Internally and externally magnetic combined fluid processing method and preocessor

A fluid treatment and external magnetic technology, applied in the fields of magnetic field/electric field water/sewage treatment, permanent magnet, etc., can solve the problem that the internal magnetic processor or the external magnetic processor cannot achieve the desired effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

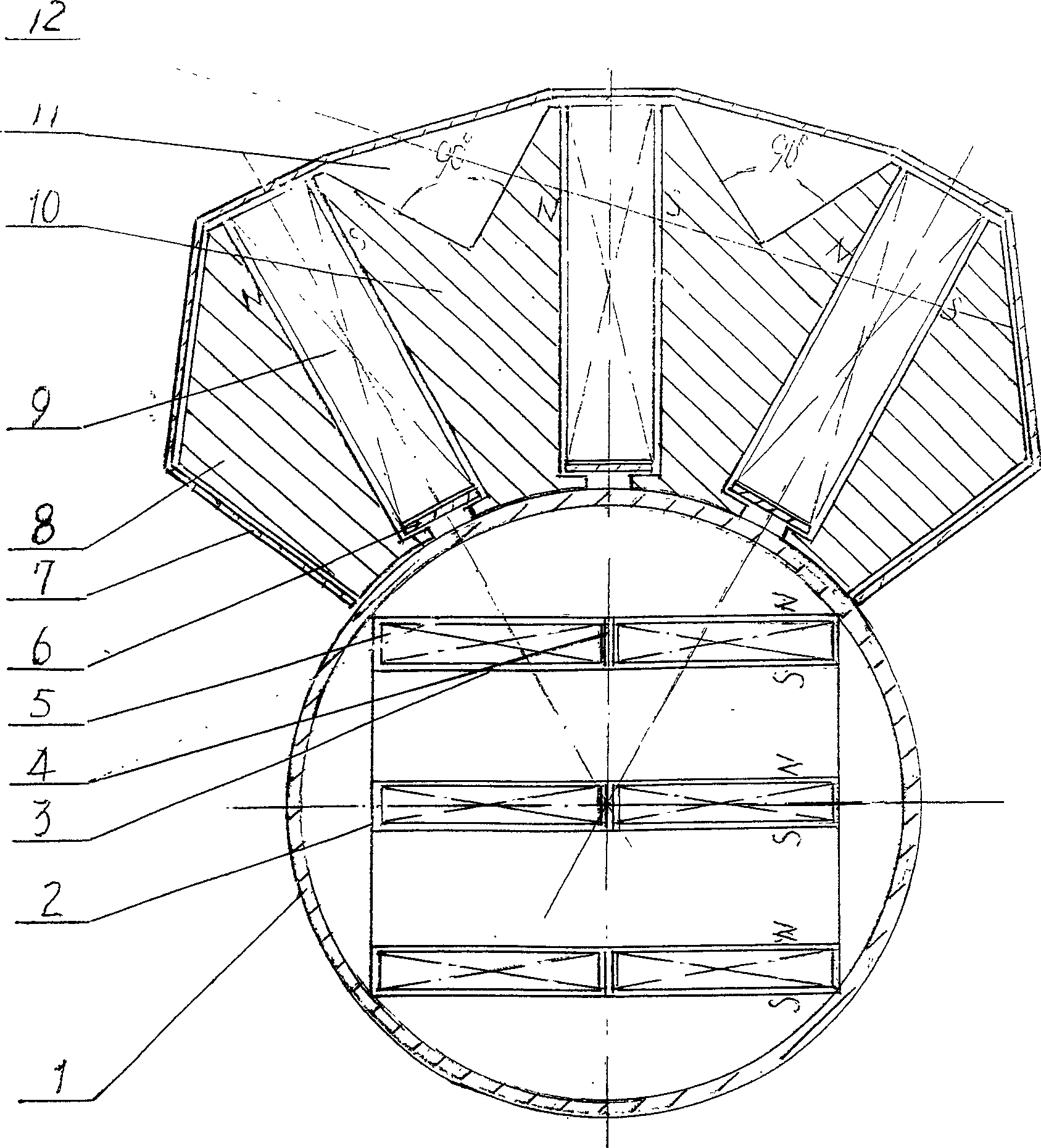

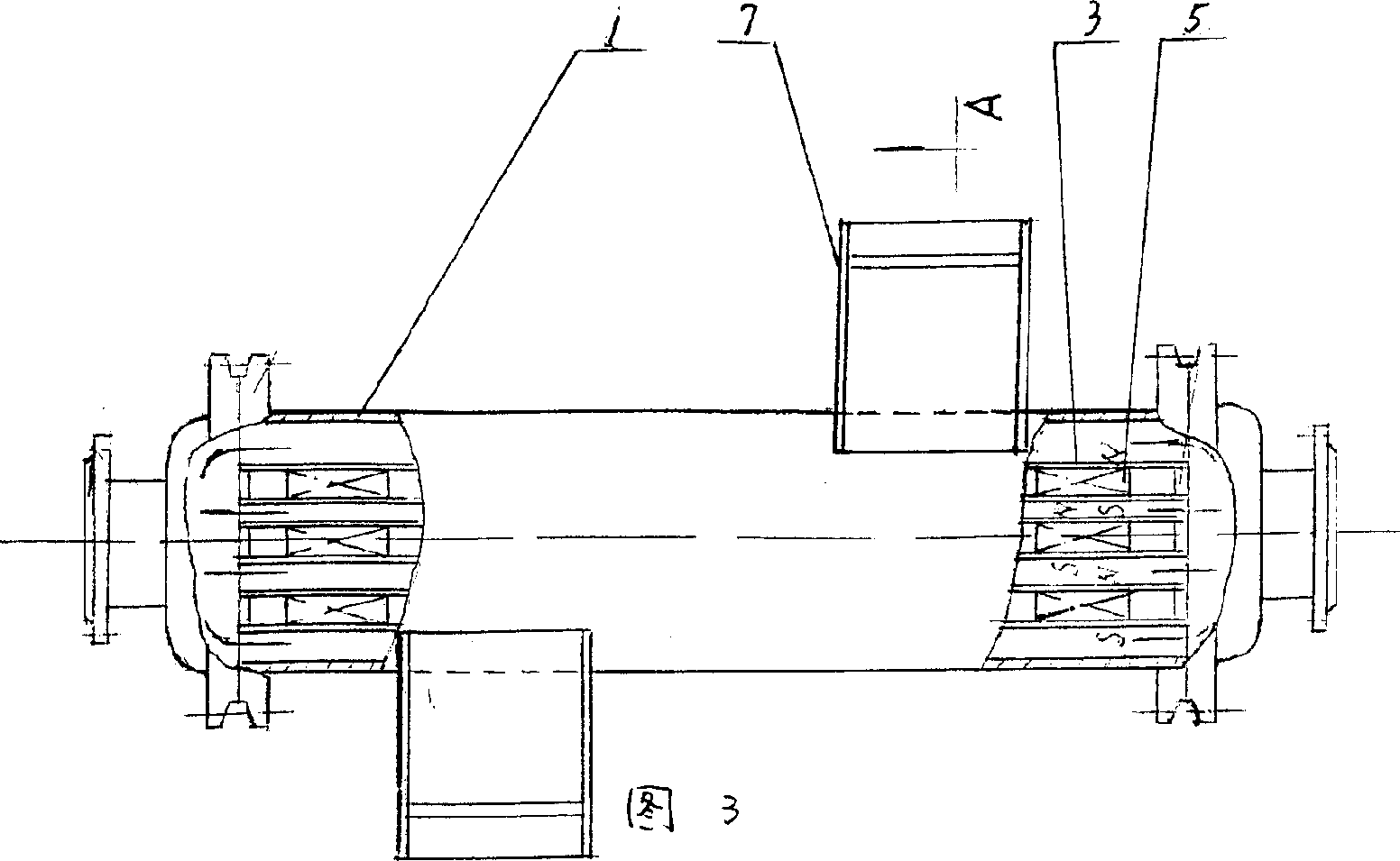

[0005] Embodiment 1: Referring to Fig. 1, the inner and outer magnetic combined fluid processing method and processor, including inner magnetic member and outer magnetic member, the inner and outer magnetic members are arranged on the inner and outer walls of the outer casing 1 at the same time, the outer magnetic member is triple, the inner magnetic member is The magnetic member adopts a frame-type mosaic structure, and a multi-layer magnetic plate can be arranged in the frame. Each layer of the magnetic plate is provided with two inner magnetic blocks 5. The magnetic poles of the inner magnetic blocks are opposite between the two magnetic plates. perpendicular to the outer wall of the outer casing 1 . The outer magnetic component includes an outer magnetic permanent magnet 9 , an outer magnetic concentrating yoke 8 , an outer magnetic intermediate yoke 10 , an outer magnetic filler 11 , an outer magnetic protective cover 7 , an outer magnetic protective plate 6 , and an outer...

