Method of resin encapsulation, apparatus for resin encapsulation, method of manufacturing semiconductor device and resin material

A technology of resin encapsulation and resin materials, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as voids, resin curing, and resin waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

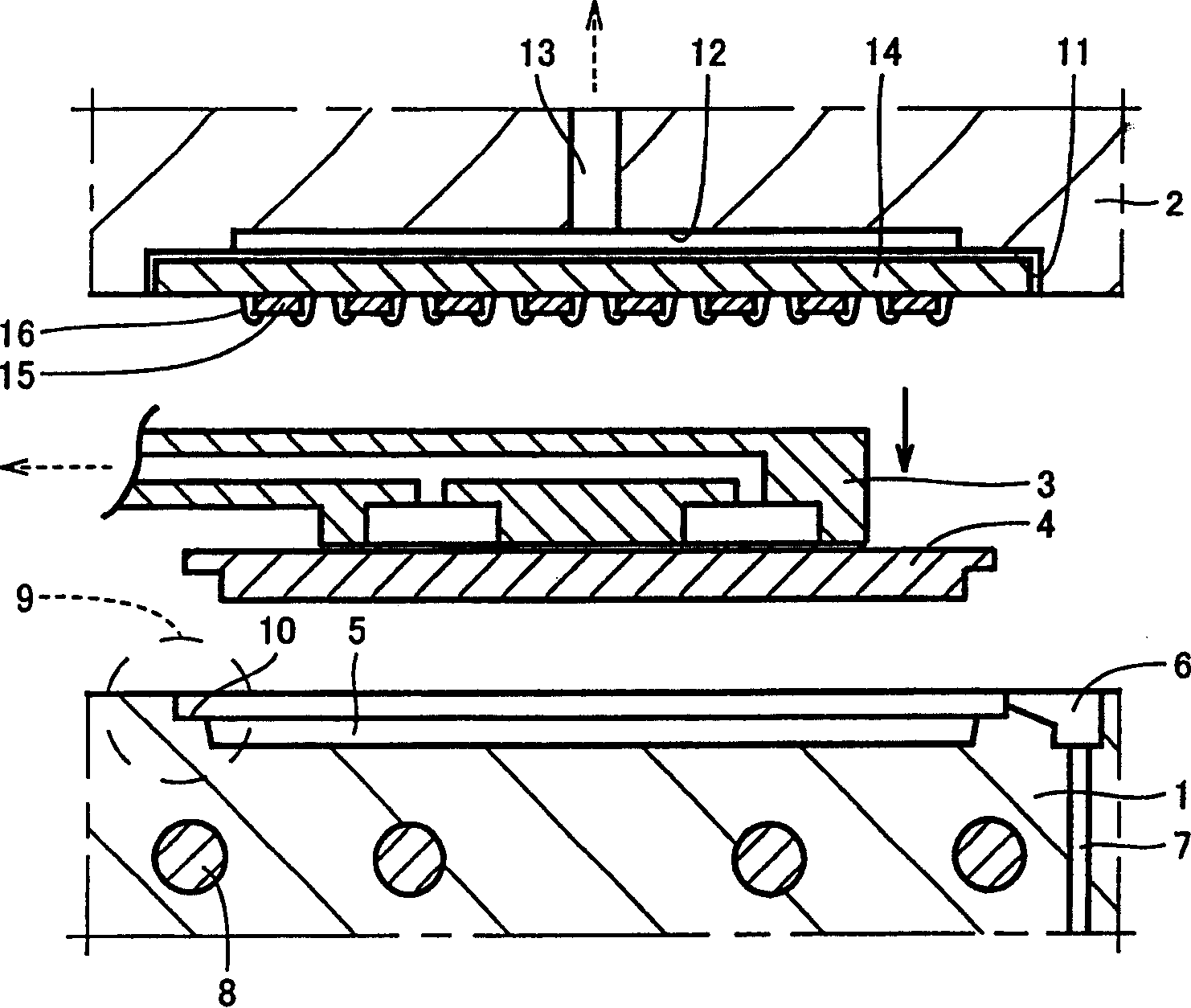

[0040] refer to Figure 1A ~ Figure 3B The resin sealing method of Embodiment 1 will be described.

[0041] Such as Figure 1A and Figure 1B As shown, in the resin encapsulation device used in the resin encapsulation method of this embodiment, a metal mold pair in which a lower mold 1 and an upper mold 2 face each other is provided. In addition, a pressurizing device (not shown) for closing and opening the lower mold 1 and the upper mold 2 is provided in the resin packaging device.

