Production method for semiconductor chip

A manufacturing method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as difficult peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

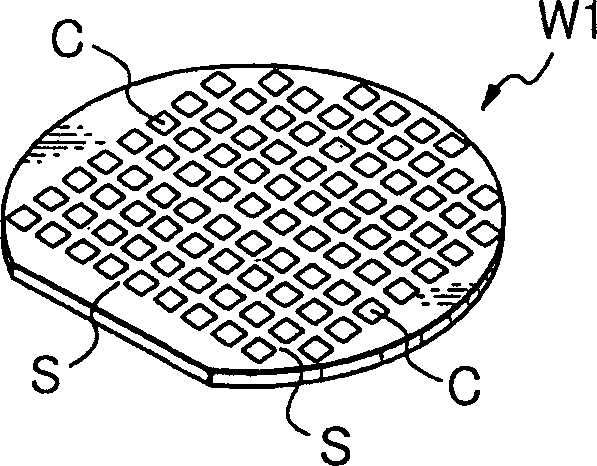

[0035] As the best mode for implementing the present invention, such as figure 1 As shown, a method of dividing a semiconductor wafer W1 having a plurality of semiconductor chips C formed on its surface by dividing by dividing streets S into individual semiconductor chips C will be described.

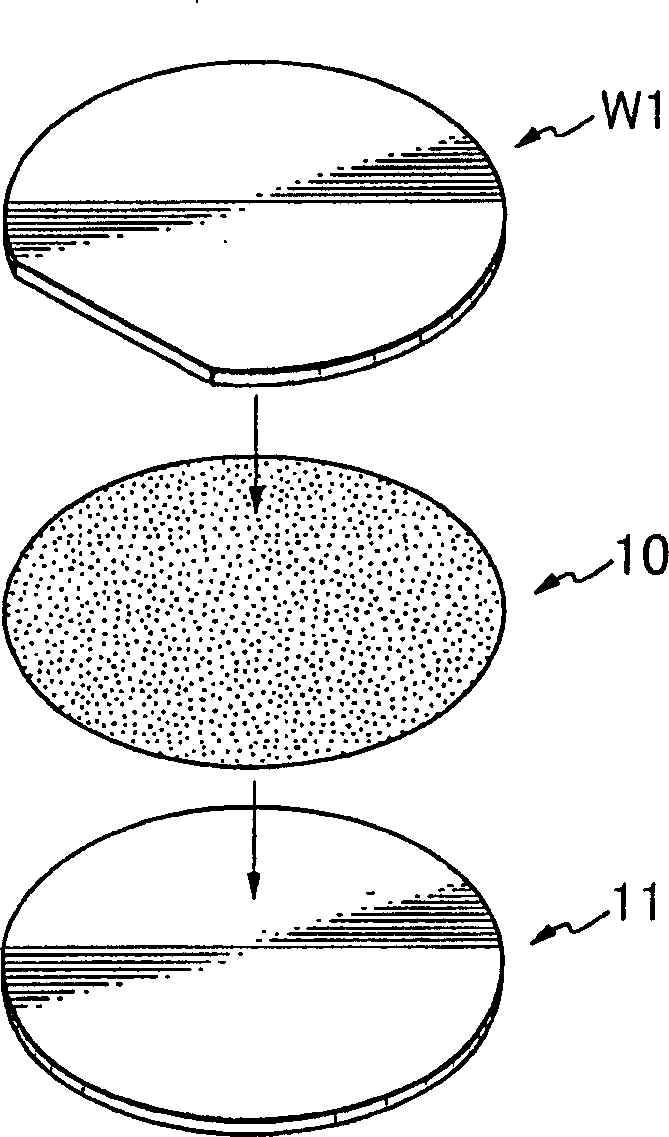

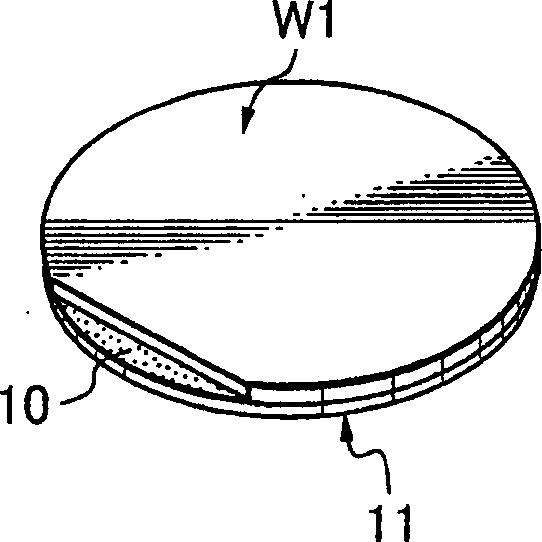

[0036] First, if figure 2 As shown, the semiconductor wafer W1 is turned over, and the surface of the semiconductor wafer W1 is pasted on the plate support member 11 through the adhesive tape 10, as shown in FIG. image 3 The state shown (plate support member integration process).

[0037] This adhesive tape 10 is an adhesive layer for adhering the semiconductor wafer W1 and the plate support member 11 , and is configured such that the adhesive force is reduced due to external factors. The sticking force mentioned here is composed of adhesive force and adhesion force. For example, adhesive tapes disclosed in JP-A-63-17981 and JP-A-4-88075 can be used as the adhesive tape 10 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com