Construction reinforcing steel high strength fast screw thead joint

A technology of threaded joints and building steel bars, which is applied to building reinforcements, buildings, building components, etc., can solve the problems of inability to judge the connection status of the joints, hidden dangers of quality and safety, and influence of connection strength, etc., to achieve intuitive and convenient inspection and fast connection speed Fast, less labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

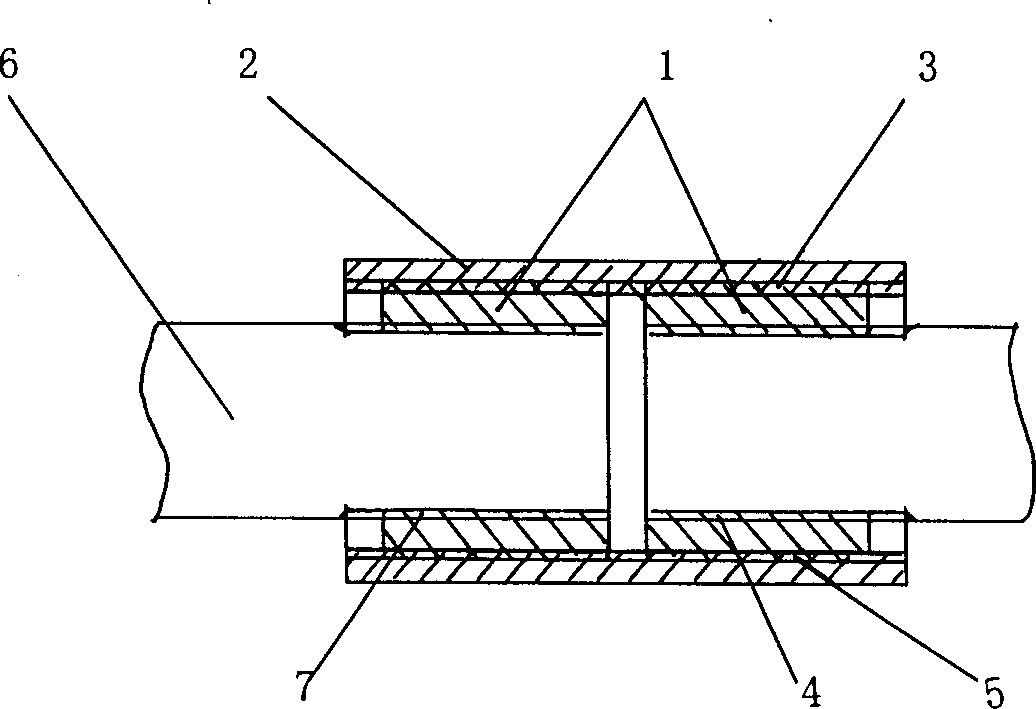

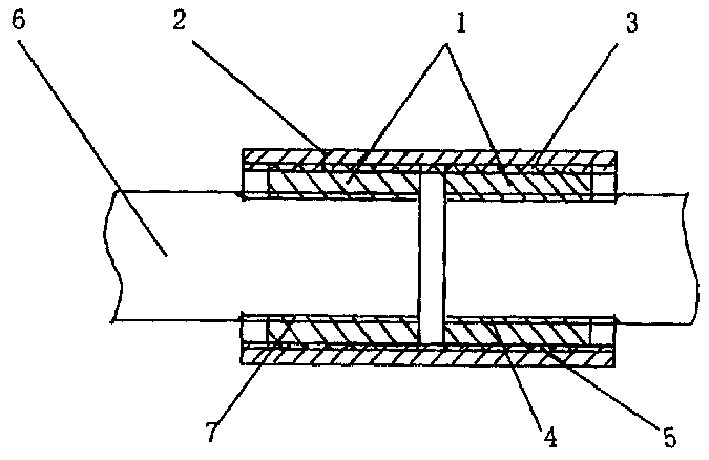

[0013] A high-strength fast threaded joint for building steel bars, which is characterized in that it is composed of two inner sleeves 1 and an outer sleeve 2, the outer sleeve 2 is processed with internal threads 3, the inner sleeve 1 is processed with internal threads 4 and outer threads 5, and the inner sleeve 1 passes through the inner The external thread 5 on the sleeve 1 is connected with the internal thread 3 of the outer jacket 2, and the internal thread 4 on the inner sleeve 1 is connected with the external thread 7 on the steel bar 6 joint. All threads have the same direction of rotation and can be both left-handed or right-handed.

[0014] The material of the inner cover 1 and the outer cover 2 can be made of ordinary No. 45 steel.

[0015] The invention can be used not only for the connection of threaded steel bars, but also for the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com