Bimetallic valve push rod

A bimetal, push rod technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems affecting engine power and fuel consumption, affecting the opening and closing timing of intake and exhaust valves, and valve noise, etc. Machining, simplifying maintenance work, reducing the effect of valve noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

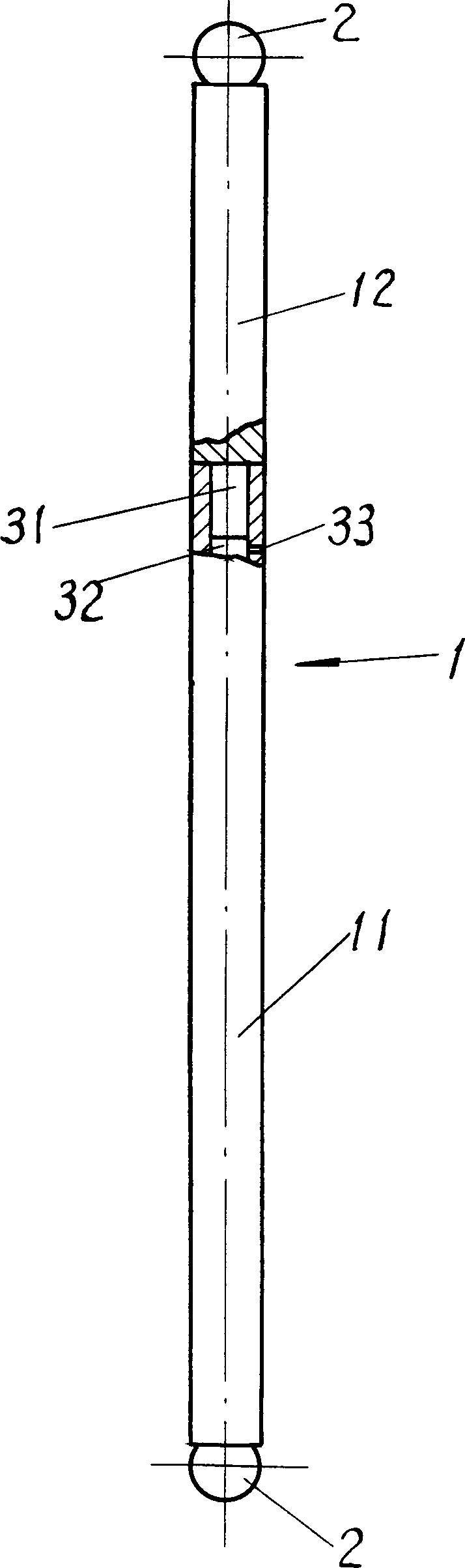

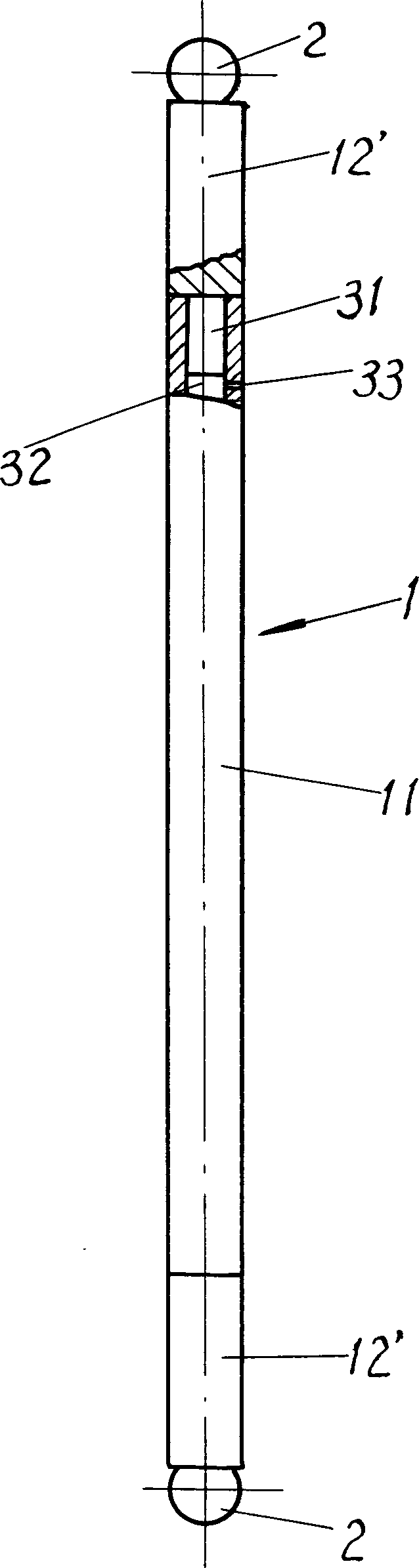

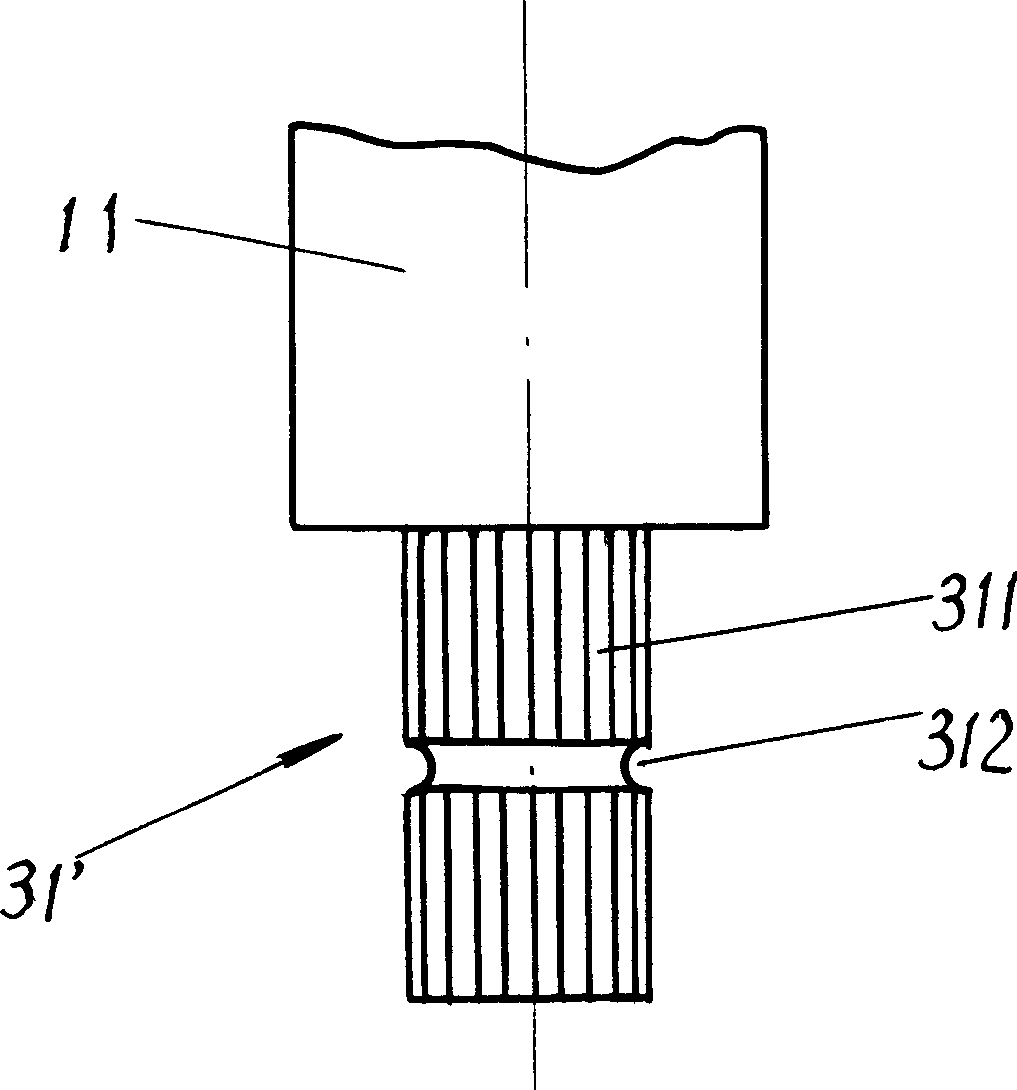

[0016] see figure 1 The shown engine valve push rod has a cylindrical shaft 1 and steel balls 2 arranged at both ends of the shaft 1 . The shaft 1 is composed of two shaft parts 11 and 12 . The shaft part 11 is larger than the overall expansion coefficient of the engine by the expansion coefficient (for example, is 20 * 10 -6 mm / 1℃), for example, the expansion coefficient is 23×10 -6 mm / 1℃ aluminum alloy. The shaft part 12 is then made of a material whose expansion coefficient is less than the overall expansion coefficient of the engine, for example, the expansion coefficient is 12×10 -6 mm / 1℃ carbon steel or 17.6×10 -6 mm / 1°C 1Cr18Ni9Ti alloy steel. By adjusting the respective length ratios of the shaft parts 11 and 12, the overall expansion coefficient of the shaft 1 is equal to or close to the overall expansion coefficient of the engine. The shaft part 11 and the shaft part 12 are connected by a mortise and tenon structure 3 . Usually, the bare body mortise 31 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com