Process for selectively separating IgY antibody from anseriforme birds eggs and IgY antibody produced therefrom

An avian egg, selective technology, applied in the direction of antibodies, egg-derived immunoglobulins, analytical materials, etc., can solve the problem of successful purification that does not provide any hint, complex and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Immunization program for stimulating specific antibody production

[0056] Twelve artificially bred ducks (Anasplatyrhynchos var. domestica) aged 16 weeks for antibody and egg production were housed separately. The ducks received an initial subcutaneous injection of 1-5 mg / ml of C-reactive protein (CRP; purified from human ascites), formulated in phosphate buffer at pH 7.5 with The volume is completely emulsified in Freund's adjuvant. The concentration of antigen used is generally in the range of 1 to 5 mg / ml. Following this initial injection, young hens received three additional injections of 1-5 mg antigen every two weeks. One week later, eggs were collected, labeled and stored at 4°C until antibody extraction and purification. During the experiment, the booster procedure was repeated every four weeks. Blood sampling was performed on day 7 after each booster injection. Each blood sample was centrifuged and the resulting serum collected.

Embodiment 2

[0057] Example 2: Antibody Extraction by Duck Egg Yolk

[0058] The egg yolk collected from the eggs laid by the highly immune ducks in Example 1 was washed thoroughly with a weak column of distilled water to thereby remove the egg white. Measure the volume of egg yolk, and then fully mix it with distilled water in an amount 10 times the measured volume of egg yolk. Subsequently, the mixture was kept at 4°C for at least two hours, and then centrifuged for one hour at 10,000 rpm in a Hitachi CR22F centrifuge. A light supernatant layer and a semi-solid easily disturbed layer form in the centrifuge tube.

Embodiment 3

[0059] Embodiment 3: Treat with adsorbent

[0060]In the crude extract prepared in Example 2, one of the following adsorbents was added: 2% (w / v) fumed silica (purchased from Sigma), 3% (w / v) di Silica (Sigma), 3% (w / v) Celite diatomaceous earth (available from Celite Corporation) and 3% or 5% (w / v) Celite diatomaceous earth hyflo-Cel (Celite Corporation). The resulting suspension was incubated at 4°C for 60 minutes with gentle agitation. After the incubation was completed, the adsorbent was precipitated with a Hitachi CR-22F centrifuge at 20,000 rpm at 4°C, and the supernatant and precipitate were collected respectively. A 10 μl sample was taken from each supernatant for non-reducing SDS-polyacrylamide gel electrophoresis analysis (SDS-PAGE).

