System and method for treating siderite

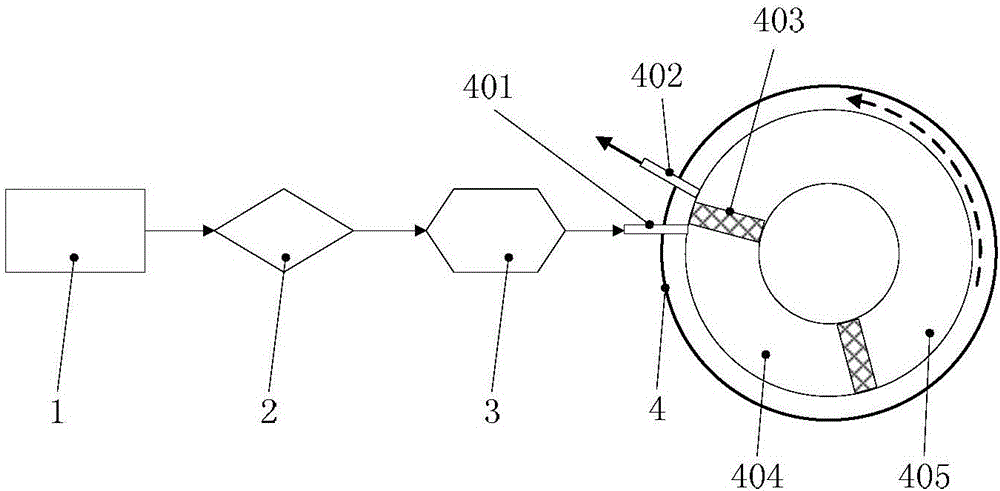

A technology of siderite and rotary hearth furnace, applied in the field of smelting, can solve the problems of density, low specific magnetic susceptibility, poor selectivity, etc., and achieve the effects of sufficient magnetization, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

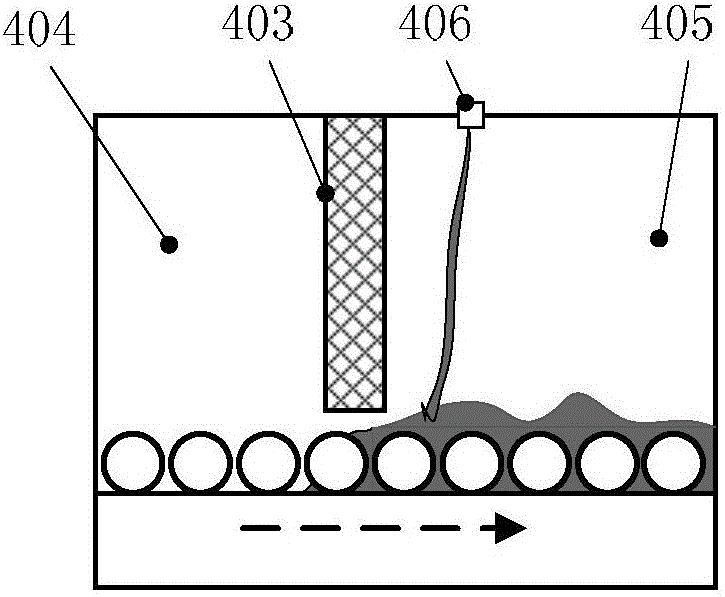

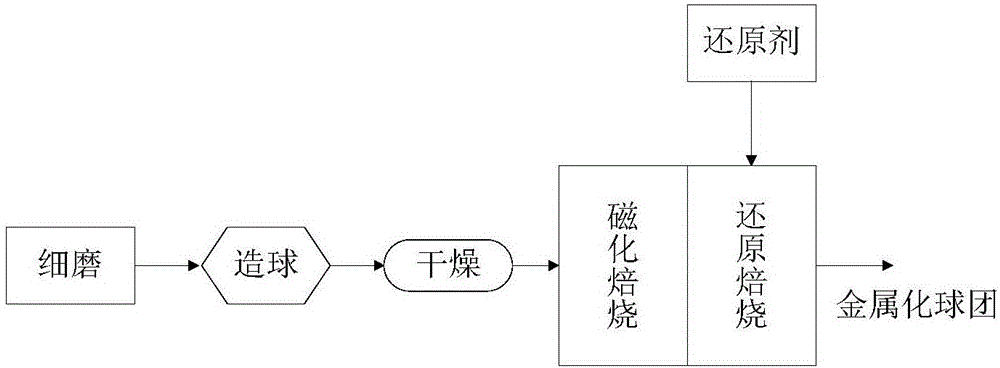

[0053] Grind a certain siderite ore until the particle size of 86.32% mass ratio is ≤200 mesh, make pellets (pellets with a particle size of 8-12mm), and enter from the feed port of the rotary hearth furnace after drying. The arc of the magnetization roasting area of the rotary hearth furnace is 130 °, the temperature is controlled at 500°C, the temperature in the reduction roasting zone is controlled at 1250°C, and the bottom of the furnace rotates for 2 hours. When the dry pellets after magnetization and roasting enter the reduction roasting zone, the reduced coal (mass component of carbon: 82.03%, particle size 2mm) Dry pellets are covered from the reducing agent inlet, and the dry pellets covered with reduced coal are reduced to metallized pellets in the reduction roasting zone and discharged from the discharge port.

Embodiment 2

[0055] Grind a certain siderite ore until the particle size of 88.55% mass ratio is ≤200 mesh, make pellets (pellet particle size 10-14mm), and enter from the feed port of the rotary hearth furnace after drying. The arc of the magnetization roasting area of the rotary hearth furnace is 170 °, the temperature is controlled at 800°C, the temperature in the reduction roasting zone is controlled at 1200°C, and the furnace bottom rotates for 1.5 hours. When the dry pellets after magnetization roasting enter the reduction roasting zone, the reduced coal (mass component of carbon: 80.26%, particle size 3mm ) is covered with dry pellets from the reducing agent inlet, and the dry pellets covered with reduced coal are reduced to metallized pellets in the reduction roasting zone and discharged from the discharge port.

Embodiment 3

[0057] Grind a certain siderite ore until the particle size of 87.45% by mass ratio is ≤200 mesh, make pellets (pellets with a particle size of 10-16mm), and enter from the feed port of the rotary hearth furnace after drying. The arc of the magnetization roasting area of the rotary hearth furnace is 130 °, the temperature is controlled at 700°C, the temperature in the reduction roasting zone is controlled at 1300°C, and the time for one rotation of the furnace bottom is 2.5 hours. ) is covered with dry pellets from the reducing agent inlet, and the dry pellets covered with semi-coke are reduced to metallized pellets in the reduction roasting zone and discharged from the discharge port.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com