602BReduce frequency crackingHigh quality factorGlass reforming apparatusResonanceControl system

Owner:NAT UNIV OF DEFENSE TECH

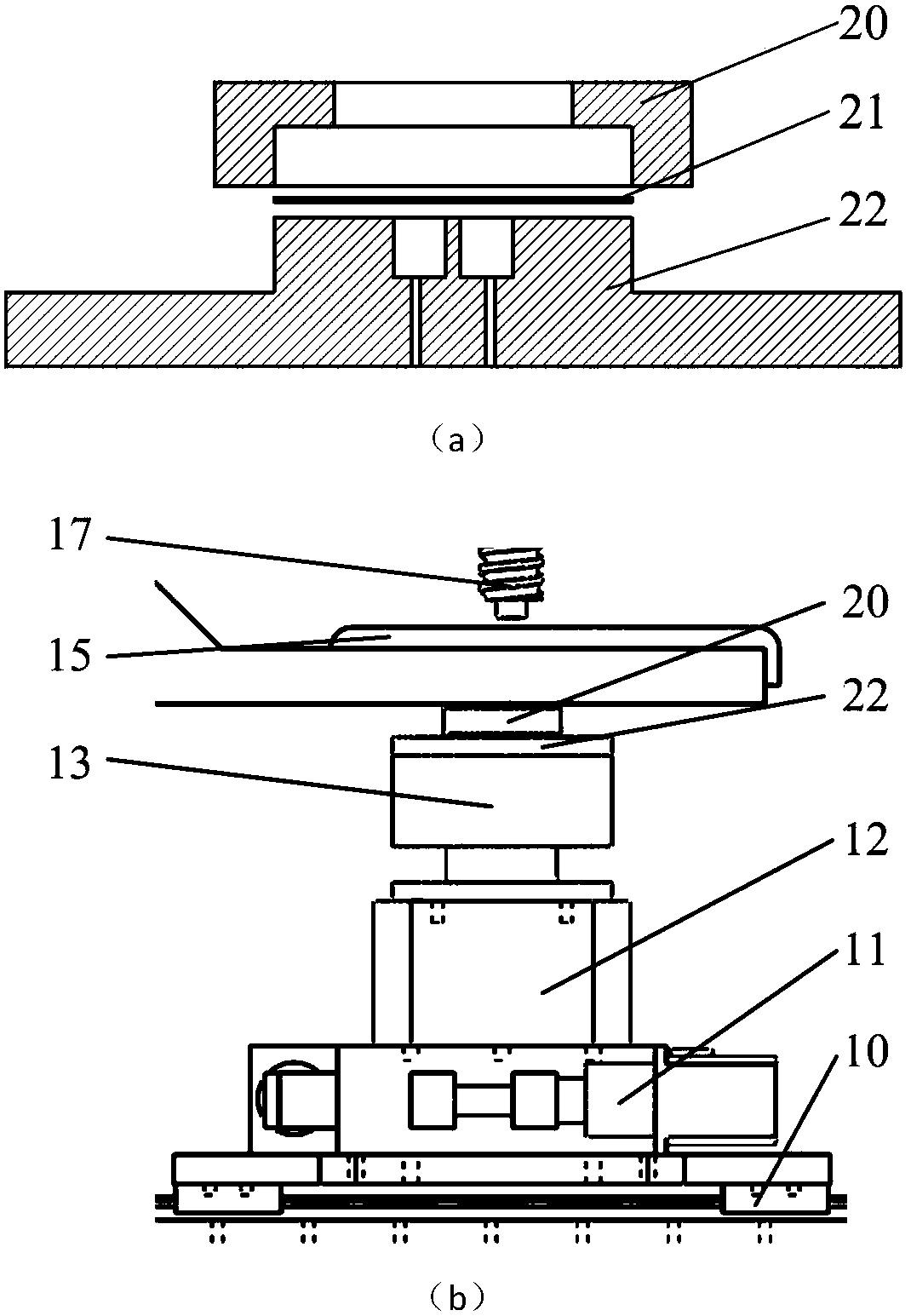

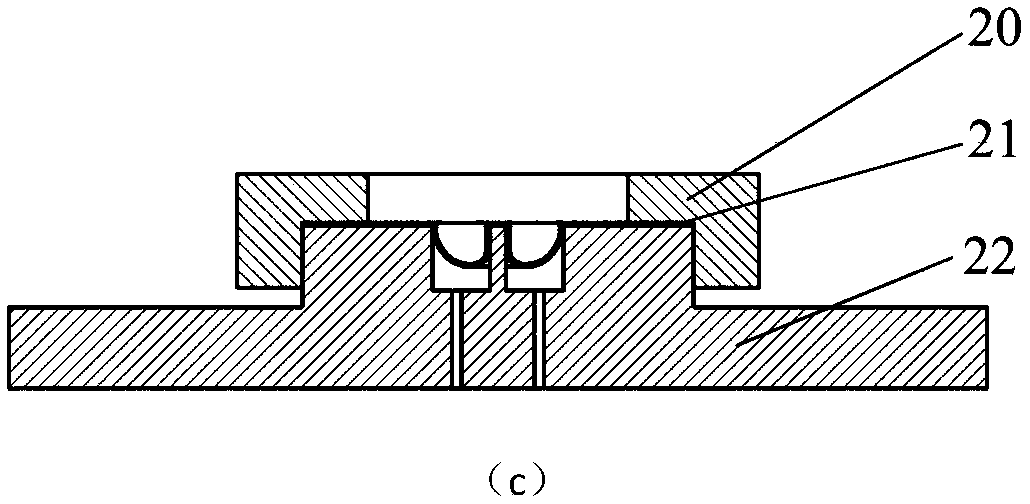

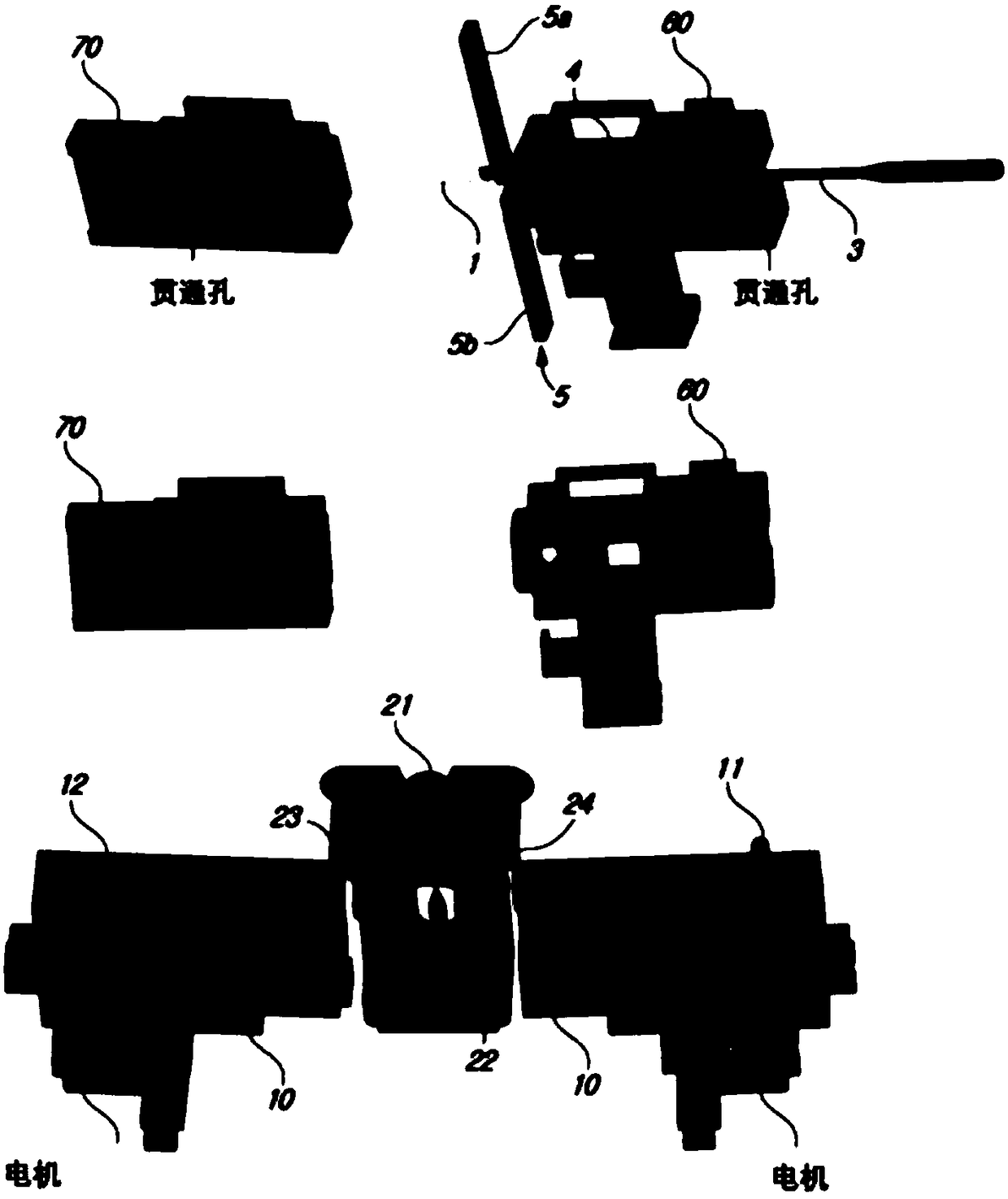

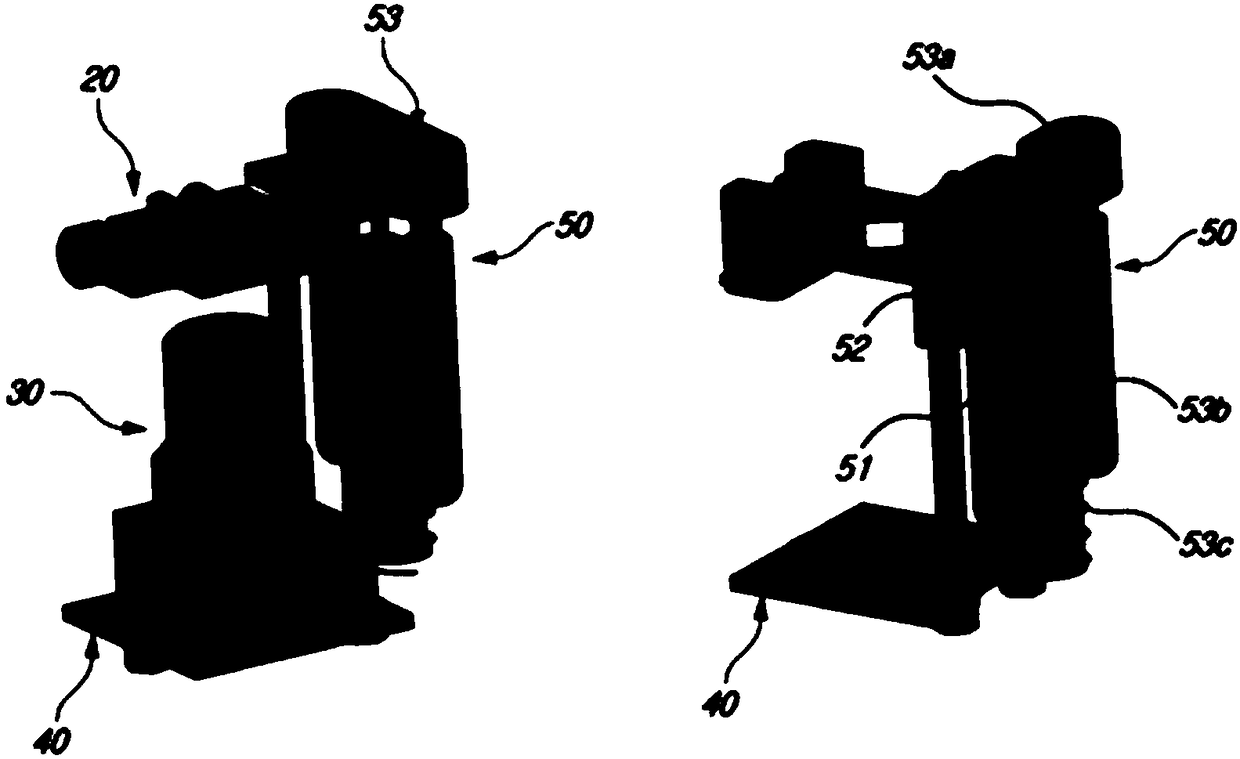

Fibre optic fusion splicer

ActiveCN108089265AStable separationEliminate alignment errorsCoupling light guidesOptical ModuleEngineering

The present invention relates to a fiber optic fusion splicing technique, in particular to a fiber optic fusion splicer for reliable and stable fiber optic fusion splicing, that is characterized by comprising: an alignment part for fixing and aligning first and second optical fibers that are to be fusion spliced; a fusion splicing module having an electrode bar for fusion splicing the first and second optical fibers that are fixed to and aligned in the alignment module; an optical module for photographing the aligned state of the first and second optical fibers aligned by the alignment module,and the fusion-spliced state of the first and second optical fibers fusion-spliced by the fusion splicing module; a support part in which the fusion splicing module and the optical module are mounted; and a lift module for moving the support part up and down.

Owner:SOLTECH INFONET

A welding tool for electric tricycle assembly

ActiveCN113369779BEliminate alignment errorsBig distanceWelding/cutting auxillary devicesAuxillary welding devicesMachiningPiston rod

The invention belongs to the technical field of mechanical processing, and specifically relates to a welding tool for electric tricycle assembly, including a tooling platform body; a group of fixing holes are evenly distributed on the top of the tooling platform body, and a pair of vertically arranged welding tools are fixed on the top of the tooling platform body through bolts. Limiting block; the top of the tooling table body between the two limiting blocks is provided with a through groove, and a cylinder is hinged on one side of the tooling table body corresponding to the through groove; the end of the piston rod of the cylinder is fixedly connected with a right-angled top block, There is a U-shaped groove on the side of the top block close to the through groove; the bottom of the tooling table body is equipped with a jacking unit, and the lifting unit is rotatably connected to the corresponding position of the through groove with a grinding disc, which runs through the through groove and extends to the top of the tooling table body The present invention drives the grinding disc to rise through the jacking unit to grind the incision of the steel pipe to increase the flatness of the incision, eliminate the alignment error of the steel pipe, and improve the automation efficiency of the frame welding.

