Method of removing photosensitive resin and residual polymer

A photosensitive resin, polymer technology, applied in photosensitive material processing, electrical components, semiconductor/solid-state device manufacturing, etc., can solve difficult removal, loss of top oxide layer 108, and inability to completely remove sidewall grid polymers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

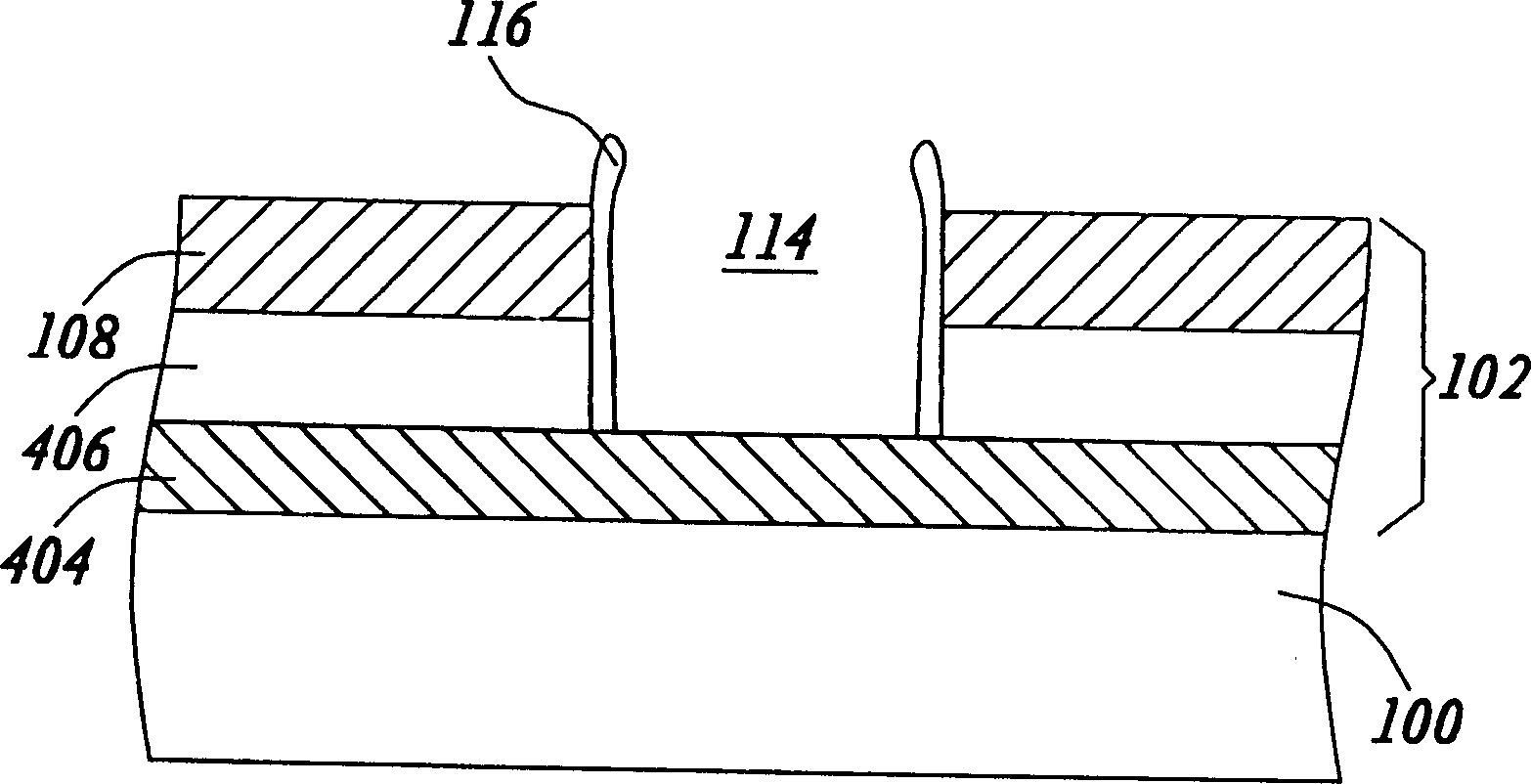

[0019] In this preferred embodiment, a flash memory (flash memory) is taken as an example to illustrate how to remove photo-resist (PR) with the method of the present invention after the formation of a contact hole. And residual polymer (polymer residue) such as sidewall grid polymer (sidewall polymer fence). However, the present invention is not limited to the flash memory, and can also be applied to other semiconductor devices. In addition, in order to express the present invention more clearly, some well-known elements that are irrelevant to the present invention will be omitted from description and not shown in the drawings.

