Optical scanner

A scanner and optical technology, applied in the field of optical scanners, can solve problems such as the inability to ensure equidistant distance between the optical system and the scanned document, many assembly steps, and the guide rail is easy to fall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0068] Please refer to Figure 4 , is a side sectional view of an optical scanner according to the first embodiment of the present invention.

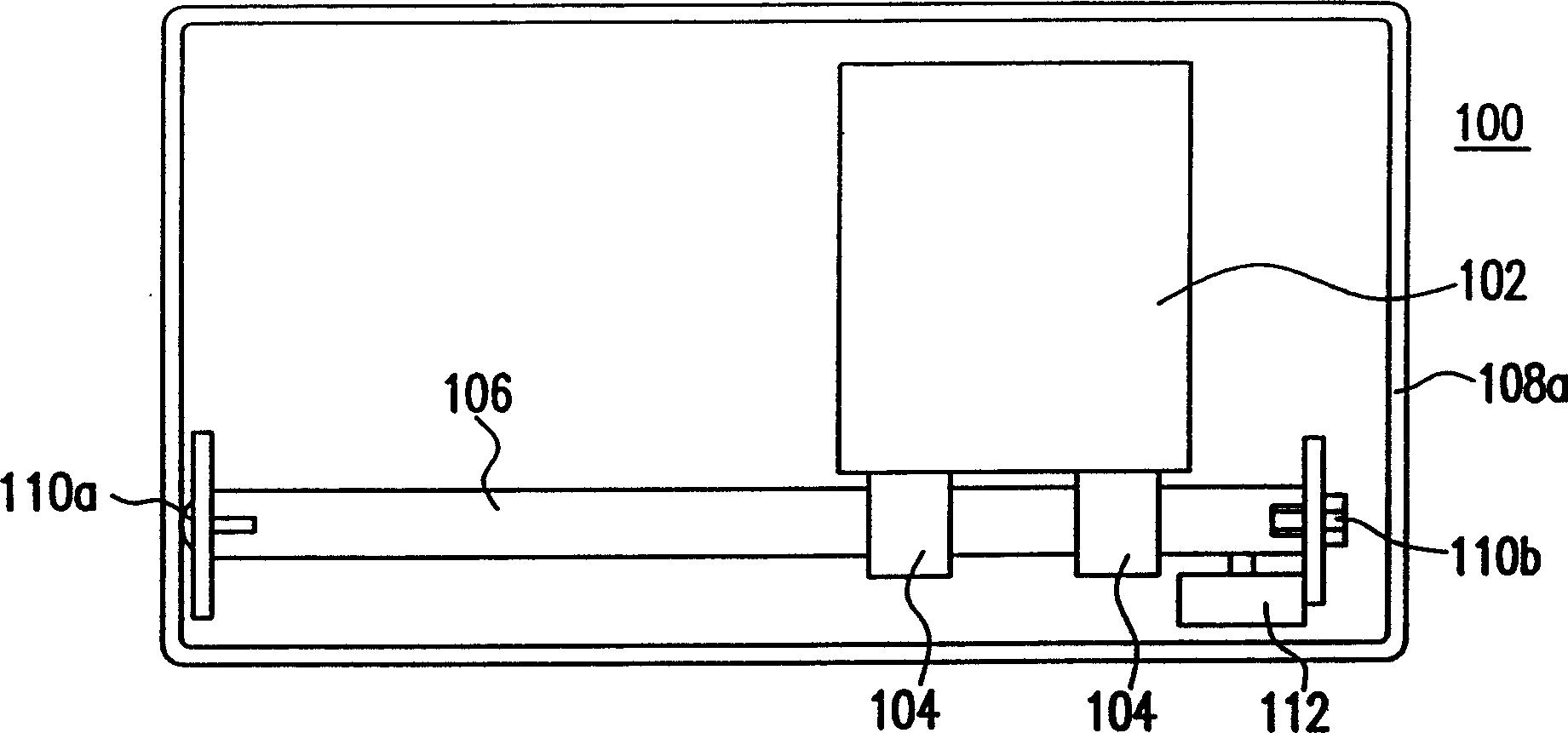

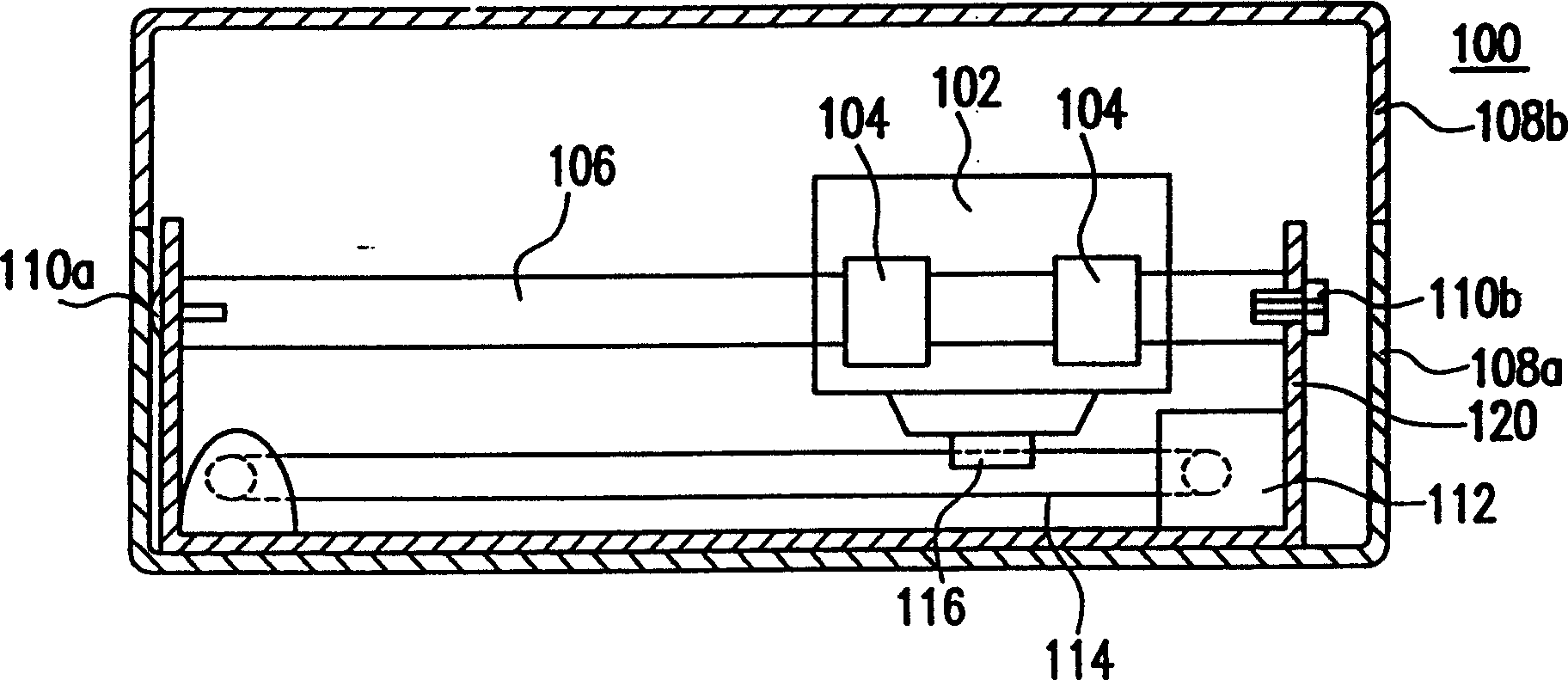

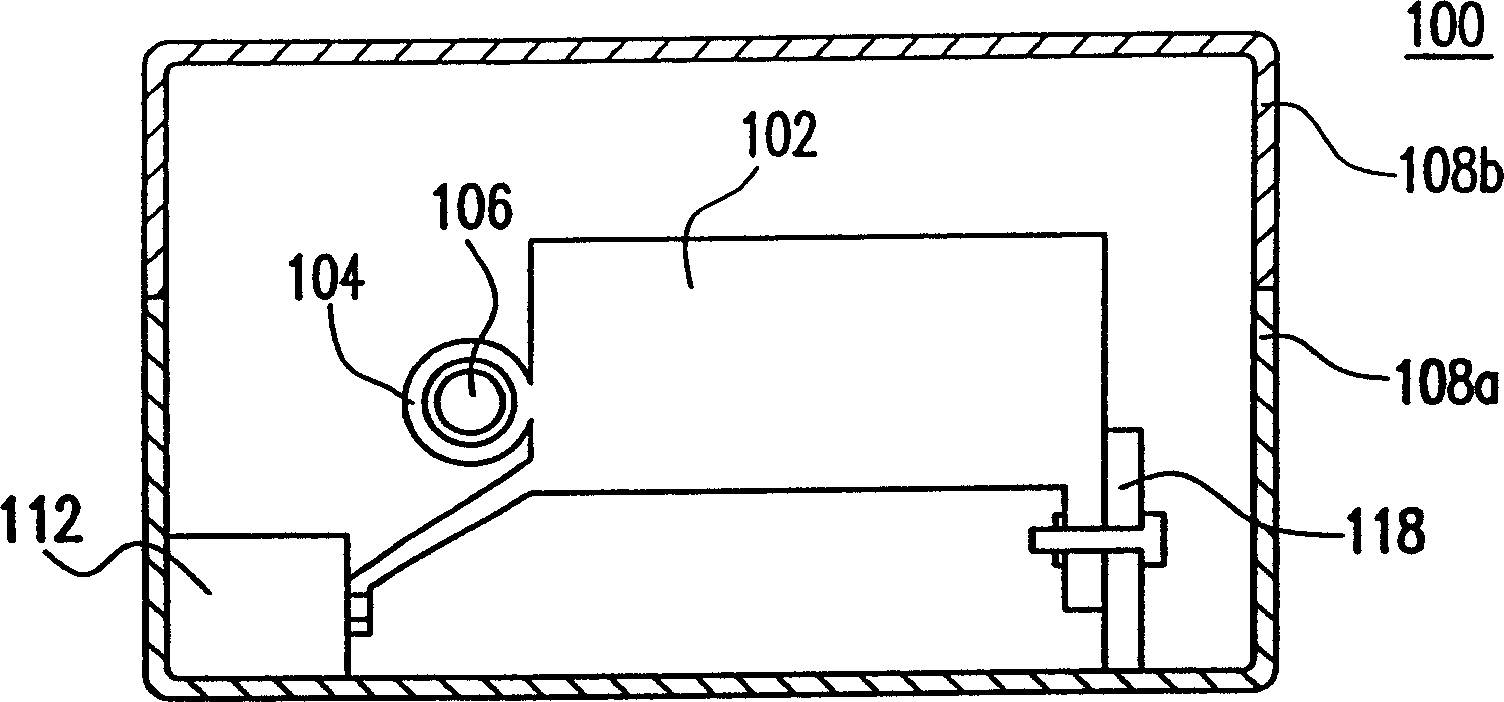

[0069] The optical scanner 200 of the present invention includes: a carrier 202 , a casing 208 , a driving unit 212 and a transmission unit 214 . Wherein, the carrier 202 has a buckle 204, and an optical system (not shown in the figure) is