Strip steel pickling complete equipment

A complete set of equipment, the technology of steel acid, applied in the field of strip steel pickling complete sets of equipment, can solve the problems of difficult maintenance, environmental pollution and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

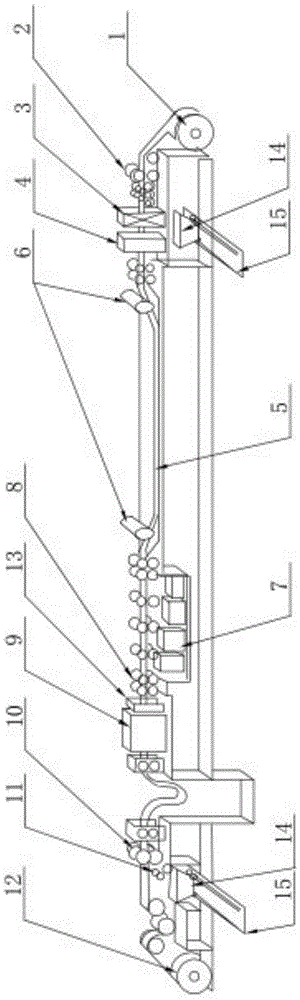

[0019] Below in conjunction with accompanying drawing, the present invention will be further described.

[0020] see as figure 1 As shown, this specific embodiment adopts the following technical scheme: it includes uncoiler 1, pinch straightening machine 2, head cutting hydraulic shear 3, angle cutting shear 4, pickling tank 5, stone roll 6, rinsing tank 7, extrusion Dry roll 8, hot air dryer 9, disc shears 10, scrapping shears 11, coiler 12; Head hydraulic shear 3, one side of cutting head hydraulic shear 3 is provided with angle cutting shear 4, one side of angle cutting shear 4 is provided with pickling tank 5, and the two ends of pickling tank 5 are provided with stone roll 6; One side of the groove 5 is provided with a rinse tank 7, one side of the rinse tank 7 is provided with a squeeze roller 8, one side of the squeeze roller 8 is provided with a hot air dryer 9, and one side of the hot air dryer 9 is provided with a disc shear 10, and One side of the disc shears 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com