Owner:江苏鸿迅机车有限公司

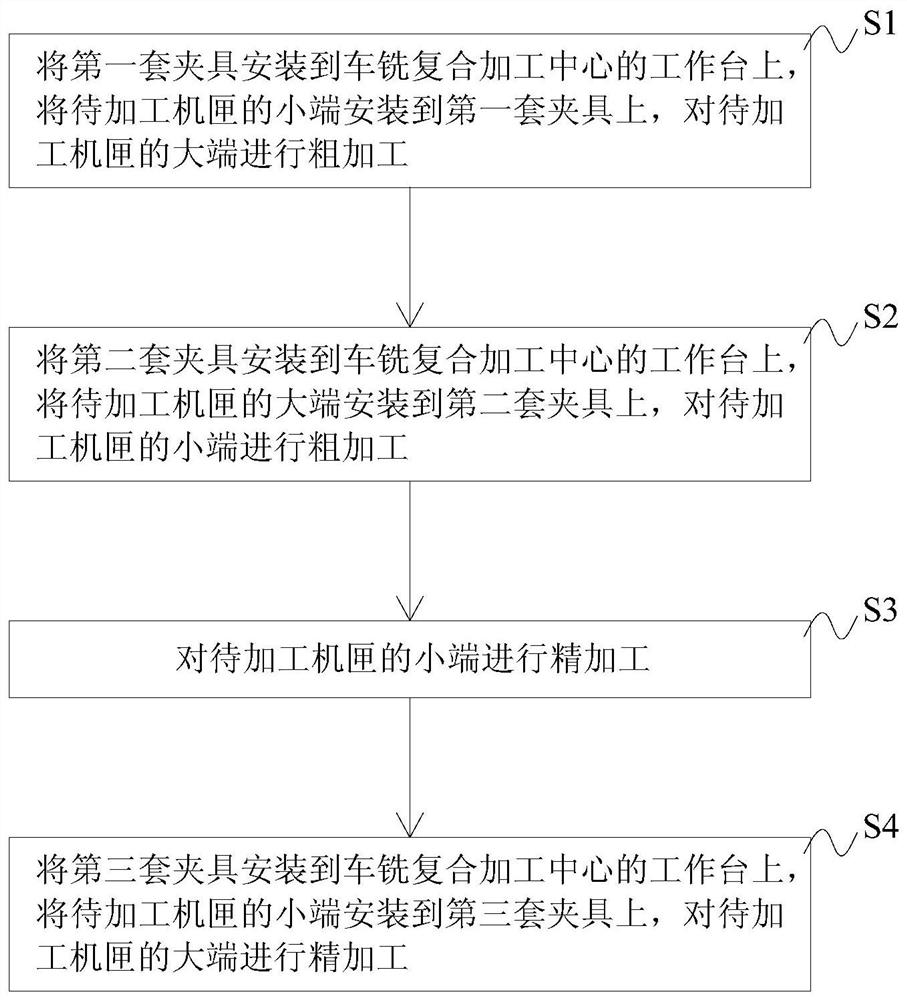

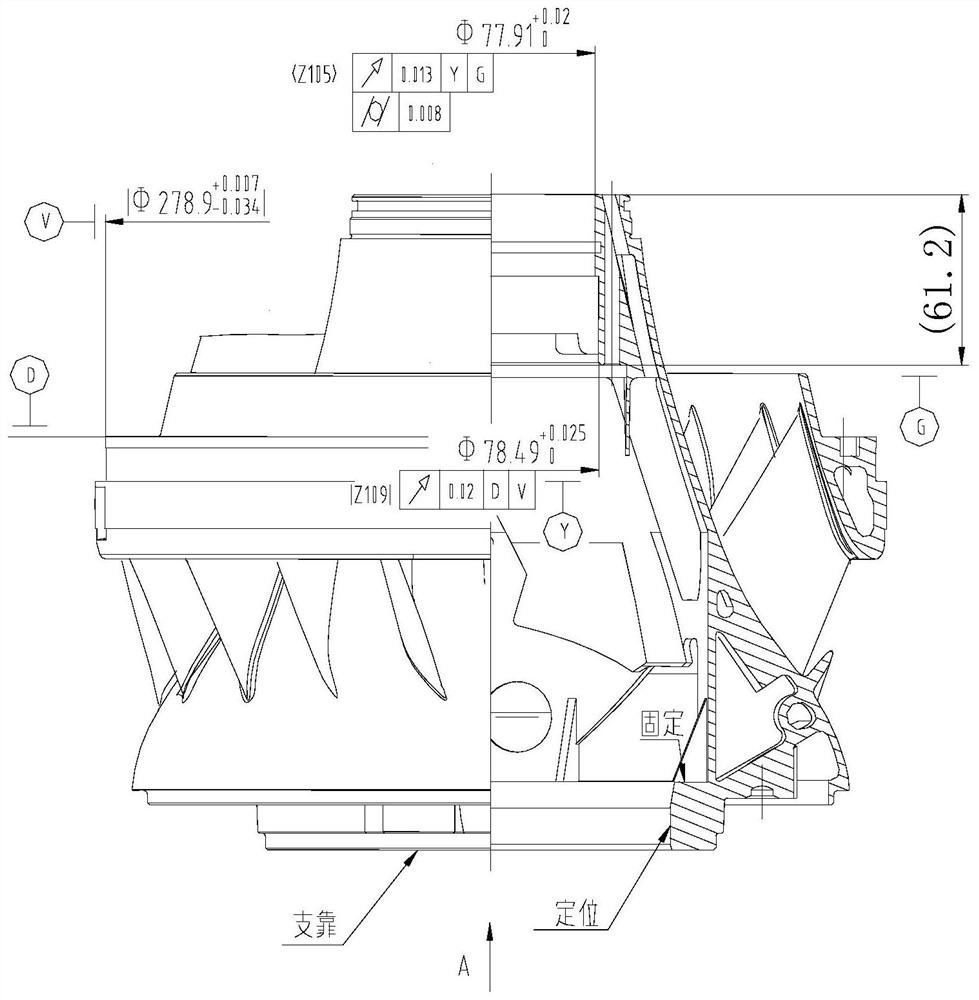

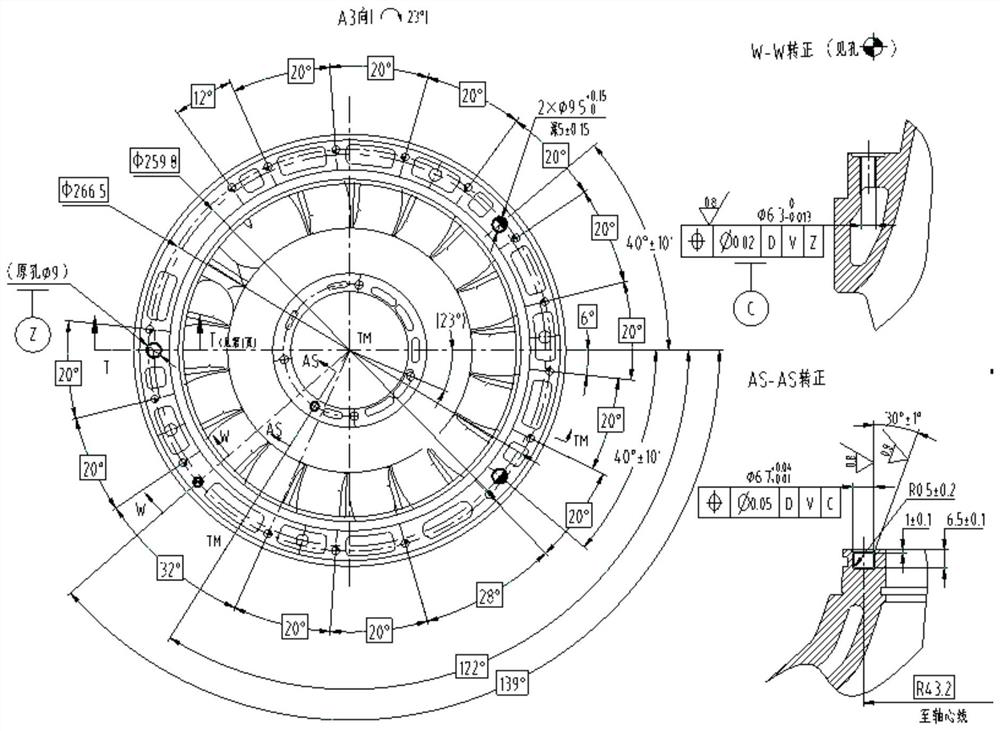

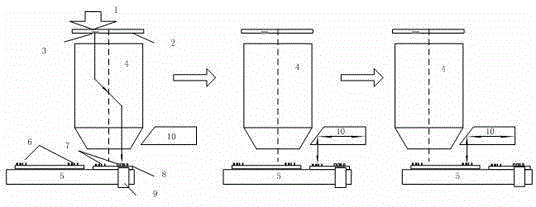

Machining method of rotary casing

ActiveCN112355579BReduce alignment errorsEliminate alignment errorsProcess engineeringIndustrial engineering

The invention discloses a processing method of a rotating casing. By combining the processing procedures of the rotating casing parts into four turning-milling composite processes, the part transfer, production waiting time and processing preparation time are greatly shortened, and the process route of the parts is shortened. Divided into rough and finish machining, the parts only need to be clamped three times in total, so that the reference conversion of the parts is reduced to 3 times, the alignment error of the parts is greatly reduced, and the turning and milling composite technology is adopted, and the reference and precision holes can be processed in one process , can eliminate repeated clamping and alignment errors, improve the pass rate of precision hole position, and greatly improve the processing quality.

Owner:CHINA HANGFA SOUTH IND CO LTD

Self-referencing interferometric alignment system for lithography equipment

ActiveCN103365122BQuality improvementEliminate alignment errorsPhotomechanical exposure apparatusMicrolithography exposure apparatusOptical ModuleLight beam

The invention discloses a self-reference interference alignment system for photoetching equipment. The system comprises a laser light source module, an optical module, a signal acquisition module and a processing module, wherein the laser light source module is used for providing illumination beams; the optical module is used for marking the illumination beams to form a diffraction optical signal; the signal acquisition module is used for processing the optical signal to acquire a light intensity signal; the processing module is used for processing the light intensity signal to acquire an alignment position by combining position data of a workpiece table; the optical module comprises a first optical channel and a second optical channel; an optical signal in the second optical channel is processed to be used for eliminating optical noises in the first optical channel.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Method of manufacturing high-integrated semiconductor device and semiconductor device manufactured using the same

InactiveUS20120077337A1Excellent characteristicsHigh yieldSolid-state devicesSemiconductor/solid-state device manufacturingBit lineSemiconductor

A semiconductor device comprises a plurality of vertical transistors each comprising barrier metal layers corresponding to source / drain regions in which a conduction region is formed under a channel region having a pillar form, and a bit line comprising a metal layer to connect the plurality of vertical transistors.

