Two-dimensional display device

A flat display and display area technology, applied in static indicators, nonlinear optics, optics, etc., can solve the problems of increasing mass production costs and increasing the complexity of process precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the structure, characteristics and purpose of the present invention, the accompanying drawings and preferred specific embodiments are described in detail as follows:

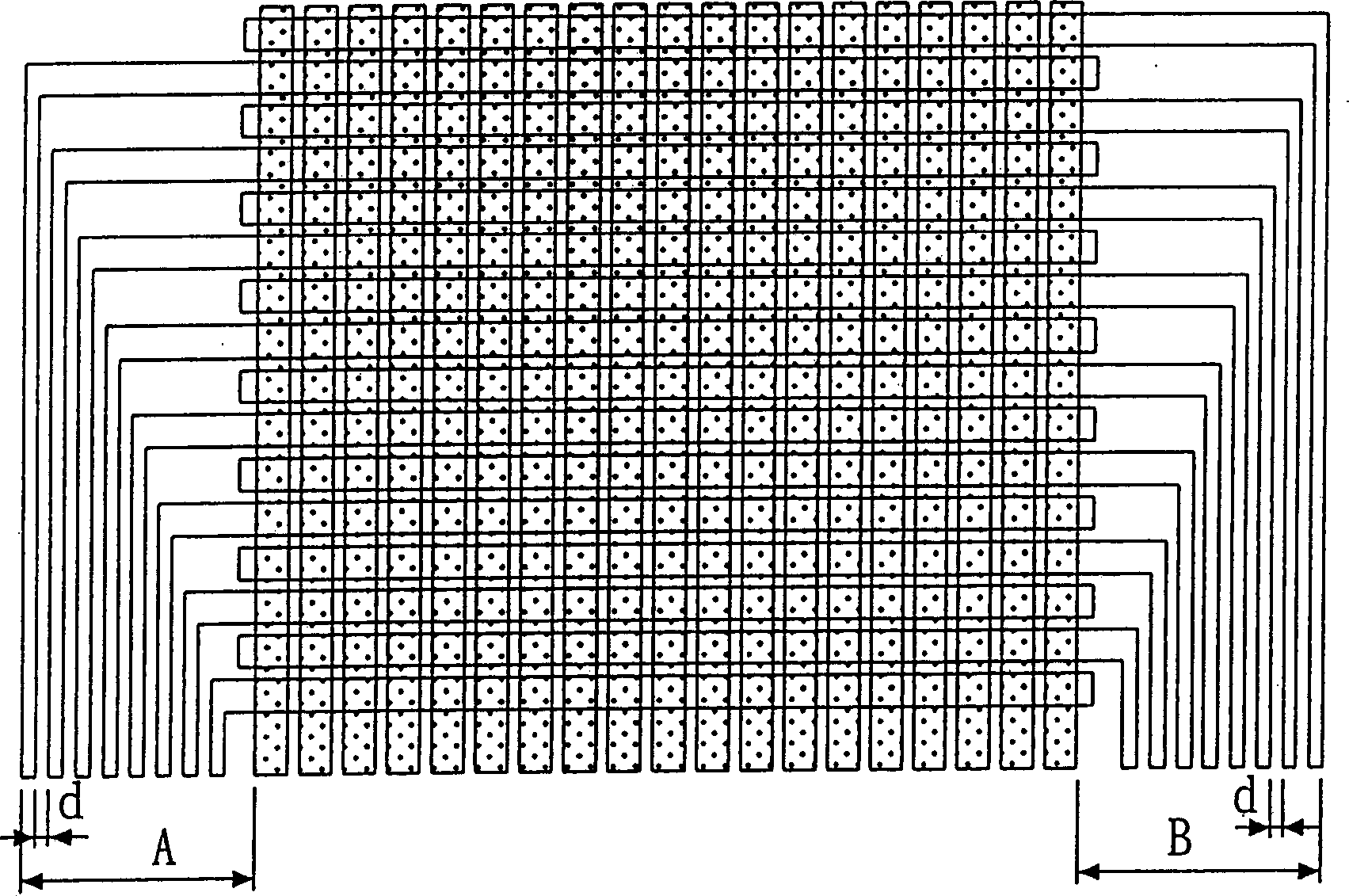

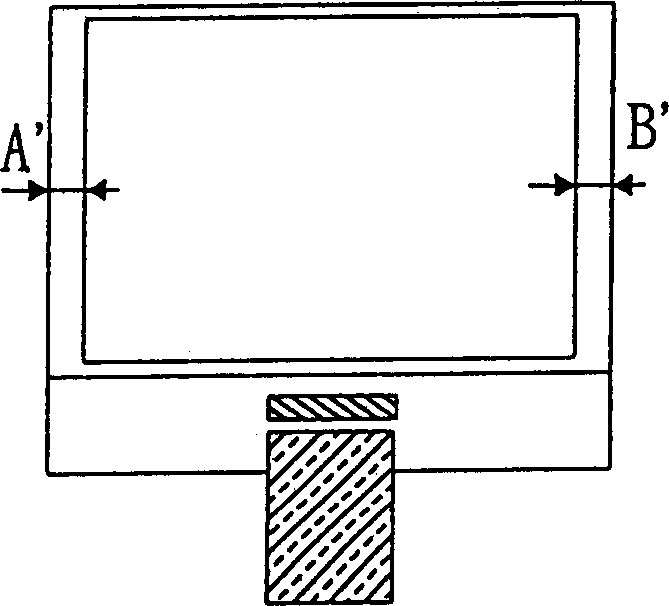

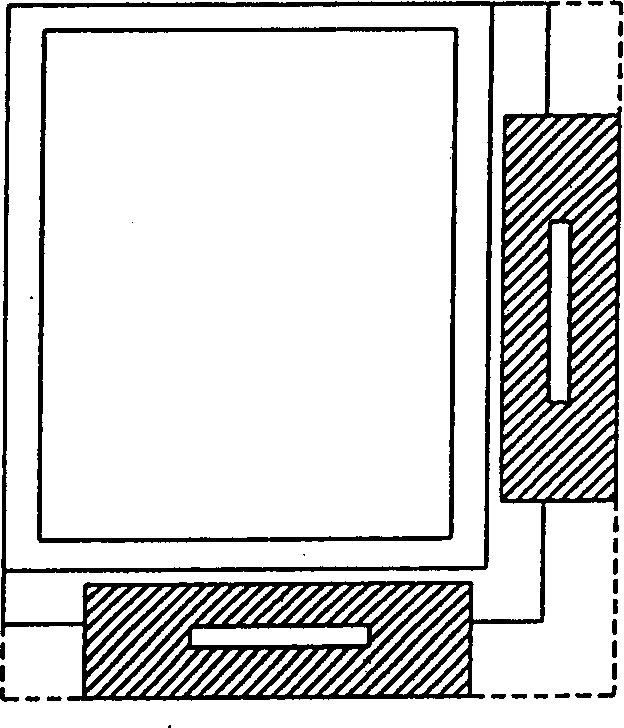

[0031] A preferred embodiment of the present invention, please refer to Figure 4 The three-dimensional exploded schematic diagram of the two-layer panel wiring shown. The display panel of the present invention is mainly composed of a first substrate 1 , a second substrate 2 , and a sealant 3 .

[0032] The materials of the first substrate 1 and the second substrate 2 of the display panel of the present invention are not limited, and may be any commonly used substrates, preferably a glass substrate. The material of the frame glue 3 can be any commonly used frame glue, preferably a frame glue mixed with a conductive substance. In this example, the conductive substance is made of conductive particles 31 (see Figure 6 ).

[0033] The first substrate 1 is the lower substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com