Embodiment 2

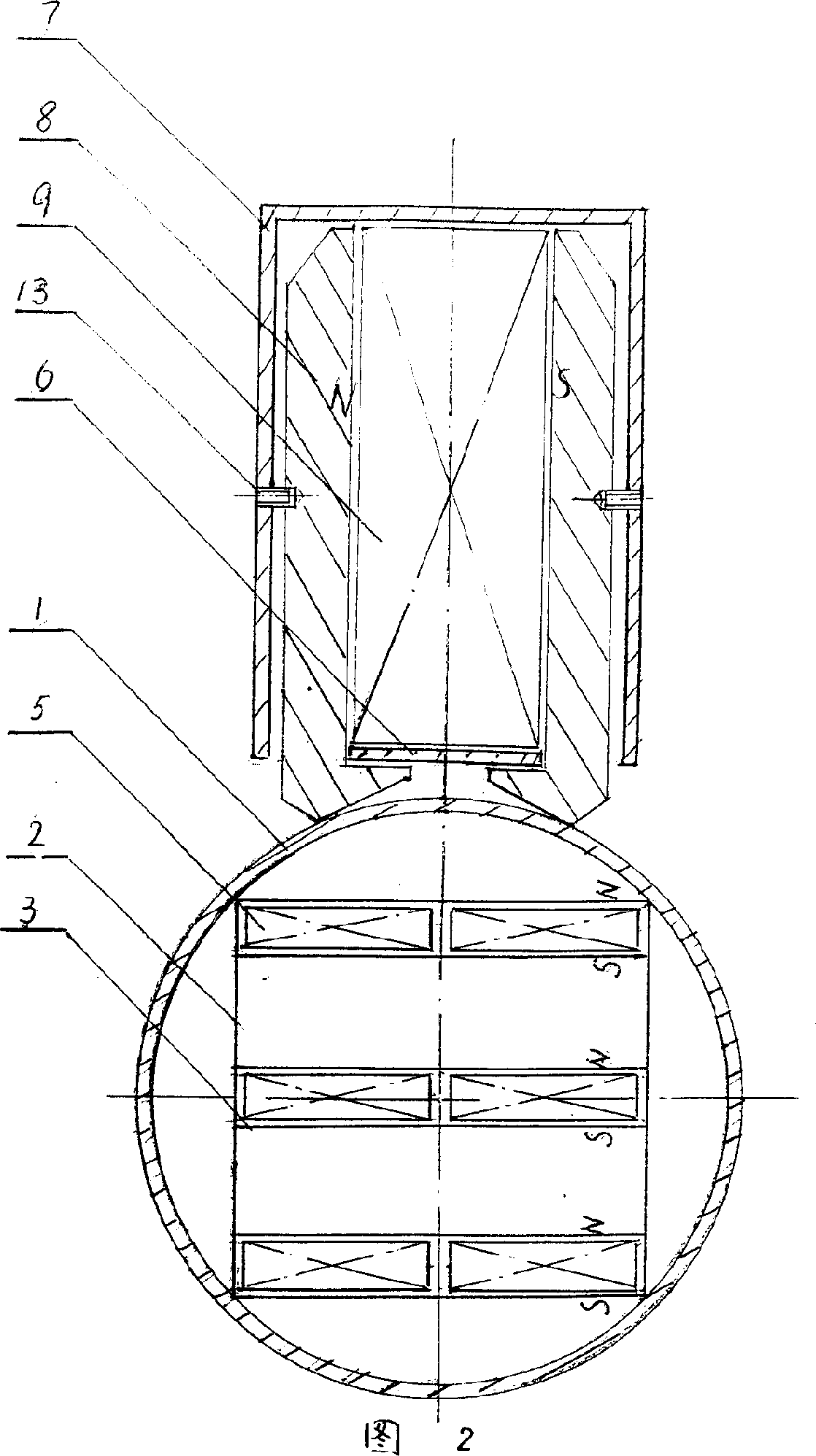

[0006] Embodiment 2: Referring to FIG. 2 , the outer magnetic member is a single unit and is a cylindrical member. A sealing protective layer 12 is provided between the outer magnetic protective cover 7 and the outer magnetic concentrating yoke 8 and is fixed by a fixing pin 13. The clamping angle of the yoke iron 8 is in the shape of an inner caliper, and is in line contact with the outer casing 1, and the rest is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com