Melting method and its device

A melting device and melting mechanism technology, applied in chemical instruments and methods, chemical/physical processes, heat treatment, etc., can solve problems such as thermal aging, long retention time, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

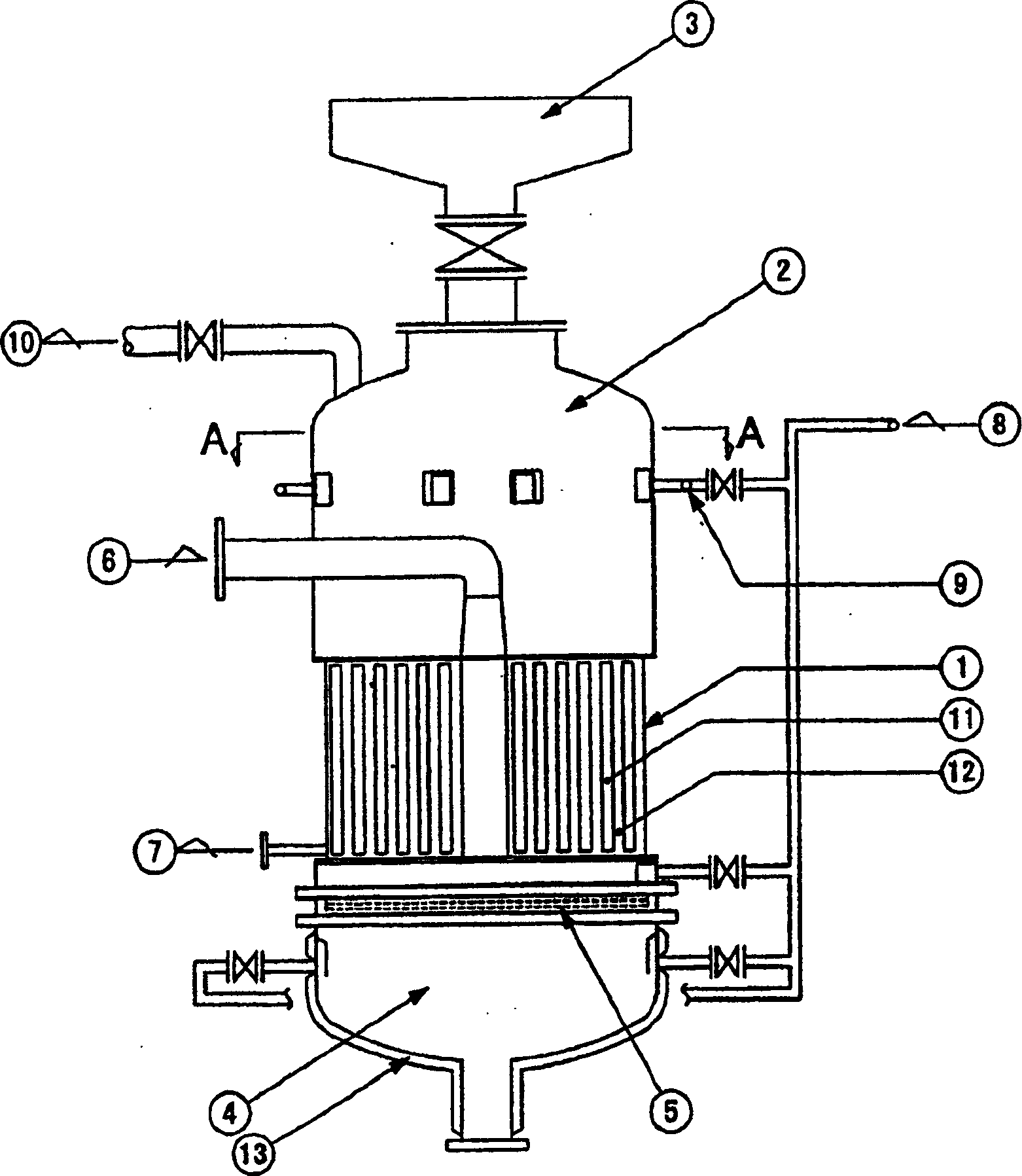

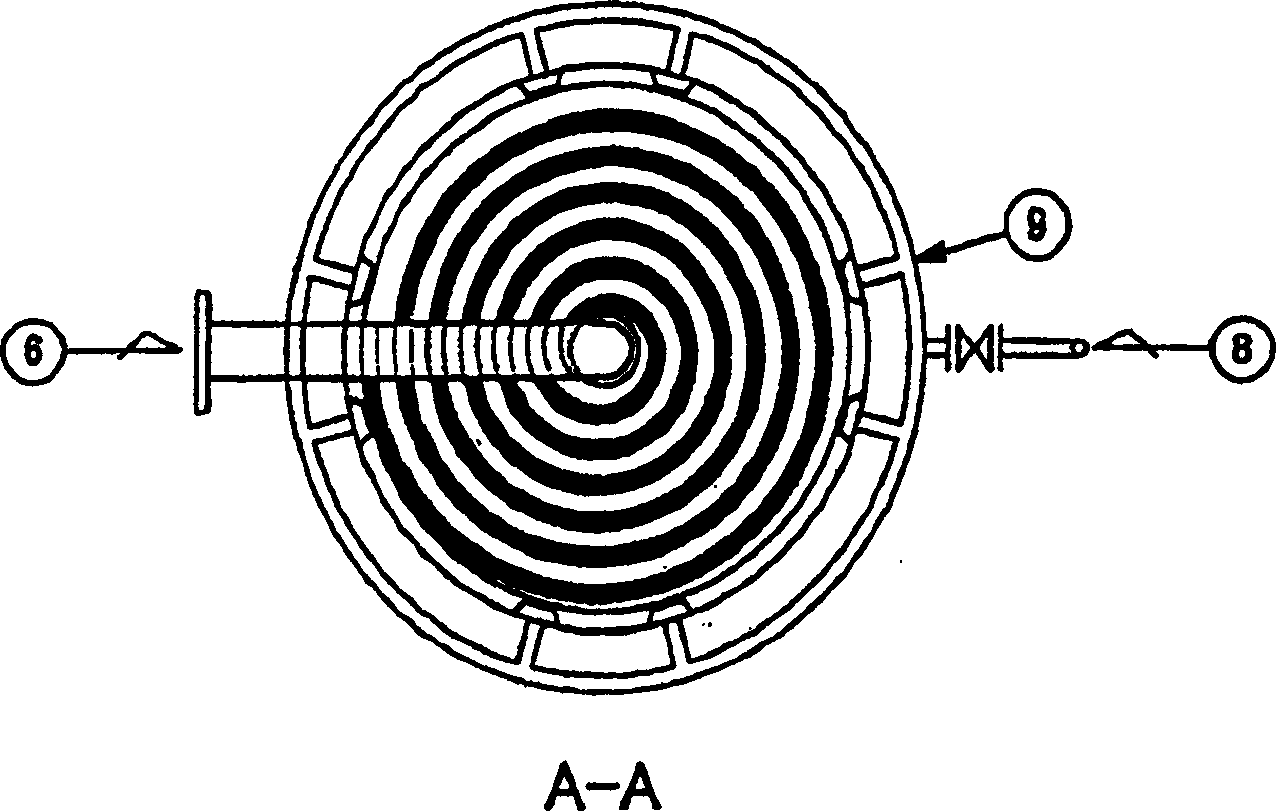

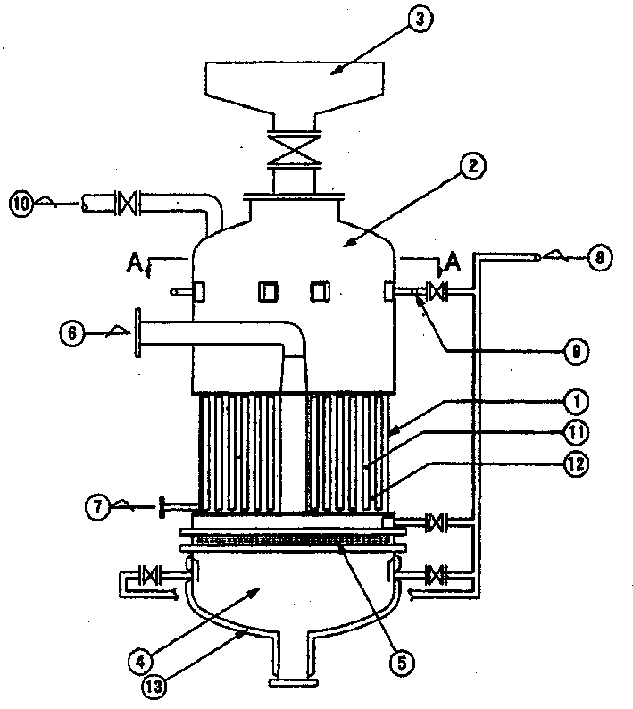

[0050] to have figure 1 The melting device with the structure shown, that is, the upper part has a feeding hopper (2), the bottom of the spiral heating and melting mechanism (1) has a metal mesh with a mesh of 0.25mm (5) with a support plate, and the lower part has a discharge of the melt mouth, with a heat transfer area of 4m 2 And the width of the helical axial flow path b is 8mm, and the spiral flow path a and the axial flow path b with the spiral length of 40cm are provided in the melting device of the KSH-2 type helical heat exchanger manufactured by Clothy Company. Saturated steam of 0.5MPaG, 158°C, while vacuum exhausting and nitrogen flow flow, continuously supply in the shape of a meniscus lens (circular diameter of the outer peripheral edge is 5mmφ, the height of the convex surface is 4mm, and the depth of the concave surface is 300μm) The bis(2-hydroxyethyl) terephthalate pellets are melted, and as a result, bis(2-hydroxyethyl)terephthalate at 120°C can be contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com