Impeller installing structrue of turbocompressor

A technology for a turbo compressor and an installation structure, applied in the field of turbo compressors, can solve problems such as falling off and nut detachment, and achieve the effects of improving assembly efficiency, solid installation structure, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

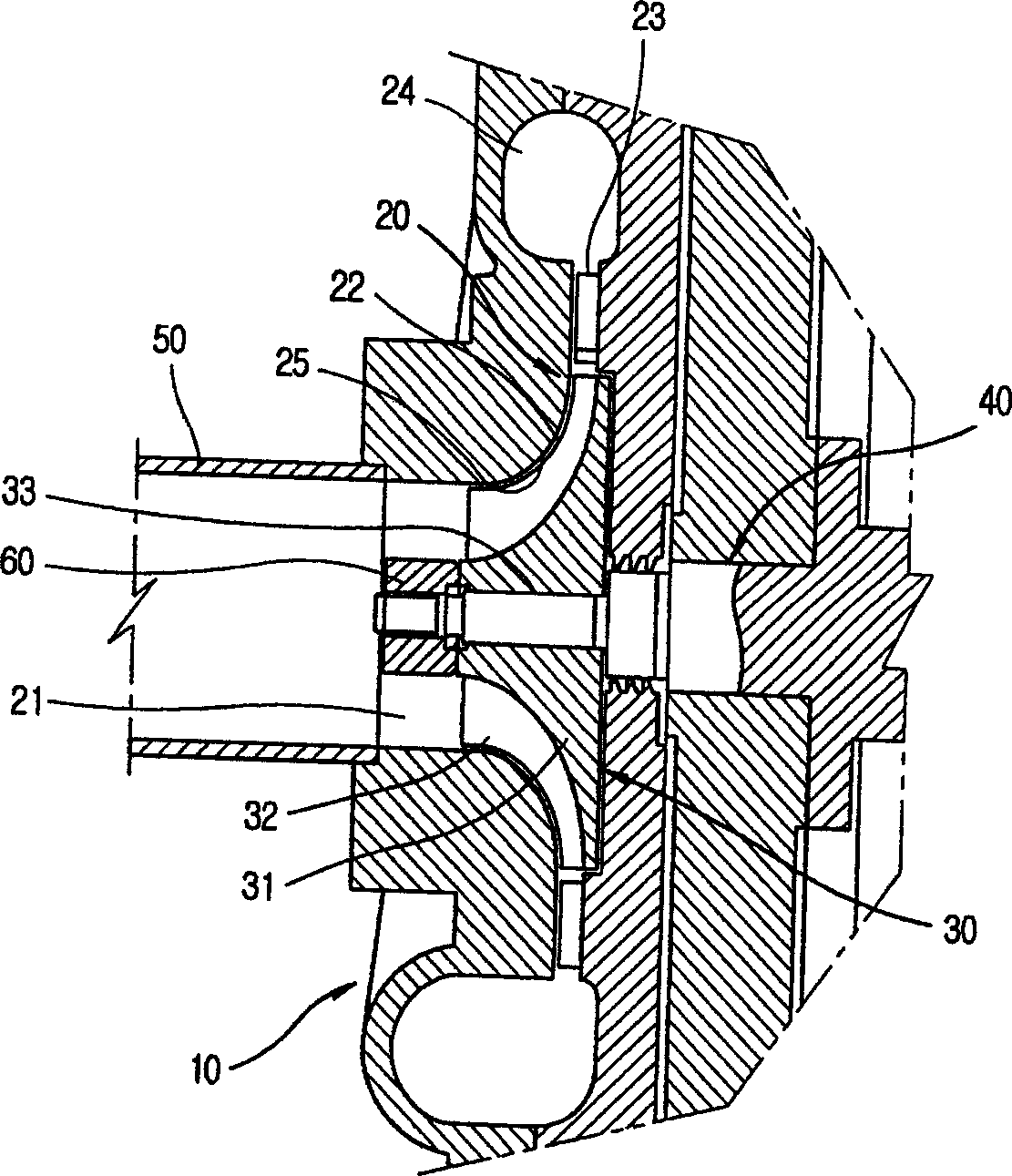

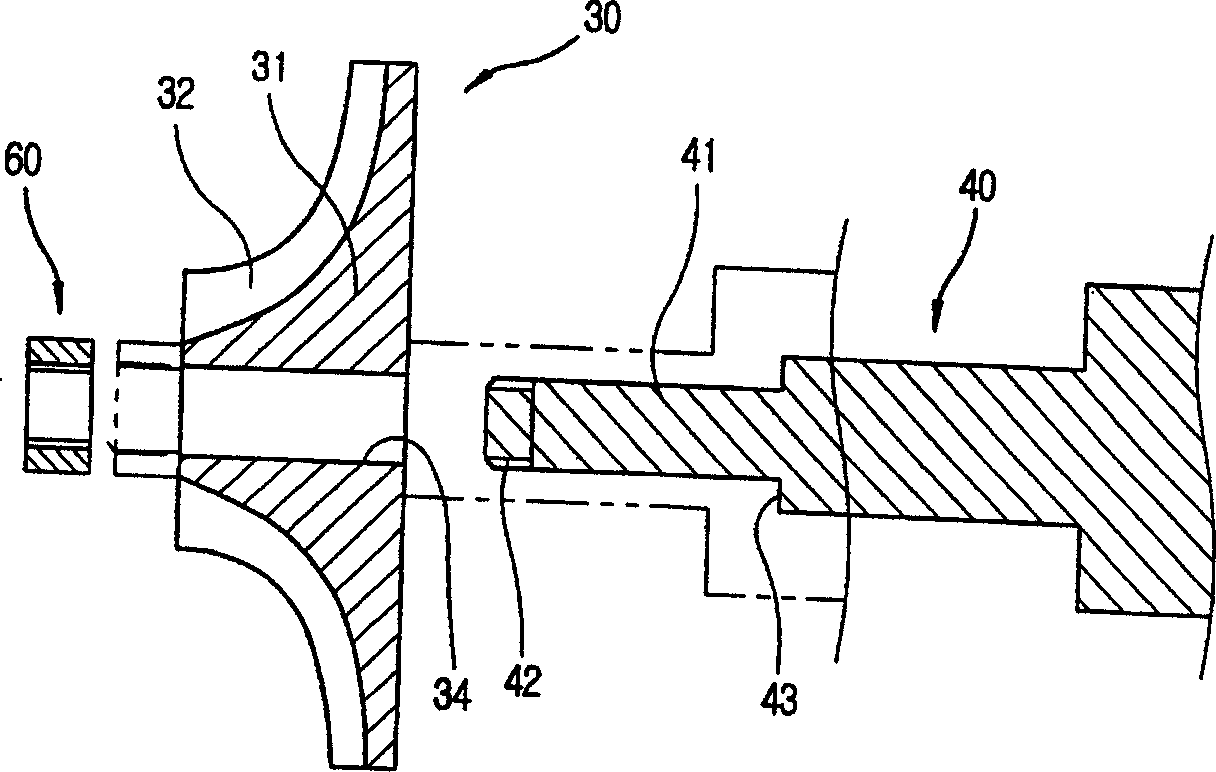

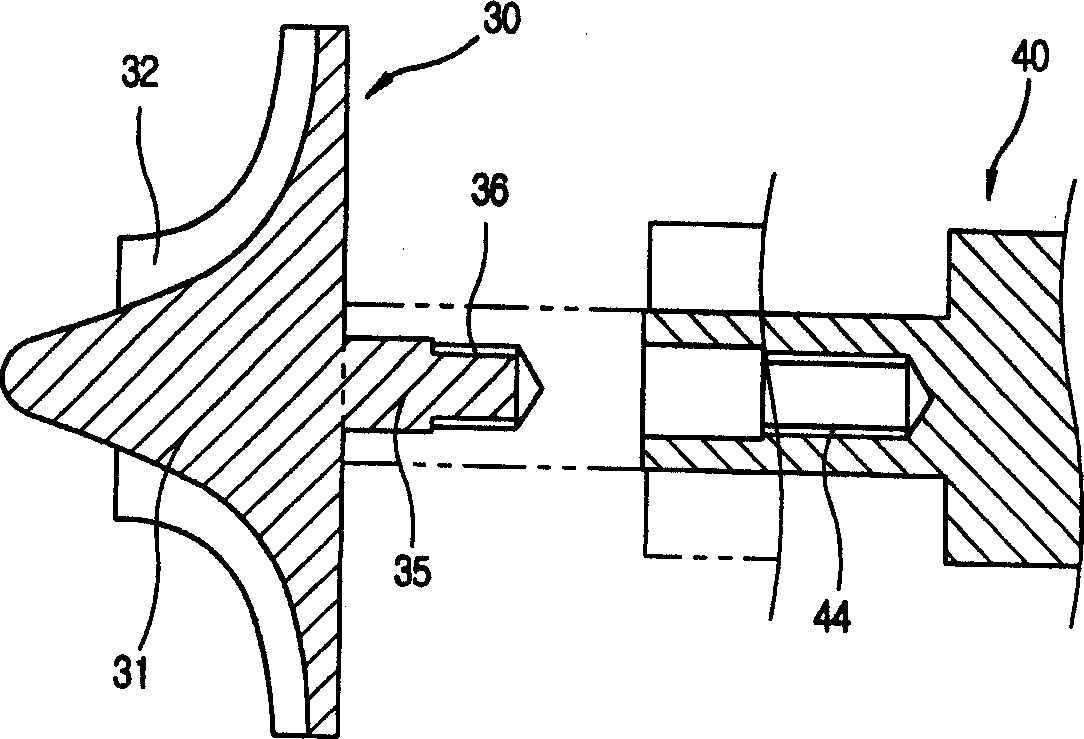

[0026] The impeller installation structure of the turbocompressor of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments: Figure 4 A cross-sectional view showing a compression part of a turbo compressor provided with the turbo compressor impeller mounting structure proposed in the present invention. The description is as follows: First, the compression part of the turbo compressor is provided with a compression chamber 20 connected with the suction passage inside the shell 10 , and a rotatable impeller 70 is inserted into the compression chamber 20 . The impeller 70 is combined with a motor provided inside the casing 10 through a rotating shaft 80 .

[0027] The compression chamber 20 is composed of an induction impeller 21 for introducing gas, an impeller insertion space 22 into which a rotating impeller 70 can be inserted, a diffuser 23 for converting gas kinetic energy into a positive pressure 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com