Duplex type machine for straightening and cutting off reinforcing steel bars

A technology of cutting machine and cutting mechanism, which is applied in the field of wire rod processing or processing, can solve the problems of high pay-off frame, waste of scrap ends, poor straightening quality, etc., and achieve reasonable and compact structure, wide straightening range, straightening high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

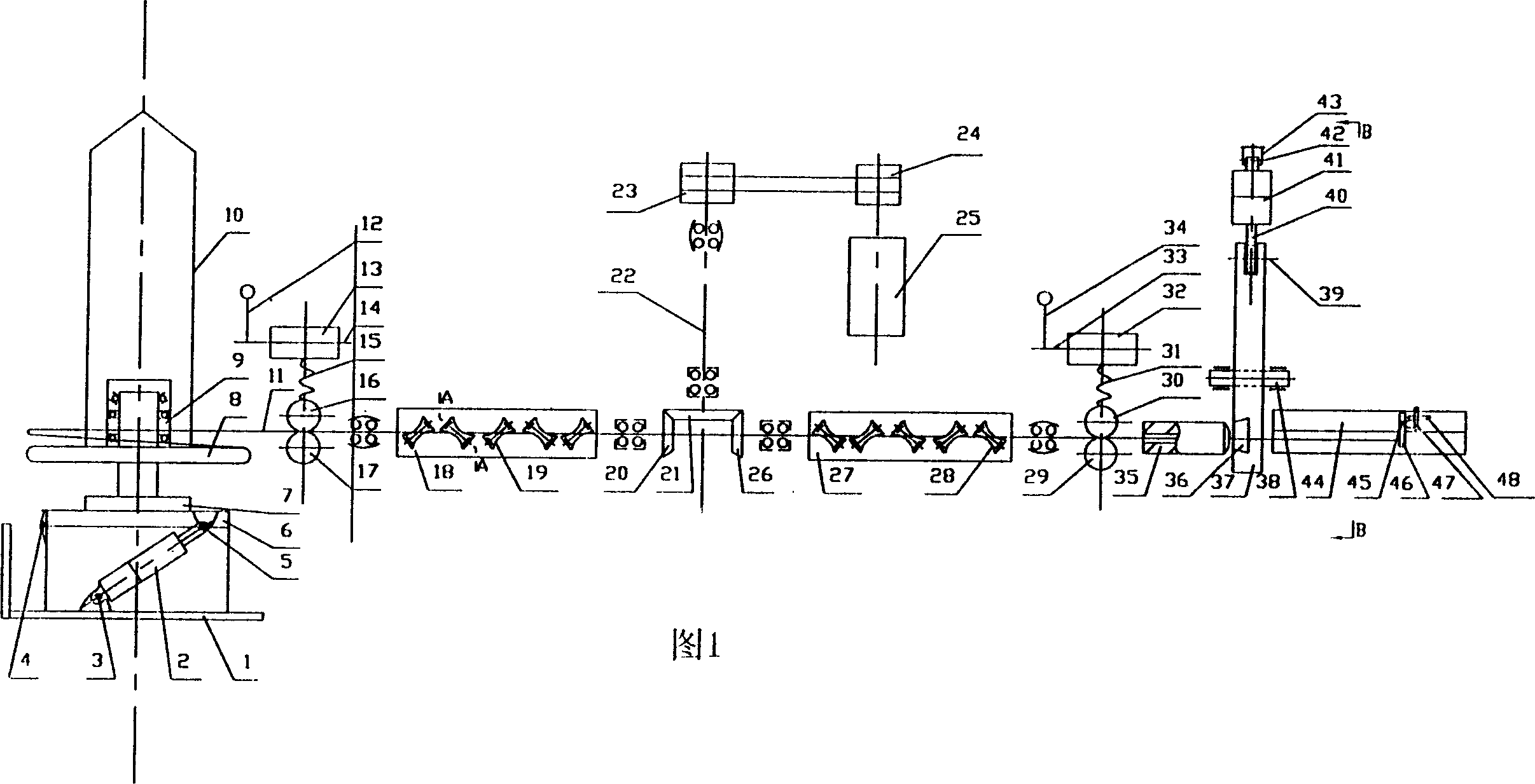

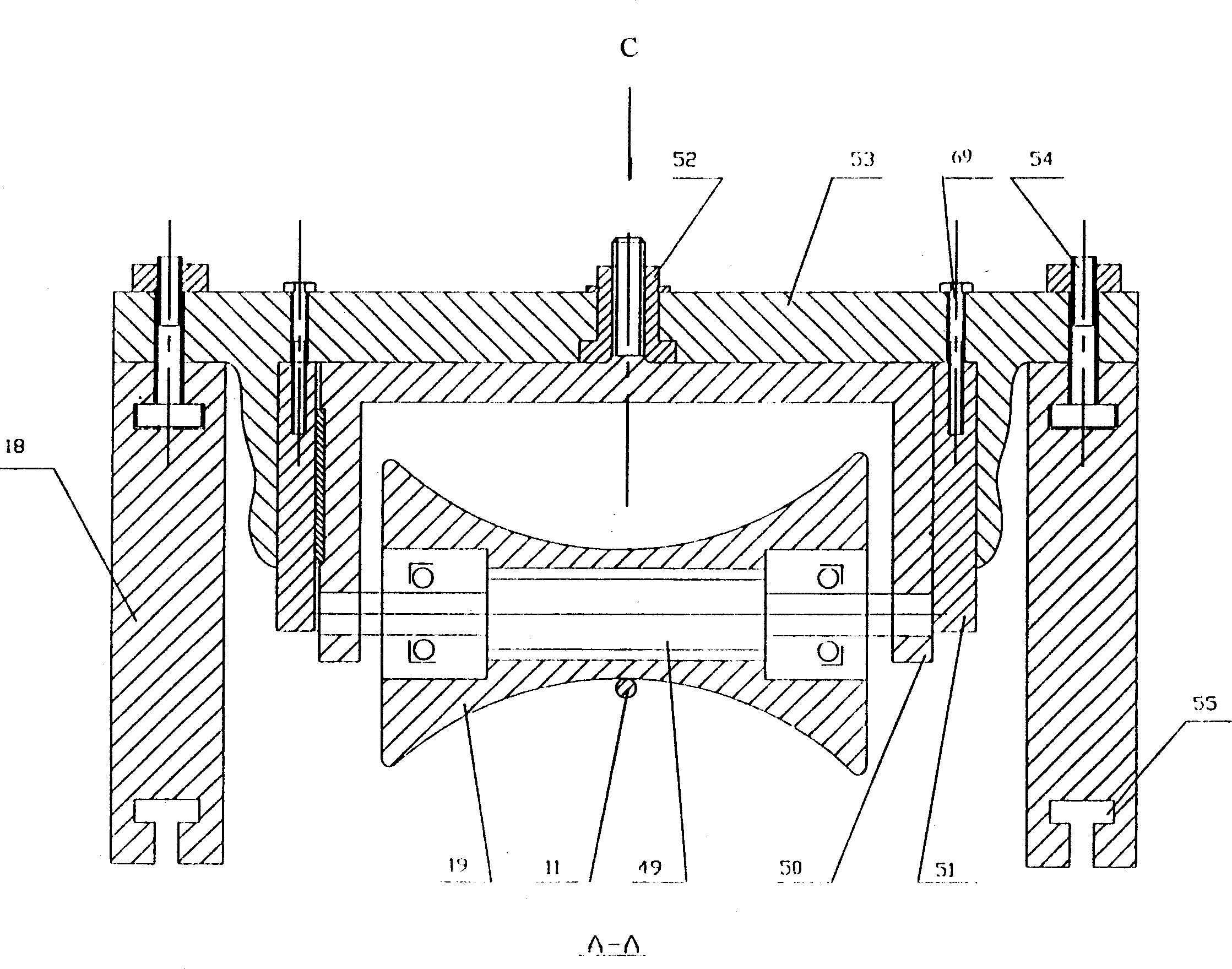

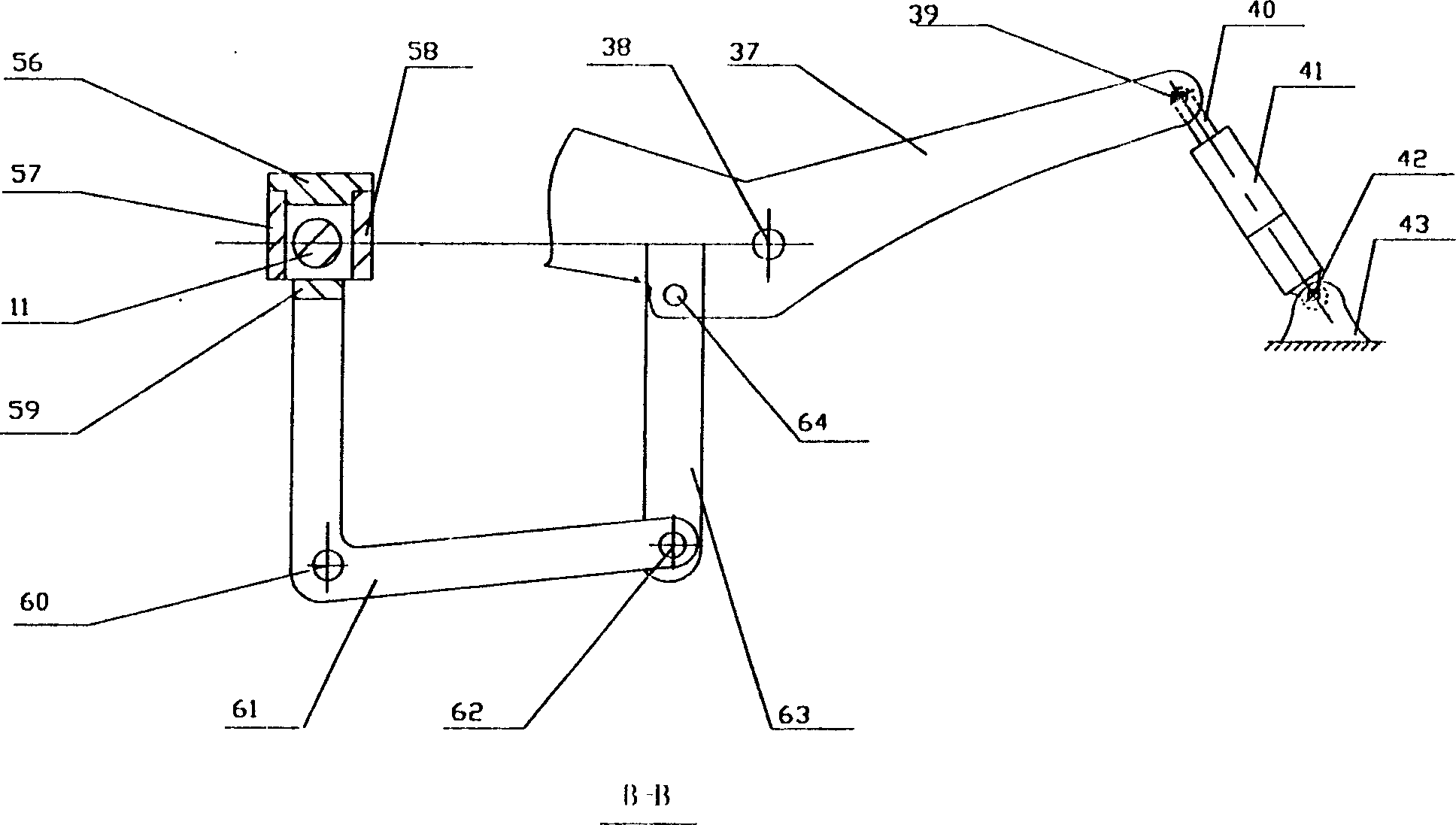

[0017] Accompanying drawing 1 discloses an embodiment of the present invention (see Fig. 1), on pay-off rack base 1 and loam cake 6, winch 3 and 5 are respectively arranged, and base 1 is connected with loam cake 6 with winch 4, oil cylinder 2 is installed on the winches 3 and 5; the upper cover 6 is equipped with a column shaft 7, and a bearing seat 9 is installed on the column shaft 7, and a tray 8 and a core frame 10 are installed on the