Owner:SK HYNIX INC

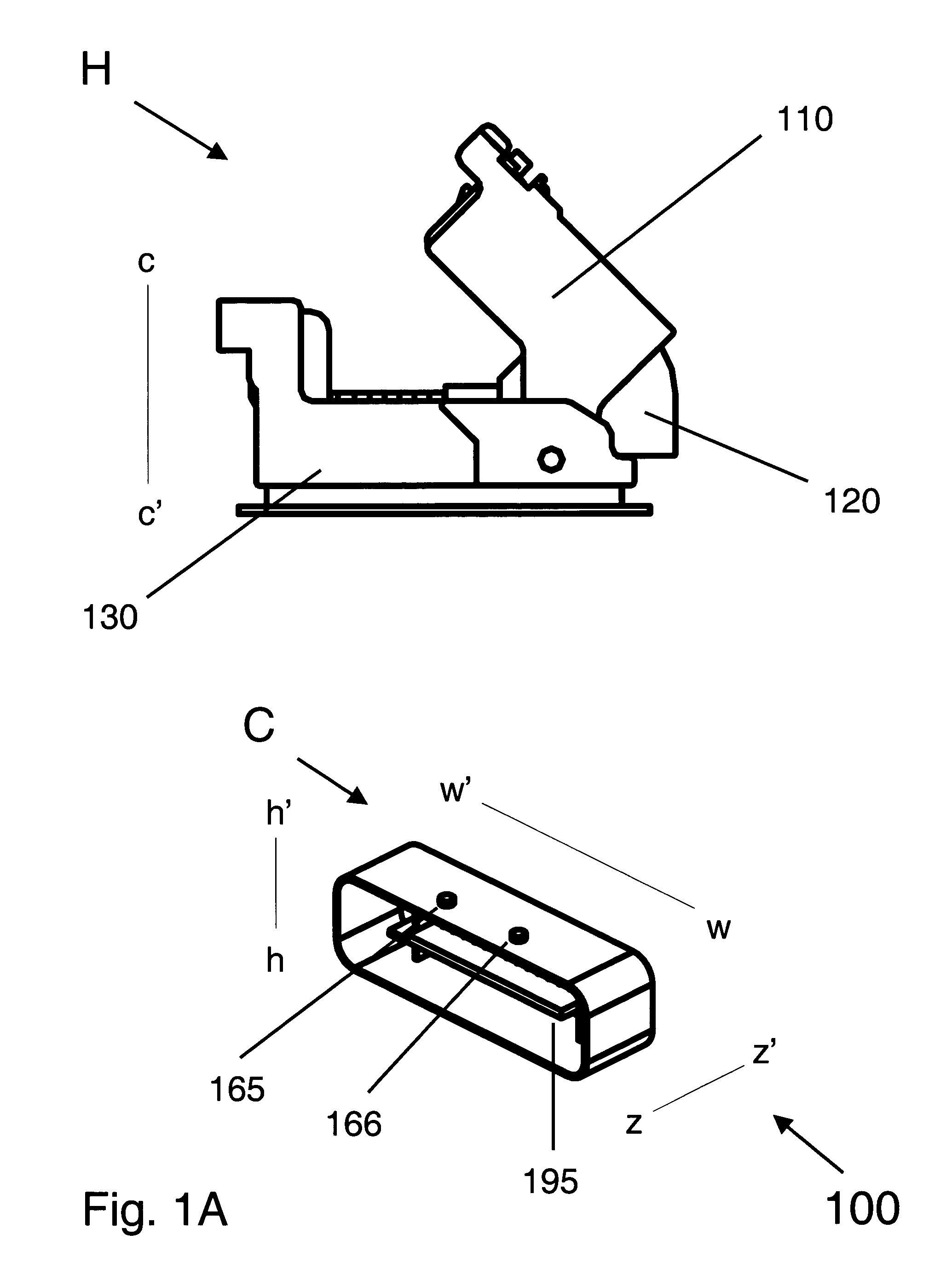

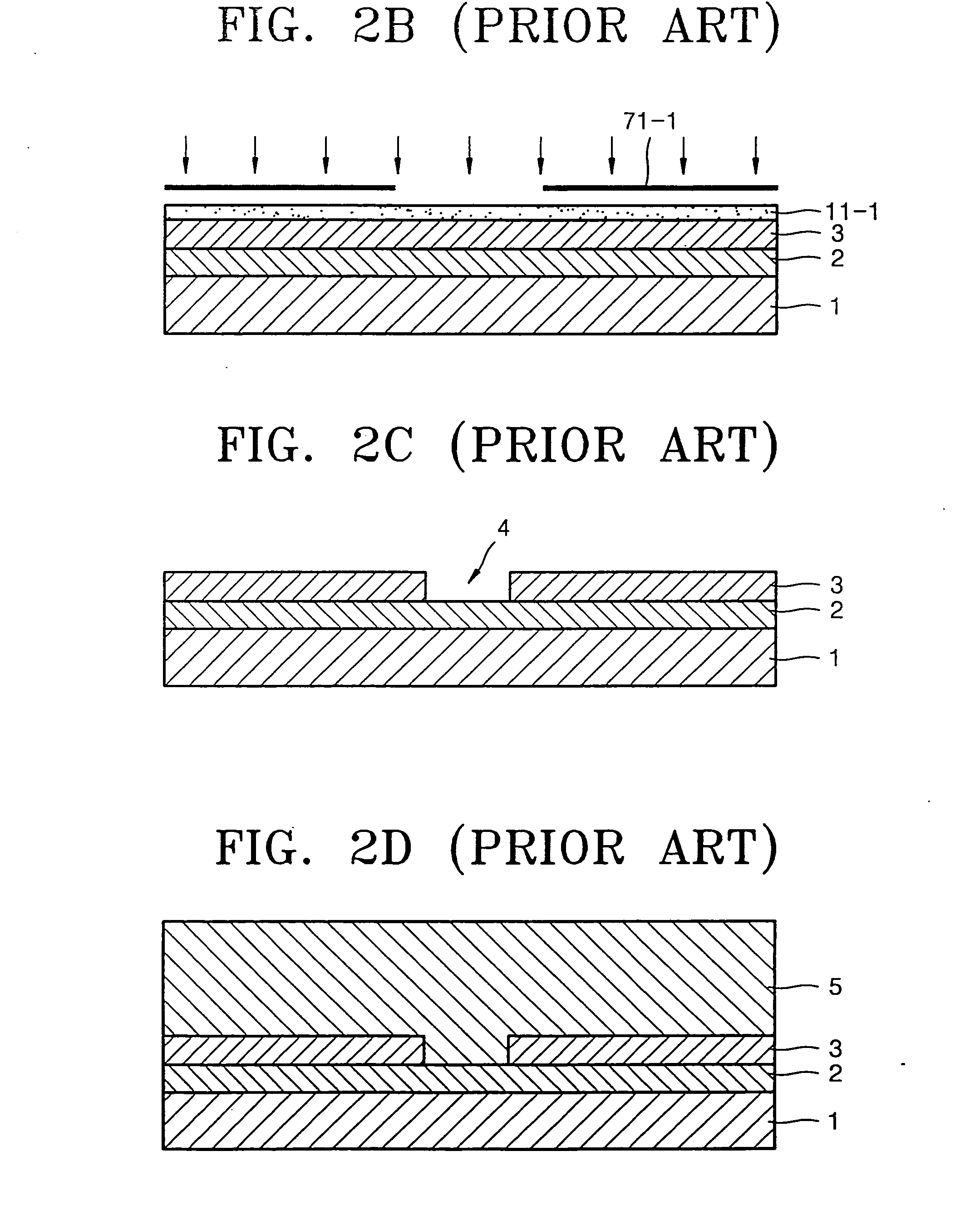

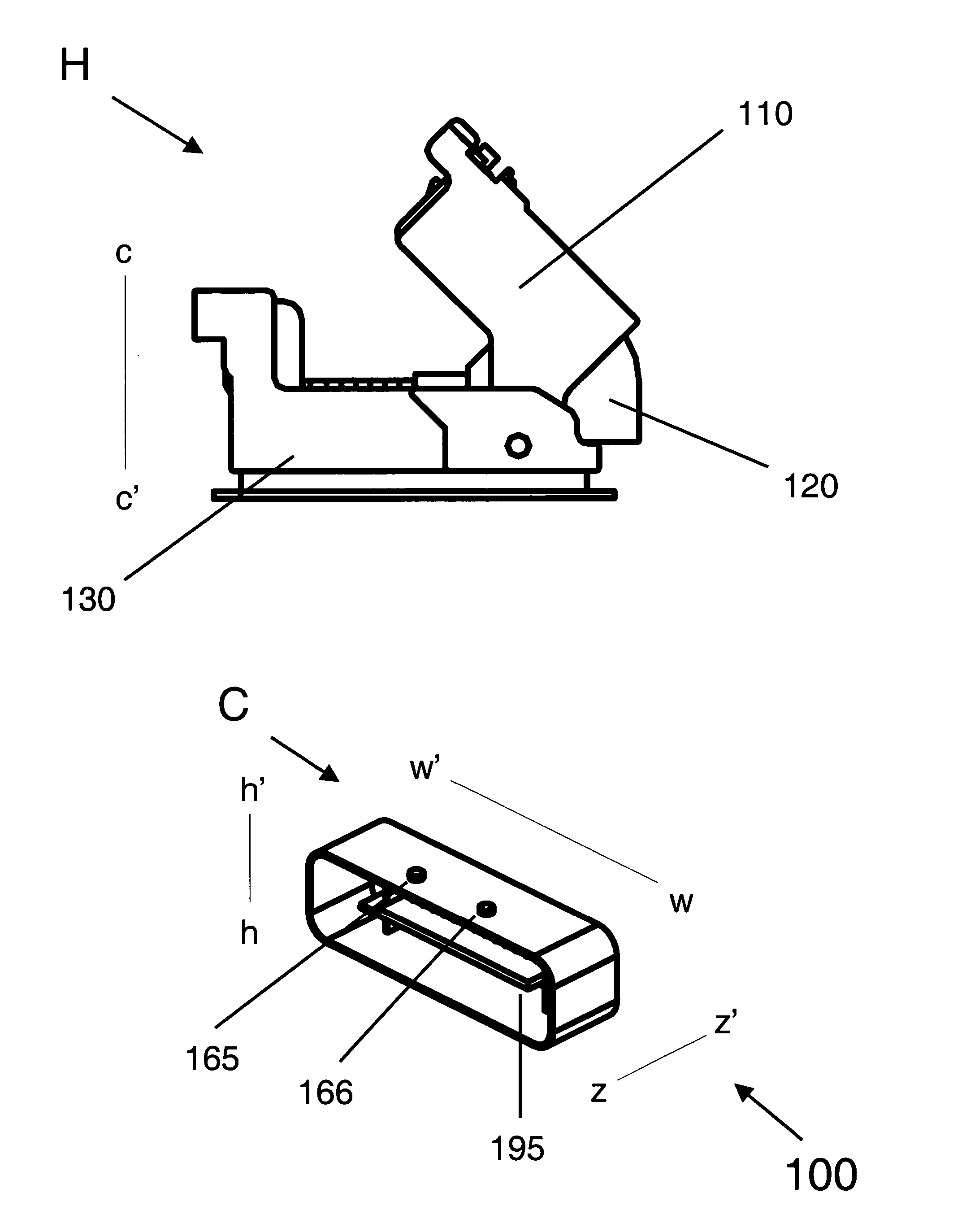

