Wefting inserter for air-jet loom

A technology of weft insertion device and air-jet loom, which is applied in looms, textiles, textiles and papermaking, etc., and can solve problems such as cost defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

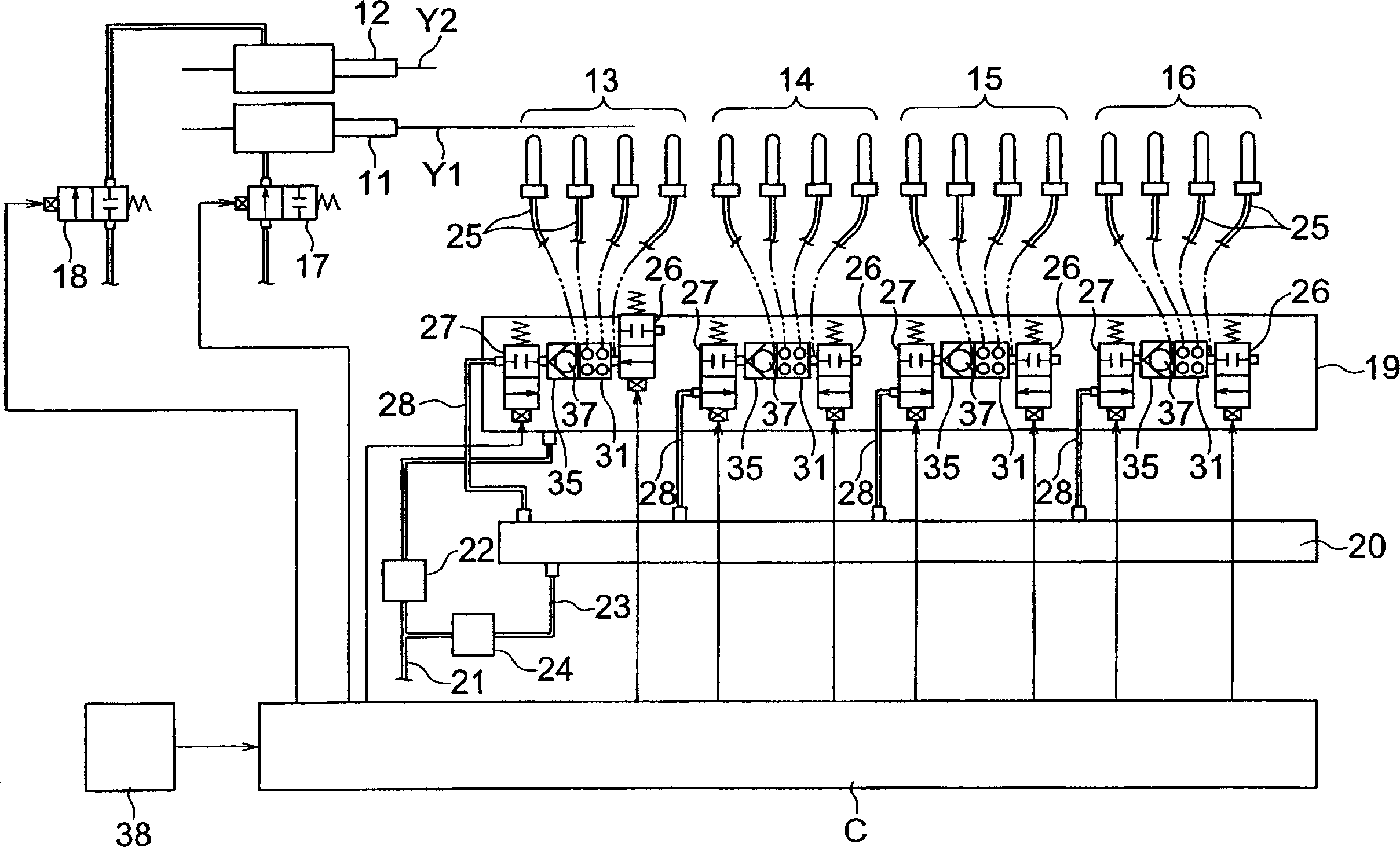

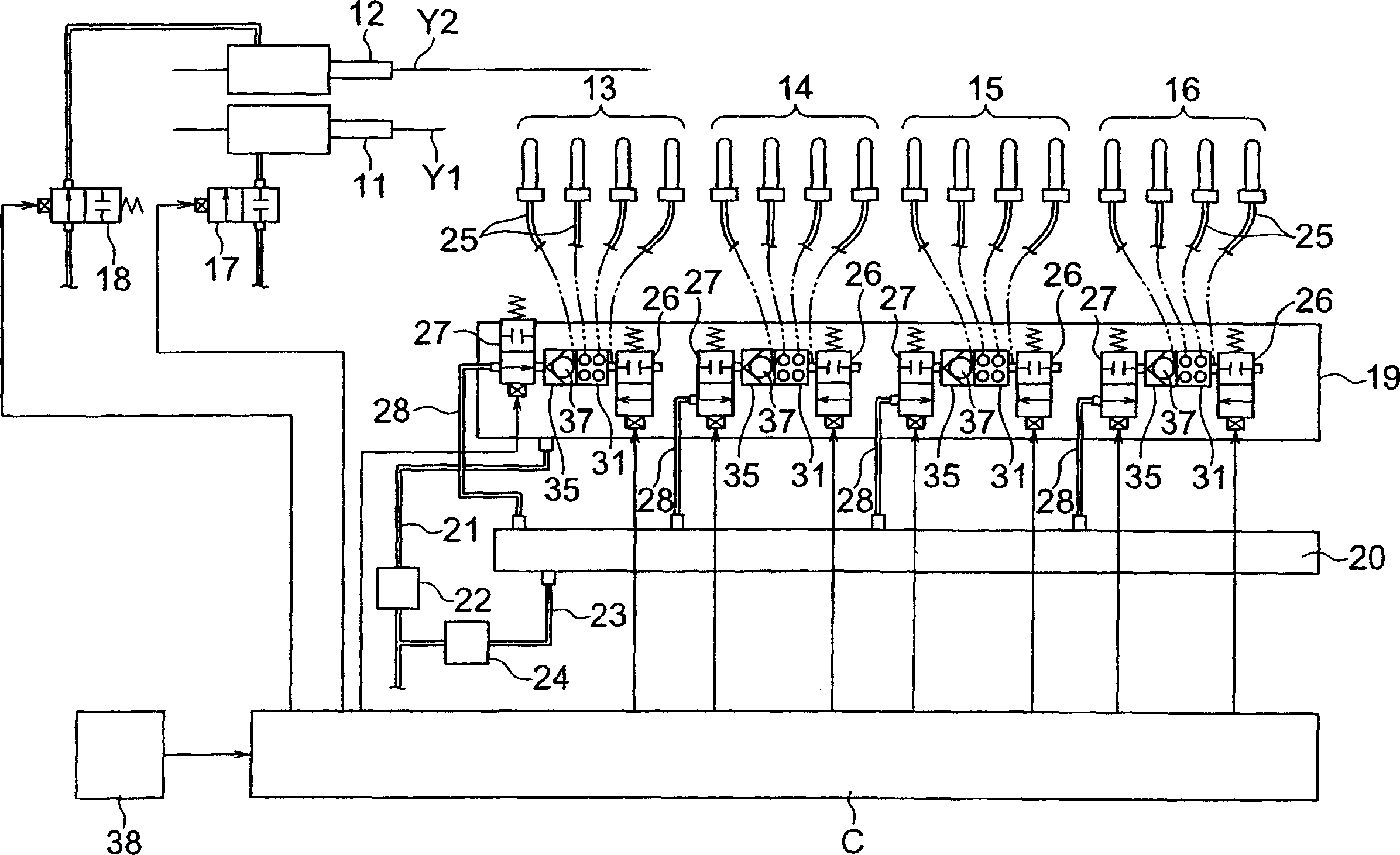

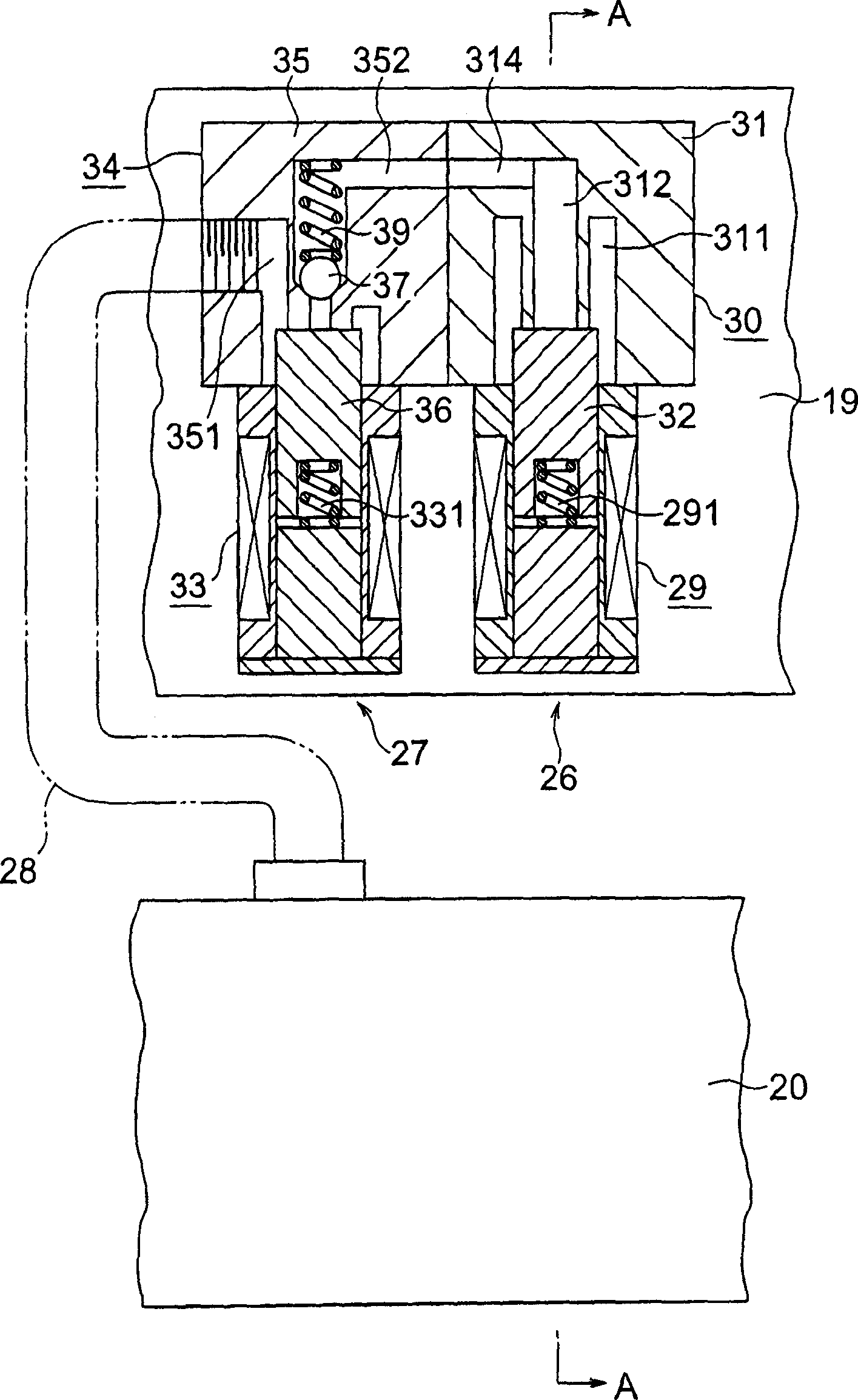

[0029] Combine below Figures 1 to 4 A first embodiment embodying the present invention will be described.

[0030] Such as figure 1 As shown, a pair of weft insertion main nozzles 11 and 12 inject weft yarns Y1 and Y2 into a warp yarn opening (not shown) according to a predetermined weft yarn selection pattern. The weft insertion auxiliary nozzle groups 13, 14, 15 and 16 complete the continuous spraying from the weft insertion main nozzles 11 and 12 sides. The alternate jets draw the weft yarns Y1 and Y2 into the warp openings. Weft insertion main nozzles 11 and 12 are connected to an air tank (not shown) through intermediate electromagnetic on / off valves 17 and 18, and the air tank receives pressurized air provided by a pressurized air source (not shown). The electromagnetic on / off valves 17 and 18 are energized and demagnetized according to the weft selection pattern.

[0031] The weft insertion auxiliary nozzle groups 13 to 16 are provided with pressurized air by a pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com