[0042] Figure 1A It shows the state where the conveyance unit 3 is installed in the space between the lower mold 1 and the upper mold 2 . The transfer unit 3 is in a state of being inserted into the space between the lower mold 1 and the upper mold 2 by the function of a driving device not shown. The transfer unit 3 can be transferred from the space between the lower mold 1 and the upper mold 2 to the outside by utilizing the function of the driving device. In addition, the resin material 4 ...

Embodiment approach 2

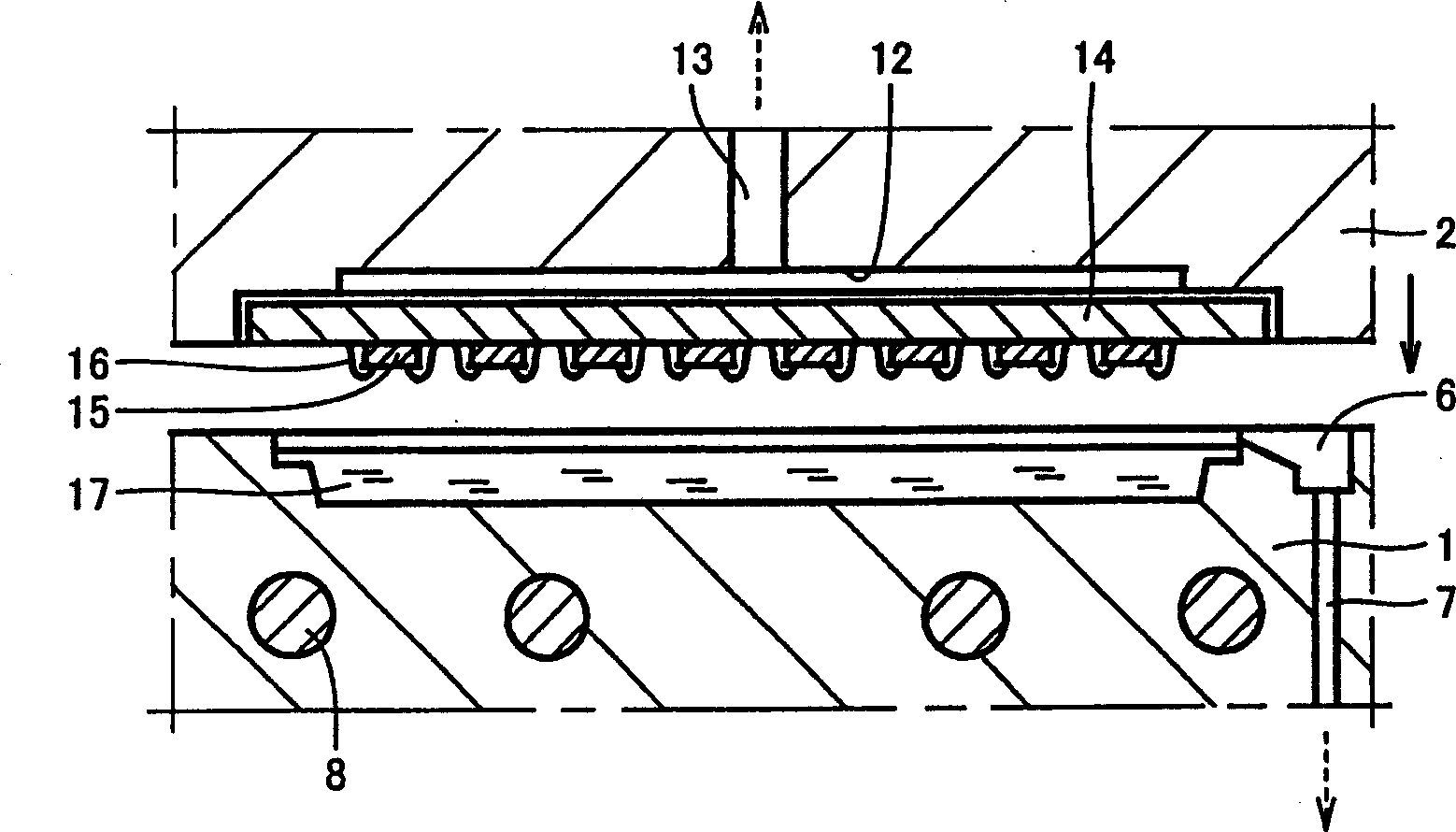

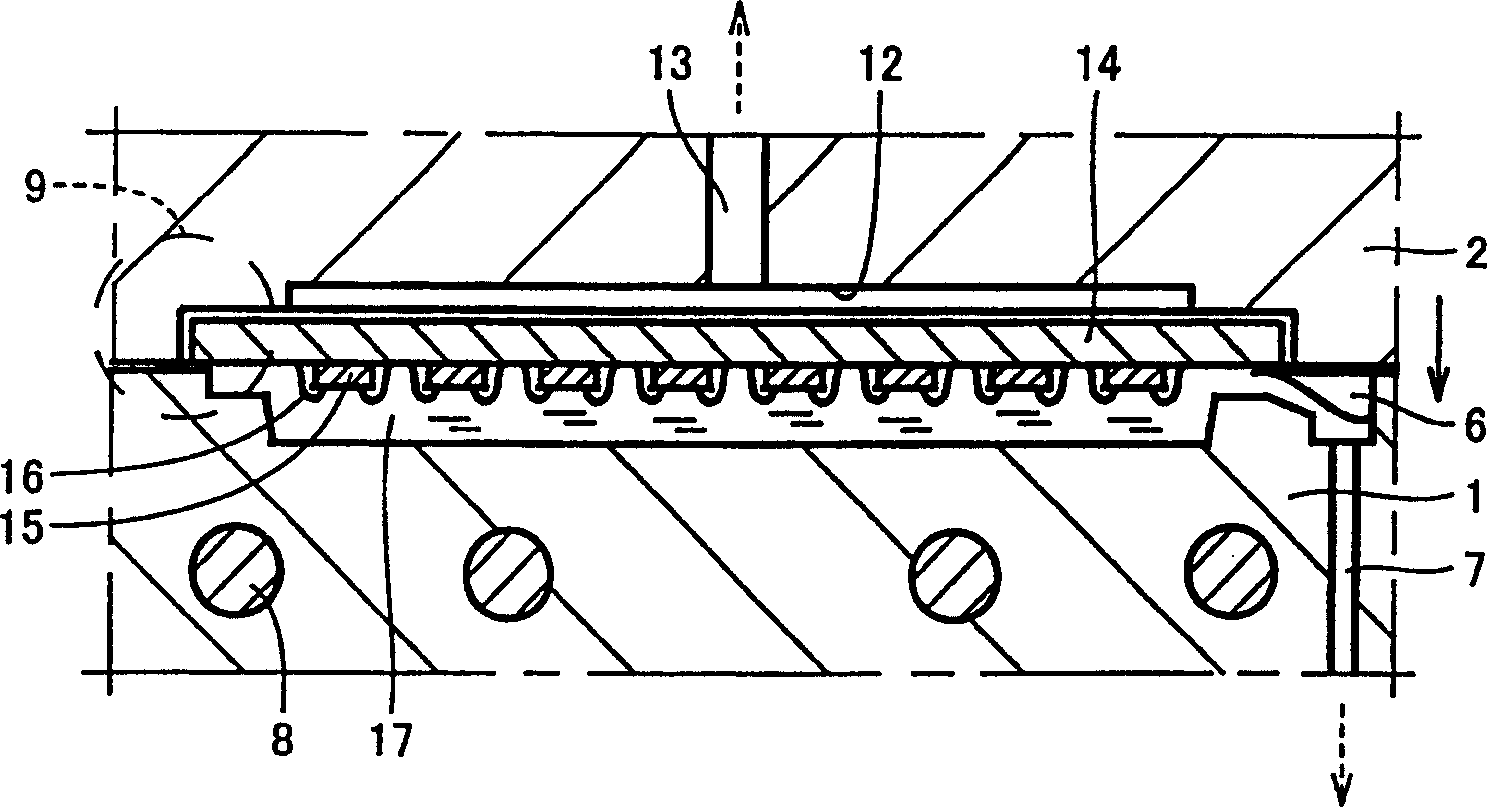

[0063] Below, refer to Figure 4A ~ Figure 5B The resin sealing method of Embodiment 2 will be described. Figure 4A ~ Figure 5B The structure of the resin sealing device of this embodiment is shown. Figure 4A ~ Figure 5B in and adopted Figure 1A ~ Figure 3B Components having the same names as the components of the resin sealing device according to Embodiment 1 described above have the same functions as those described in Embodiment 1, and therefore descriptions of the functions of these components will not be repeated.

[0064] Such as Figure 4A ~ Figure 5B As shown, in the resin sealing device of this embodiment, the substrate 14 is placed on the lower mold 21 , and the resin material 22 is placed on the substrate 14 . The resin material 22 has a size and shape corresponding to the size and shape of a cavity (described later) provided in the upper mold 25 . In addition, the resin material 22 is composed of a flat plate portion 23 and an edge portion 24 . Such as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com