Phase-transition-liquid bathing heat exchanger

A technology for heat exchangers and heat exchanger tubes, applied in the field of phase change-liquid bath heat exchangers, achieving the effects of high safety, superior regulation performance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

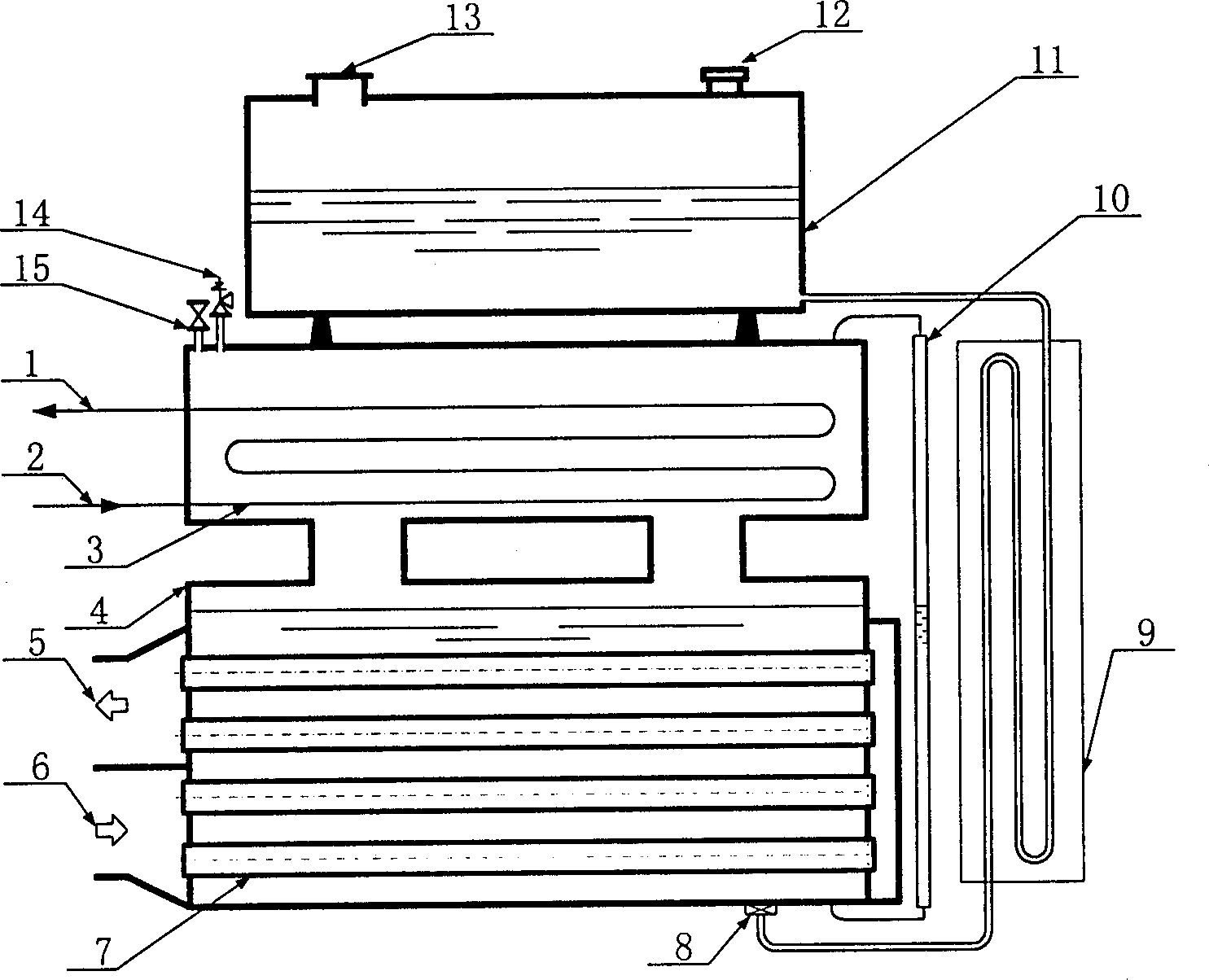

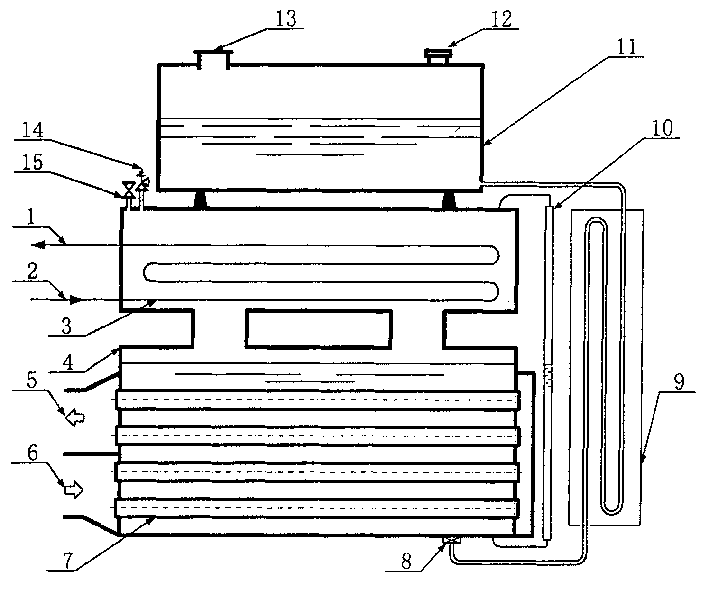

[0024] Depend on figure 1As shown, in the pipeline of the heat exchanger, a heat exchange chamber 4, a gas trap 8, a U-shaped pipe 9, a liquid storage tank 11, and a floating cover 13 are sequentially connected in series, and the top of the heat exchange chamber 4 is equipped with an air release valve 15 And a safety valve 14, a liquid level gauge 10 is installed on the side, a heated fluid heat exchange surface 3 is arranged on the upper part of the heat exchange chamber 4, and a preheated fluid heat exchange surface 7 is arranged on the lower part, the liquid storage tank 11 is located above the top of the heat exchange chamber 4, and its The volume is greater than the sum of the remaining volume of the heat exchange chamber after deducting the space occupied by the heat exchange surface and the volume of the U-shaped tube 9, the floating cover 13 is located on the top of the liquid storage tank 11, and there is a certain gap between the floating cover 13 and the top of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com