bearing seat 9; through the hydraulic cylinder 2, the The upper cover 6 is tilted 90 degrees with 4 as the fulcrum, and after the steel bar 11 is installed, the upper cover 6 is returned to its original position by the hydraulic cylinder 2; Figure 4 ). The left end and the right end of the straightening mechanism are provided with clamping mechanism respectively (see Figure 5 ): consisting of lower clamping rollers 17 and 29, upper clamping rollers 16 and 30, clamping springs 15 and 31, eccentric wheels 13 and 32, handle shafts 14 and 33...

Embodiment 2

[0021] Figure 7 It is the second embodiment of the present invention (see example Figure 7 ), motor 73 drives belt pulleys 72,71, and motor 76 drives belt pulleys 75,74 to drive two sets of straightening swivels 18,27 of the straightening mechanism respectively to rotate and straighten in opposite directions with the same rotating speed. The settings and actions of other mechanisms are the same as in Embodiment 1.

Embodiment 3

[0023]In the third embodiment of the present invention, a set of straightening swivels can be removed, and the settings and actions of other mechanisms are the same as in embodiment 1.

[0024] Its working principle is: when the wire rod 11 is installed on the core frame 10 of the pay-off frame, the double-acting oil cylinder installed on the base 1 and the upper cover 6 will stretch out the piston rod under the action of high-pressure oil, pass through the fulcrums 3 and 5, and go up. The cover 6 uses the fulcrum 4 as the axis to tilt the column shaft 7 tray 8 bearing seat 9 core frame 10 together with the upper cover 6 for about 90 degrees. After the steel wire rod 11 is installed, the piston rod returns to the original position under the action of high-pressure oil The pay-off frame is in a vertical state. Tray 8 bearing seats 9 core frames 10 rotate on the column shaft 7 during setting-out. Upper clamping rollers 16 and 30 are passed through handle rods 12 and 34 handle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com