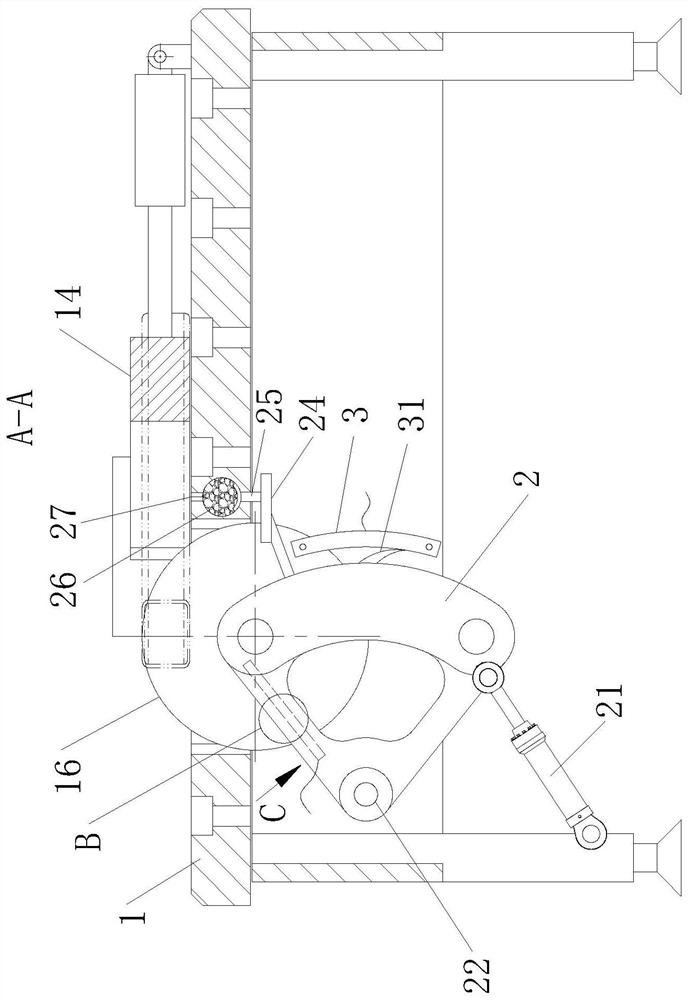

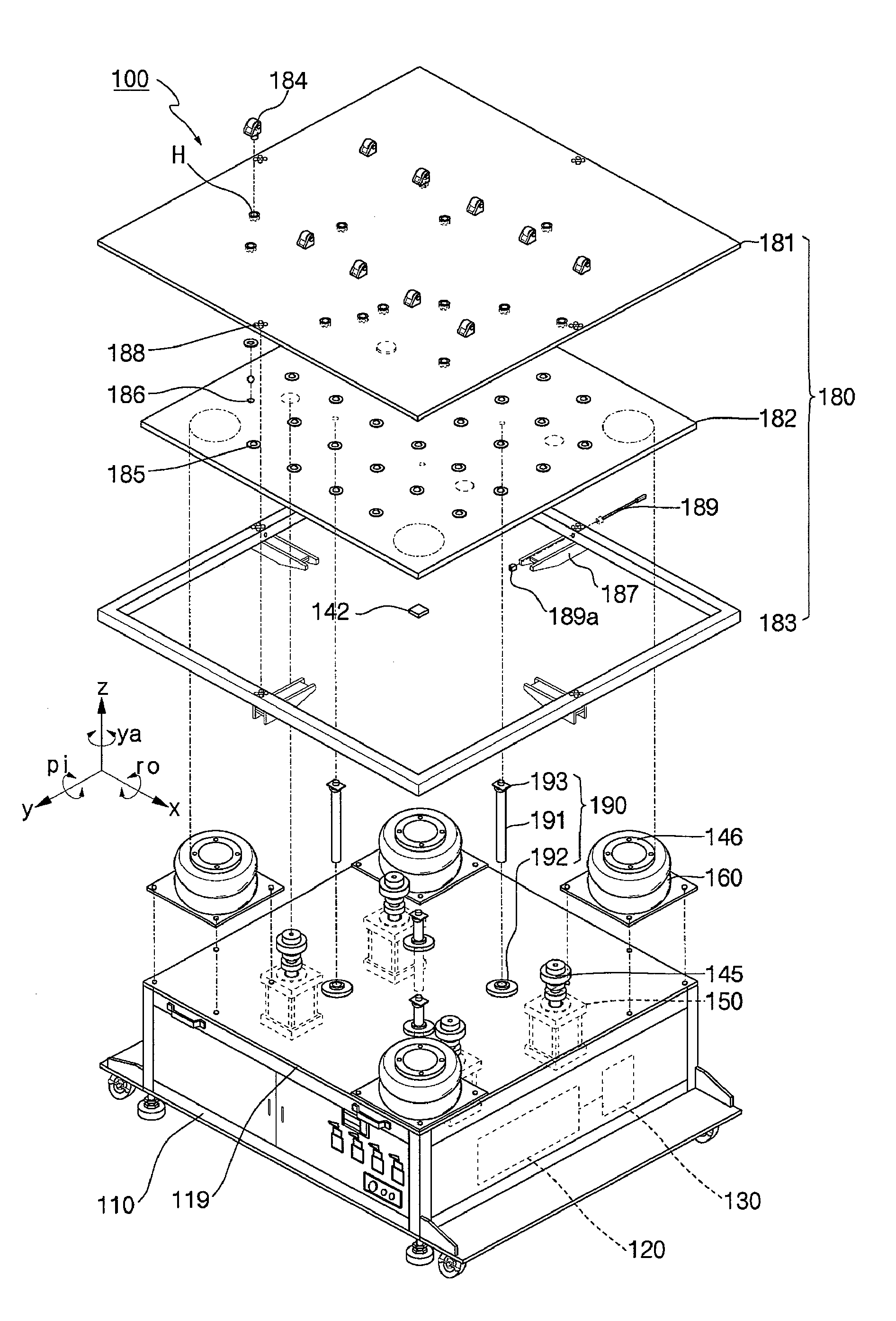

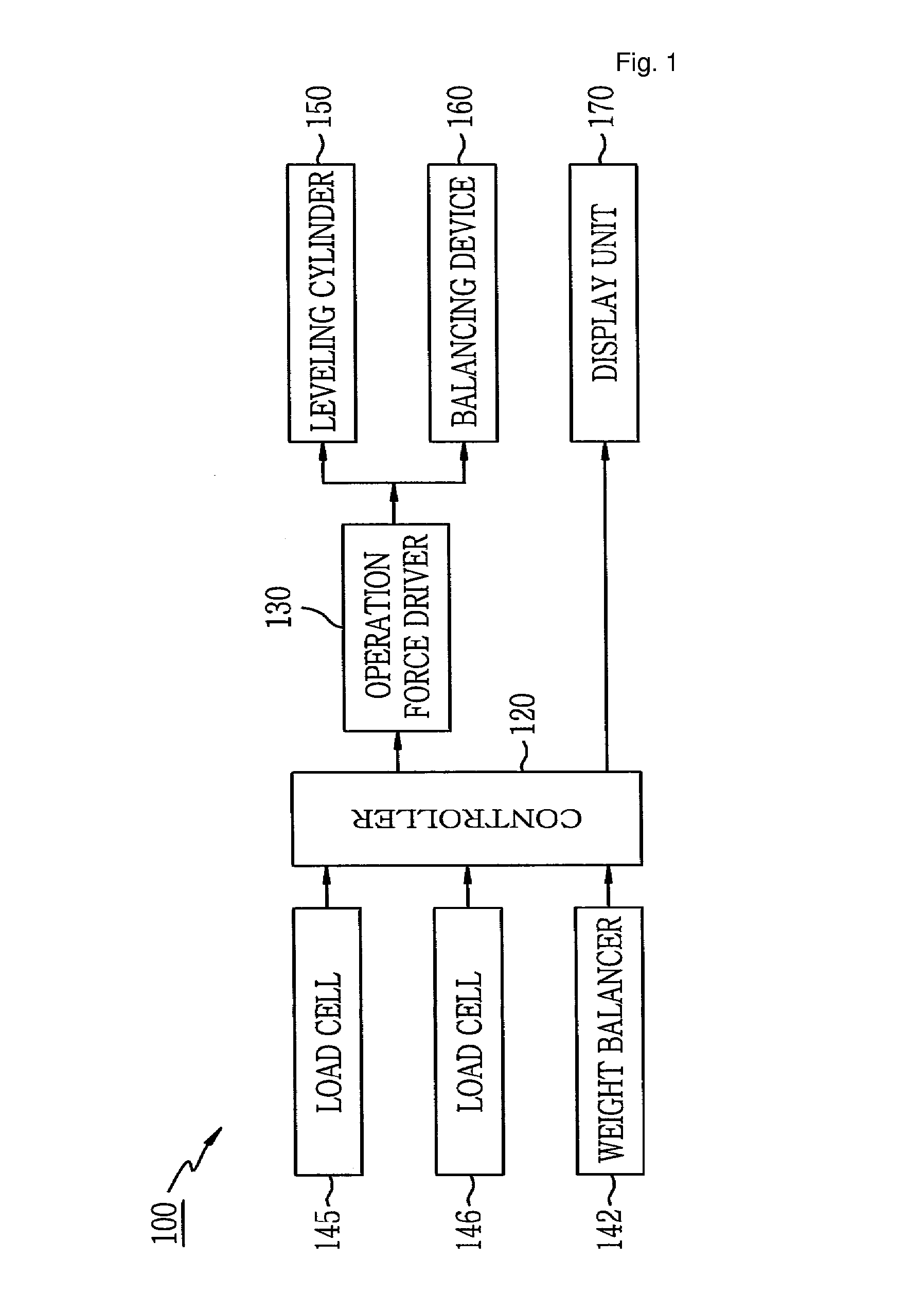

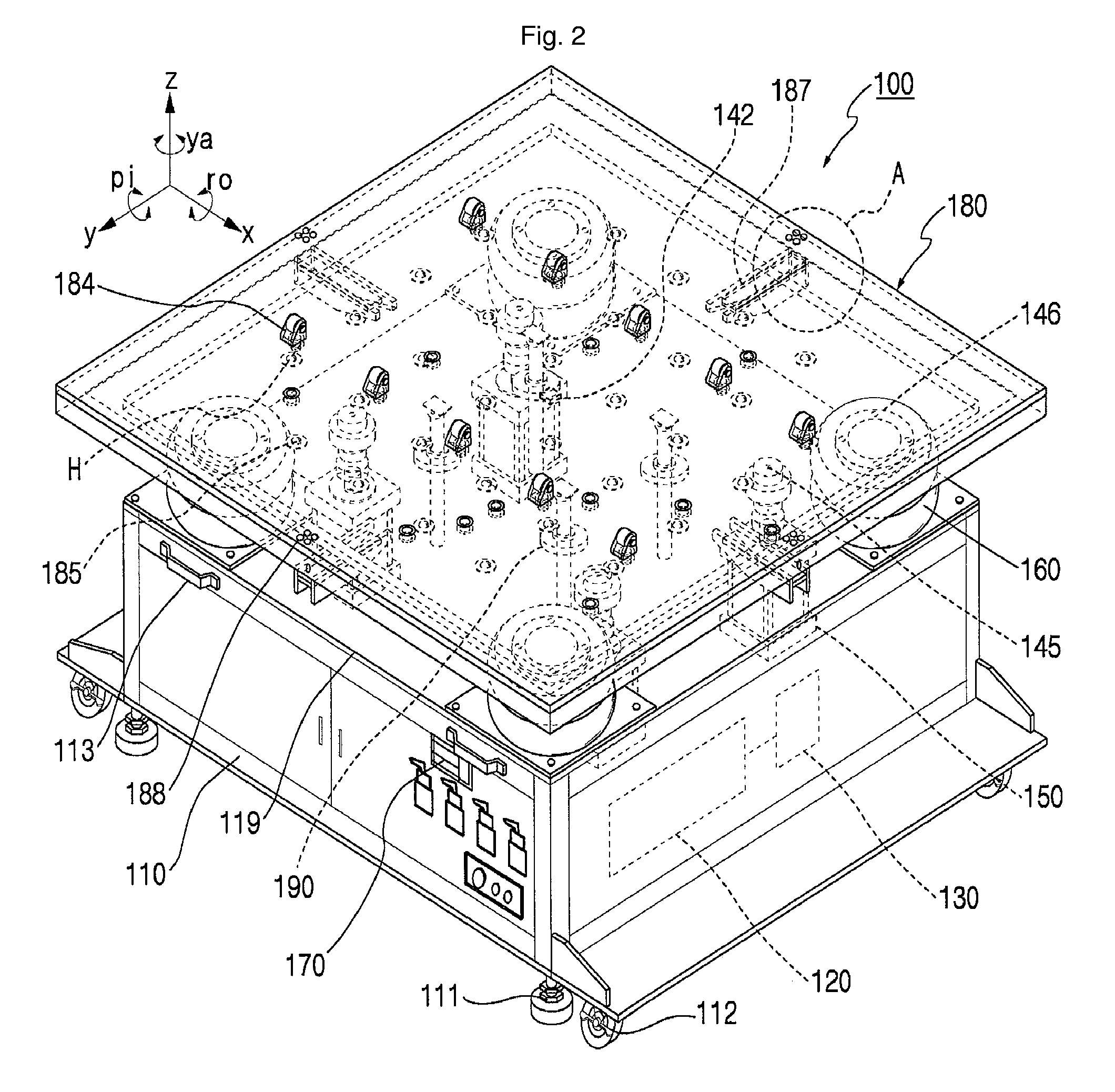

Weight balancer and pipe joining method

ActiveUS8714434B2Eliminate alignment errorsPrecise alignmentAutomatic control devicesPrecision positioning equipmentControl signalEngineering

