Feed and fuel crop stalk forming production complete set apparatus

A complete set of equipment and feed technology, applied in feed, food science, presses, etc., can solve problems such as traffic jams, unsuitable equipment, and air pollution, and achieve the effects of easy storage, high production efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

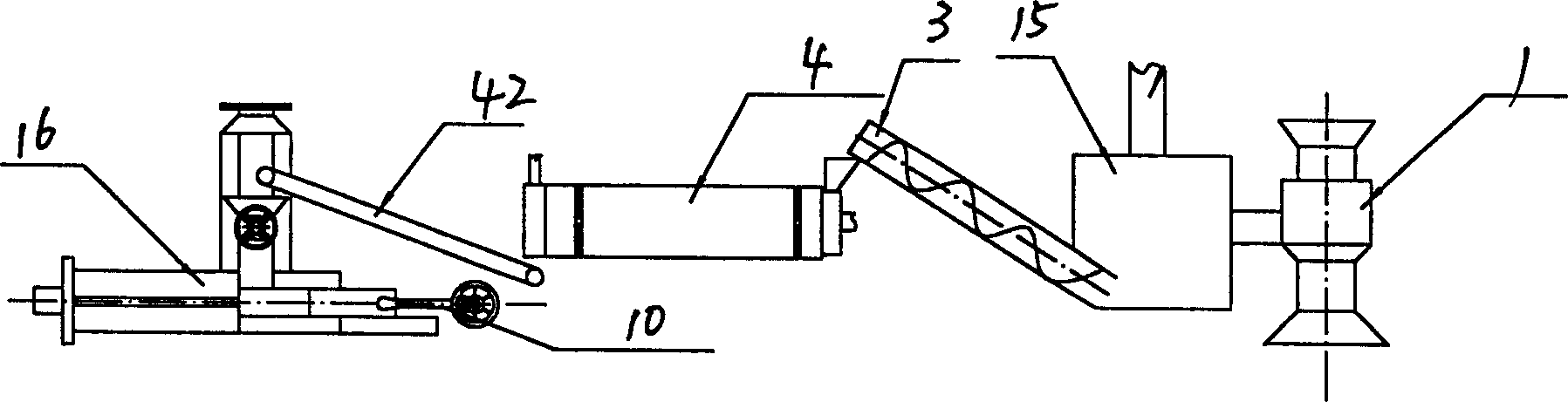

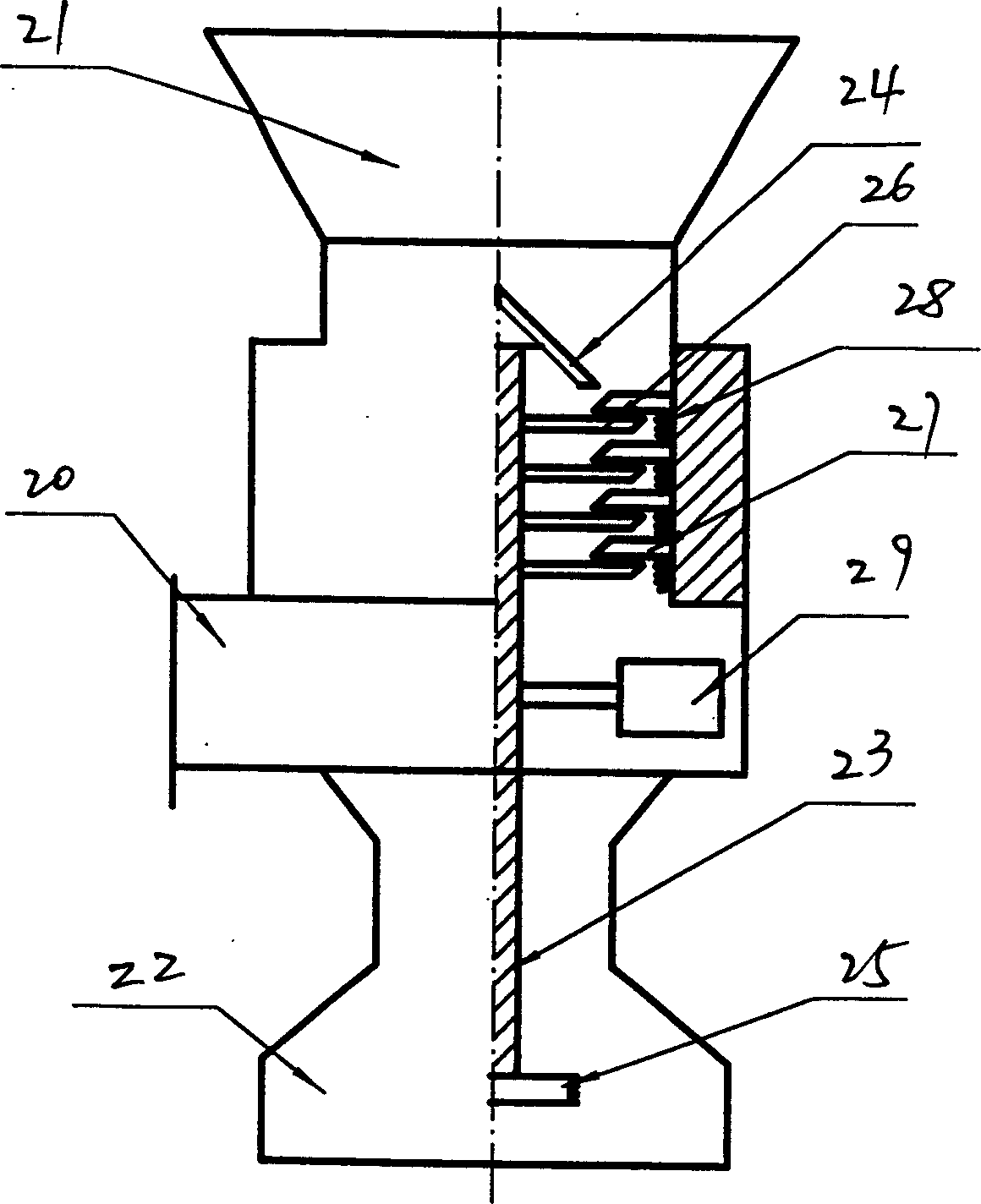

[0020] The structure of the present invention is as figure 1 Shown: it is made up of straw vertical kneading machine 1, material storage bin 15, drum dryer 4 and straw forming machine 16, the discharge port 20 of straw vertical kneading machine 1 and the feed of material storage bin 15 The outlet of the material storage