Heat treatment apparatus

A technology for heat treatment devices and furnaces, which is applied to furnace control devices, maintenance of heating chambers, lighting and heating equipment, etc. It can solve the problems of not adjusting the zero point and difficult to maintain measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

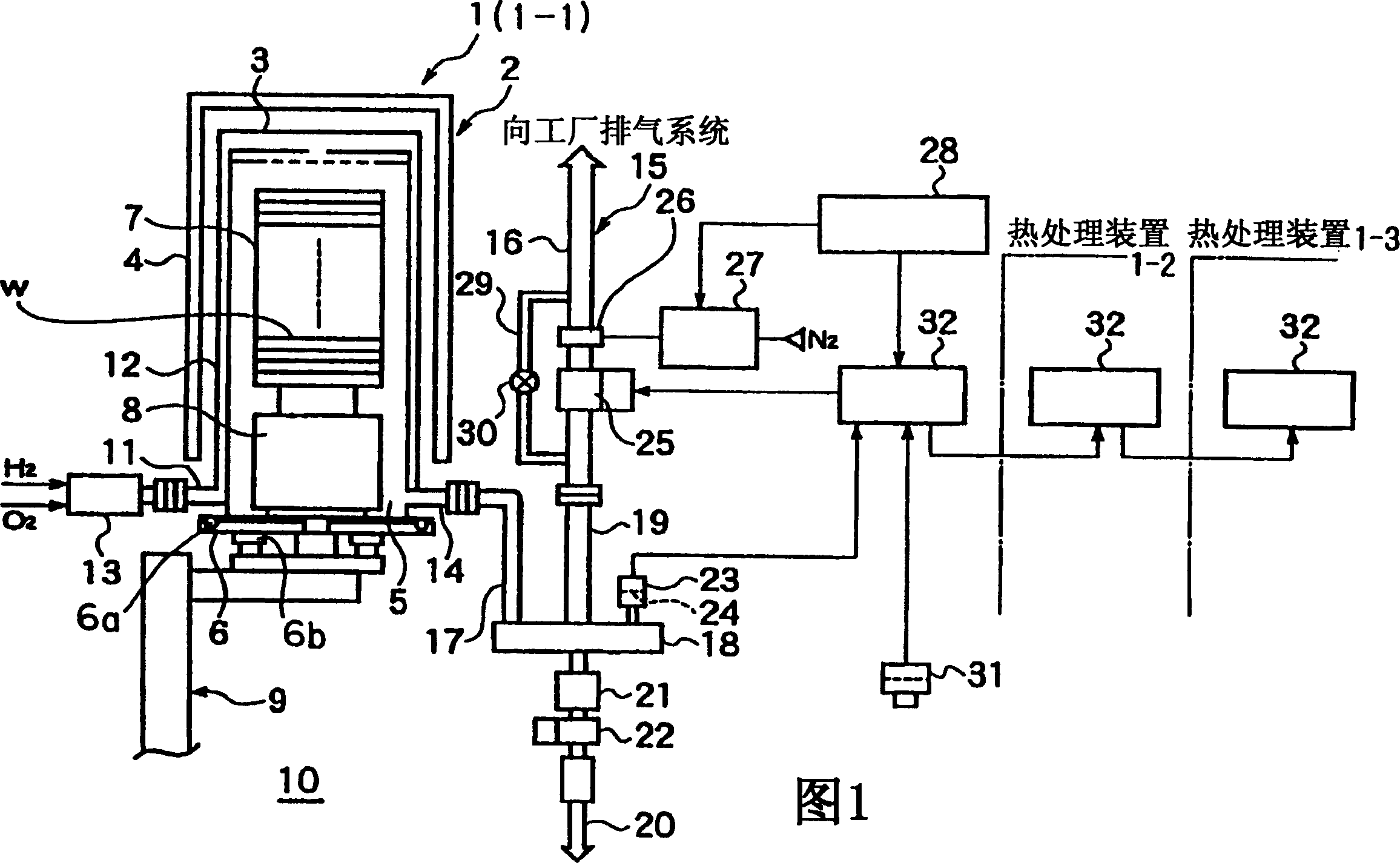

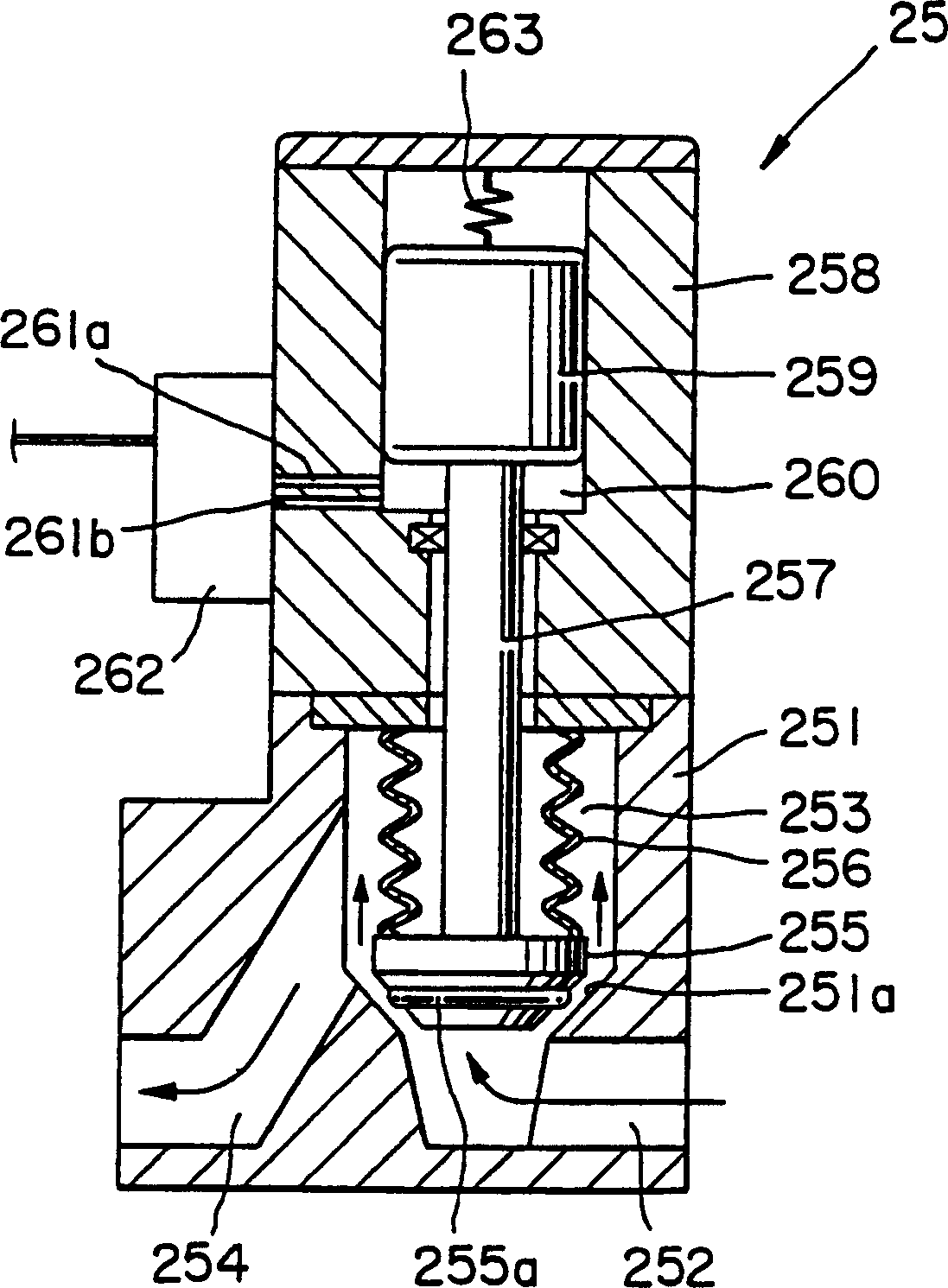

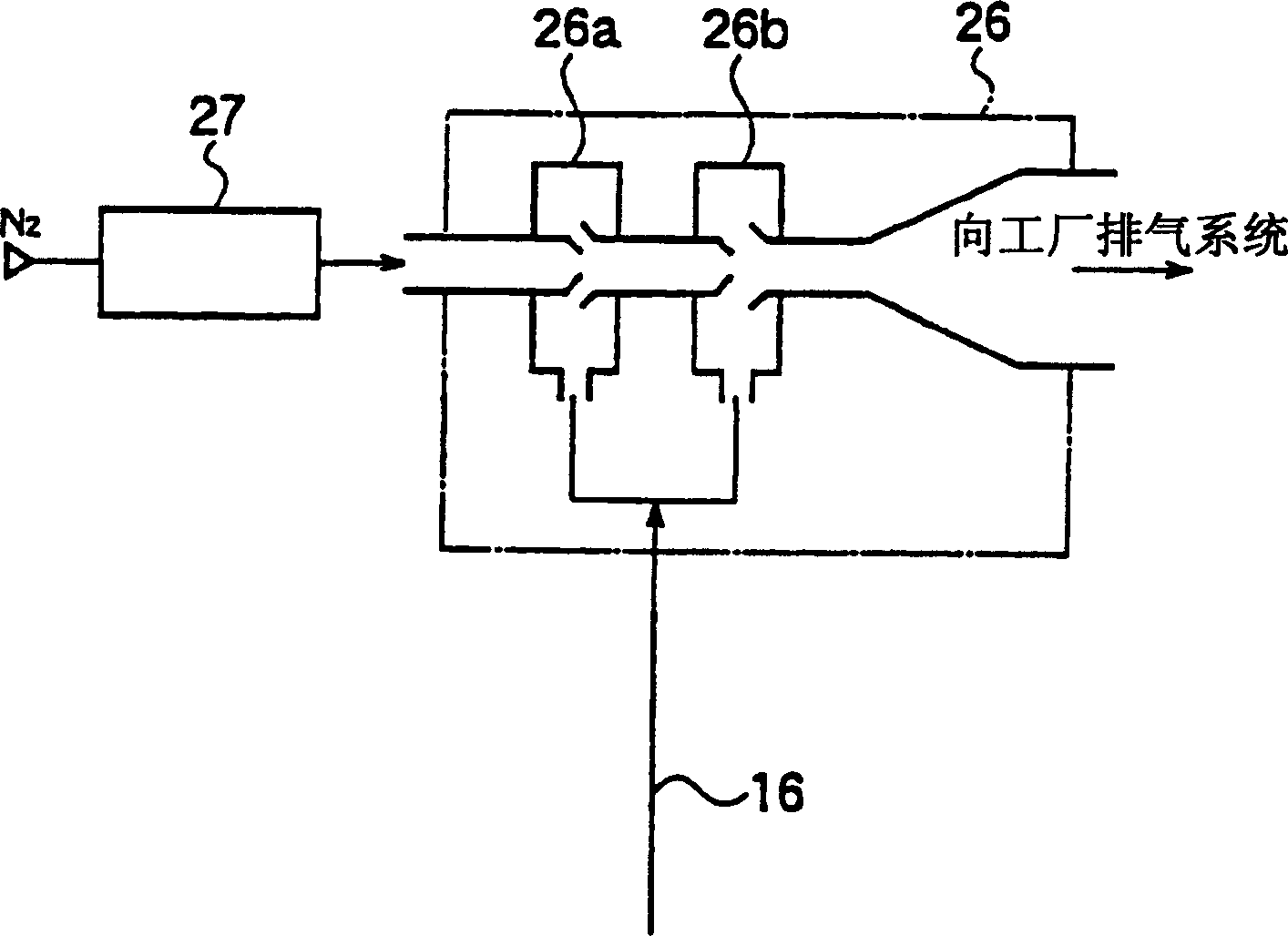

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0024] In FIG. 1, reference numeral 1 denotes a heat treatment apparatus configured for thermal oxidation treatment. The heat treatment apparatus 1 has a vertical batch type treatment furnace 2 . After the semiconductor wafer W is placed in the processing furnace 2, a processing gas is introduced into the processing furnace 2, and a thermal oxidation treatment is performed at a high temperature of about 850°C. As the processing gas when performing the thermal oxidation treatment, a gas containing moisture (for example, a mixed gas of water vapor or water vapor and hydrogen chloride gas) and a gas capable of reacting in the treatment furnace 2 to generate moisture (for example, hydrogen chloride gas and hydrogen chloride gas) can be used. Oxygen mixture). The processing furnace 2 has a vertically long cylindrical shape with a closed upper end and an open lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com