Rotating mechanism of close compressor

A technology of a closed compressor and a rotating mechanism, which is applied in the field of compressors and can solve problems such as the inability of the crankshaft 5 to rotate, and achieve the effects of smooth rotation, reduced friction, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

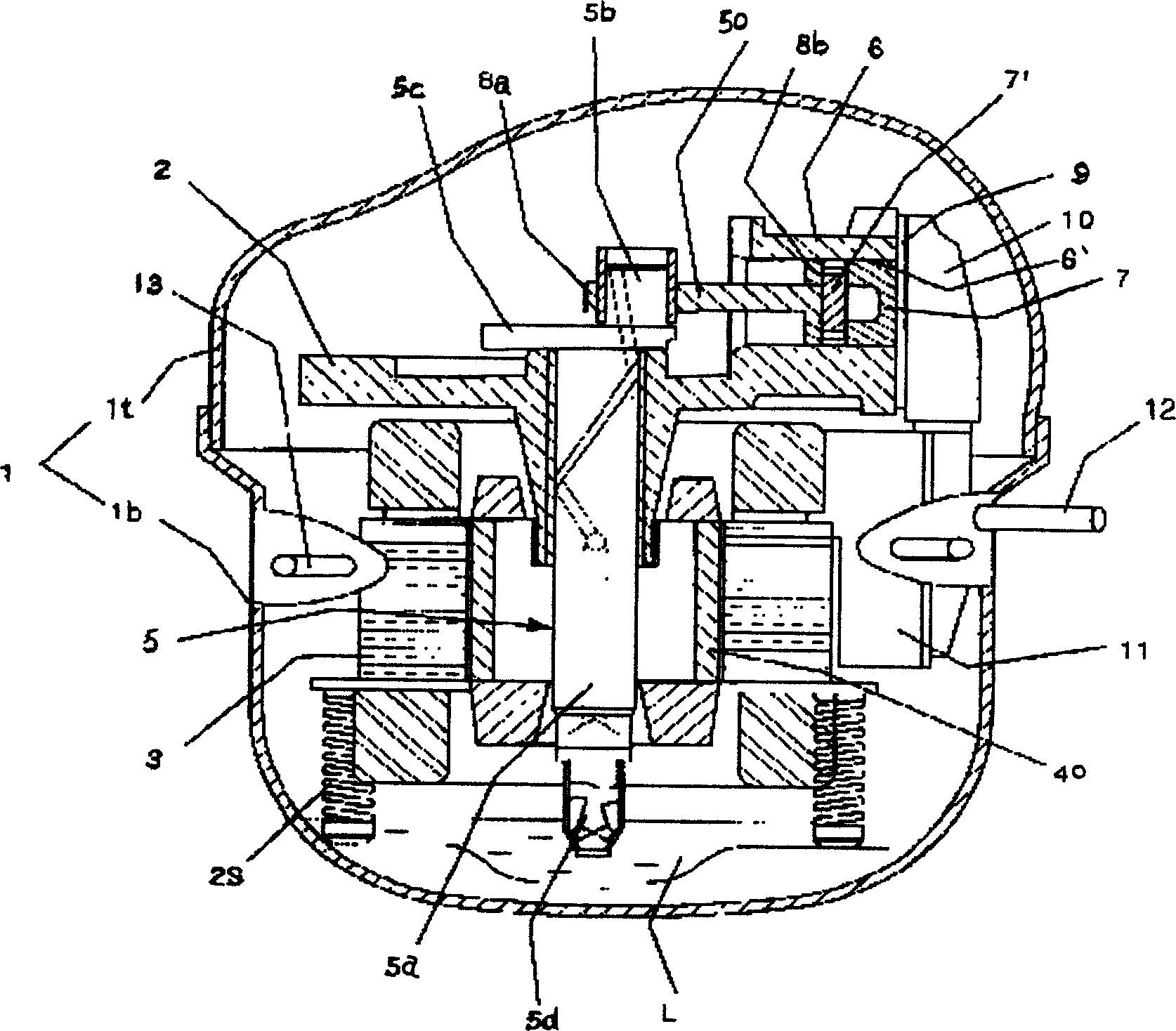

[0016] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

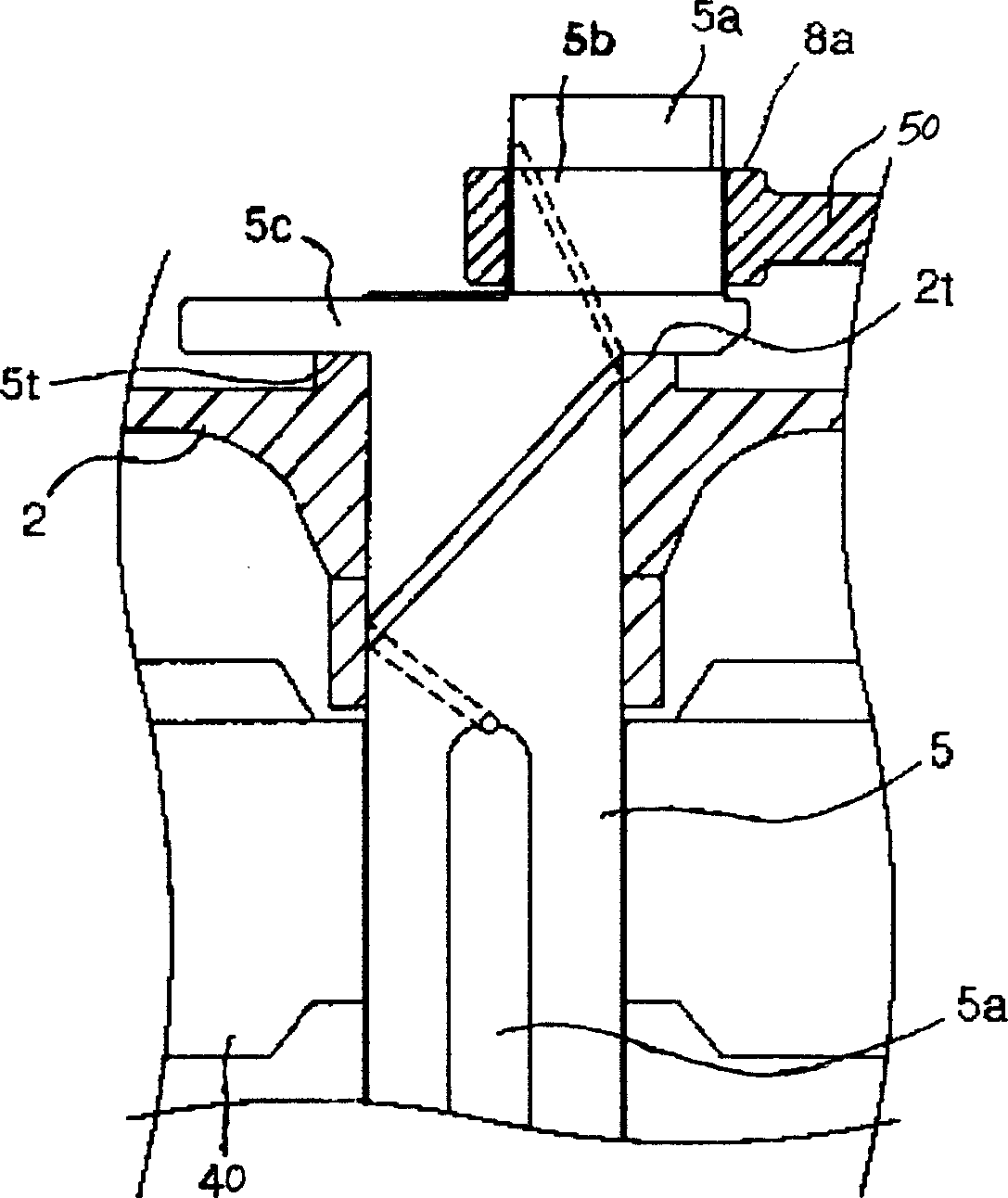

