Process for producing glass optical element and method for determining glass component of glass blank

A technology for optical components and manufacturing methods, which are used in optical components, glass molding, glass pressing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0148] Next, the present invention will be described in more detail while finding the best embodiment.

[0149] In the following examples, the refractive index n is used d , Abbe number γ d as an optical constant.

reference example 1

[0151] Using barium borate optical glass (basic composition: SiO 2 37.8wt%, B 2 o 3 24.0wt%, Al 2 o 3 5.3wt%, Li 2 O8.5wt%, CaO5.0wt%, BaO16.1wt%, La 2 o 3 3.3wt%, As 2 o 3 0.5wt%, Sb 2 o 3 0.2 wt%, Tg: 500 degrees), to produce glass lenses.

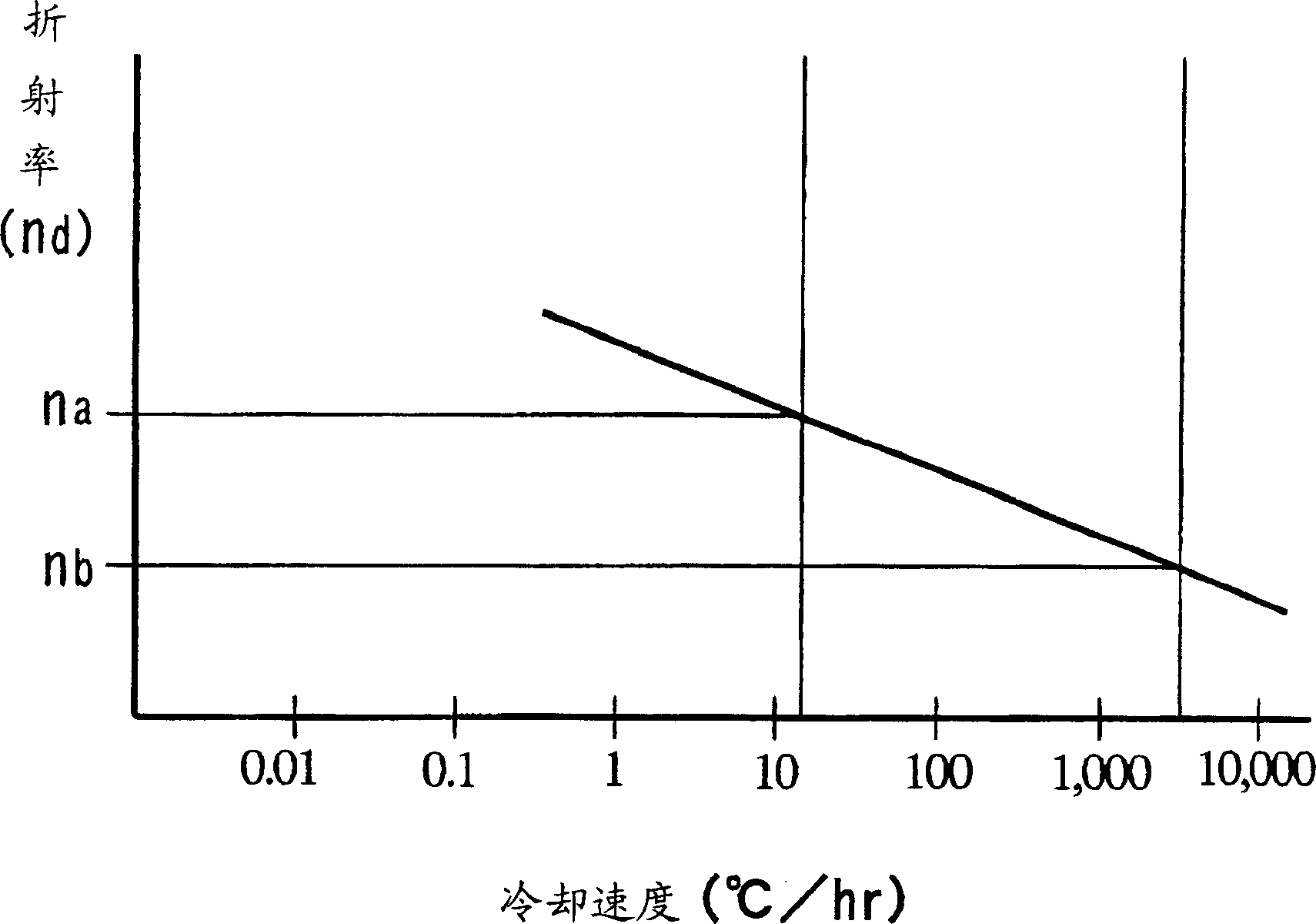

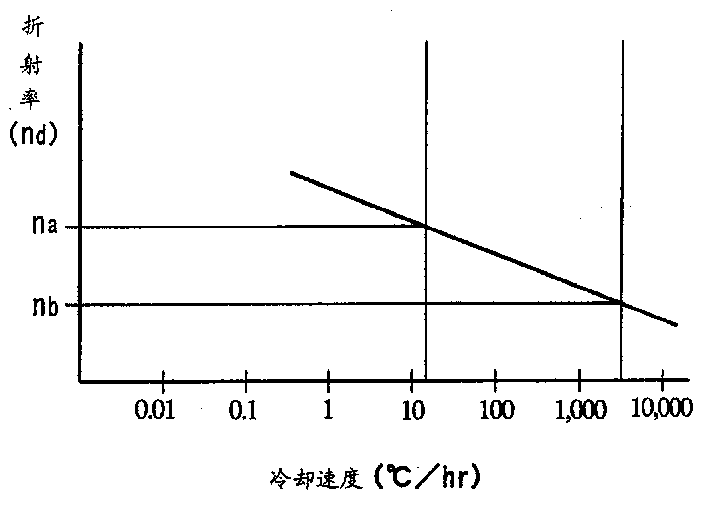

[0152] The above-mentioned barium borate glass was melted, flowed down from an outflow pipe, cut and cooled (quenched in the atmosphere) to obtain a preform (glass blank for press molding) in the shape of an oblate sphere. The strain of this preform was large, and the refractive index could not be measured, but it was estimated to be a rather low value. Keep at Tg+30 degrees for 2 hours, cool to the strain point below -50 degrees at a cooling rate of 30 degrees / hour, and measure the refractive index (n) at room temperature d 1.58900, gamma d 61.30). These are referred to as the standard refractive index and the standard Abbe number.

[0153] The above-mentioned quenched preform is sent to a press-forming process to be pres...

Embodiment 1

[0157] Implement the refractive index n of the preform shown in reference example 1 under Tg+30 degrees for 2 hours, and cooling (processing under specified conditions) at a cooling rate of 30 degrees / hour d 1.58900 and the Abbe number¶ d 61.30 is the standard refractive index and standard Abbe number, which is determined by n 1 And γ1 said the refractive index and Abbe.

[0158] In addition, in Reference Example 1, by press-forming the glass of the above-mentioned composition under the above-mentioned conditions, it becomes n d 1.58600, Abbe number γ d 61.25. That is, n 2 for n d 1.58600, γ2 for γ d 61.25.

[0159] That is, n 1 -n 2 300×10 -5 , γ1-γ2 is 0.05.

[0160] And, as the expected value of the lens design (n 3 and γ3), select and n 1 and the same n as γ1 d 1.58900 and gamma d 61.30, try lens shaping.

[0161] Alternatively, the modulation standard refractive index ratio n 3 High 300×10 -5 The glass blank is used as a preform (glass blank), so that af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com