Motor with earthing structure to reduce radio noise

A motor, elastic contact technology, applied in the field of motors, can solve problems such as increased cost of parts, loose electrical connections, loose connections between motor seat rings and end panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

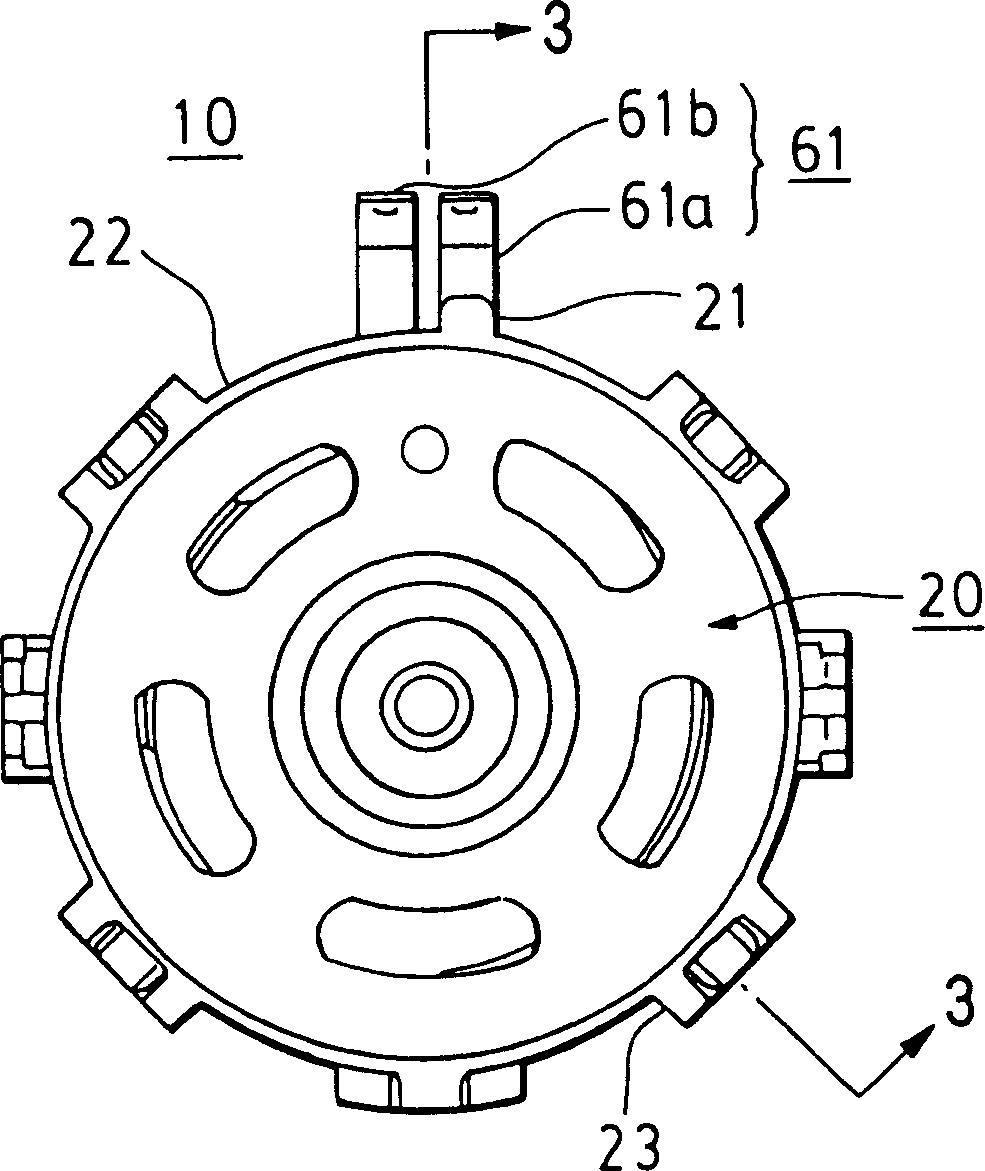

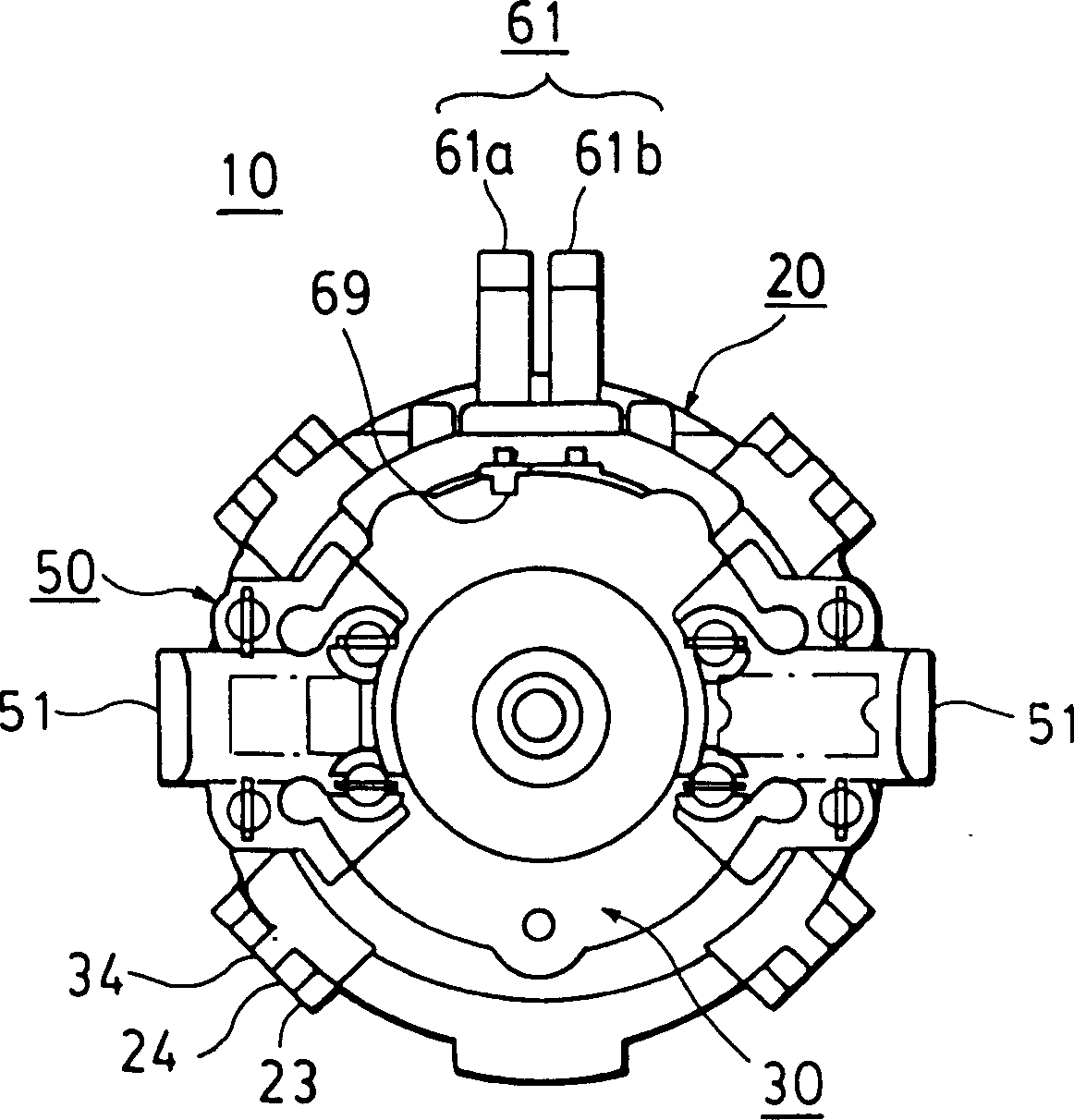

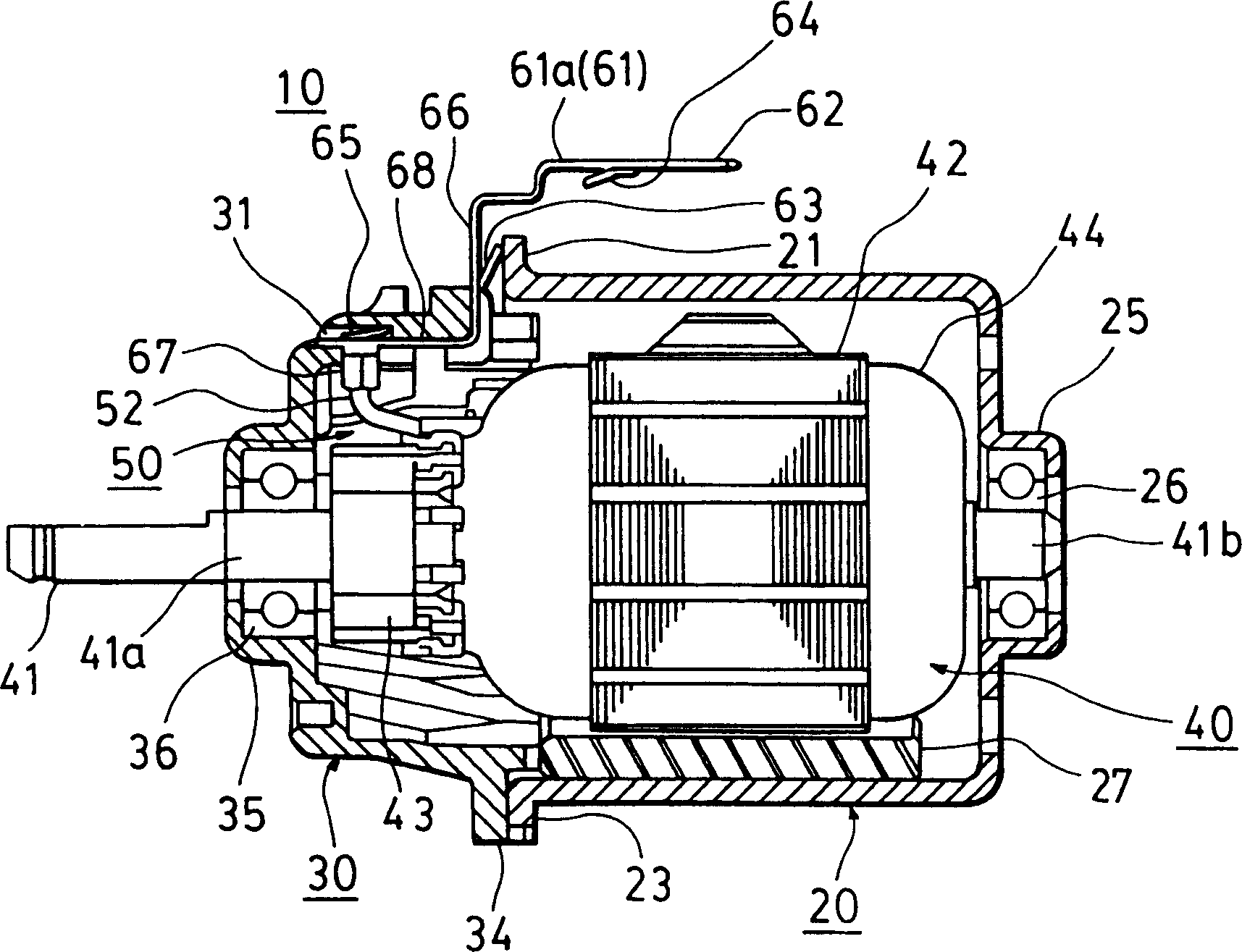

[0017] refer to Figures 1 to 3 , the motor 10 includes a motor race 20 , an end plate 30 , an armature 40 and a brush assembly 50 . The electric motor 10 is used for the blower on the vehicle. The motor race 20 is substantially formed in a cylindrical shape with one end closed for accommodating the armature 40 . The closed end of the motor race 20 has a concave bearing housing portion 25 . The bearing housing portion 25 houses a ball bearing 26 . A stator 27 consisting of magnets of substantially sector-shaped cross-section is disposed around the inner wall of the motor race 20 with a fixed gap in the circumferential direction.

