Surface state checking method and circuit board checker

A surface state and inspection device technology, applied in measurement devices, color measurement devices, optical devices, etc., can solve problems such as increased cost, difficulty in detecting leads, and difficulty in realizing optical systems, and achieves the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

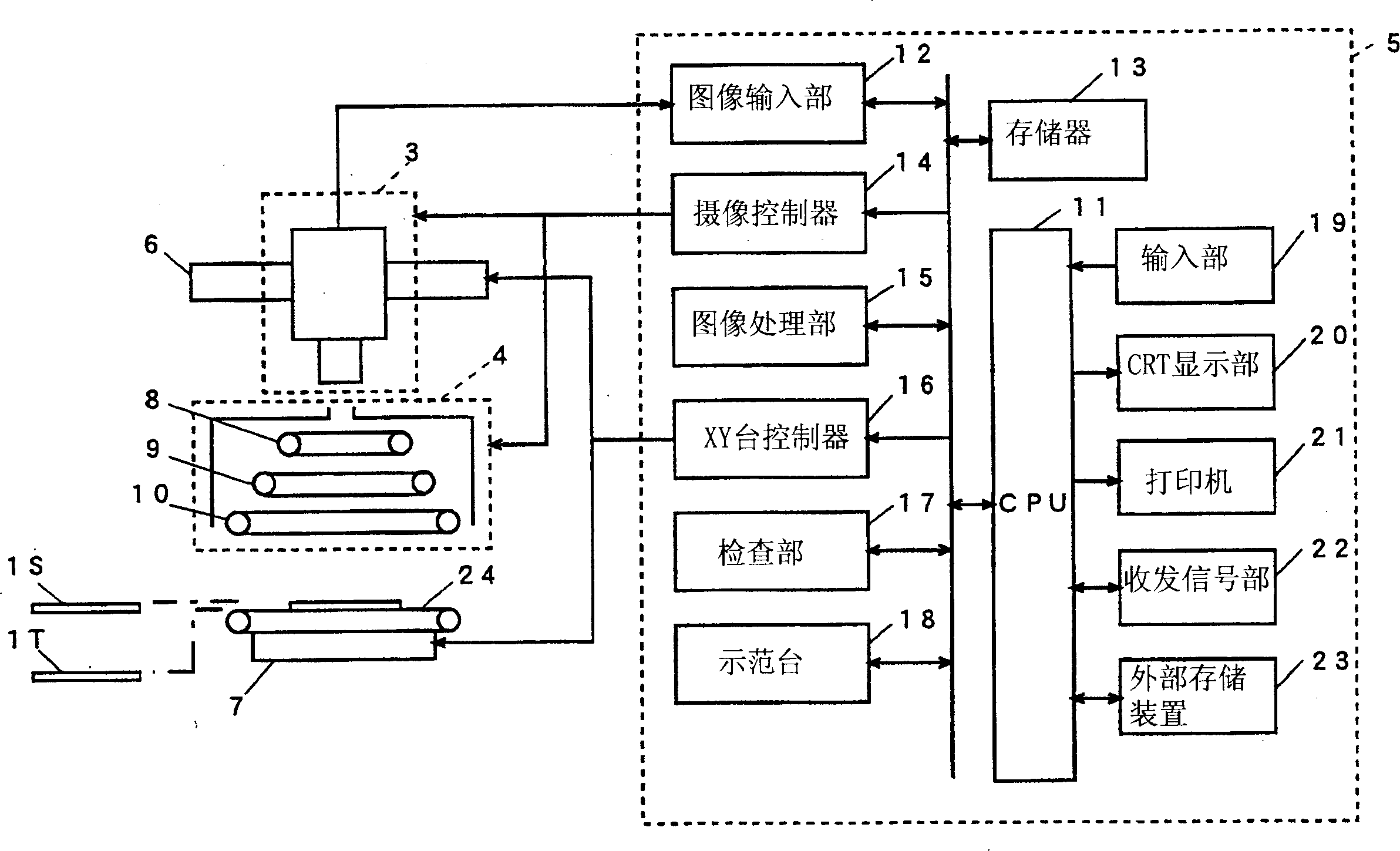

[0066] figure 1 The configuration of a circuit board inspection device according to an embodiment of the present invention is shown.

[0067] This circuit board inspection device is a device that first photographs the circuit board of the inspection object, then processes the obtained image, and then judges whether the solder joint on the circuit board is qualified. It consists of an imaging unit 3, a light projection unit 4, Control processing part 5, X-axis table 6, Y-axis table 7 etc. constitute.

[0068] 1T in the figure is an inspection target circuit board (hereinafter referred to as "inspected circuit board 1T"). 1S is a standard circuit board with good solder joint state and device mounting state, and is used for demonstration before inspection.

[0069] The above-mentioned Y-axis table 7 is equipped with a conveyor belt 24 supporting the circuit boards 1S, 1T, and the conveyor belt 24 is driven by a motor not shown in the figure to make the above-mentioned circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com