Micro-mirror with completely symmetrical differential capacitance angle feedback

A differential capacitance, completely symmetrical technology, applied in the field of micromirrors with completely symmetrical differential capacitance angle feedback, can solve problems such as poor control accuracy, inability to apply high frequency and low frequency at the same time, and complex system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

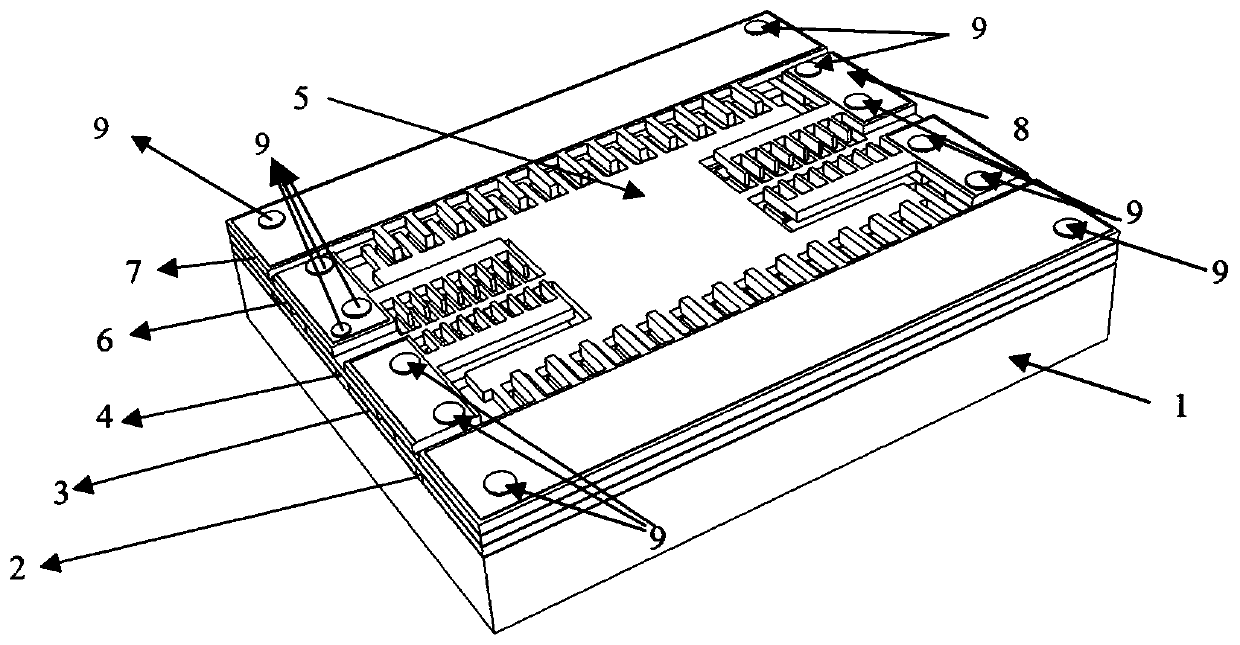

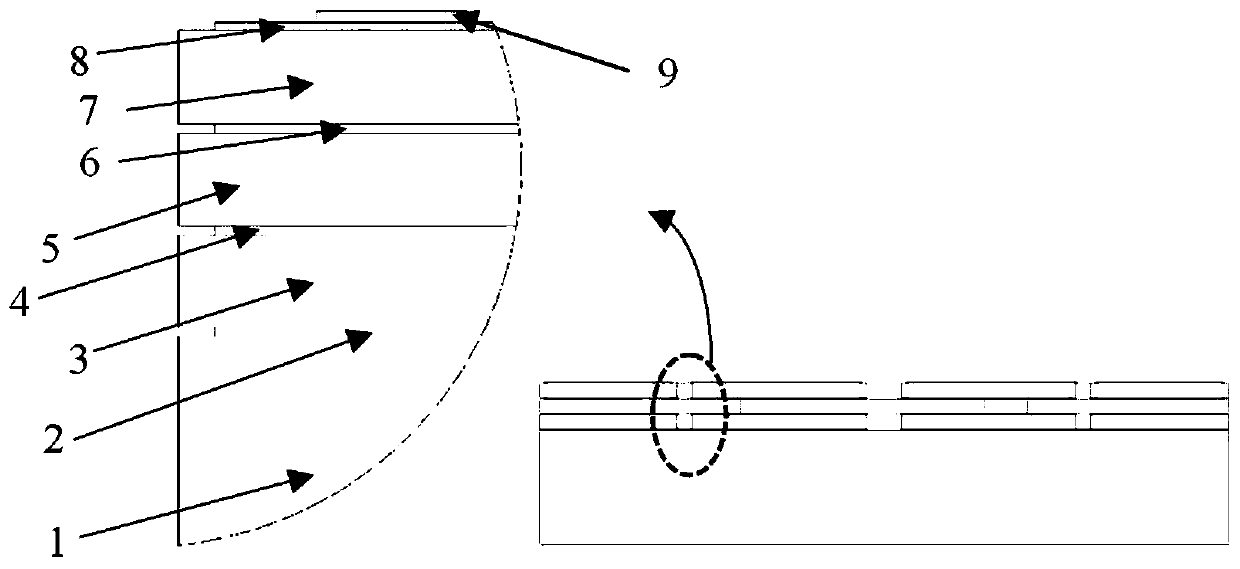

[0081] The micro-mirror with fully symmetrical differential capacitance angle feedback described in this embodiment, see Figure 1-Figure 3 , comprising a base 1, the upper surface of the base 1 is provided with a first insulating layer 2, the upper surface of the first insulating layer 2 is provided with a first fixed layer 3, and the upper surface of the first fixed layer 3 is provided There is a second insulating layer 4, the upper surface of the second insulating layer 4 is provided with a reflective element layer 5, the upper surface of the reflective element layer 5 is provided with a third insulating layer 6, and the upper surface of the third insulating layer 6 is A second fixed layer 7 is provided on the surface, and a fourth insulating layer 8 is provided on the upper surface of the second fixed layer 7 , and a welding pad 9 is provided on the fourth insulating layer 8 . There are 13 pads in total. The pads are electrically connected to each structural layer through...

