Dish shaped plastic water pool and its processing method

A pool and plastic technology, applied in swimming pools, public buildings, gymnasiums, etc., can solve the problems of low processing efficiency, high processing cost, and many weld lines, and achieve improved work efficiency, weight reduction, surface strength and compressive strength increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

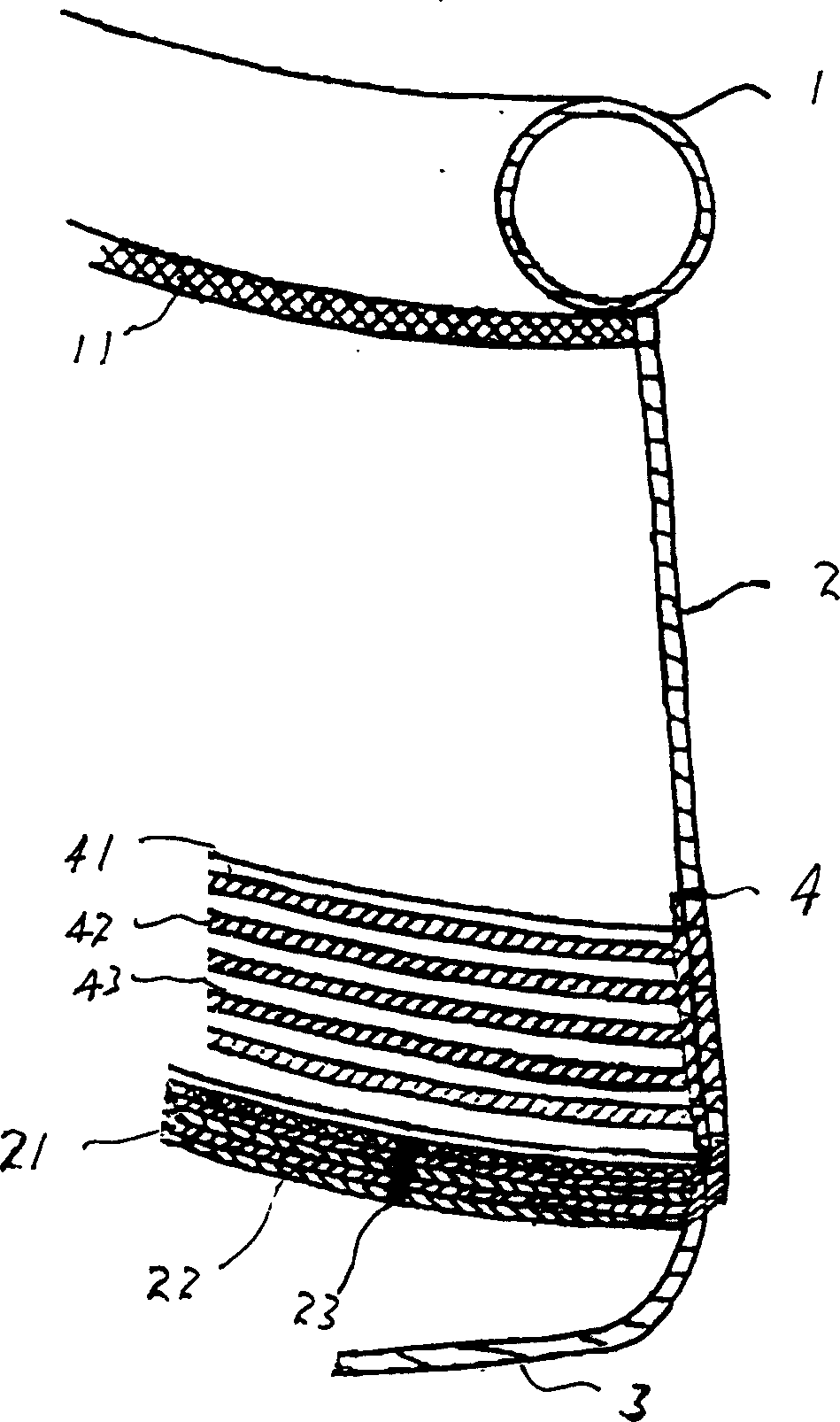

[0020] Embodiment 1, as attached figure 1 As shown, it includes a continuous surrounding sheet 2 and a negative sheet 3, and the joints of the two are arc-shaped welded, and the distance between the welded lines 23 in the circumferential direction is 40 inches, forming a continuous reinforced sealing area; a continuous surrounding The top of the side wall is self-closing, and the upper ring 1 is an upright ring-shaped air strip shaped like a pool. The bottom of the upper ring 1 is welded to the top of the surrounding sheet 2; a continuous reinforcing sheet 4 passes through a continuous reinforced sealing area 41 is bonded to the surrounding sheet 2 to strengthen the strength of the surrounding sheet 2;

[0021] The details are as follows:

[0022] The upper ring 1 is a continuous closed tubular inflatable chamber structure made of vinyl plastic with a gas nozzle. When the plastic pool is filled with water, the topmost inflatable upper circle 1 can make the continuous surroun...

