Method for measuring plate coating metal weight

A technology of weight and coating, which is applied in the direction of measuring devices, material weighing, and analyzing materials, etc., can solve the problems of troublesome preparation of samples by chemical dissolution weighing method, poor control of coating dissolution end point, etc., to reduce under-dissolution or over-dissolution The effect of error, easy operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

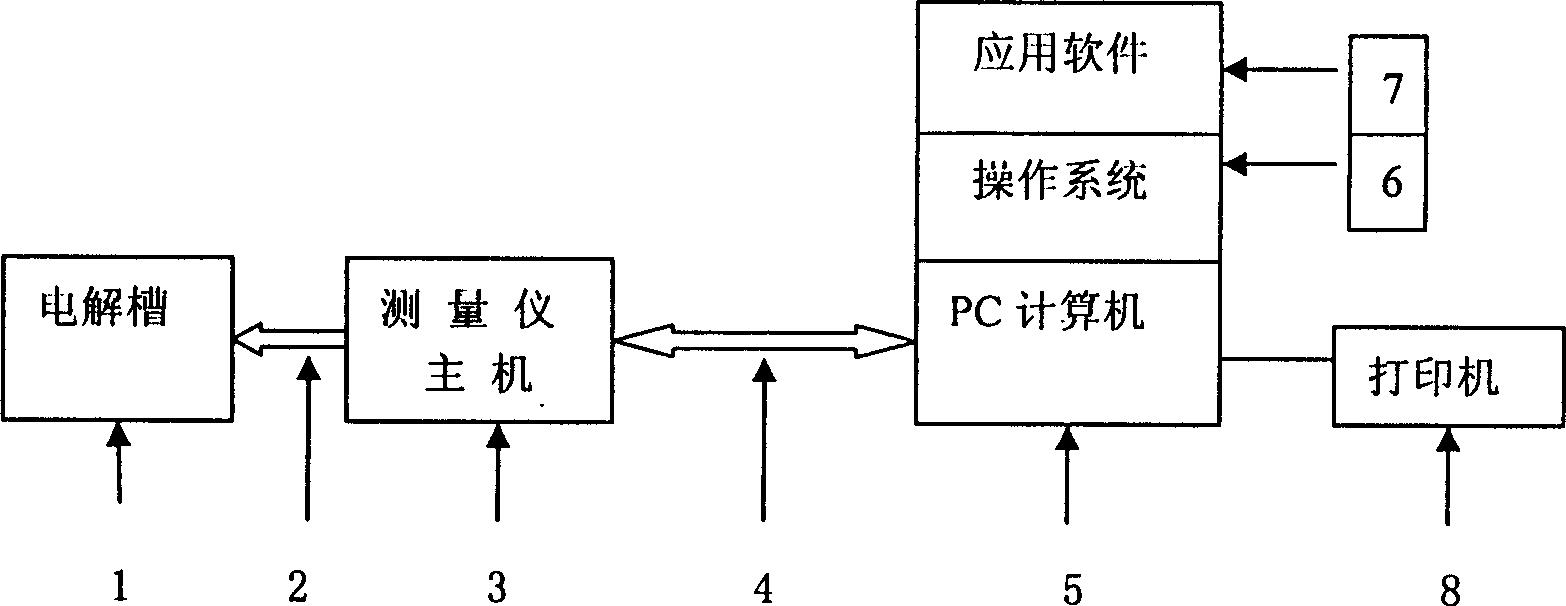

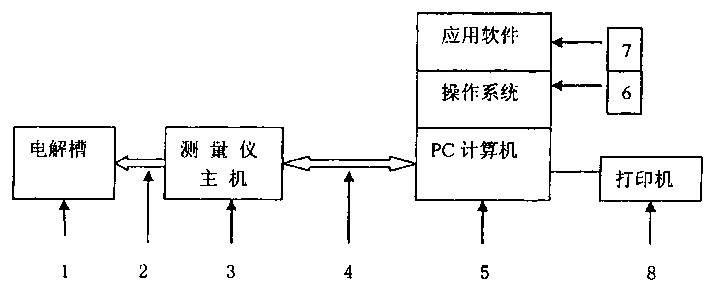

[0026] according to figure 1 - As shown in Figure 3, the measurement method is as follows:

[0027] ① Prepare samples as required;

[0028] ②Clean and dry the sample, weigh it, and write down the weight data;

[0029] ③ Put the sample into the special test fixture, leaving an area of 75-3000mm to be dissolved;

