Self-reference interference alignment system for photoetching equipment

A technology of self-referencing interference and alignment system, which is applied in microlithography exposure equipment, optics, photoplate making process of pattern surface, etc., and can solve problems such as alignment errors and affecting signal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings. For the convenience of describing and highlighting the present invention, relevant components existing in the prior art are omitted from the drawings, and the description of these known components will be omitted.

[0025] The purpose of the present invention is to provide an improved self-referencing interference alignment system, which can effectively eliminate the signal quality deterioration caused by the light intensity fluctuation (that is, optical noise) irradiated on the mark, and obtain better alignment signals , thereby improving the repeatability of the alignment.

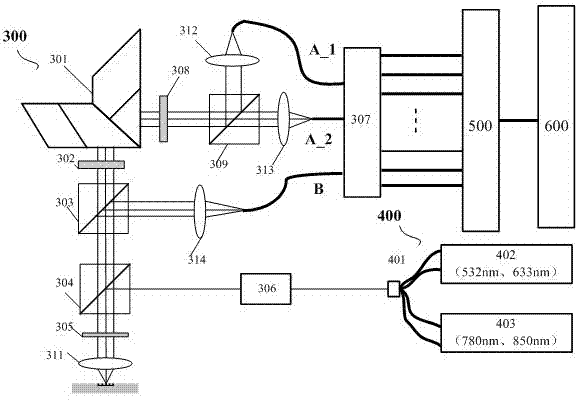

[0026] Such as image 3 As shown, the alignment system provided by the present invention includes a laser light source module 400 , an optical module 300 , an electronic acquisition module 500 , and a software module 600 . Wherein, the laser light so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com