Making method for label with anti-fogery seal

A production method and technology of anti-counterfeiting labels, which are applied in the printing, sealing, and printing of special varieties of printed matter, can solve the problems of weakened anti-counterfeiting effect of metallized paper, inconspicuous visual effect, poor three-dimensional effect, etc., and achieve remarkable visual effect, Good three-dimensional effect and high embossing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings and embodiments.

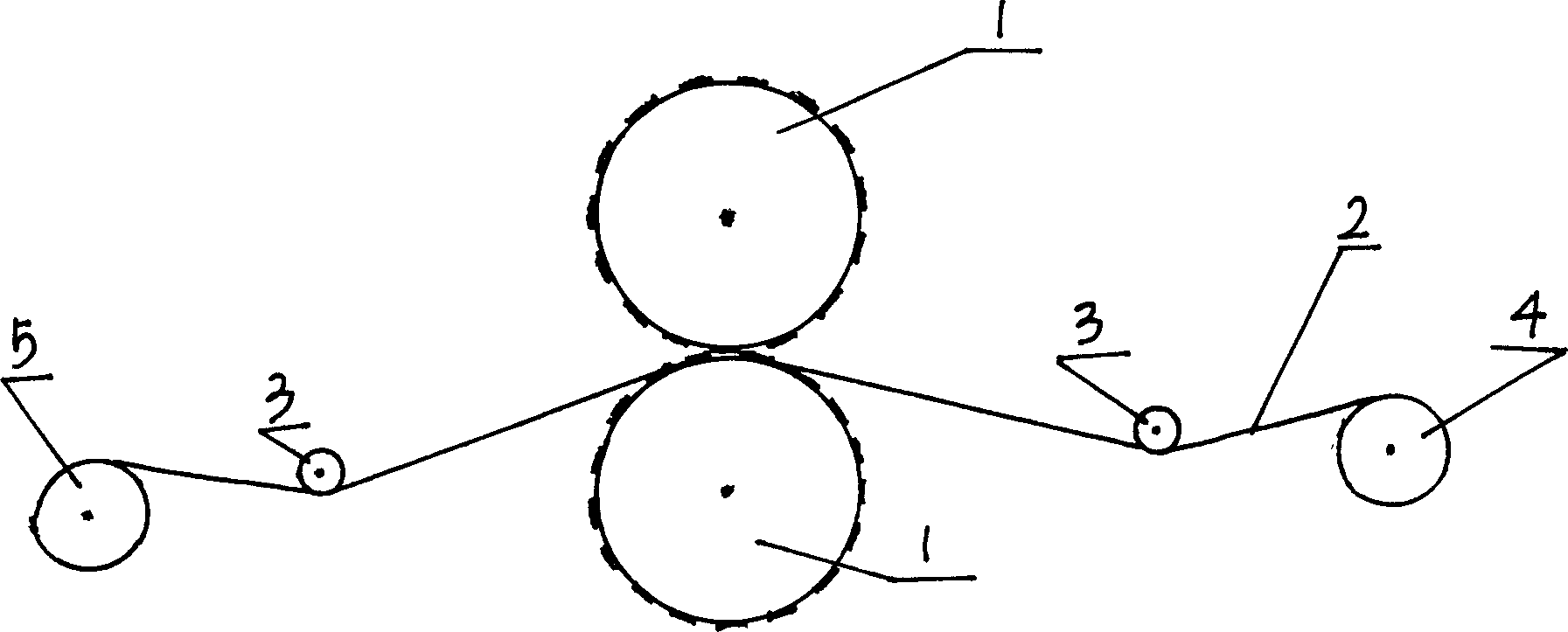

[0017] refer to figure 1 , the metal foil is aluminum foil with a thickness of 0.0115 mm to 0.2000 mm. First, the aluminum foil is color-printed, and then the color-printed aluminum foil is set on the discharge roller, and the color-printed aluminum foil is flattened by the guide roller. Set the color-printed aluminum foil on two bumps Rolling is carried out between steel rolls, and the rolling pressure is controlled between 4 kg / cm2 and 6 kg / cm2. After rolling, the color-printed aluminum foil is recovered by the take-up roller, and finally cut into a seal according to the size of the product. Anti-counterfeiting label.