Embodiment 2

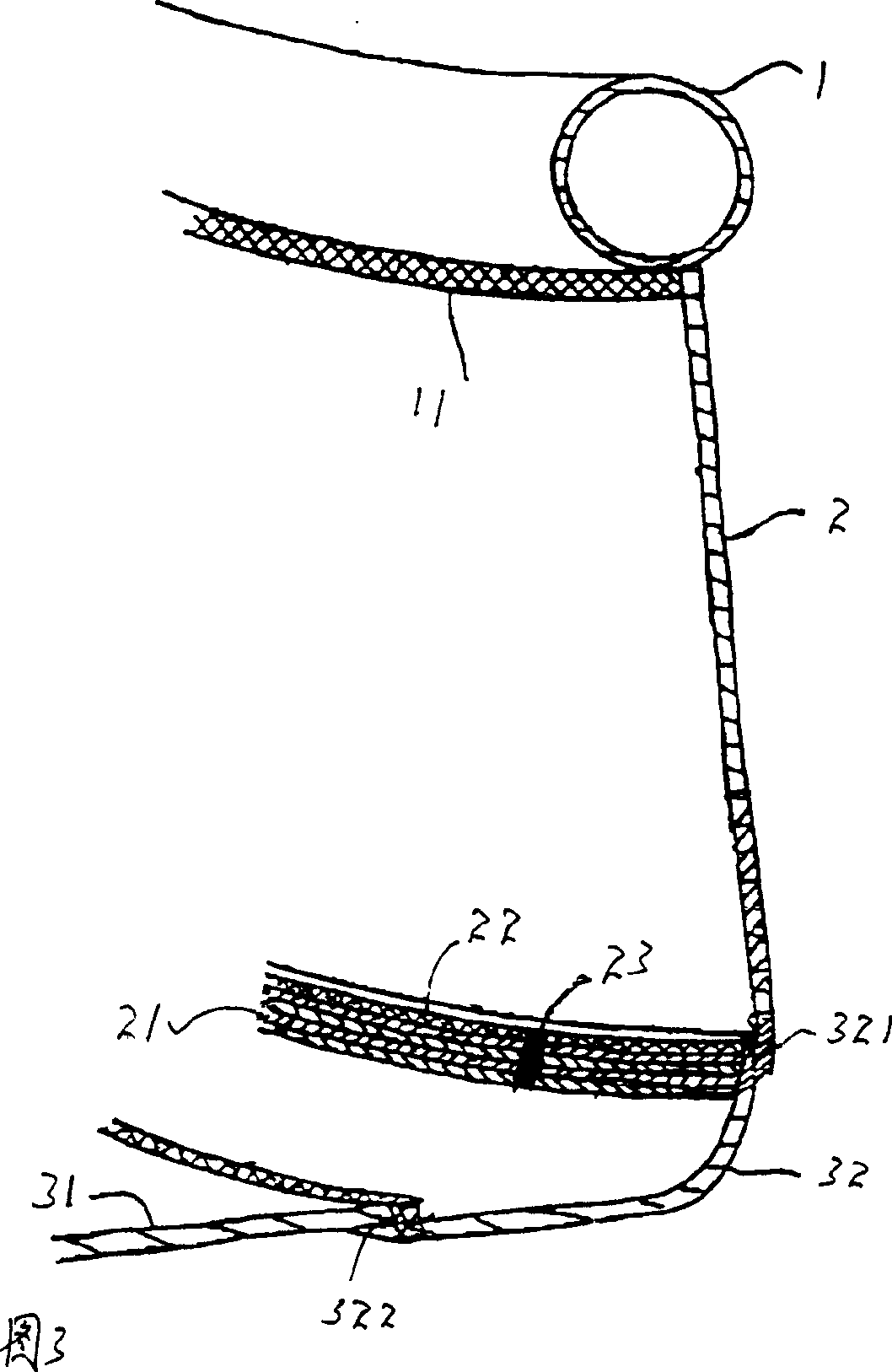

[0033] Embodiment 2, as shown in accompanying drawing 3, the plastic pool of the present invention is a small plastic pool, and is made up of upper ring 1, surrounding sheet 2, bottom sheet 3. The bottom sheet 3 comprises the bottom sheet 3 and the bottom connecting piece 32, and the bottom connecting piece 32 is a ring-shaped sheet body, which can be bonded by several radial sections; its outer ring 321 is welded with the bottom of the surrounding sheet 2 with a high-frequency three-dimensional mold. The weld lines 23 of the weld were spaced at 40 inches. The inner ring 322 of the bottom connecting sheet 32 is welded with the bottom sheet 31 of the pool; In this embodiment, the surrounding sheet 2 and the bottom connecting sheet 32 are made of high-strength sandwich tape, and the bottom sheet 31 is made of PVC engineering plastic film with a lower price than the sandwich tape. Under the premise of ensuring the use function, the cost of raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com