Venting apparatus for a tire vulcanizing mold

A technology of tire vulcanization molds and exhaust devices, which is applied to tires, household appliances, and other household appliances, and can solve problems such as loss of elasticity, failure of exhaust devices to work, and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation

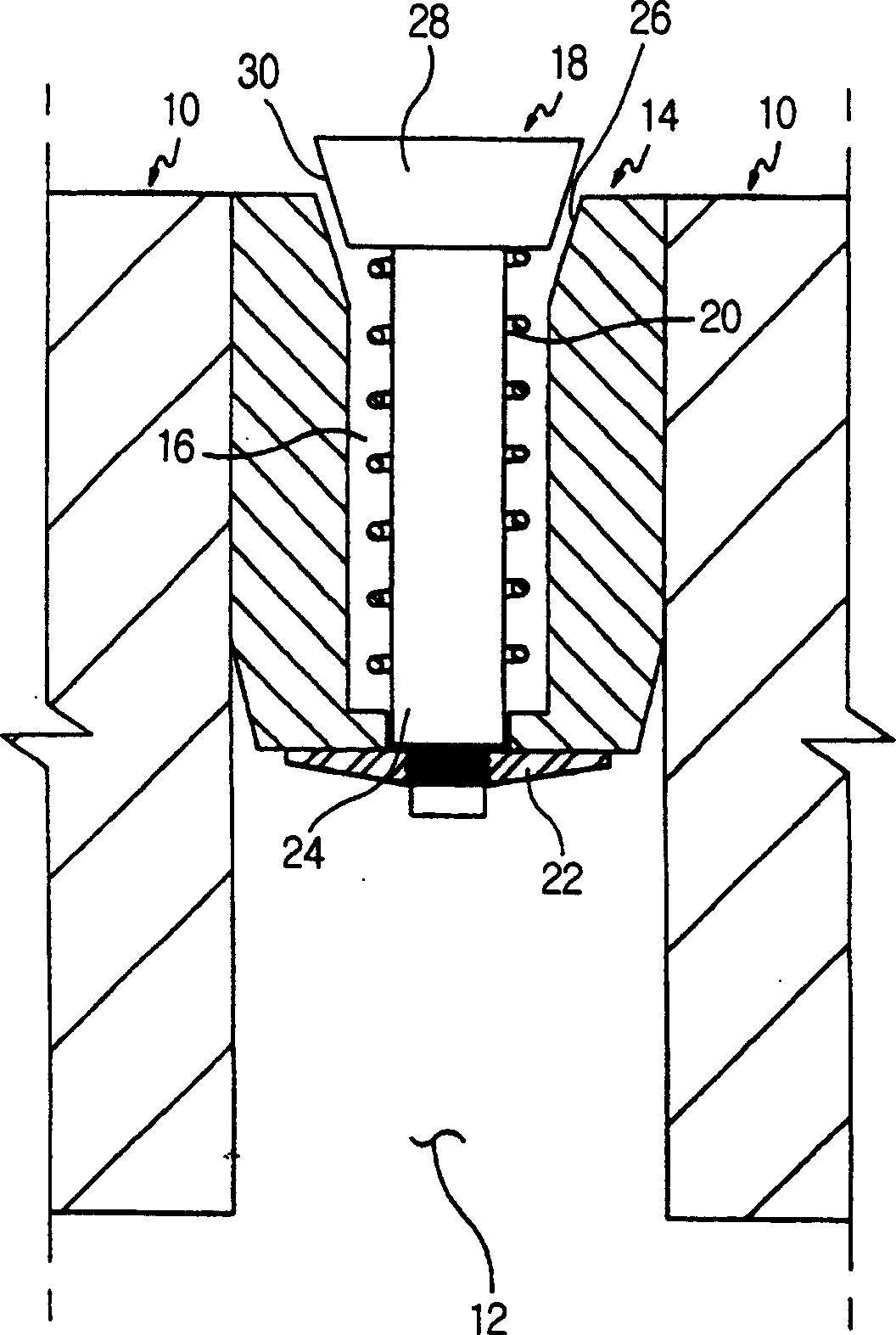

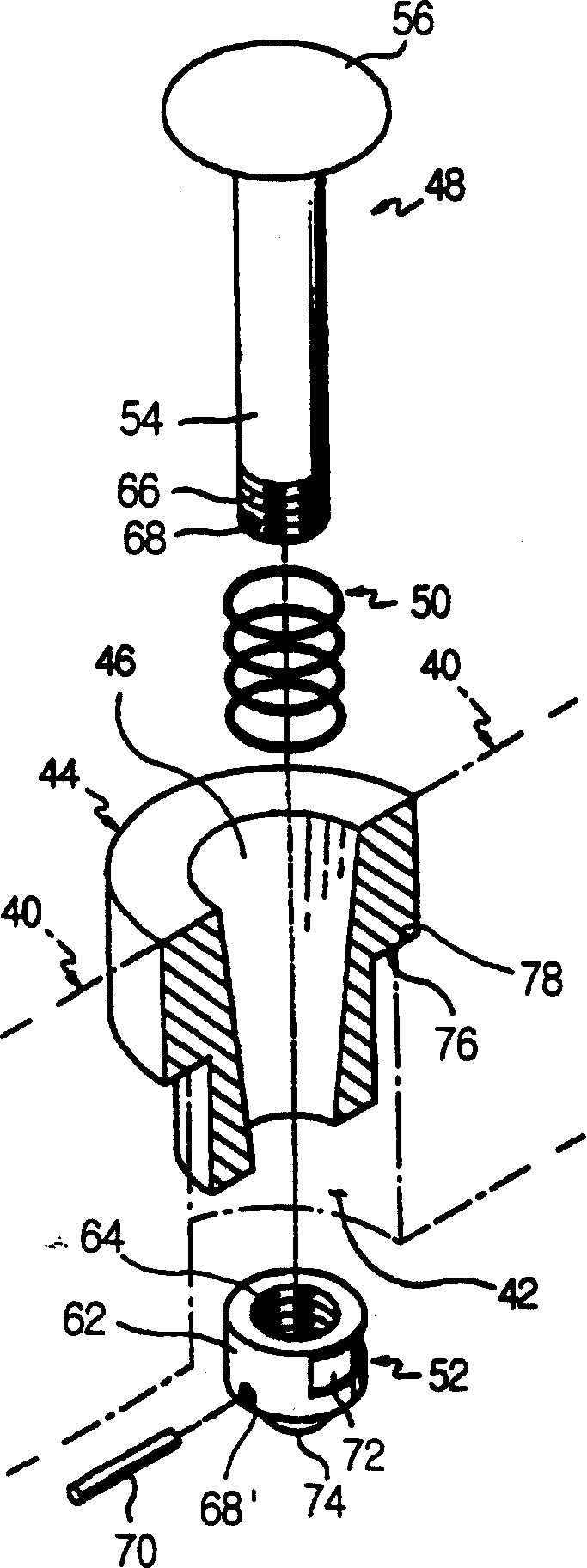

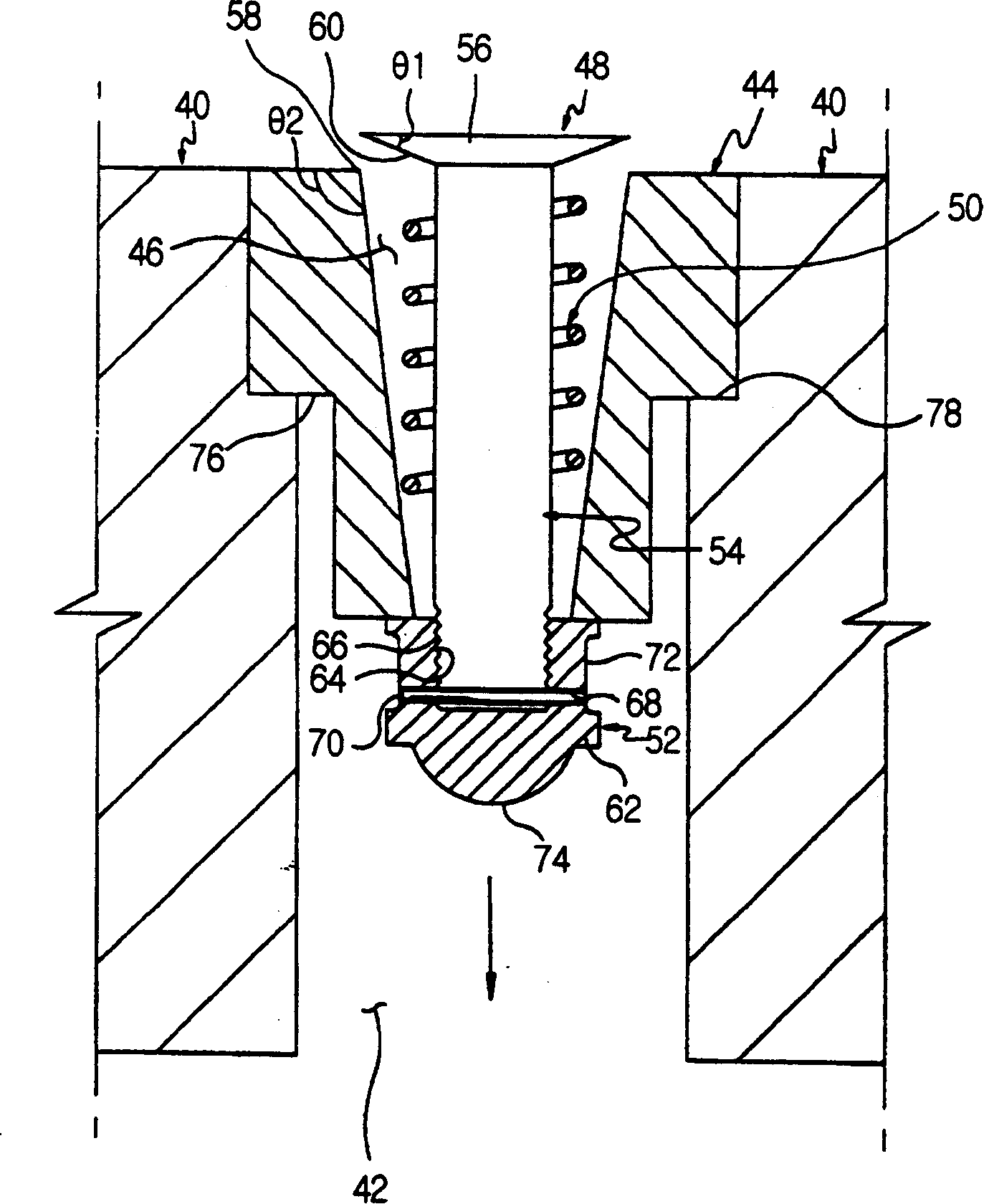

[0022] figure 2 It is an exploded perspective view of the exhaust device according to the first embodiment of the present invention. image 3 is in figure 2 A cross-sectional view of the entire body cut in the longitudinal direction in the state where the exhaust unit is combined with the mold.

[0023] Such as figure 2 and image 3 As shown, the exhaust device of the first embodiment of the present invention is roughly divided into: a housing 44 inserted into the exhaust hole 42 of the mold 40, a valve body 48 inserted into the central through hole 46 of the housing 44, and a valve body 48 inserted into the valve body. 48 applies elastic force to surround the lower part of the spring 50, and the stopper 52 is connected to the lower front section of the valve body 48 and substantially controls the moving distance of the valve body 48 in the vertical direction.

[0024] Here, the central through hole 46 formed in the above-mentioned hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com