Laser lofting apparatus

A laser and laser beam technology, applied in the direction of measuring devices, instruments, surveying and navigation, etc., can solve the problems of inconvenient operation, cross-hair cursor limitation, etc., and achieve the effects of convenient operation, simple and compact overall structure, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

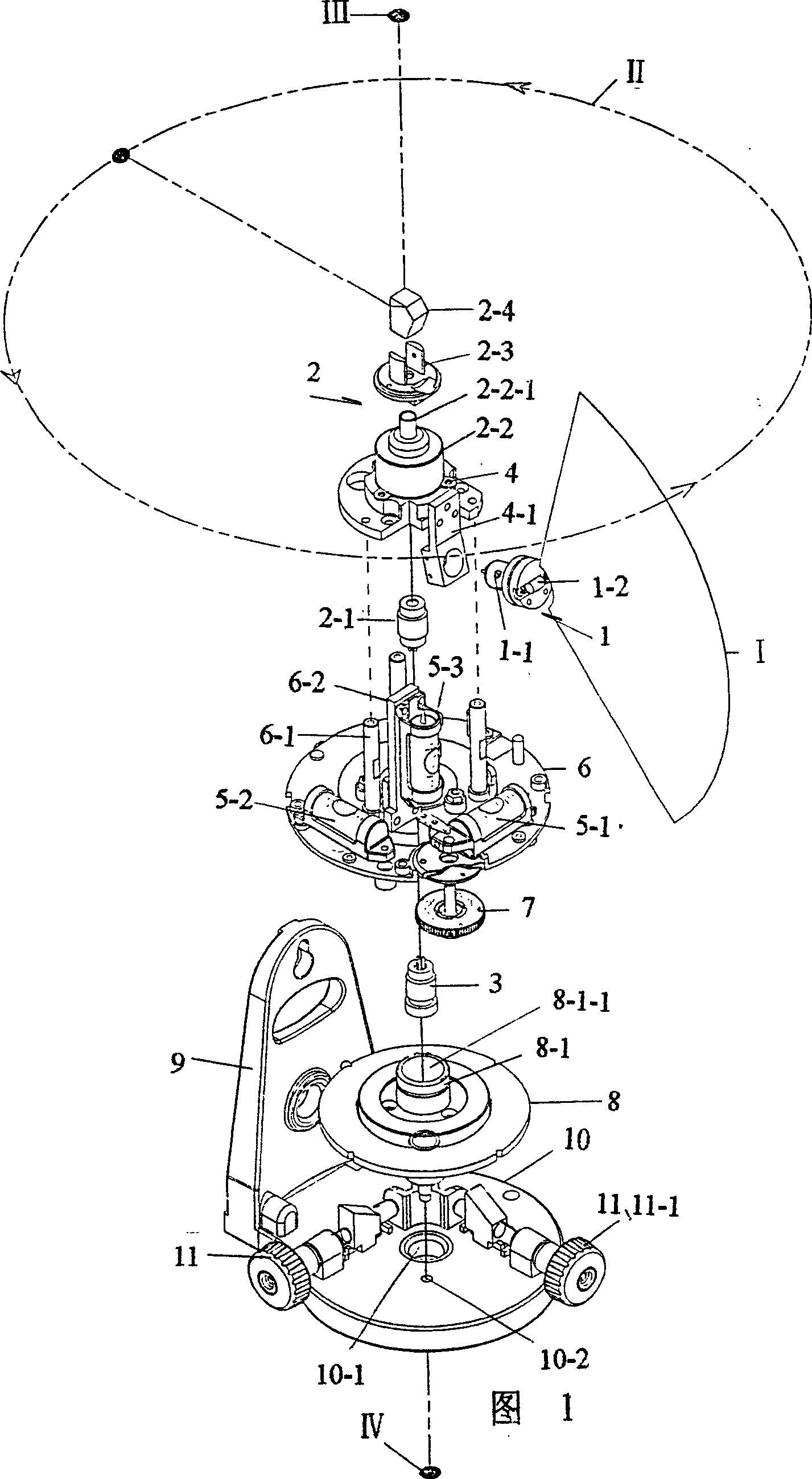

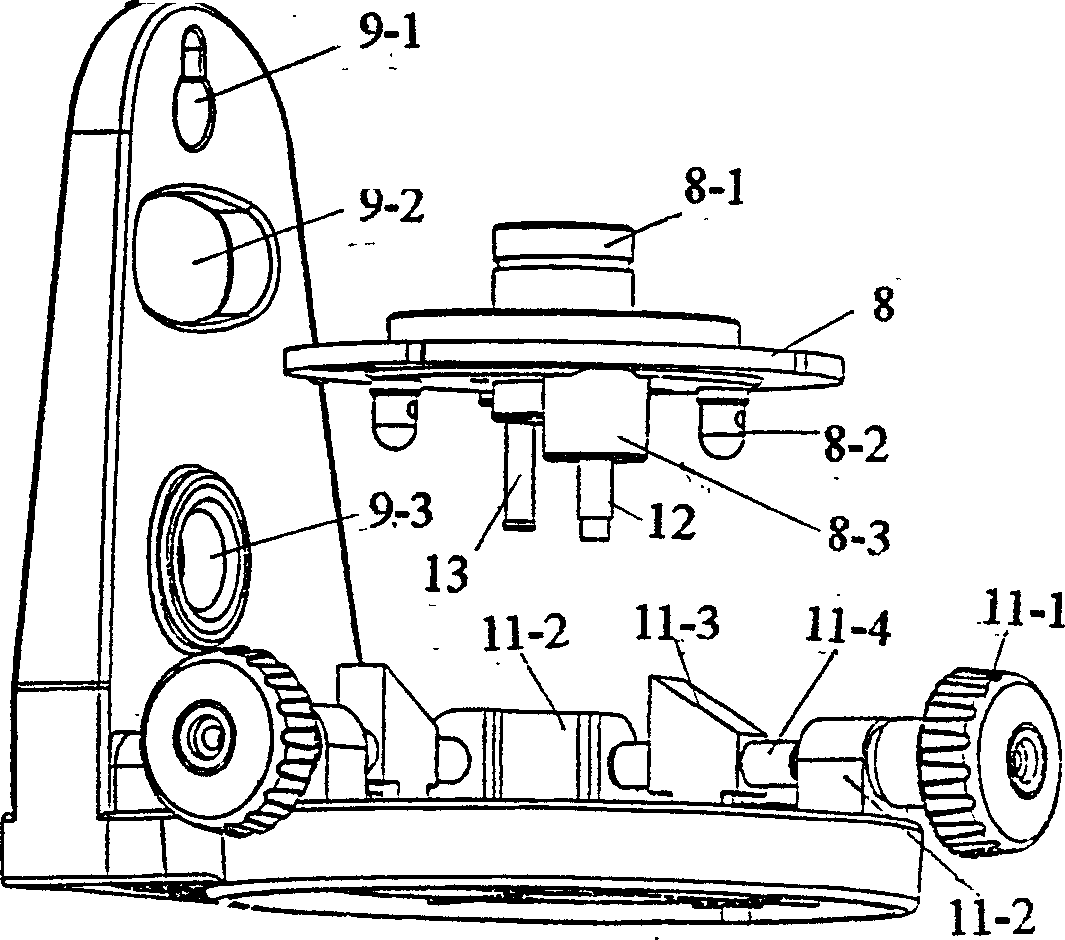

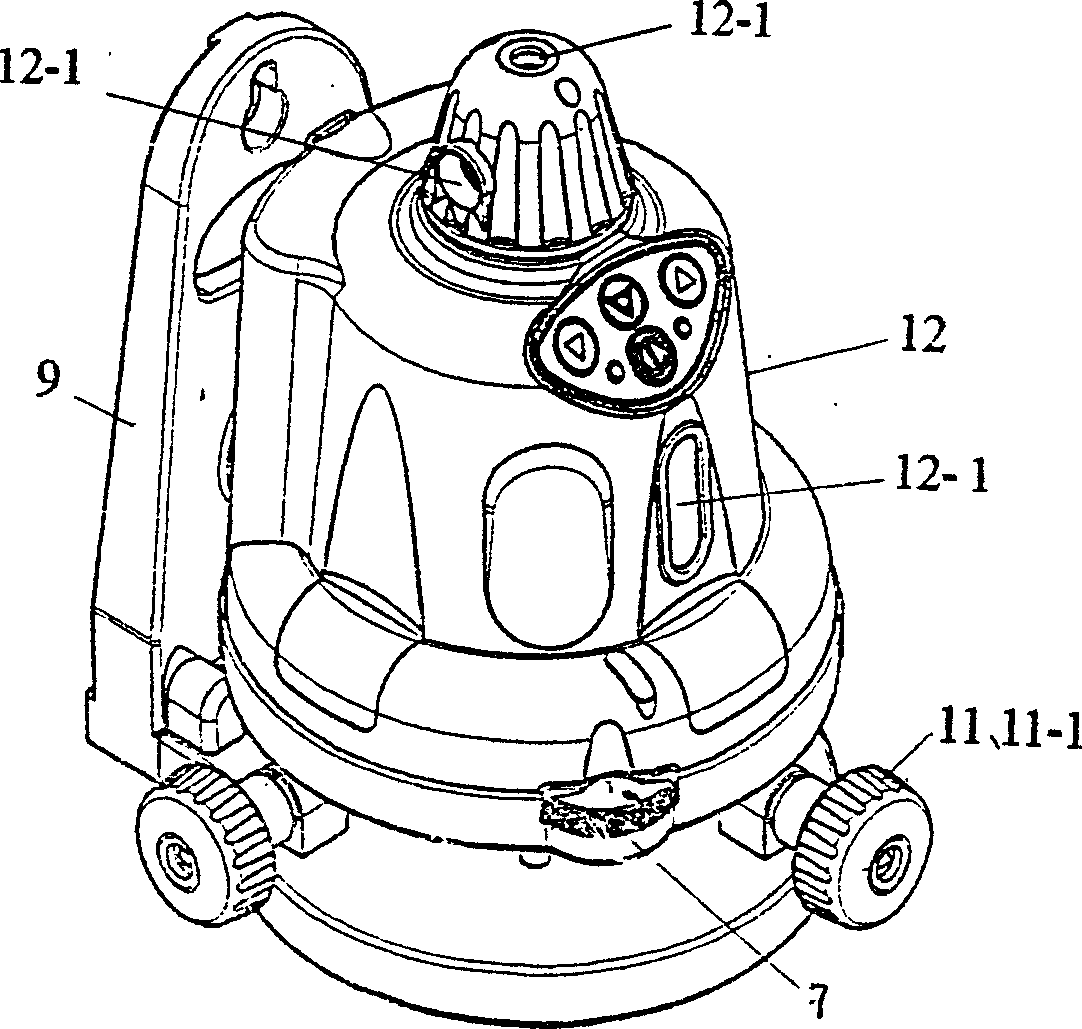

[0021] As shown in the drawings, the present invention has a base body, a line laser part 1 and a spot laser part 2 . The base body includes a base 10, a tray 8, a base frame 6, and levels 5-2, 5-1, and 5-3 with X, Y, and Z coordinate axes, respectively. The base 10 is provided with a central hole 10-1; Y , The X-coordinate axial level 5-1, 5-2 is fixed on the base frame 6 at 90°, and the Z-coordinate axial level 5-3 is fixed on the bracket 6-2 of the base frame 6. The base frame 6 is connected with the tray 8 for relative rotation. Between the base 10 and the tray 8, there are two wedge adjustment mechanisms 11, ball head struts 12, and limit components, which are fixed on the base 10 and correspond to the levels 5-2 and 5-1 of the X and Y coordinate axes. and springs (not shown). The ball head post 12 is located between the two wedge block adjusting mechanisms 11 , the lower end of the ball head post 12 is inserted into the post positioning hole 10 - 3 of the base 10 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com