LCD and method of improving the brilliance of the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

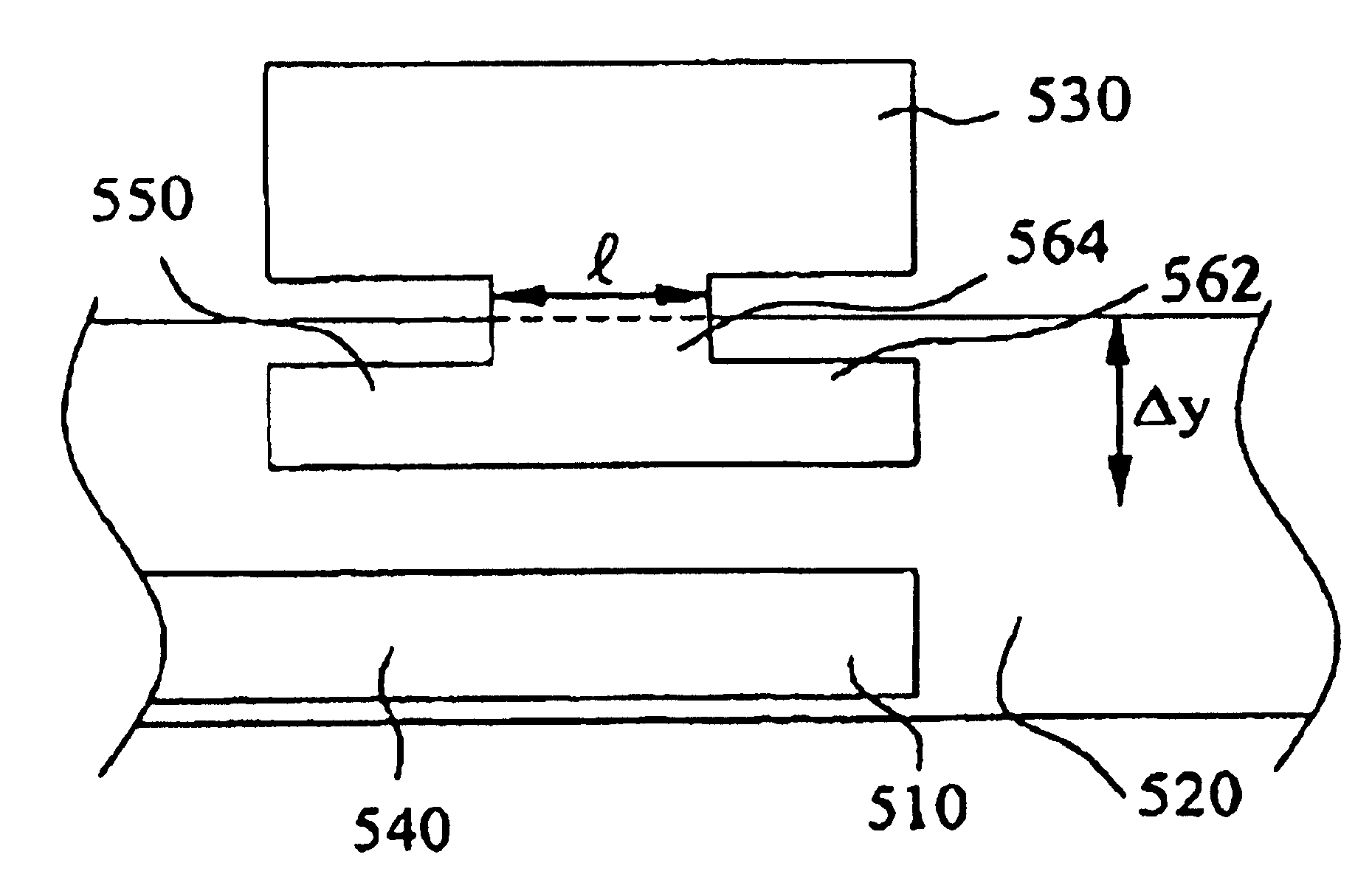

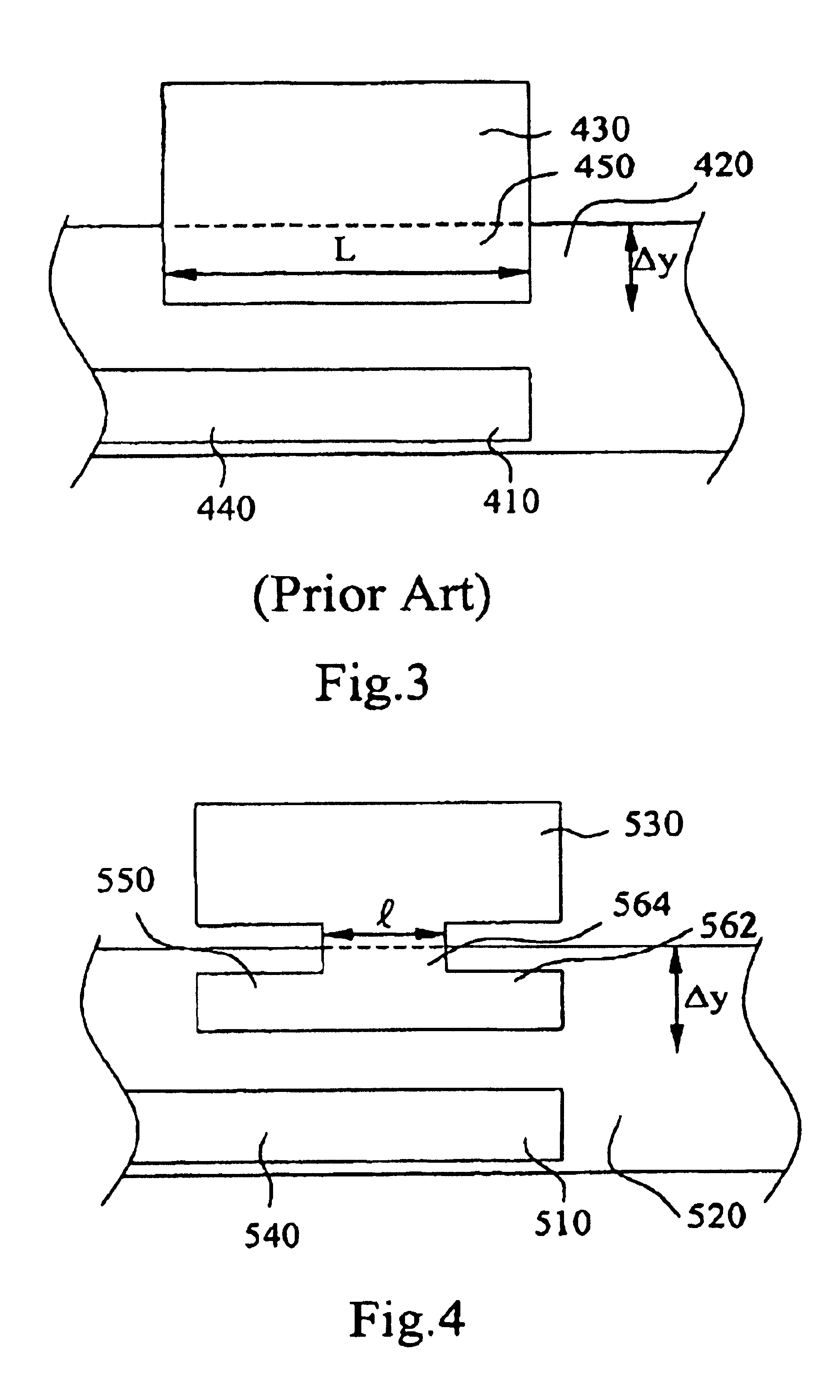

[0017]The functional components on the substrate of the LCD are so arranged that the width of the bridging zone in the direction parallel to the gate electrode peripheral side is smaller than the width of the conducting zone in the same direction parallel to the gate electrode peripheral side. Preferably, the width of the bridging zone in the direction parallel to the gate electrode peripheral side is about within the range between the width of the conducting zone in the same direction parallel to the gate electrode peripheral side and ¼ of the width of the conducting zone in the same direction in parallel to the gate electrode peripheral side. The shape of the projection of the bridging zone and the conducting zone on the gate surface is not limited. Preferably, the bridging zone and the conducting zone are integrated into “T” shape, “L” shape, “Z” shape, or “II” shape. Preferably, the LCD of the present invention comprises an orientation layer coated between the substrate and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com