Device for separating and recovering cooling liquid in cutting machine tool and grinder

A technology of cutting machine tools and recovery devices, which is applied in the field of separation and recovery devices for coolant in cutting machine tools and grinding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

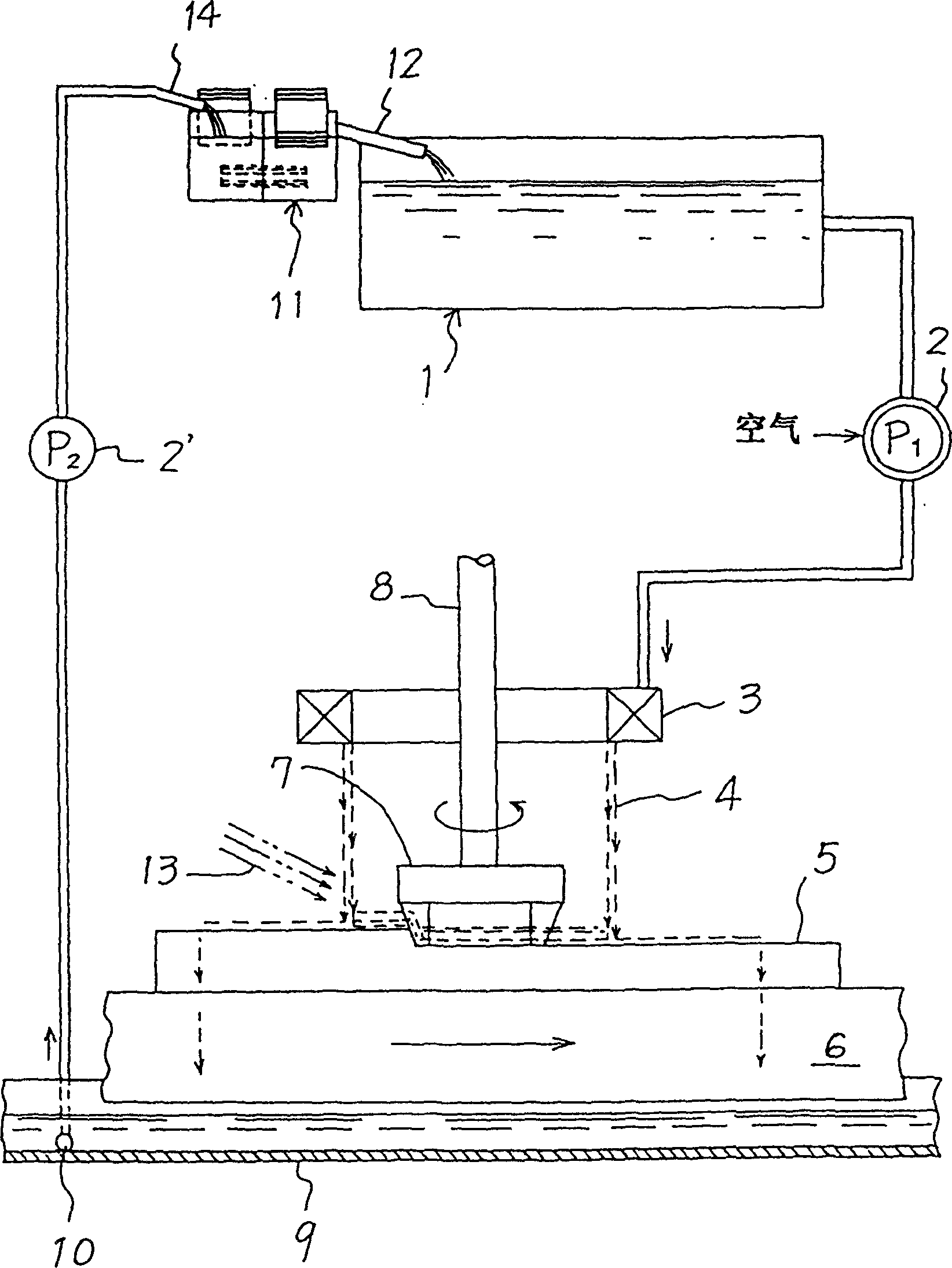

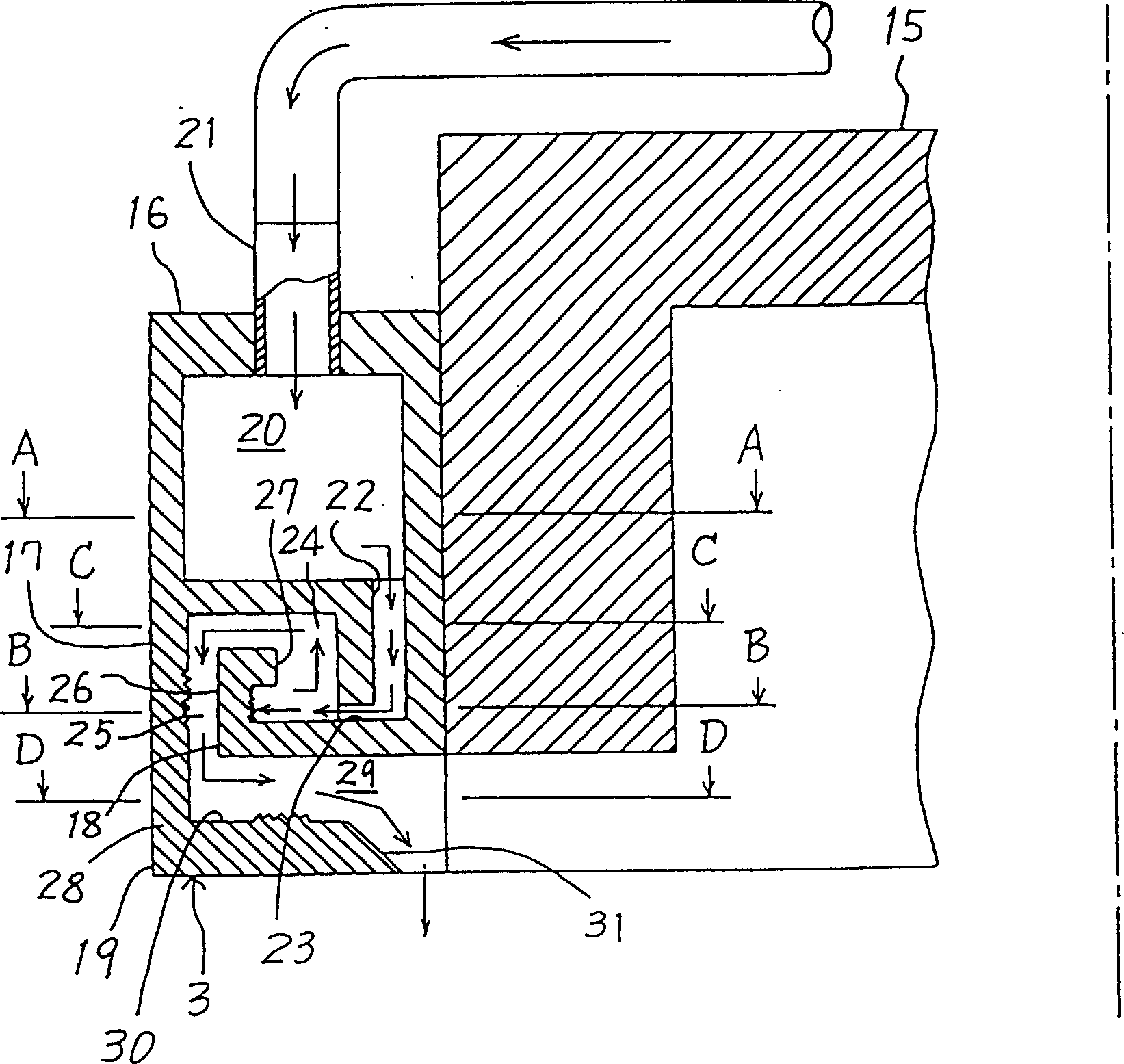

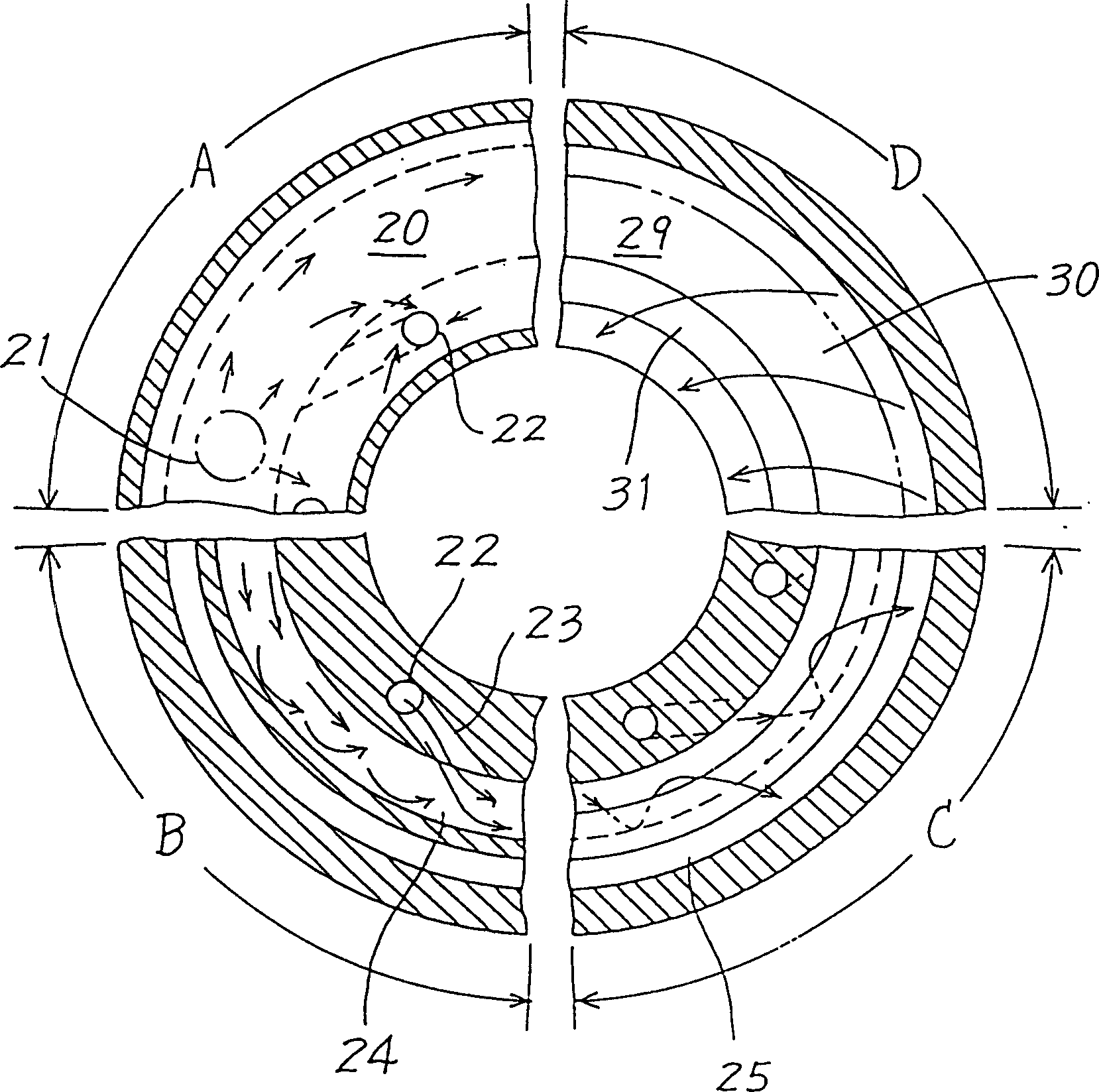

[0051] figure 1 The basic system structure of the present invention is shown in , the number 1 is a large-capacity main tank that can store coolant; 2 is a cooling pump (P1), in this example, it is used to suck air, generate air bubbles in the coolant and cool The liquid is sent into an annular nozzle 3. The annular nozzle 3 (described in detail below) is used to spray the cooling liquid sent in from the pump P1 downward in the form of a cylindrical cover 4 basically composed of a vortex formed by the confluence of granular turbulence, and impacts to on the surface of the workpiece 5. The workpiece 5 is cut on a movable platform 6 by a milling cutter 7 , which is a powerful cutting tool in this example, and a spindle 8 supporting the milling cutter passes through the annular nozzle 3 . Most of the cylinder 4 of coolant impinging on the workpiece surface at the lower end moves towards the center in a surface spiral flow to be sufficiently delivered to the contact between the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap