Elastic seat sealed plug valve

A sealing plug valve, elastic technology, applied in the field of elastic seat sealing plug valve, can solve the problems of high machining precision, high processing cost, and large frictional displacement of the sealing surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

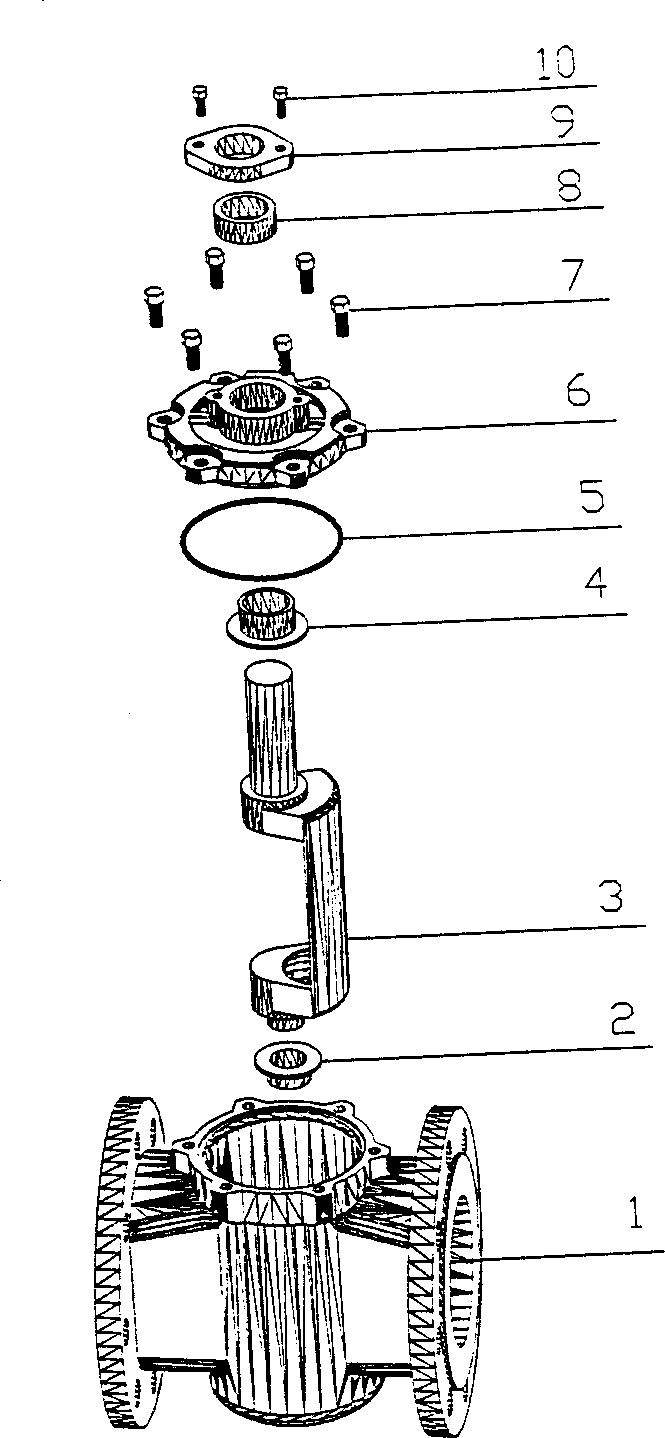

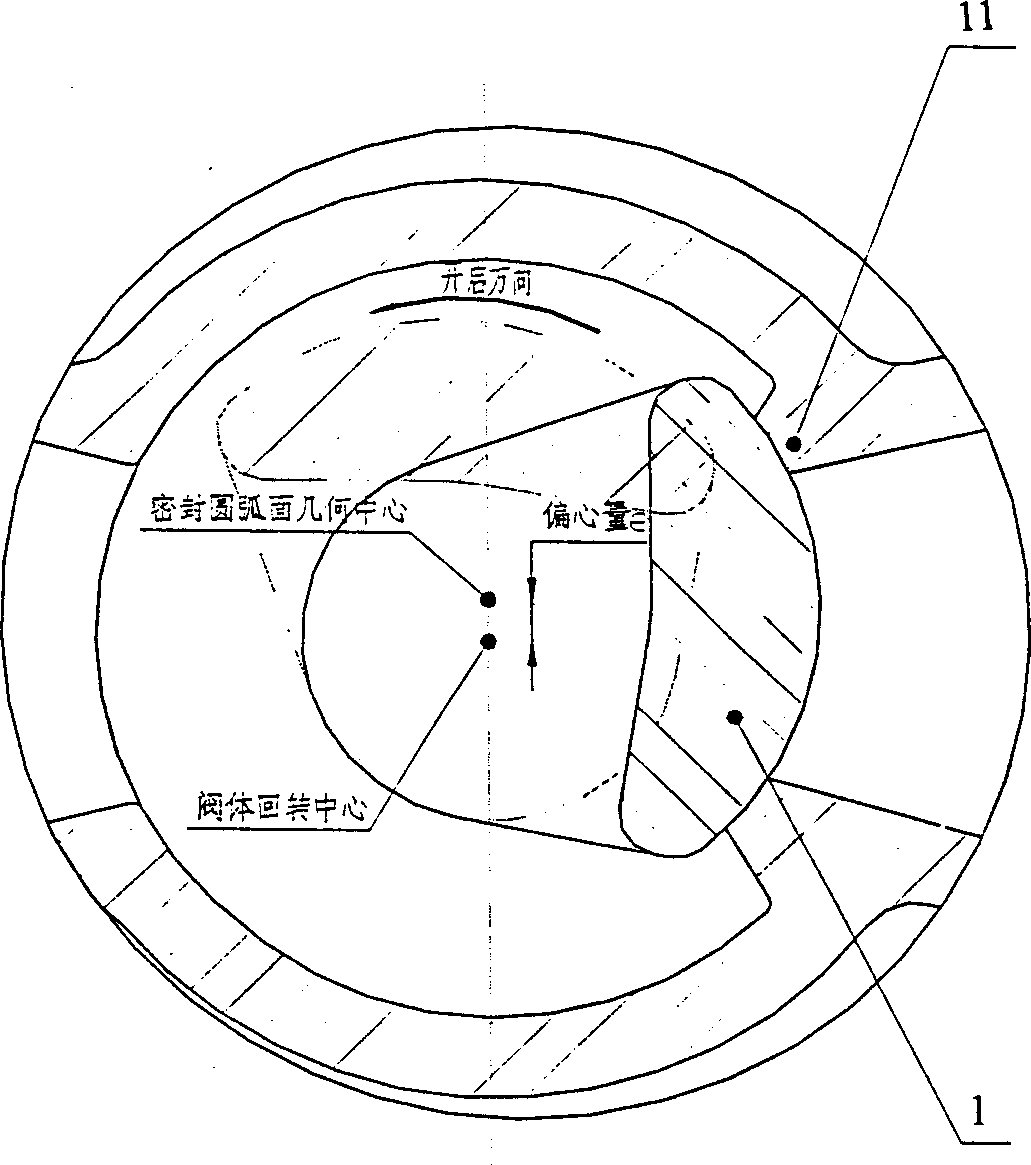

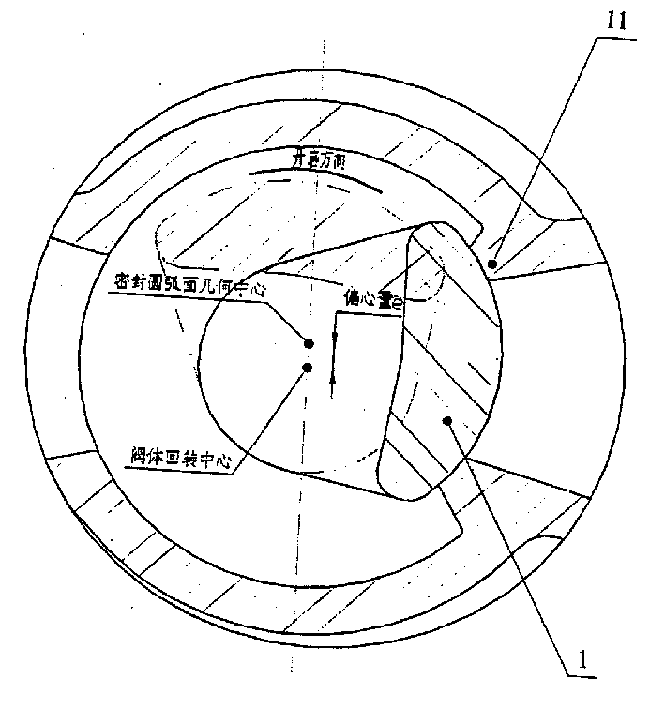

[0009] Such as figure 1 , figure 2 As shown, the elastic seated plug valve of the present invention includes a valve body 1 , a cock body 3 , a lower sleeve 2 and an upper sleeve 4 . The valve body 1 has fluid inlet and outlet passages connected with each other, a cock body installation passage and a valve seat 11 . The cock body 3 is integrally cast with the valve shaft, and the cock is molded and covered with rubber. The cock body 3 is combined with the lower bushing 2 and the upper bushing 4 and is located in the cock body installation channel of the valve body 1 . The center of rotation of the cock body 3 is located at the center of rotation of the valve body 1. The geometric centers of the sealing arc surface of the cock body 3 and the sealing arc surface of the valve seat 11 are both offset from the center of rotation of the valve body 1. The eccentricity is e, and the two sealing arcs The faces are equal in size, and the sealing faces fit together when the valve is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com