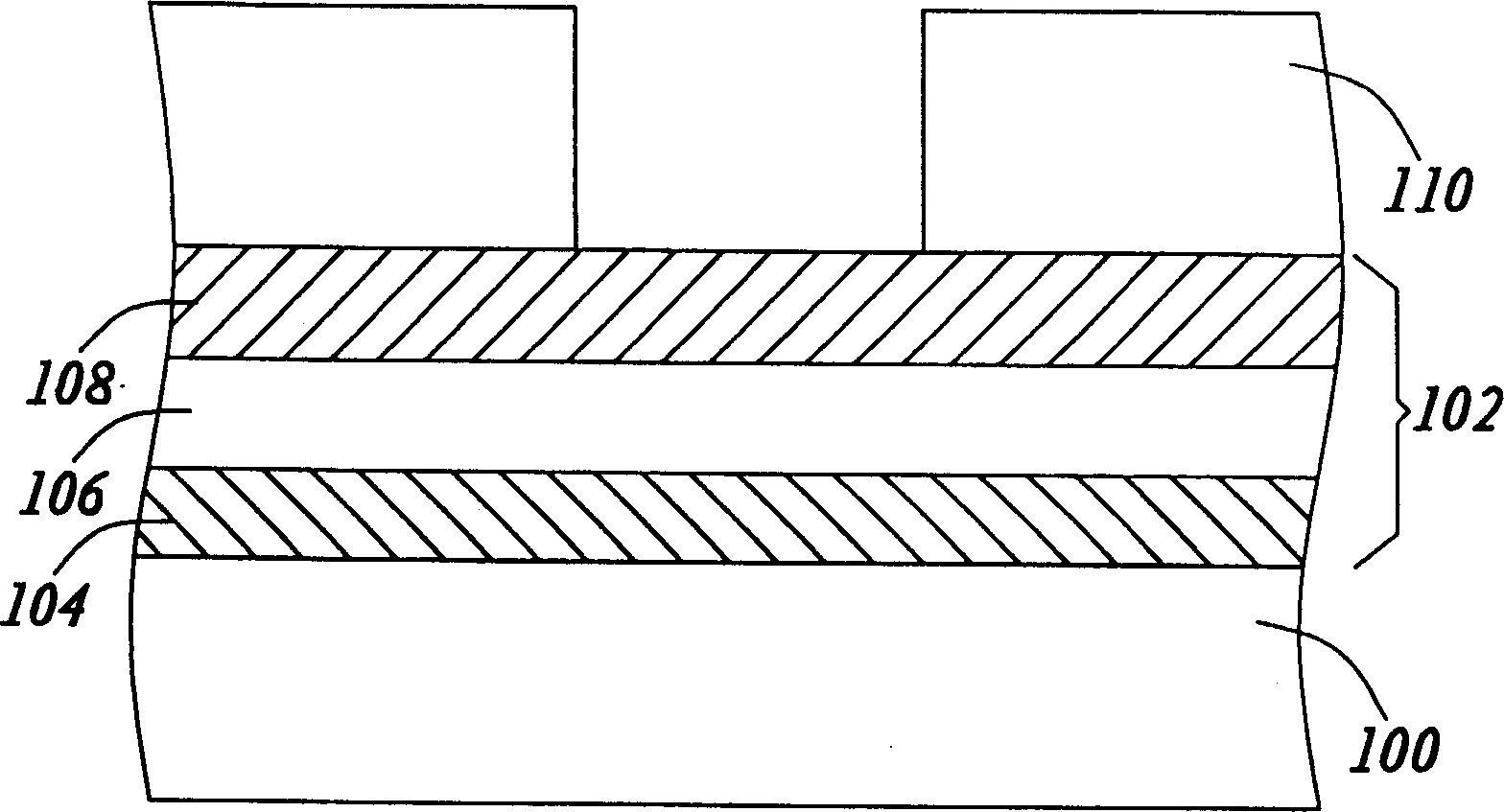

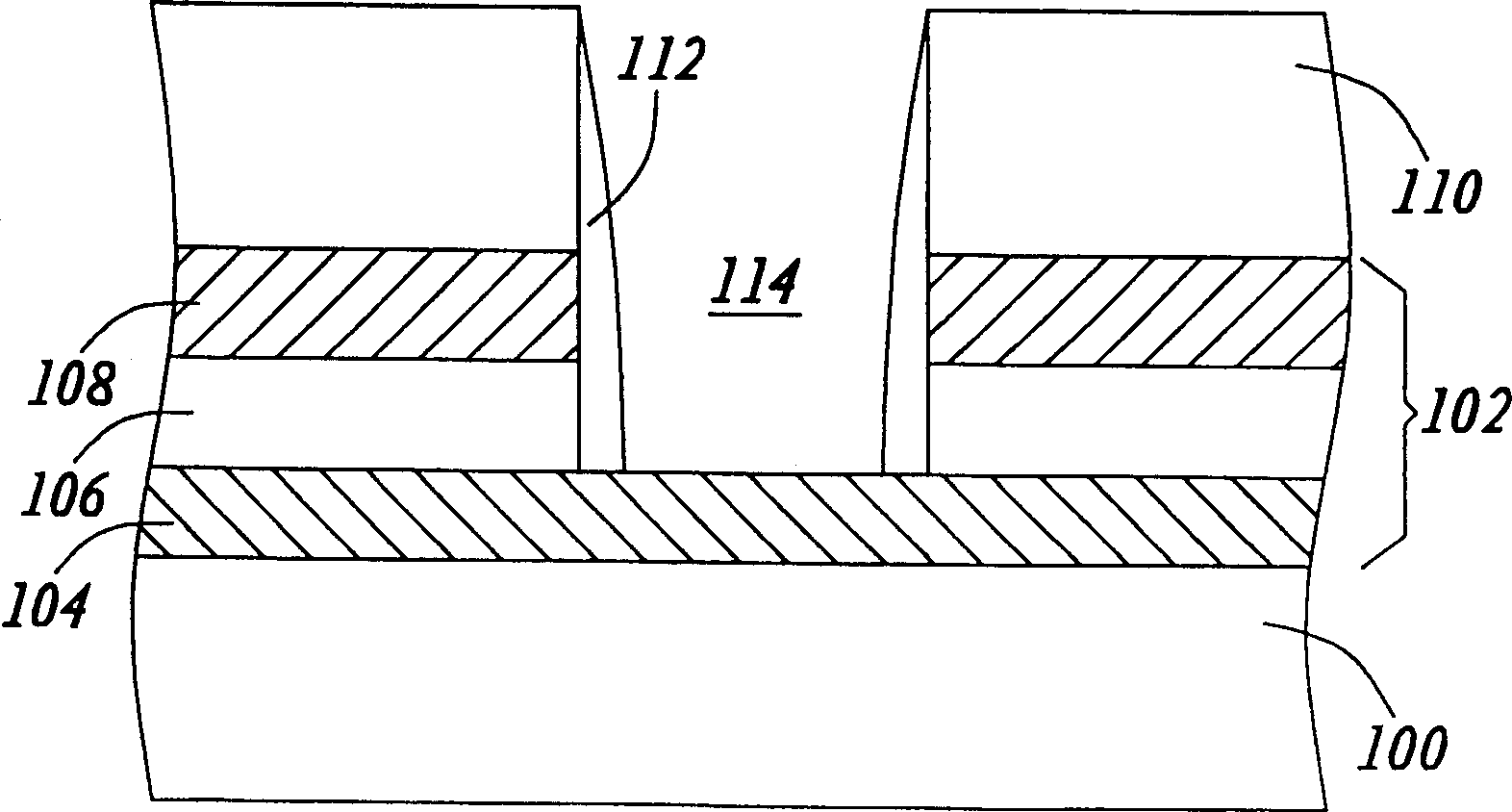

[0020] The etching process for forming the via hole is the same as the conventional method. Please refer to figure 1 and figure 2 . The insulating layer 102 deposited on the substrate 100 is covered with a photosensitive resin, and the photosensitive resin undergoes a photolithography process, such as exposure and development, to form a pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com