Device for the stepwise transport of liquid utilizing capillary forces

A technology of transmission equipment and capillary tubes, which is applied in the direction of laboratory containers, analytical materials, fluid controllers, etc., and can solve problems such as limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

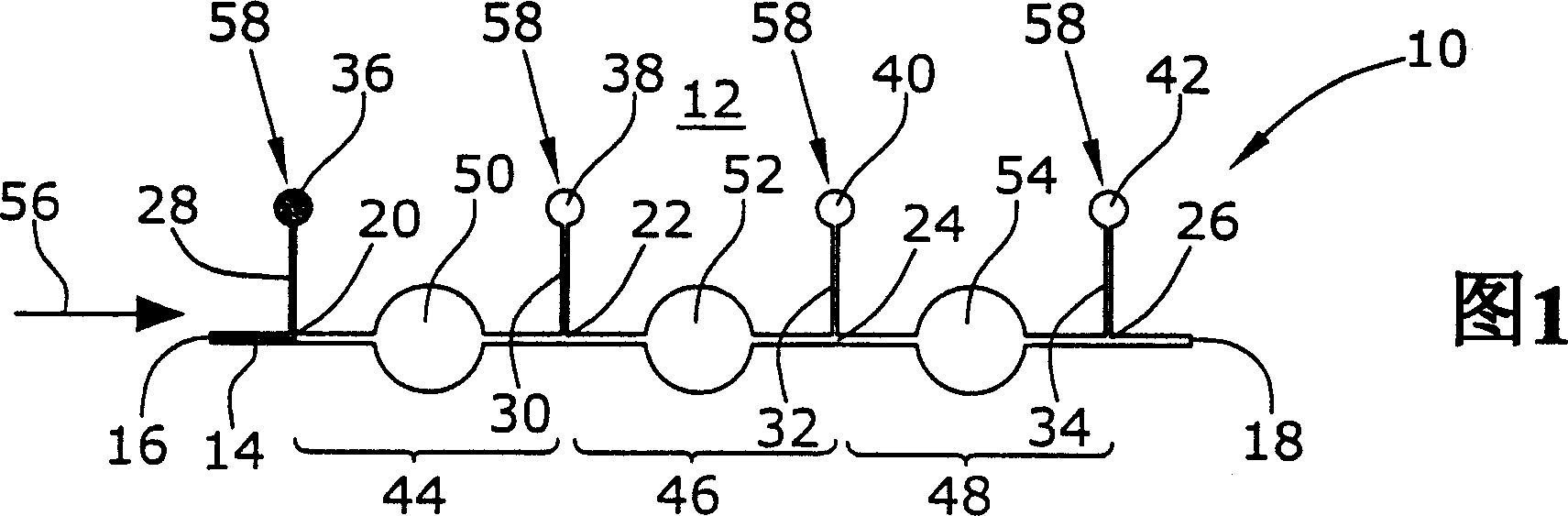

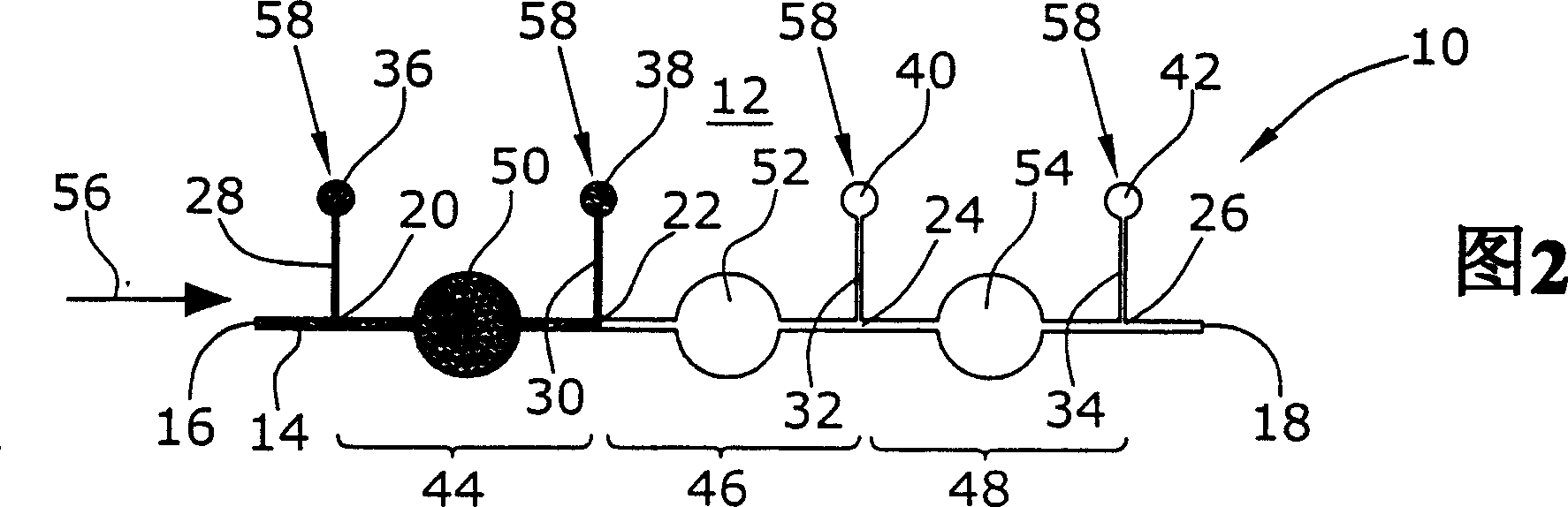

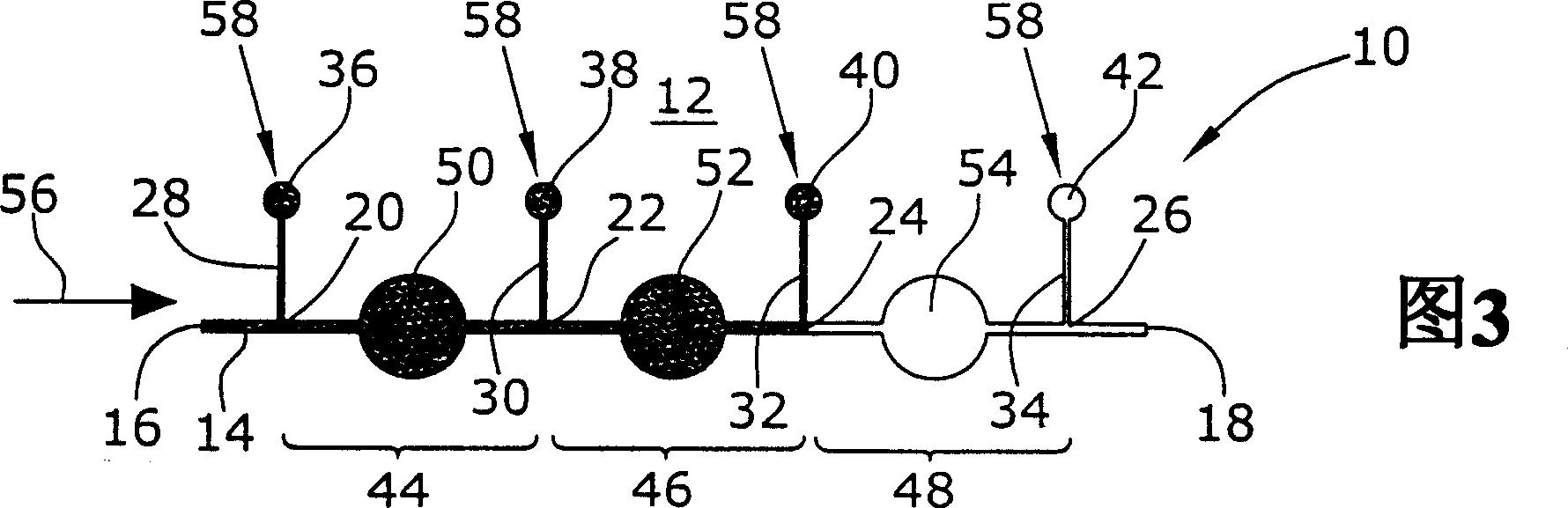

[0028] Figure 1 shows the basic structure of a capillary tubing system 10 according to the invention. Capillary tubing 10 is formed in a substrate 12 (plastic substrate, etc.) and includes conduit 14 including an inlet 16 and an outlet 18 in fluid communication with a container not shown. The liquid in the conduit 14 is transported in the conduit by capillary force.

[0029] Conduit 14 includes several connection points 20, 22, 24 and 26 (four in this embodiment) from which branch off exhaust pipes 28 terminating in exhaust holes 36, 38, 40 and 42, 30, 32 and 34. Conduit 14 is divided by connection points 20 , 22 , 24 and 26 into separate conduit sections 44 , 46 and 48 ; in each conduit section 44 , 46 and 48 there is a reaction chamber 50 , 52 and 54 .

[0030] The capillary tubing system 10 shown in FIG. 1 can be selectively filled with liquid as described below.

[0031] In the initial state, all vent holes 36, 38, 40 and 42 of duct 14 and outlet 18 are closed. If the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com