Treatment apparatus of fuel and its production method

A technology of a processing device and a manufacturing method, applied in combustion methods, chemical instruments and methods, liquid fuel supply/distribution, etc., can solve the problems of difficulty in popularization and expensive precious metals, and achieve fuel saving, long contact time, and sufficient combustion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

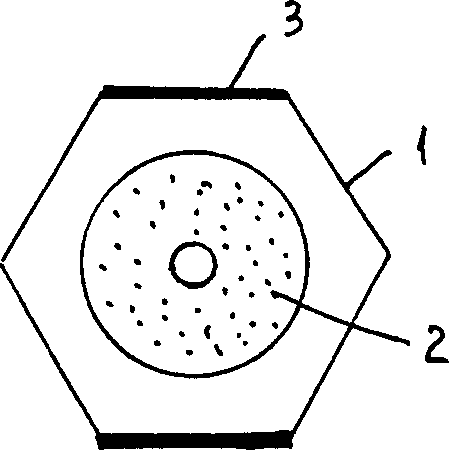

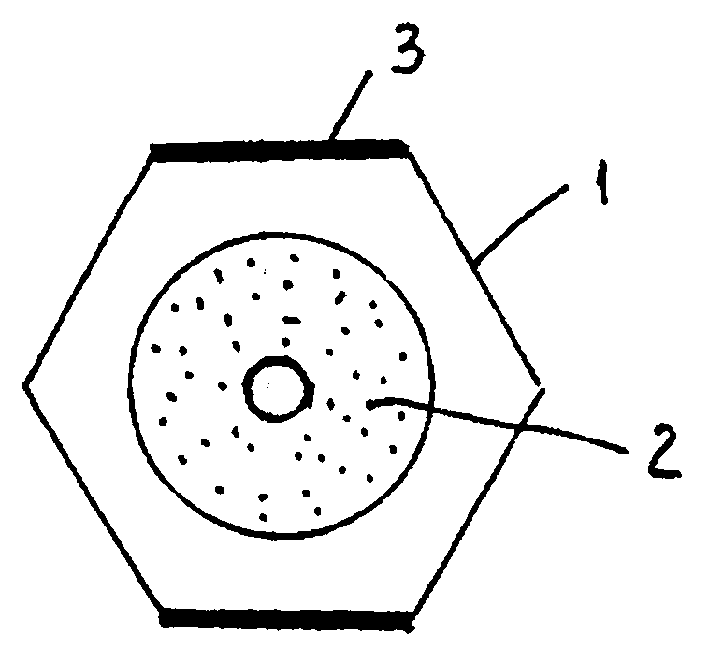

[0017] Example 1: Weigh 58gAL 2 O 3 And 42gTiO 2 , After chemically depositing 1% to 2% of metallic nickel, the residual solution of electroless plating is washed away, after drying, about 0.1-1ppm platinum is deposited in the matrix based on the mass of the base, after drying, weighing 60g of the matrix, Add 40g of composite metal oxide La 0.7 Sr 0.3 C 0 O 3-δ Add 100mL deionized water, after ball milling for 2 hours, drying at 105℃, after cooling, load 10% binder (7% PVA solution), grind and granulate, and then press to shape in a mold. Bake at ℃ for 2h and sinter at 500℃ for 2h. The obtained honeycomb cylindrical body is immersed in the sodium silicate film-forming agent for 1 min, dried at 250° C. for 20 min and cured, and then dipped once. see figure 1 , The solidified carrier 2 is assembled in a hexagonal plastic shell 1, at least two magnetic poles 3 are arranged on the outer wall of the shell 1, and the magnetic field strength is 200 Gauss, which is a cost processing devic...

Embodiment 2

[0018] Example 2: SiO in the matrix 2 Instead of TiO 2 , The composite metal oxide is LaMnO 3-δ , And the other treatments are the same as in Example 1.

Embodiment 3

[0019] Embodiment 3: After the carrier is prepared in the same way as in Embodiment 1, the carrier is put into the shell of the figure, and a wire is wound outside the shell, and direct current is applied to generate a 400 Gauss magnetic field.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com