Embodiment 2

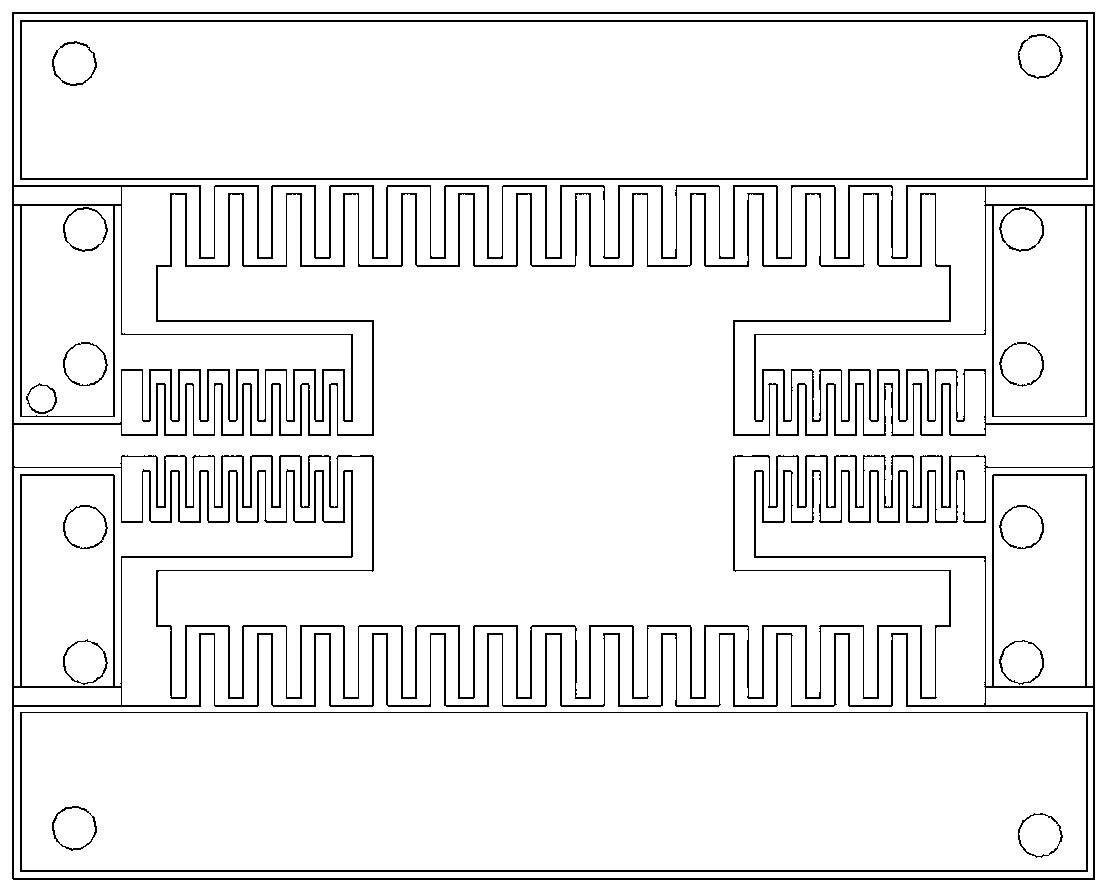

[0101] The micromirror with fully symmetrical differential capacitive angle feedback described in this embodiment includes a base 1, the upper surface of the base 1 is provided with a first insulating layer 2, and the upper surface of the first insulating layer 2 is provided with a second A fixed layer 3, the upper surface of the first fixed layer 3 is provided with a second insulating layer 4, the upper surface of the second insulating layer 4 is provided with a reflective element layer 5, and the upper surface of the reflective element layer 5 is provided There is a third insulating layer 6, the upper surface of the third insulating layer 6 is provided with a second fixed layer 7, the upper surface of the second fixed layer 7 is provided with a fourth insulating layer 8, and the fourth insulating layer 8 Pad 9 is provided on it. The base 1 is a hollow frame structure surrounded by borders, see Figure 4-Figure 5 , the first insulating layer 2, the first fixed layer 3, the s...

Embodiment 3

[0102] Embodiment 3 concrete preparation method

[0103] In order to better illustrate the manufacturing method of the micromirror with complete symmetrical differential capacitance angle feedback described in embodiment 1, in combination Figure 20(1)-Figure 20(18) The production method is listed and explained as shown.

[0104] The described micromirror with symmetrical differential capacitance angle feedback, its manufacturing method comprises the following steps:

[0105] (1) Prepare the silicon wafer. The silicon wafer is monocrystalline silicon or polycrystalline silicon, polished on both sides, with a thickness of 150 μm and a resistivity of 0.01Ω·cm. See Figure 20(1).

[0106] (2) The first photolithography on the front side defines the corresponding pattern of the vertical position change of the oxygen ion implantation area on the front side. See Figure 20(2).

[0107] (3) For the first dry etching on the front side, a groove-like structure is etched on the front...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com