Teat rubber

A teat and head technology, applied in the bushing field of the milking cup shell, can solve the problems that affect the good adaptability of the teat and cannot be manufactured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For ease of further explanation, the direction and orientation of the liner herein refers to the position of the liner when it has been pushed onto the teat. The parts shown at the top in the figures are the parts facing the bottom of the udder, therefore, the parts of the milking device that lead the milk to the collection container are connected to the parts shown at the bottom.

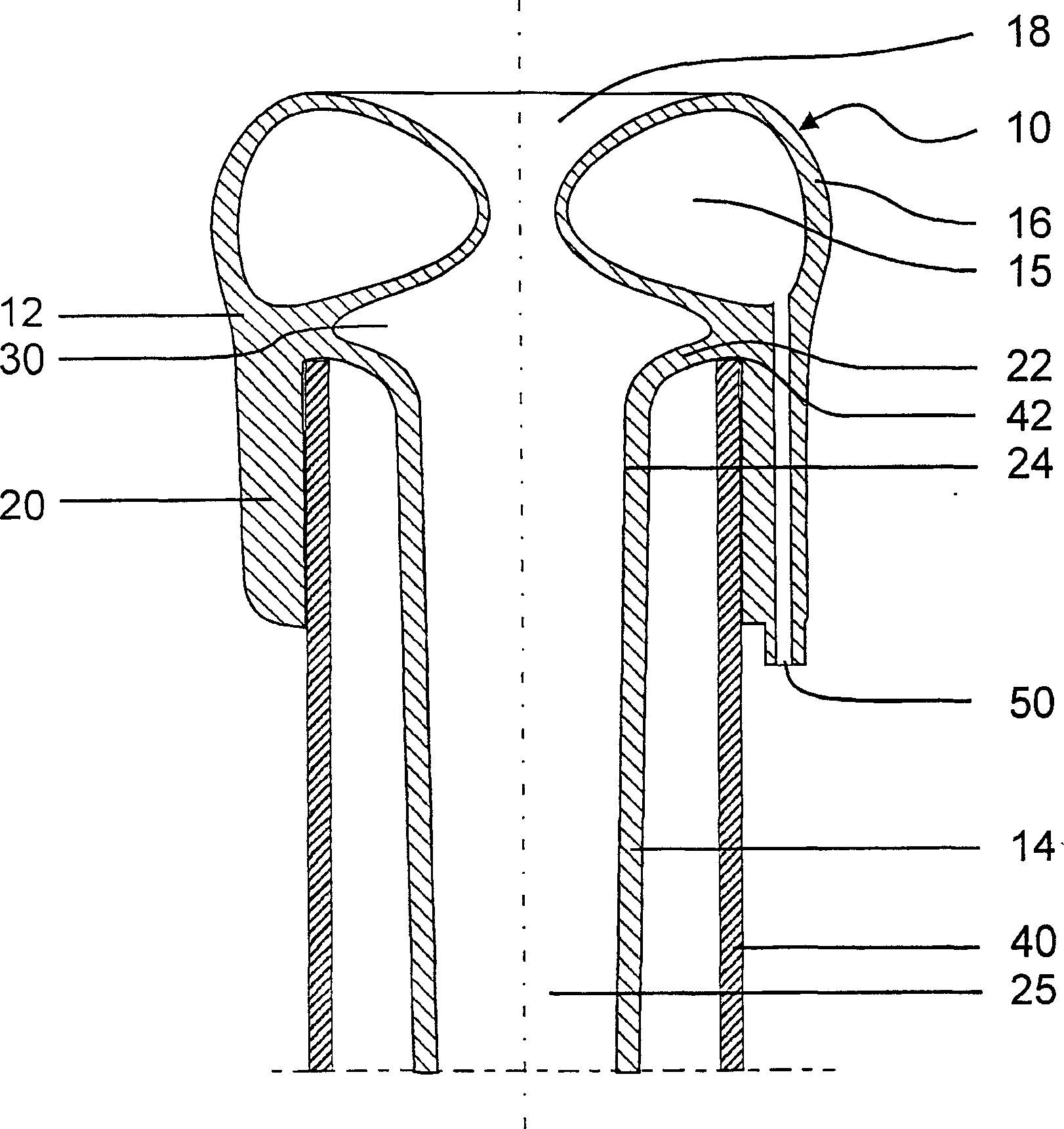

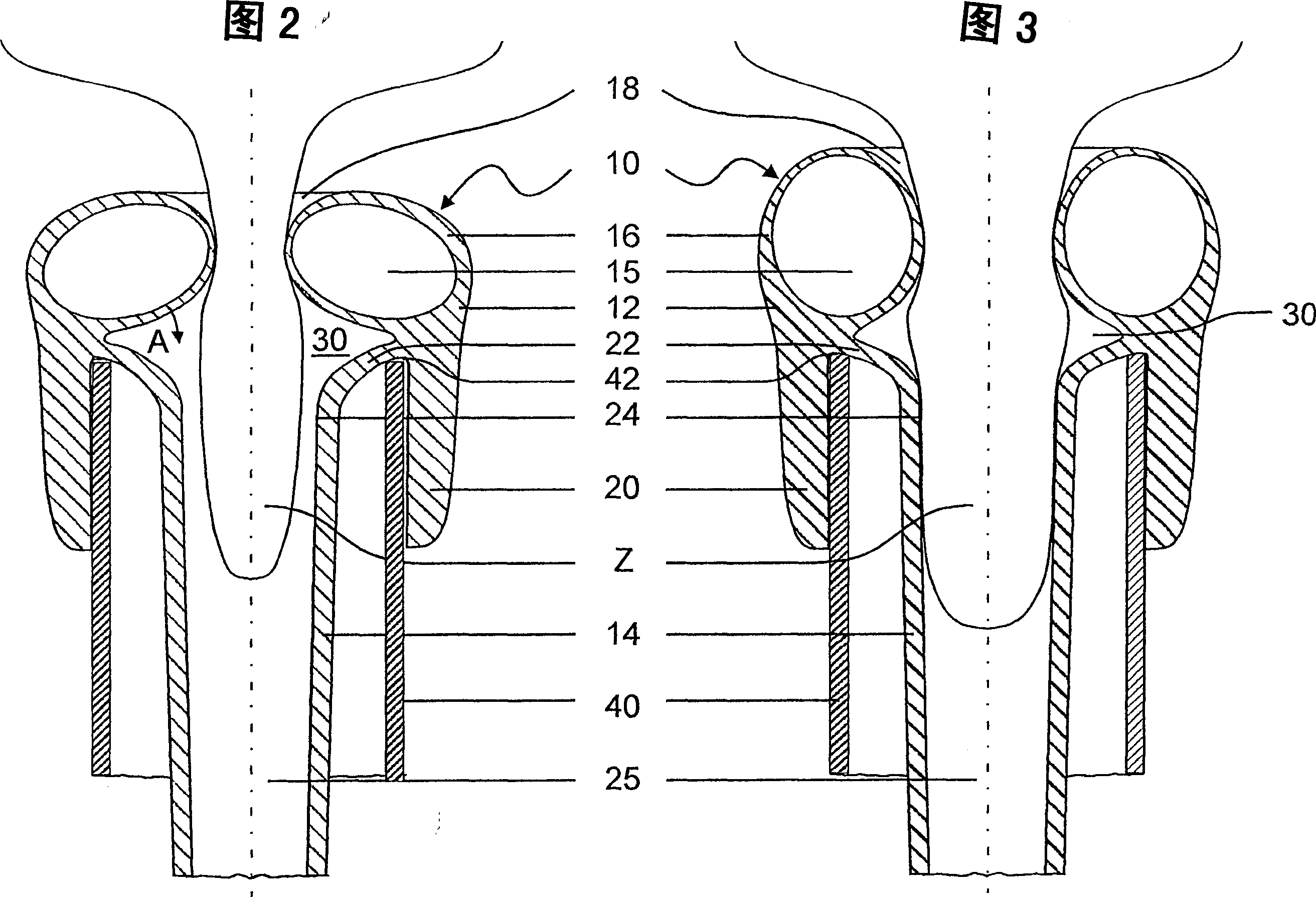

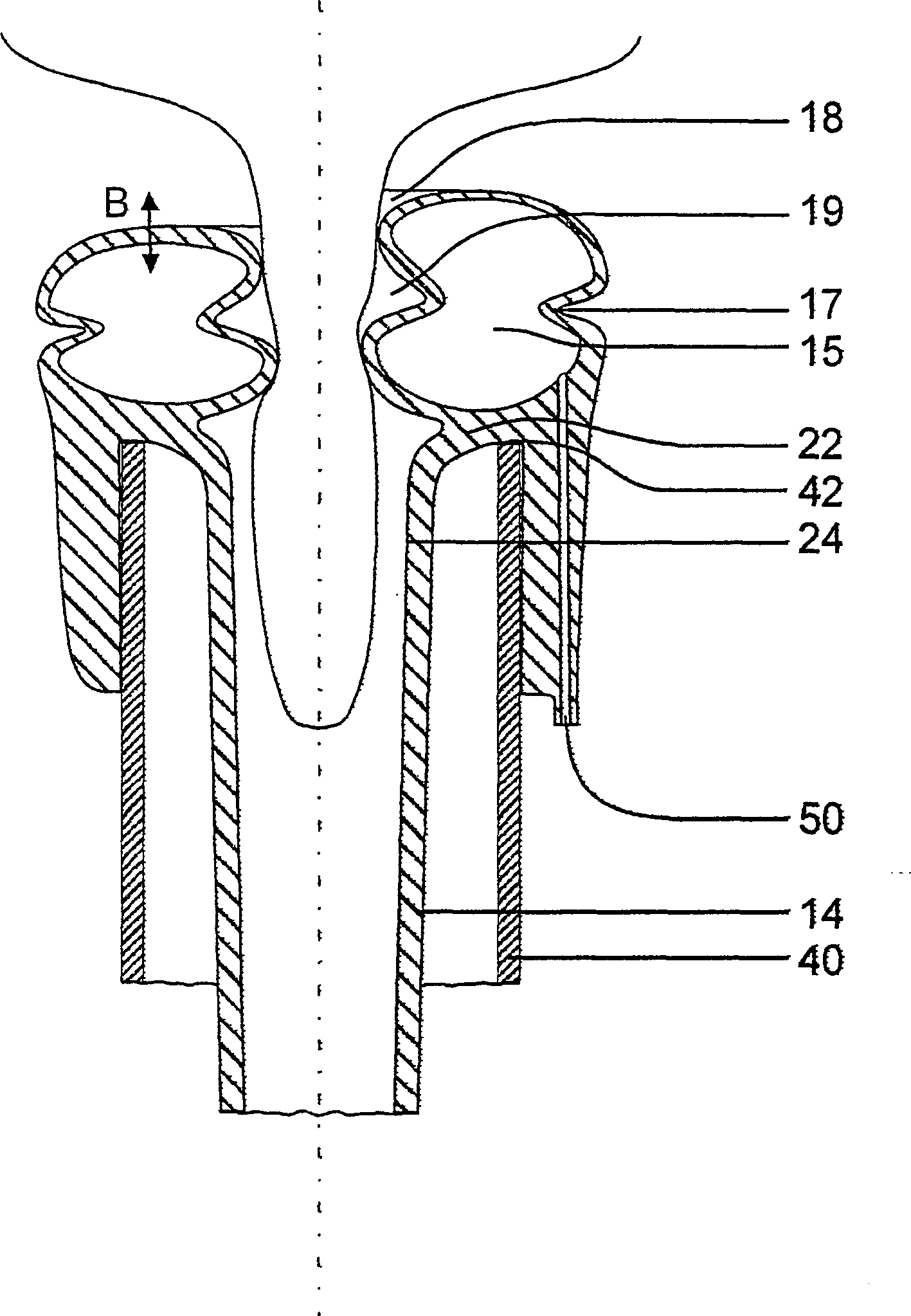

[0026]First refer to figure 1 , which describes a first preferred embodiment of the invention. In the example described, the bushing 10 comprises a barrel portion 14, a retaining edge 20 for pushing onto the housing 40, connecting the shaft or the upper edge 24 of the barrel portion 14 near the upper edge 42 of the housing 40 to the The transition portion 22 of the retaining edge 20 is connected to said transition portion 22 and the head portion 12 of the retaining edge 20 also near the upper edge 42 of the housing 40 . These elements are parts inside the teatcup, which are closely interco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com