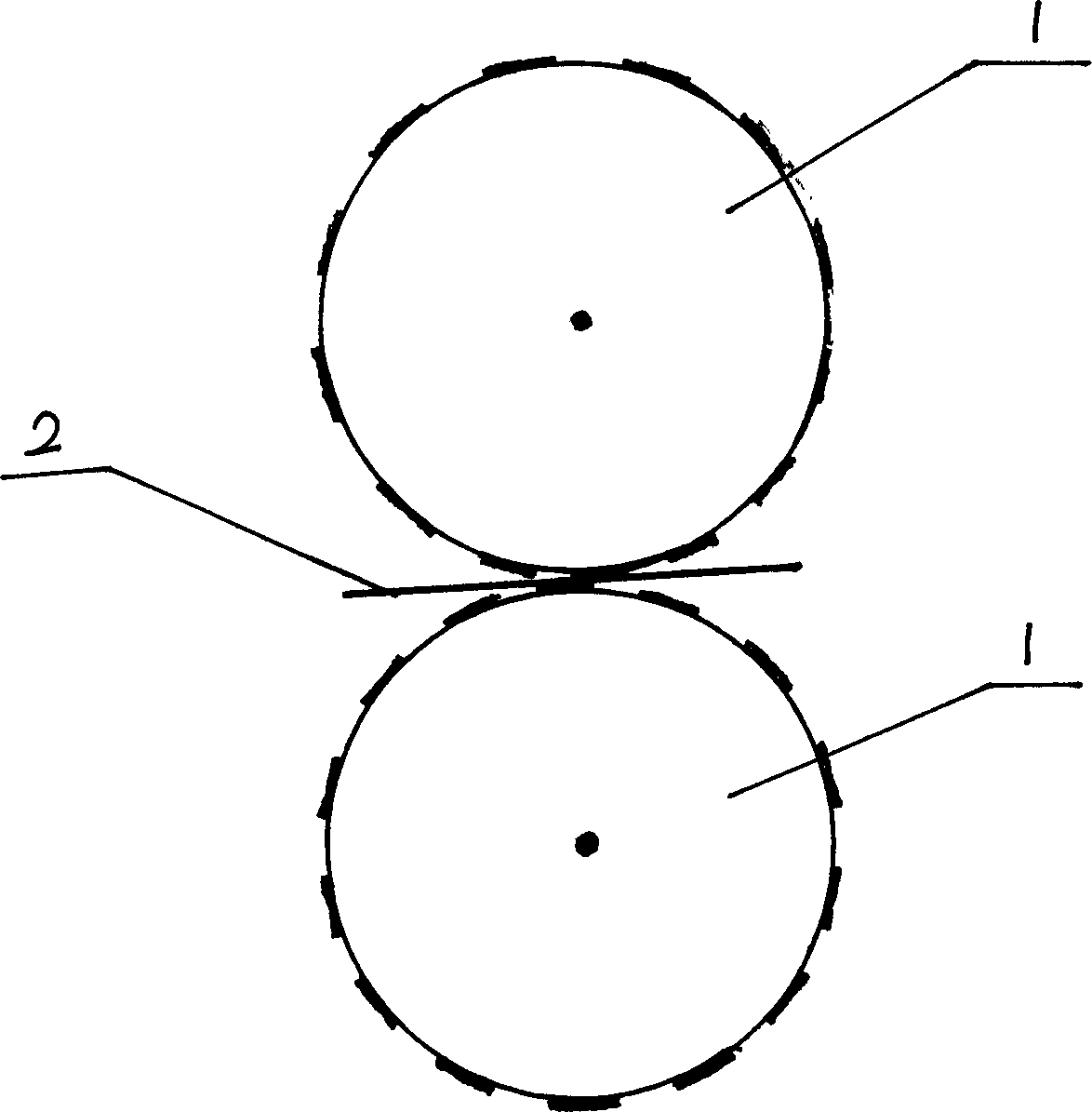

[0018] refer to figure 2 , the two roller molds are concave-convex steel roller molds, and the rolling pressure is controlled between 4 kg / square centimeter and 6 kg / square centimeter. If an aluminum foil with a thickness of 0.0115 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com