[0030] ④Insert the special test fixture into the fixture bracket in the electrolytic cell;

[0031] ⑤According to the Coulomb thickness measurement method, use the computer to display the change curve of the dissolution of the sample coating in the fixture in the electrolytic cell. When the dissolution curve in the test image of the computer has an inflection point, the dissolution of the coating is complete. As shown in Figure 3, if When there is an alloy layer or other composite layers in the covering layer, two or more inflection points will appear, as shown in Figure 2;

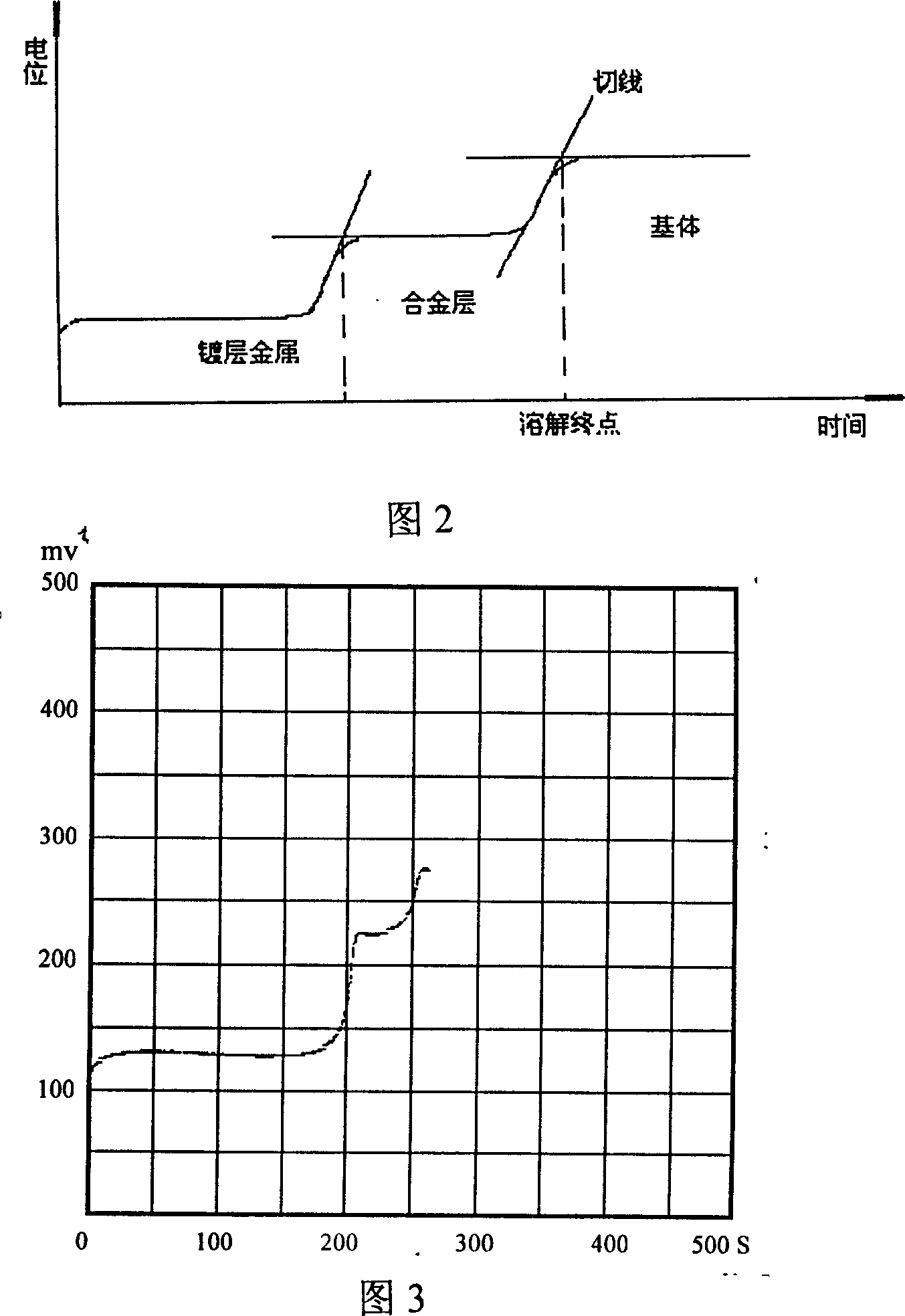

[0032] ⑥ Take out the special test fixture in the electrolytic cell in time, and take ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com