The present invention relates to a weight balancer (100) and a pipe joining method that is capable of reducing a load of pipes when arranging and welding the pipes in ships, plants, piping work sites and the like. A weight balancer (100) according to the present invention includes an operation plate (180) for putting an alignment object; a plurality of load cells (145,146) installed in the lower portion of the operation plate (180); a controller (120) which receives a detection signal generated from the load cell (145,146) and analyzes the information of the alignment object to generate a control signal; an operation force driver (130) which receives the control signal from the controller (120) to control an operational pressure of each of a plurality of pressure supply lines; and a plurality of leveling cylinders (150) and balancing devices (160) which are connected to the pressure supply lines to control a location or pose of the operation plate (180) so as to correspond to the size of the operational pressure controlled by the operation force driver (130).

Owner:SAMSUNG HEAVY IND CO LTD

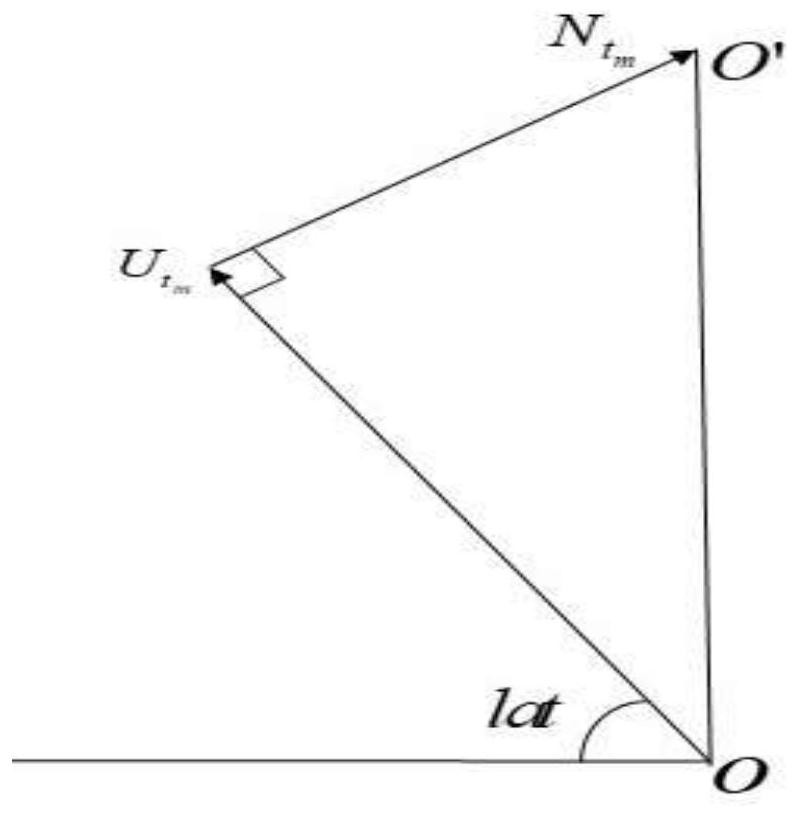

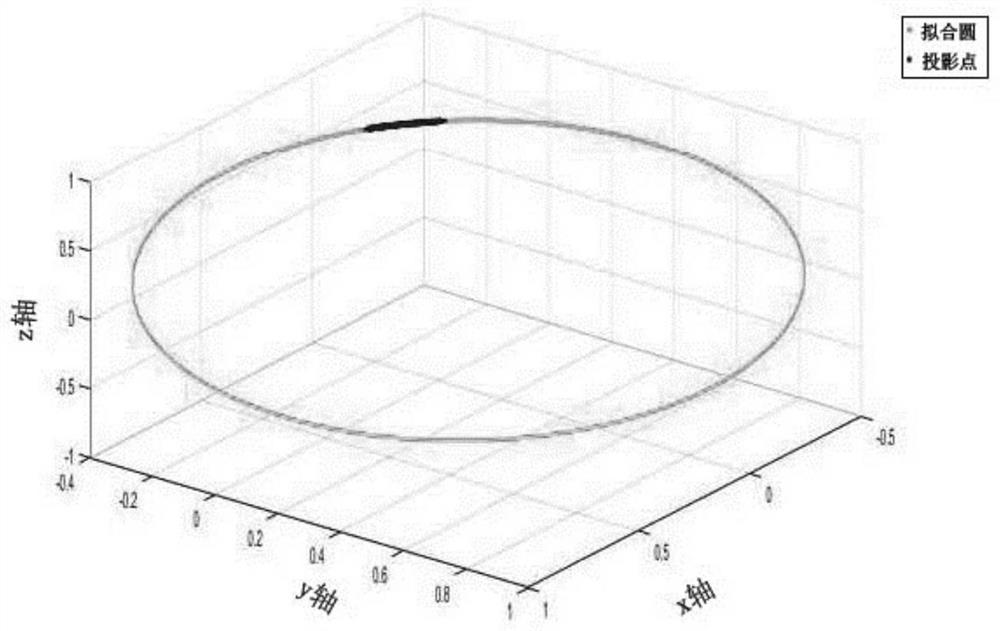

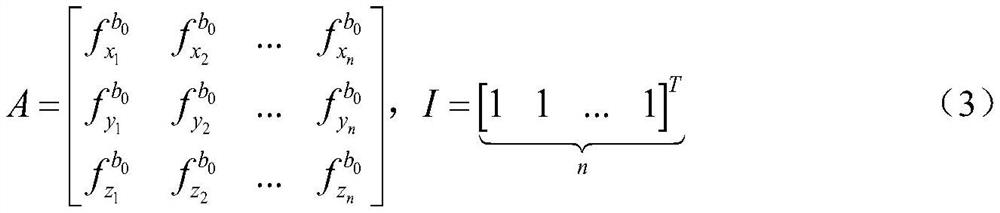

Inertial navigation initial attitude resolving method based on solidification carrier coordinate system

PendingCN113155150AReduce the number of chain multiplicationsExact latitude and longitudeMeasurement devicesClassical mechanicsLongitude

The invention relates to an inertial navigation initial attitude resolving method based on a solidification carrier coordinate system, spatial circle fitting is performed on a projection point in a carrier coordinate system at an initial moment by projecting meter measurement data according to a motion law that a gravity vector rotates around an earth axis under a solidification carrier system and gyro output, the circle center vector of the space circle is the expression of the earth axis under the solidification load system, a geographic coordinate system of the corresponding moment is obtained according to the triangular relation among the earth axis, the gravity vector and the geographic north direction, and therefore a rotation matrix between a navigation coordinate system and a carrier coordinate system is obtained, and coarse alignment of the shaking base is achieved. Compared with the prior art, the method has the advantages that accurate latitude and longitude can be obtained without knowing an alignment point; through data fitting, the error influence caused by angle shaking is relieved by fully utilizing alignment data, and the alignment precision level is greatly improved; the chain multiplication times of an attitude matrix are reduced, description of gravity in a normal gravity field is not used in the algorithm, and alignment errors caused by disturbance of the gravity can be eliminated.

Owner:中国人民解放军火箭军工程大学

Infrared detecting device and manufacturing method thereof

InactiveUS8178844B2Reduce the numberImprove featuresSolid-state devicesMaterial analysis by optical meansInfraredConductive materials

An infrared detecting device is provided that is capable of improving device characteristics thereof by narrowing the width of each beam portion. The infrared detecting device has an infrared detection portion having a thermoelectric transducing part formed over a semiconductor substrate via an air gap interposed therebetween, and the beam portions which are formed over the semiconductor substrate via the air gap interposed therebetween, support the infrared detection portion and electrically connect between the infrared detection portion and the semiconductor substrate, wherein each of the beam portions has an insulating material film and a conductive material layer exposed from the insulating material film to a side surface of each beam portion.