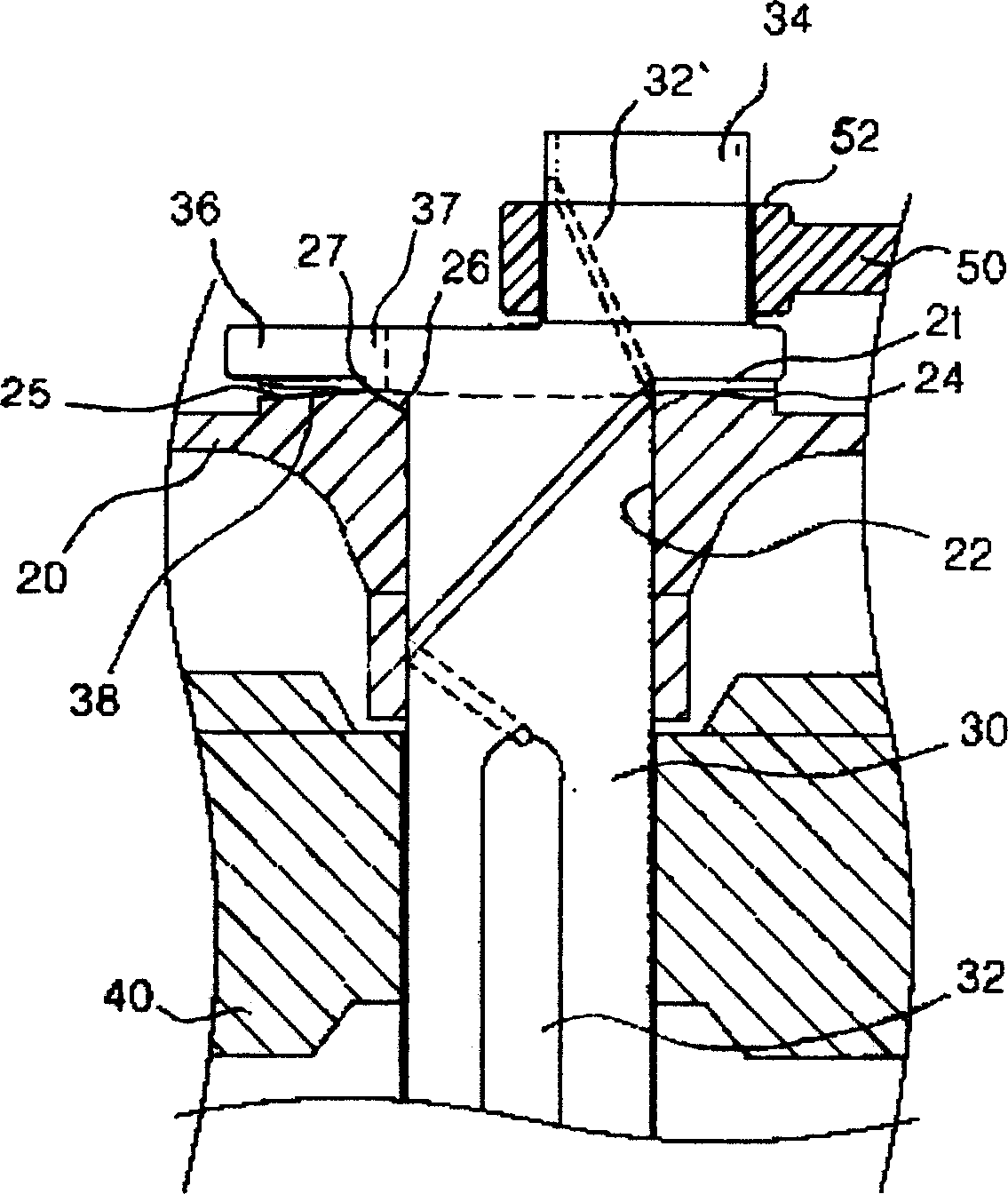

[0017] The present invention is a rotary mechanism of a hermetic compressor. Its structure includes a crankshaft 30 connected to the motor rotor and installed in the central through hole 22 of the frame 20. There is a through oil channel in the crankshaft 30 from the lower end to the upper end of the eccentric shaft 34. The contact between the truss surface 24 above the frame 20 and the balance weight 36 of the crankshaft 30 and the support surface 38 below the eccentric shaft 34 is a line contact.

[0018] The above-mentioned line contact is the contact line 27 formed by the intersection of the inverted conical surface 26 centered on the center line of the central through hole 22 of the frame 20 and the right conical surface 25 centered on the center line of the central through hole 22 of the frame 20 on the truss surface 24 .

[0019] The contact line 27 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com