Method of using film structure water bag in prepressing soft foundation

A technology of membrane structure and water bag, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems of low shear strength, long time for filling, and damage to the roadbed environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

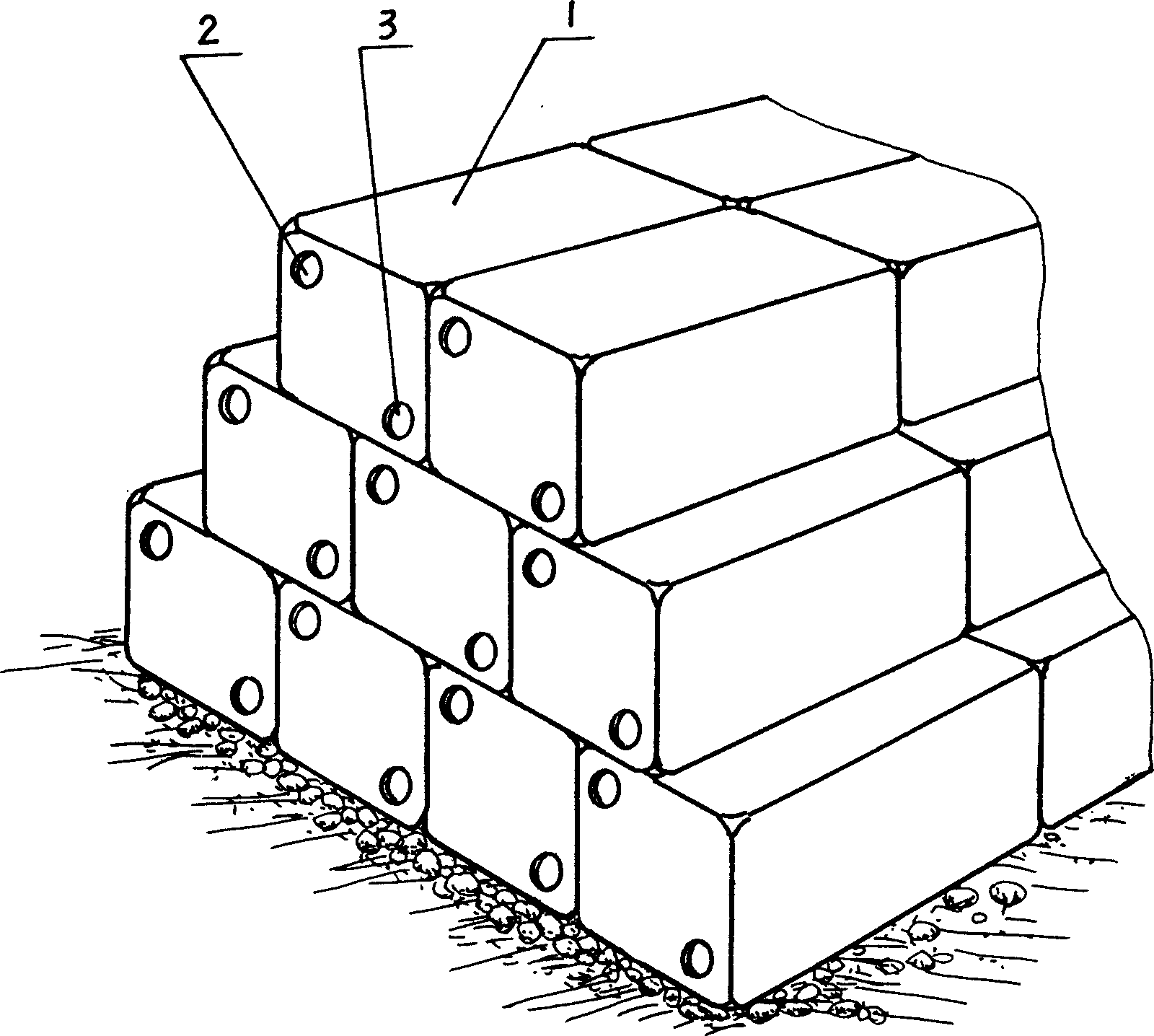

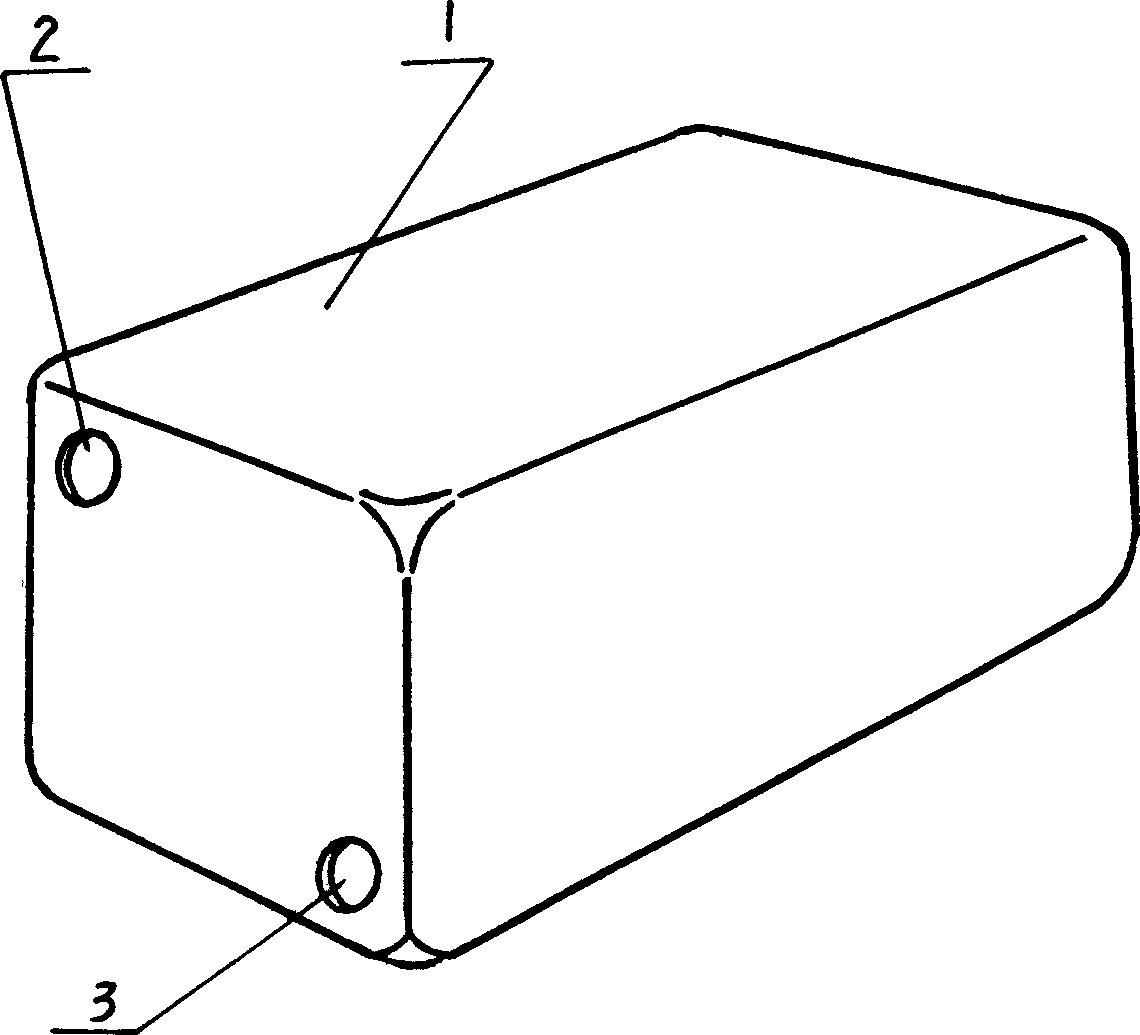

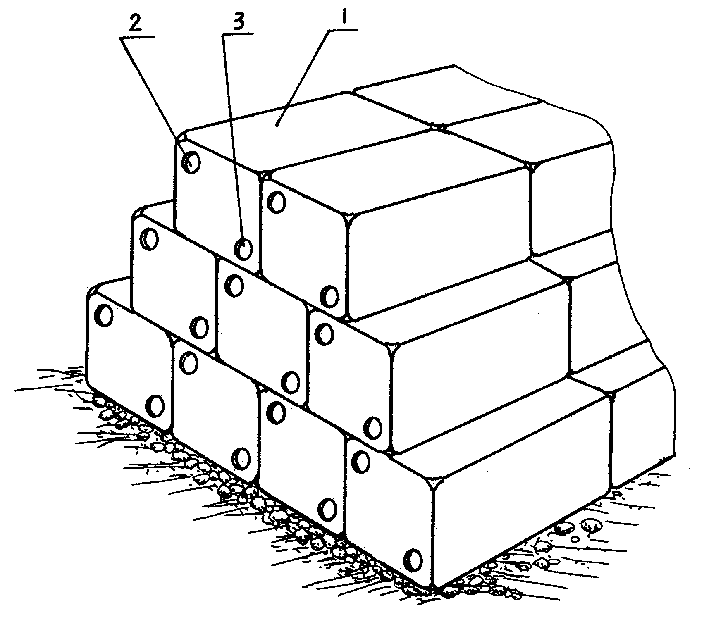

[0009] Such as figure 1 As shown, a method for pre-compressing a soft foundation with a membrane structure water bag, the method is to stack a plurality of membrane structure water bags 1 filled with water on the soft foundation for pre-loading, and the pre-loading pre-loading for a period of time reaches the soft foundation After the reinforcement is required, the water in the membrane structure water bag 1 is drained and the membrane structure water bag 1 is taken away. The number of layers of the membrane structure water bag can be determined according to the needs. The more layers, the greater the preload on the soft foundation, which can shorten the time required for preloading and shorten the construction period.

[0010] Such as figure 1 , 2 As shown, the water bags used for preloading and preloading are modular, and can be made int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com