Metal fiber felt having protective net and its making method

A technology of metal fiber felt and metal fiber, which is applied in the field of metal fiber felt, and can solve the problems of affecting the strength of the supporting net and sintering of metal fibers together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the drawings.

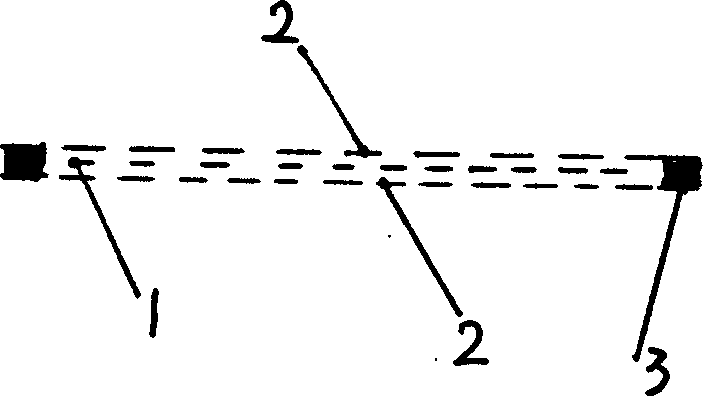

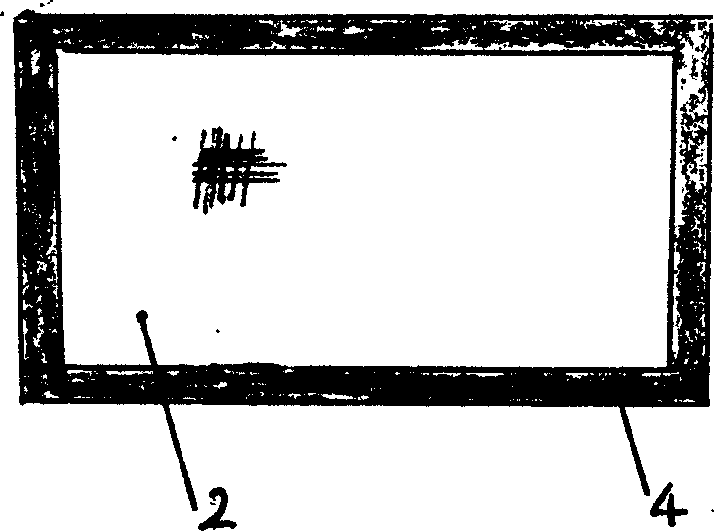

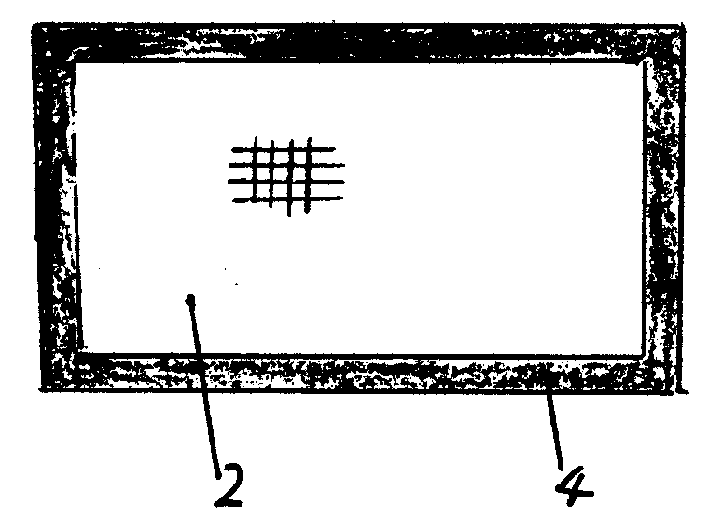

[0010] figure 1 , figure 2 The metal fiber felt with protective net shown is composed of metal fiber felt 1 and metal protective net 2. The metal fiber felt is fixed in the middle of two layers of metal protective nets, and the surroundings between the metal protective net and the metal fiber felt are bonded The elastic gasket 4 formed by the agent 3.

[0011] The production method is: coat the adhesive 3 on the front and back of the metal fiber felt, and coat the adhesive 3 around the guard net 2, then place the metal guard net and the metal fiber mat in the mold and heat it. Pressure forming, the adhesive can be a rubber type. After coating the metal fiber felt and the protective net around, it is pressed to form an elastic sealing gasket 4 around it, which can prevent liquid leakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com