bin is transported to the drum dryer 4 through the auger 3, and the dried material is sent to the feed inlet 30 of the straw molding machine 16 by the conveyor belt 42. The molded feed that is extruded into a certain density after the stalk molding machine 16 is extruded by the discharge port 31.

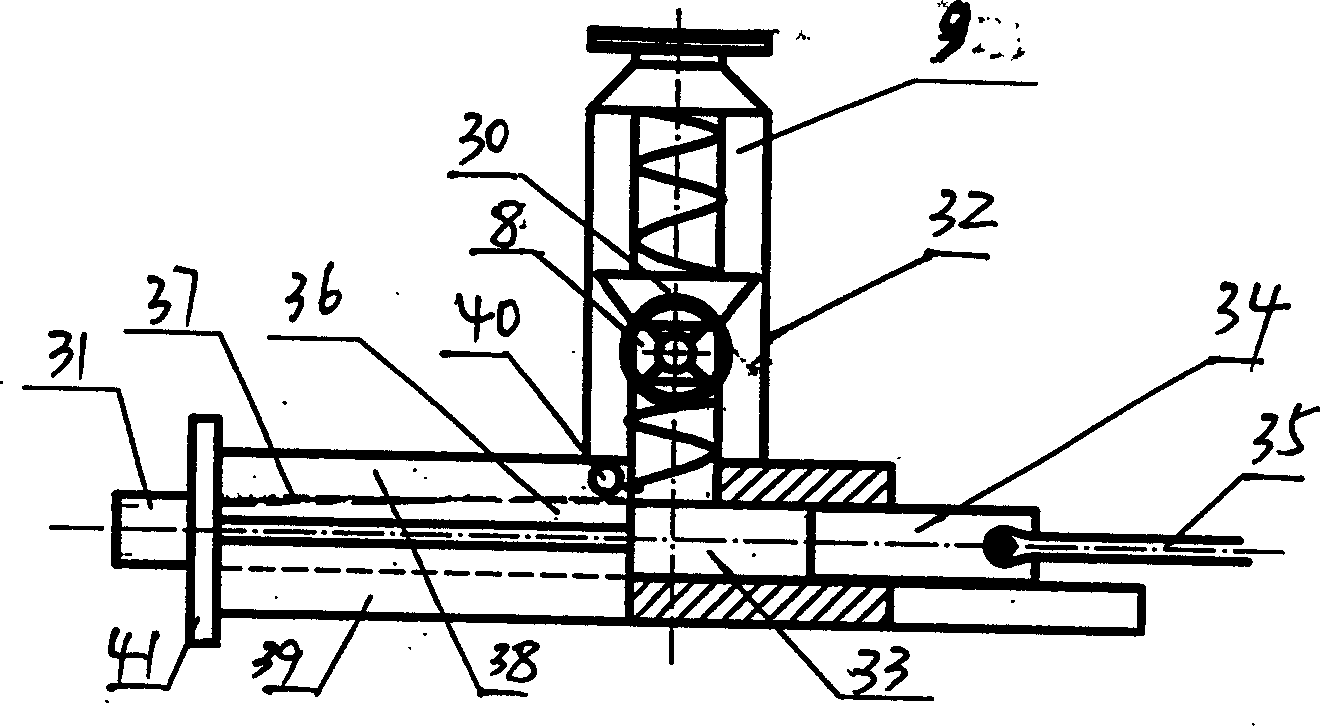

[0021] Crop straw forming machine 16 such as image 3 As shown: including body 32, feeding mechanism, discharge port 31 and forming mechanism, forming mechanism is composed of pre-compression chamber 33, punch 34 and crank connecting rod 35, pre-compression chamber 33 is connected with feeding mechanism, punch 34 It can move in the pre-compression cavity 33 and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com