arranged on the carrier 202 . The optical system at least includes: a reflection mirror group, a lens group and a photosensitive device. The photosensitive device includes a charge-coupled device and the like.

[0070] The casing 208 includes an upper casing 208 b and a lower casing 208 a, and the casing 208 has a guide rail 206 integrally formed inside the casing 208 . Moreover, the guide rail 206 has at least one buckle portion, preferably has two buckle portions 206 a, 206 b for buckling with the buckle sleeve 204 of the carrier 202 .

[0071] The driving unit 212 can be, for example, a motor....

no. 2 example

[0100] In addition to integrally forming the guide rail inside the casing as described in the first embodiment, the guide rail can also be formed separately and fixed on the inside of the casing.

[0101] Please also refer to Figure 18 and Figure 19 , are perspective schematic diagrams of a guide rail and its corresponding housing in the second embodiment of the present invention, respectively. In the second embodiment, except that the casing and the guide rail are different from the first embodiment, other components are the same as the first embodiment, and will not be repeated here.

[0102] The guide rail 256 has at least two seat buckles, preferably four seat buckles 274, and at least one sliding buckle, preferably two sliding buckles 256a, 256b. The seat buckle portions 274 are respectively used to engage with the fixing portions 276 of the housing 258 . The sliding buckle parts 256a, 256b are used to buckle with the buckle sleeve of the carrier.

[0103] Therefore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com