Multiple-section synthesizing three-dimensional profile measuring method

A three-dimensional measurement, multi-section technology, applied in the direction of measuring devices, image data processing, image data processing, etc., can solve the problems of difficult measurement needs and high cost, and achieve the effect of improving the measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Describe method and device of the present invention in detail below in conjunction with accompanying drawing:

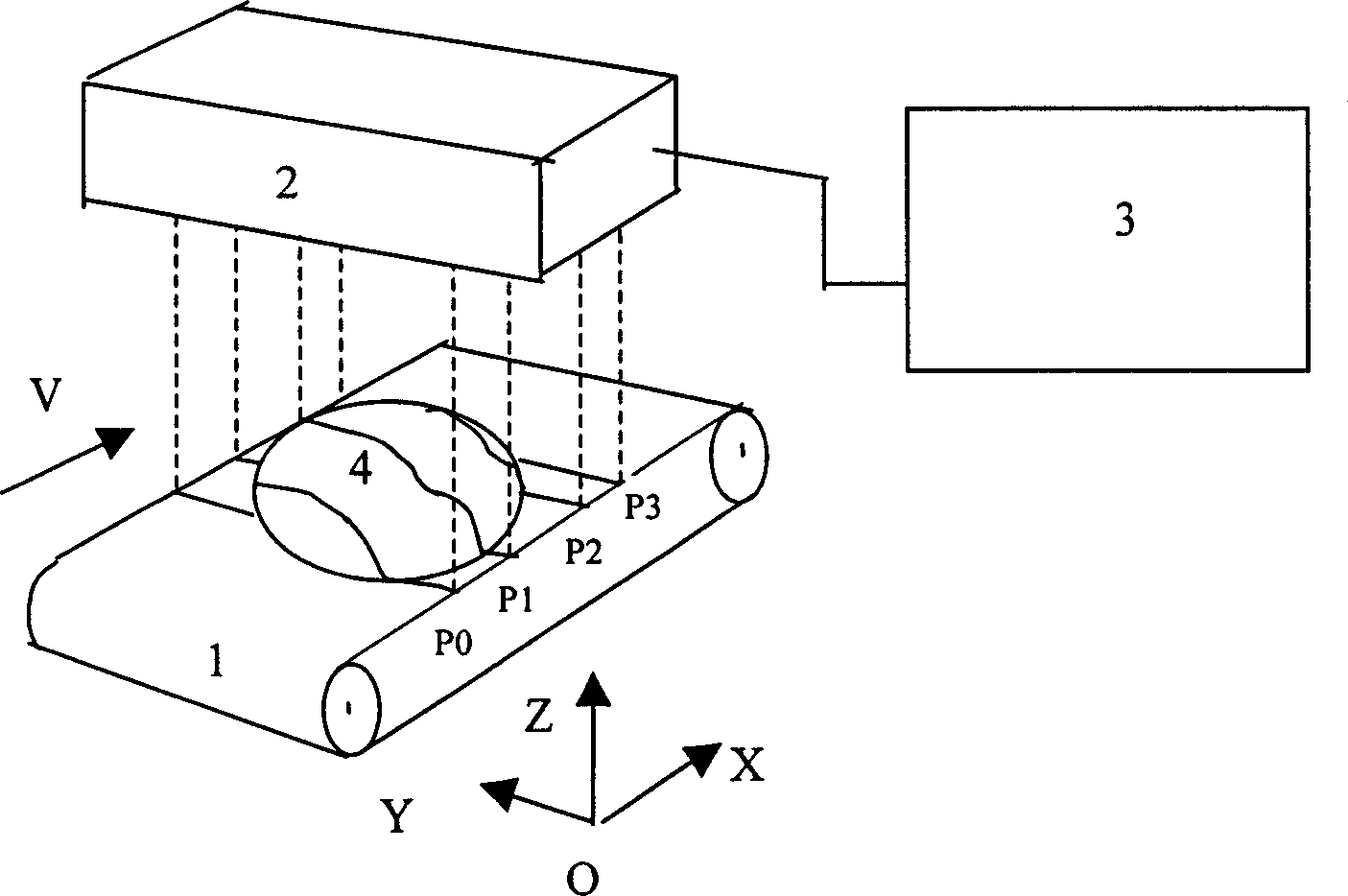

[0020] Such as figure 1 As shown, the measured object 4 is placed on the transmission device 1, and the three-dimensional measurement sensor array 2 is placed above the transmission device 1 and the measured object 4, and the image acquisition and processing device 3 receives the image measurement data sent by the three-dimensional measurement sensor array 2, and data processing. Method of the present invention is realized according to the following steps:

[0021] 1) The transmission device 1 has a measurement reference plane for placing the measured object, and can move the measured object 4 at a constant speed V;

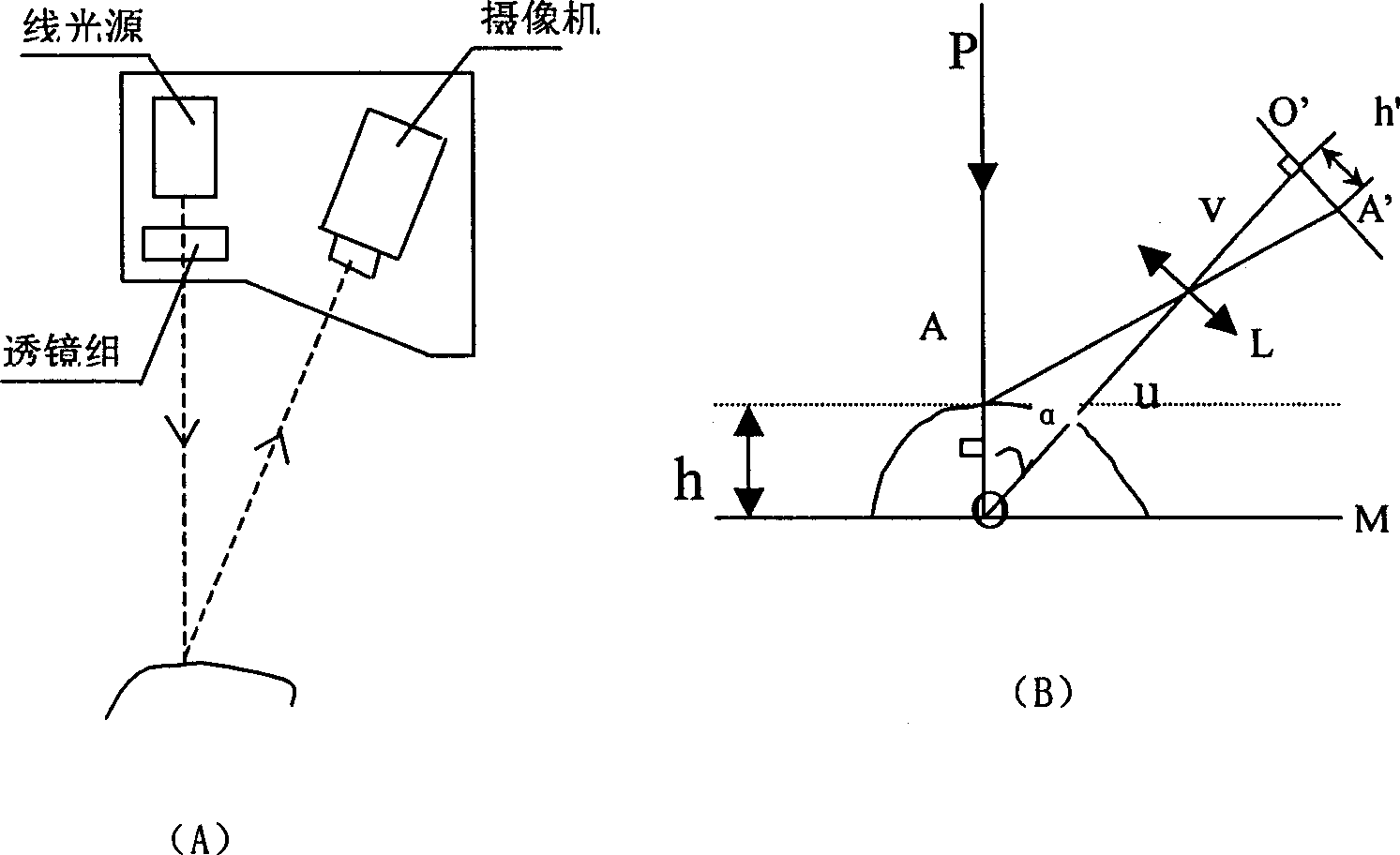

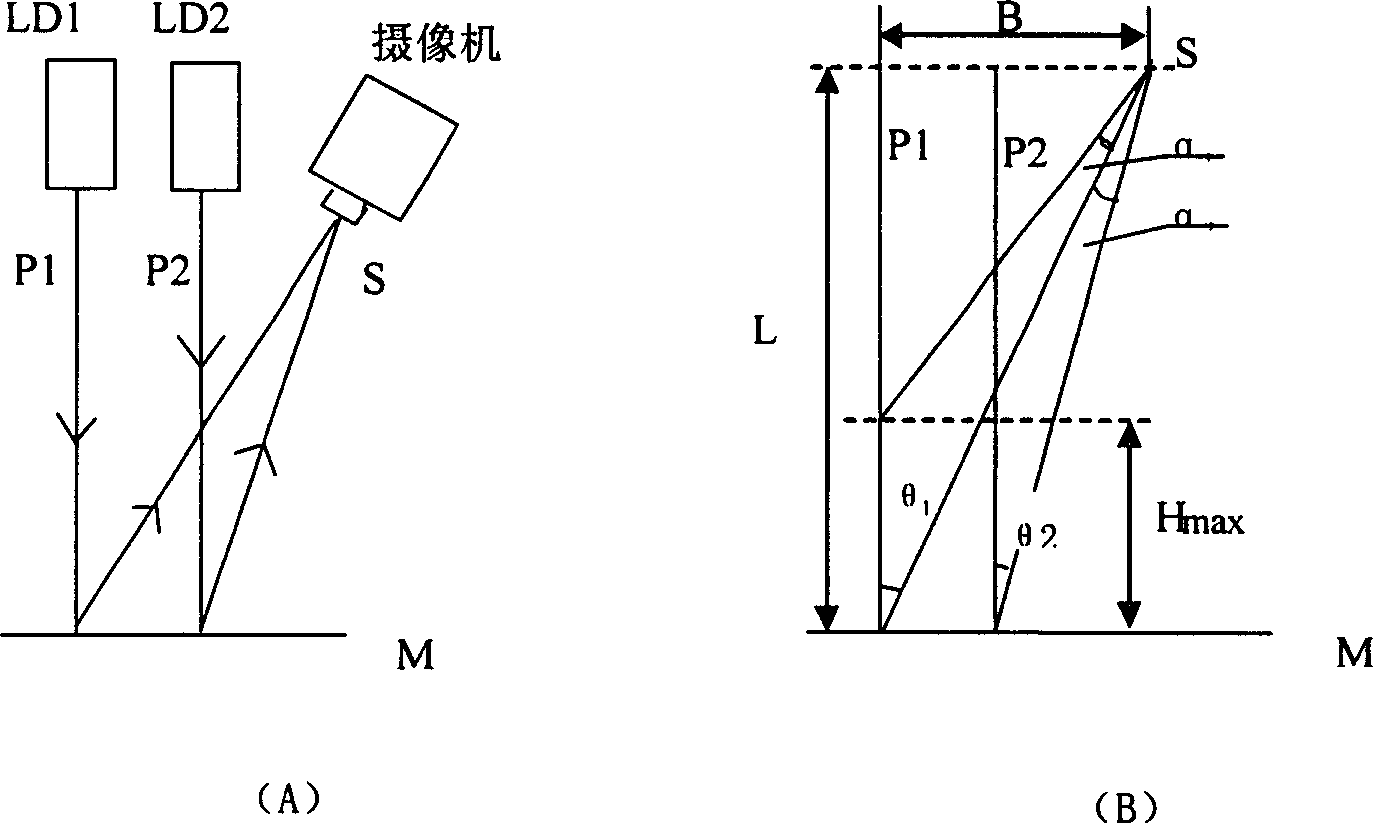

[0022] 2) Install the three-dimensional measurement sensor array 2 above the transmission device to ensure that the optical axis of the light knife of the three-dimensional measurement sensor is perpendicular to the measurement reference plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com