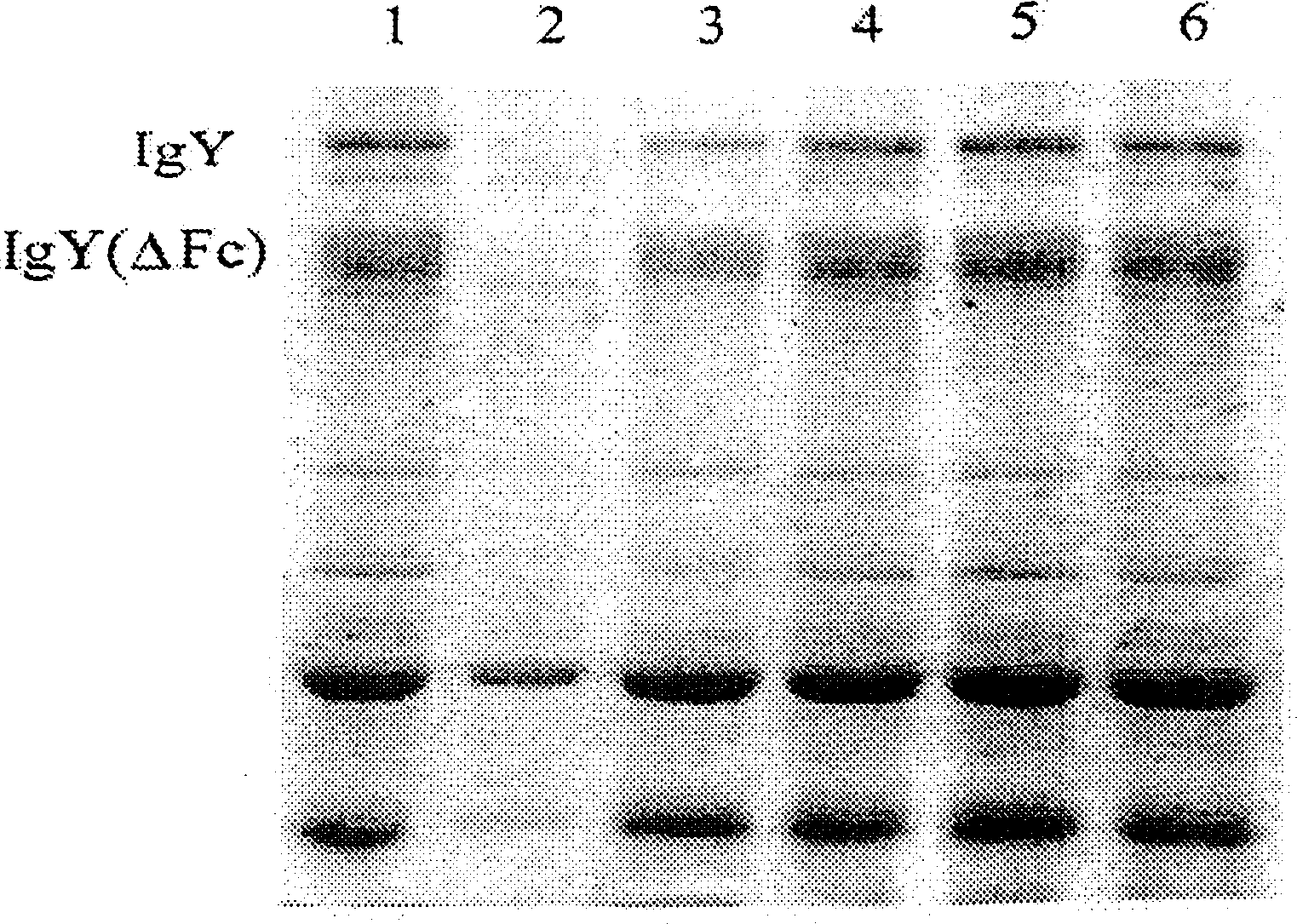

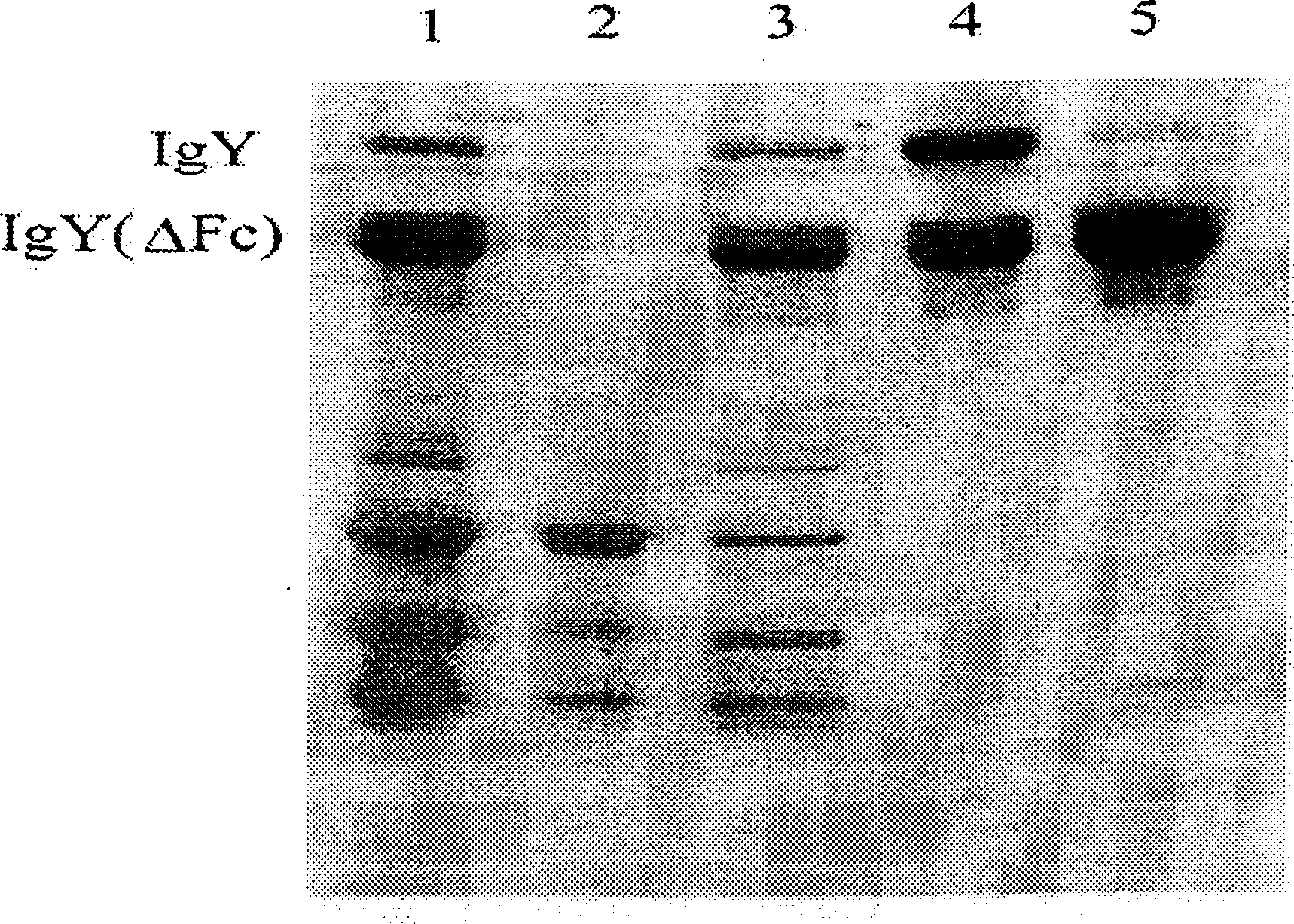

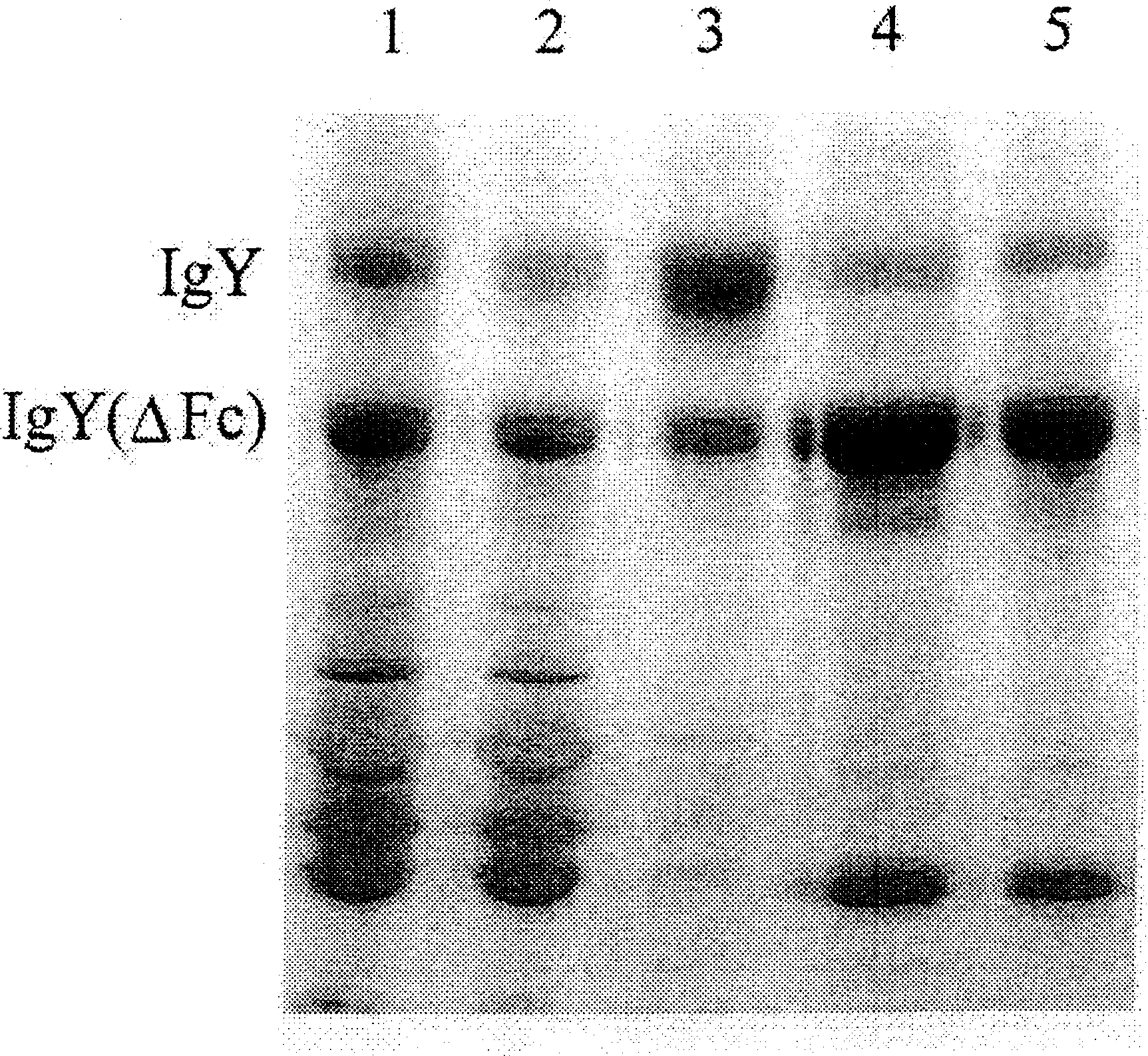

[0061] like figure 1 As shown, fumed silica had the best adsorption activity in terms of the amount of antibody adsorbed by the adsorbent, and almost no antibody was left in the flow-through solution. Silica exhibits a somewhat wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com