Owner:LAPIS SEMICON CO LTD

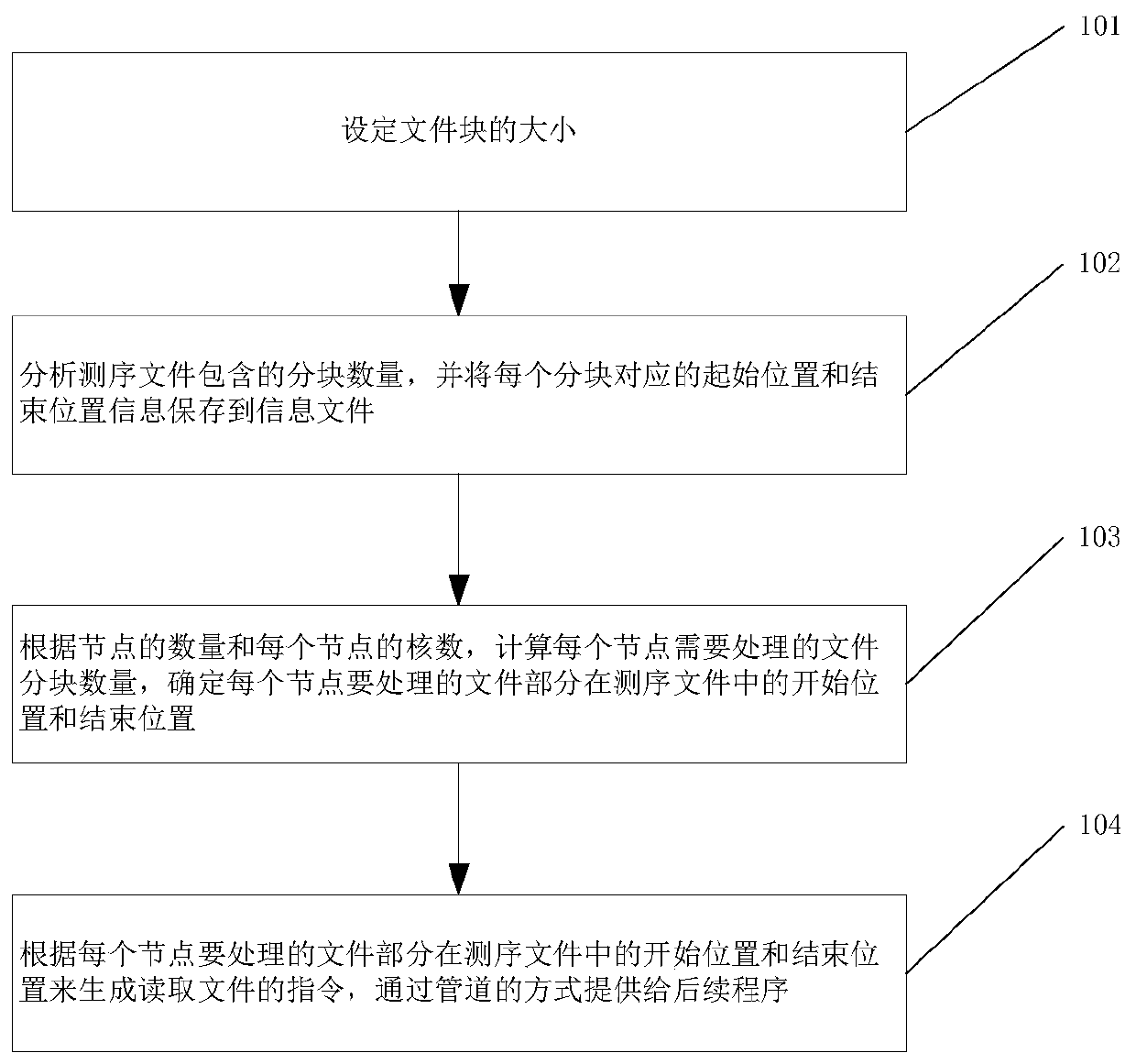

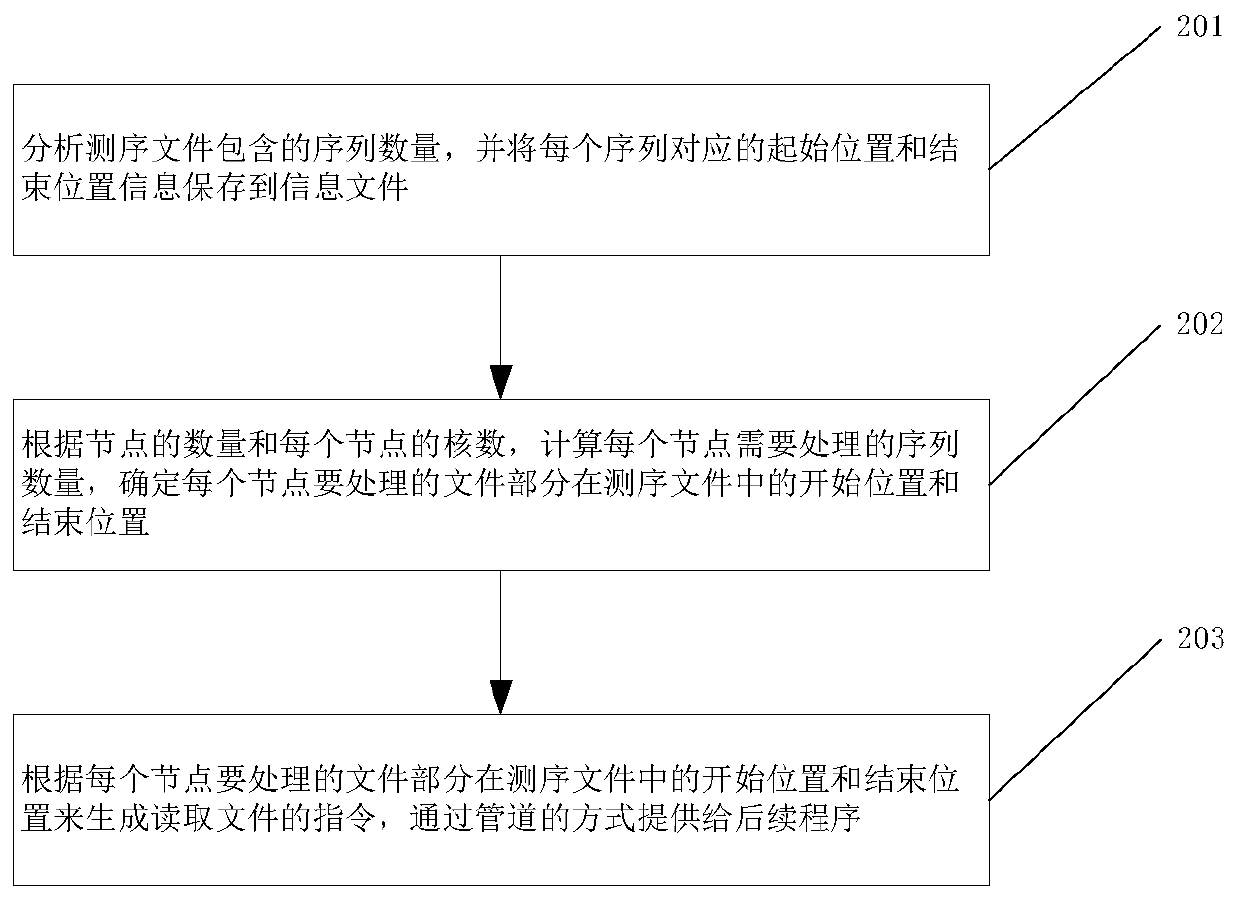

Rapid division method for big data gene sequencing files

ActiveCN111326216ASpeed up divisionAvoid reading and writingBiostatisticsSequence analysisPerformance computingGenetics

The invention relates to the field of high-performance computing. The invention in particular relates to a rapid division method of a big data gene sequencing file, so that in a multi-node genetic analysis process, the sequencing file does not need to be actually segmented, sub-files are not generated, and a flexible division scheme is provided according to a subsequent analysis program, so that the load of each node is more balanced, hard disk read-write is reduced, and the division efficiency is improved.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com