[0018] A flange 22 is formed adjacent to the opening of the motor race 20 and along its edge, also referred to as an edge flange 22 . The ground flange 21 is formed at a predetermined portion of the edge flange 22 . The ground flange 21 also protrudes outward from the edge flange 22 and is electrically connected to the motor race 20 and the nega...

no. 2 approach

[0035] refer to Figure 6 , the edge flange 22 of the motor race 20 has a ground flange including a branch portion 121 . The contact portion 63 is bent in the branch portion 121 for grounding the motor race 20 . Due to this structure, the contact portion 63 is in close contact with the motor race 20 . Therefore, even when the contact between the motor race 20 and the end plate 30 becomes loose, the negative terminal 61 a is kept in contact with the motor race 20 . The radio noise occurring at the motor raceway can thus be continuously reduced. third embodiment

no. 3 approach

[0036] refer to Figure 7 , the edge flange 22 of the motor race 20 has a substantially disc-shaped ground flange 221 . At the center of the ground flange 221 , the boss 222 is parallel to the axial direction of the motor race 20 . In place of the contact portion 63, a contact portion 263 formed protrudes from the planar portion 66 of the negative terminal 61a. The contact portion 263 is bent toward the motor race 20, and its free end is bent so that the surface of its free end is substantially parallel to the surface of the ground flange 221.

[0037] There is a boss hole 264 in the center of the free end. The boss 222 is fitted into the boss hole 264 to couple the negative terminal 61 a with the motor race 20 . When the boss 222 is fitted into the boss hole 264, the motor race 20 is grounded. The entire surface of the bent free end of the contact portion 263 is pressed against the ground portion 221 . Therefore, even when the contact between the motor race 20 and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com