Multi-color plastic injection moulding equpment and method

A technology of injection molding and molding equipment, which is applied in the field of multi-color composite plastic injection molding equipment, can solve the problems of complex process, high cost, cumbersome operation, etc., achieve uniform shrinkage of finished products, reduce equipment cost, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

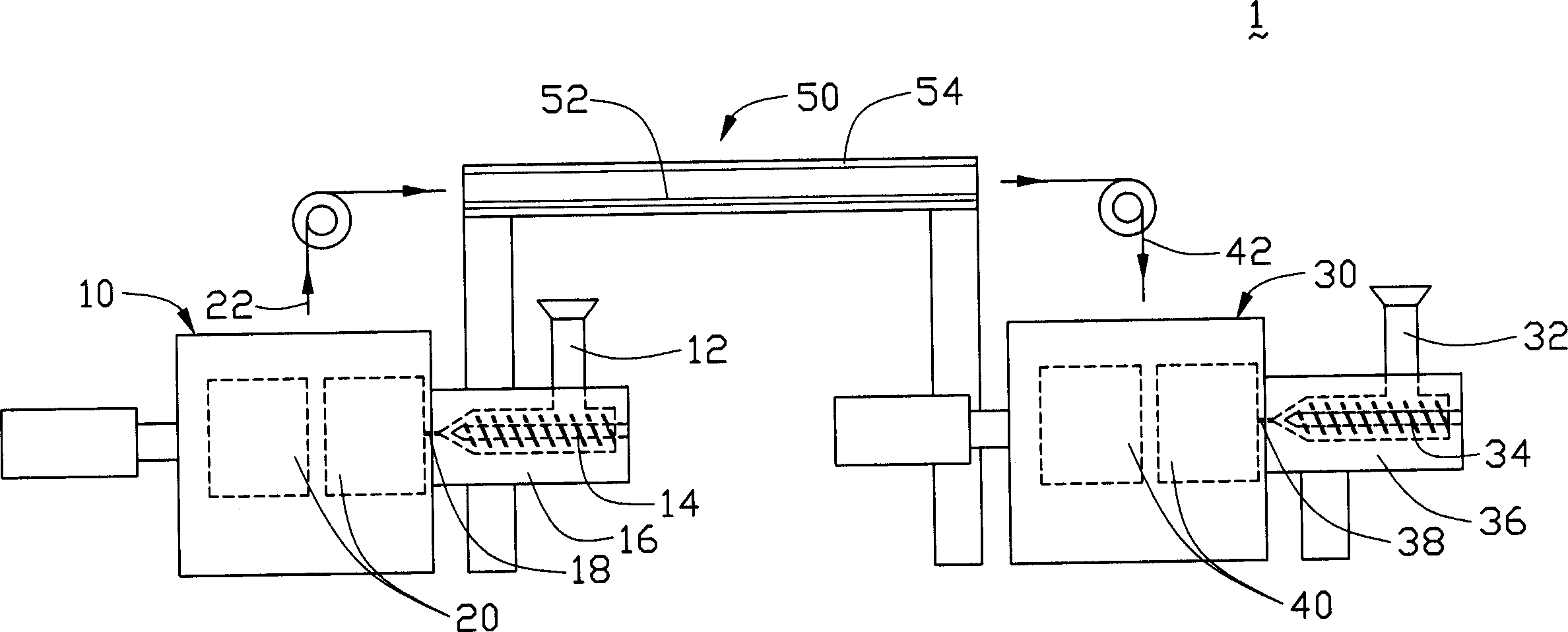

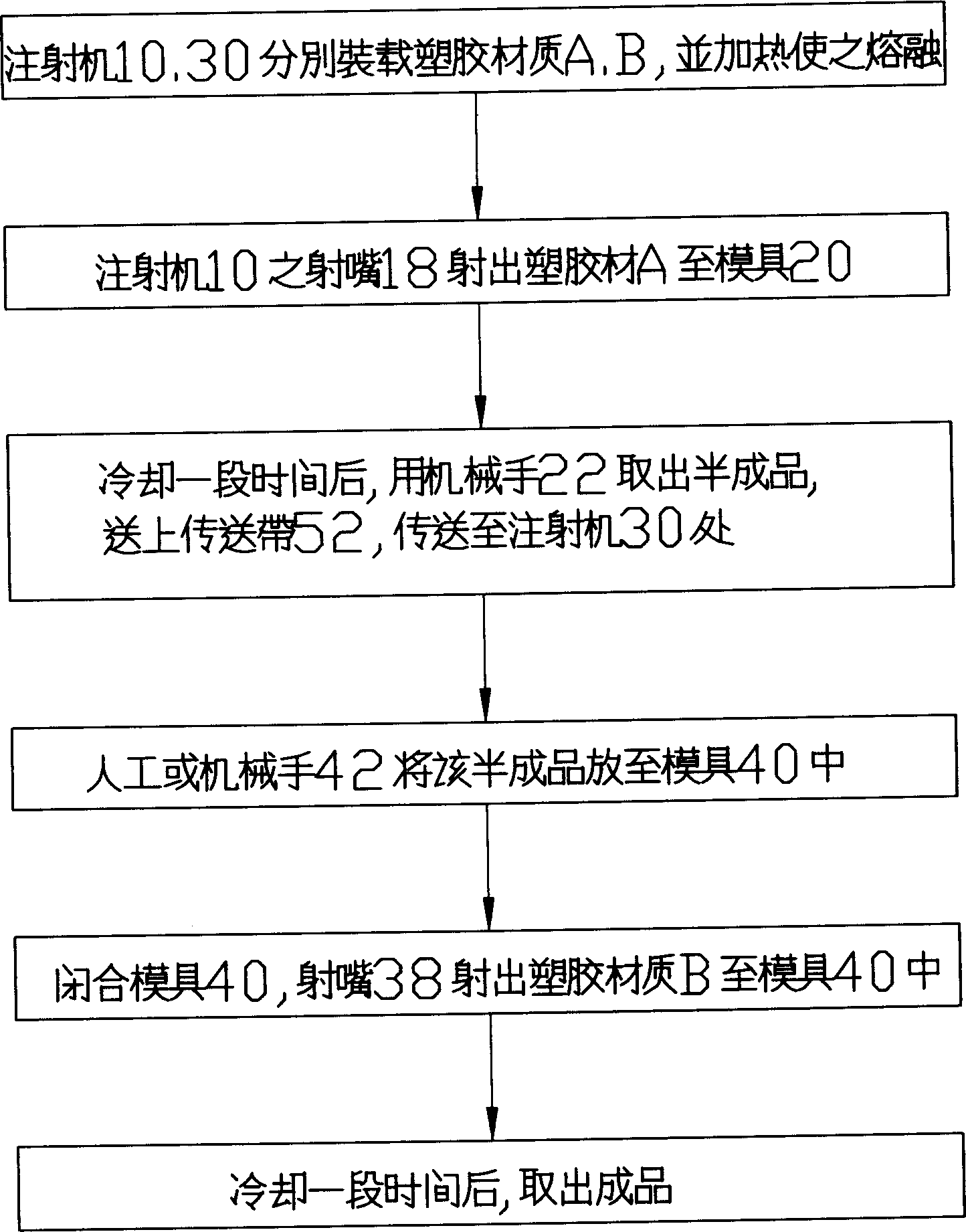

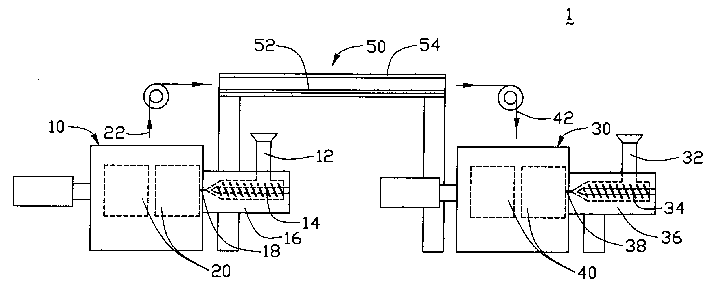

[0012] The multi-color composite plastic injection molding equipment of the present invention includes several single-nozzle injection machines and several transmission devices erected between these injection machines. The following is an example of a two-color composite plastic injection molding equipment and its molding method.

[0013] see figure 1 , a two-color composite plastic injection molding equipment 1 includes two single-nozzle injection machines 10, 30 and a transfer device 50 erected between these injection machines 10, 30.

[0014] The single nozzle injection machine 10 includes a feeding device 12 , a barrel 16 containing a screw 14 , a nozzle 18 at the front end of the barrel 16 , a mold 20 and a manipulator 22 above the injection machine 10 .

[0015] Another single-nozzle injection machine 30 is the same as the single-nozzle injection machine 10, and also includes a feeding device 32, a barrel 36 containing a screw 34, a nozzle 38 positioned at the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com