High property passive cooling device with conduit

A passive cooling, core column technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve problems such as adding fans and heat sinks, device or PC board failure, and inability to install in vertical spaces. , to increase the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

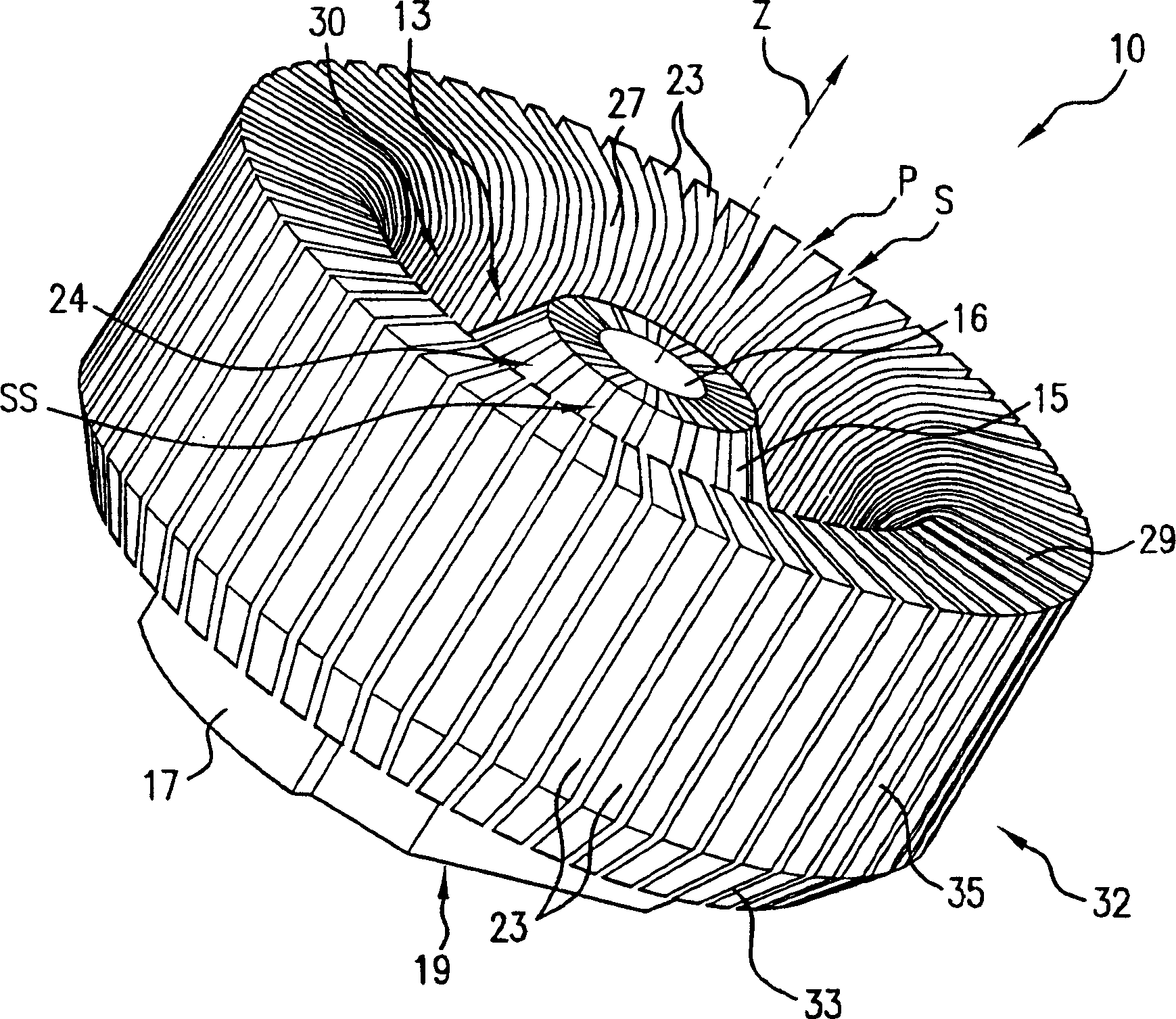

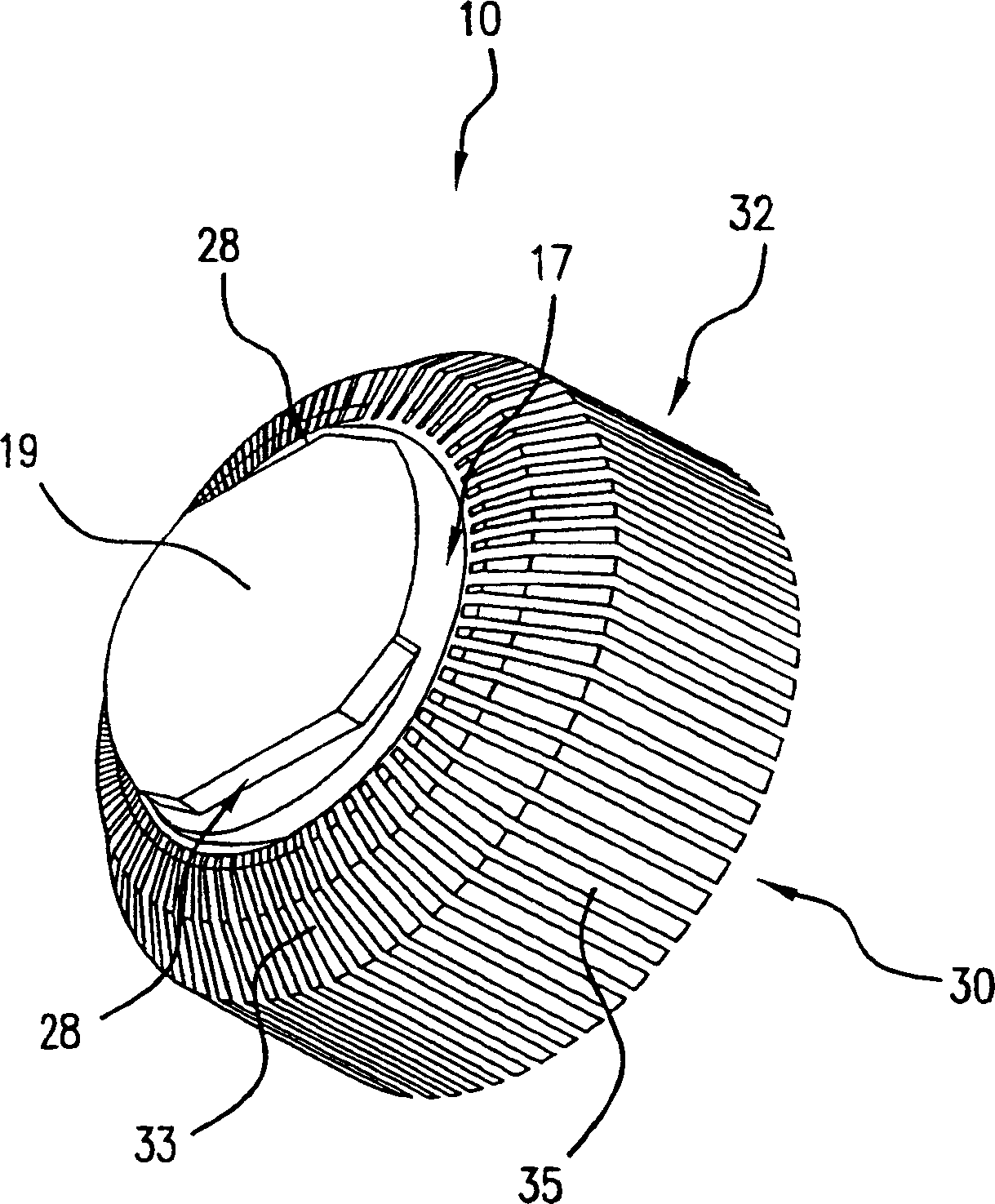

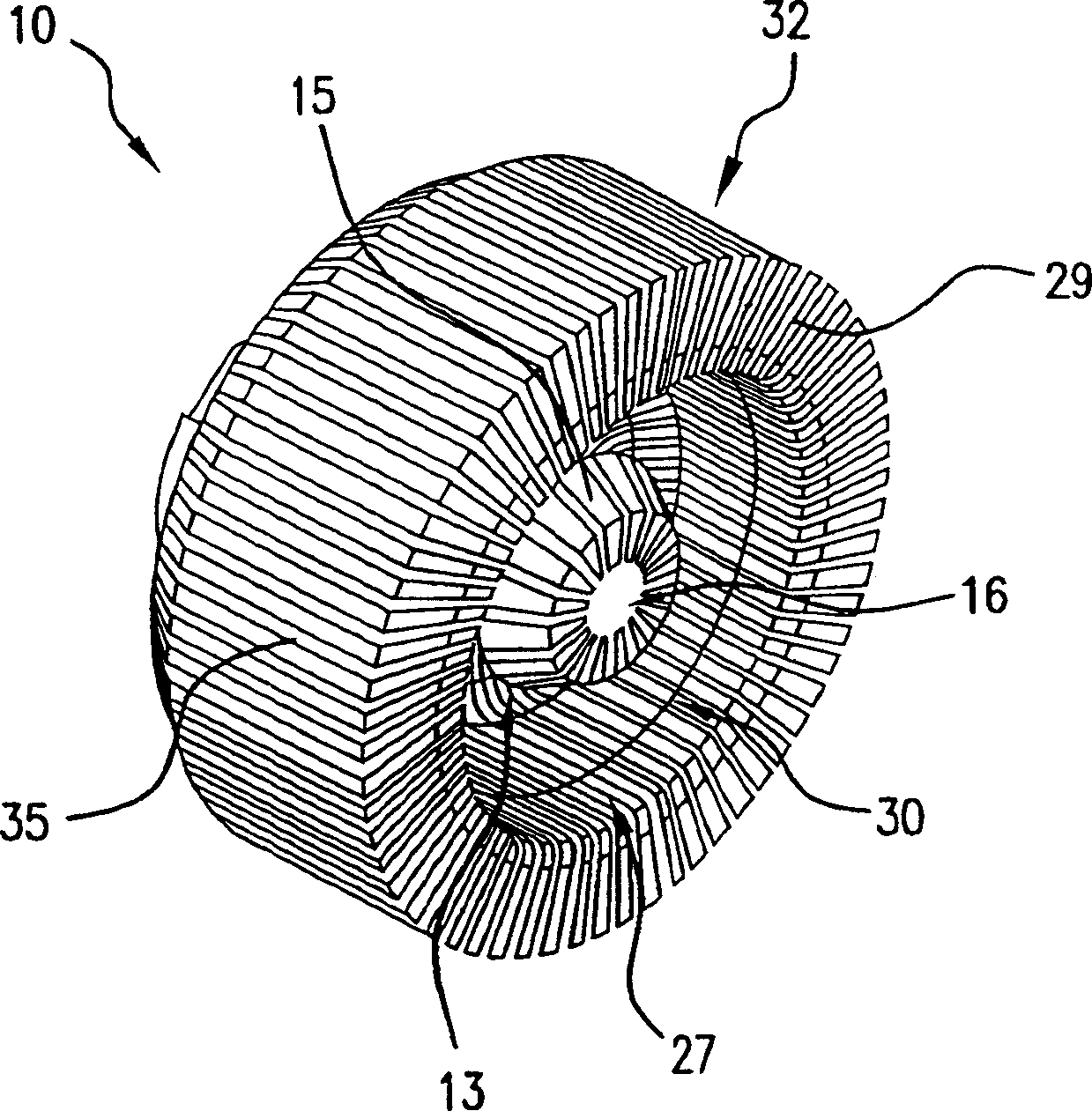

[0047] In the following detailed description and drawings, the same elements are denoted by the same reference numerals.

[0048] As shown in the drawings used to illustrate the invention, the invention is embodied in a passive cooling device for dissipating heat from the element to be cooled. The passive cooling device includes a thermal body, and a stem connected to the thermal body and extending to the outside of the thermal body. The stem is disposed symmetrically about the axis of the thermal body, the stem includes a diverter surface, an end face and a plurality of stem fins spaced apart to define between adjacent stem fins A stem slot. The stem groove extends toward the heating body. A thermally conductive base is in contact with the thermal body and includes a mounting surface suitable for thermally coupling the thermal body to the component.

[0049] A plurality of vanes, which are connected to the thermal body, are spaced apart to define primary slots between adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com