Two-step underground pipe-driving construction process

A construction method and pipe jacking technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve problems such as inability to realize multi-purpose of one machine, inability to excavate, long construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

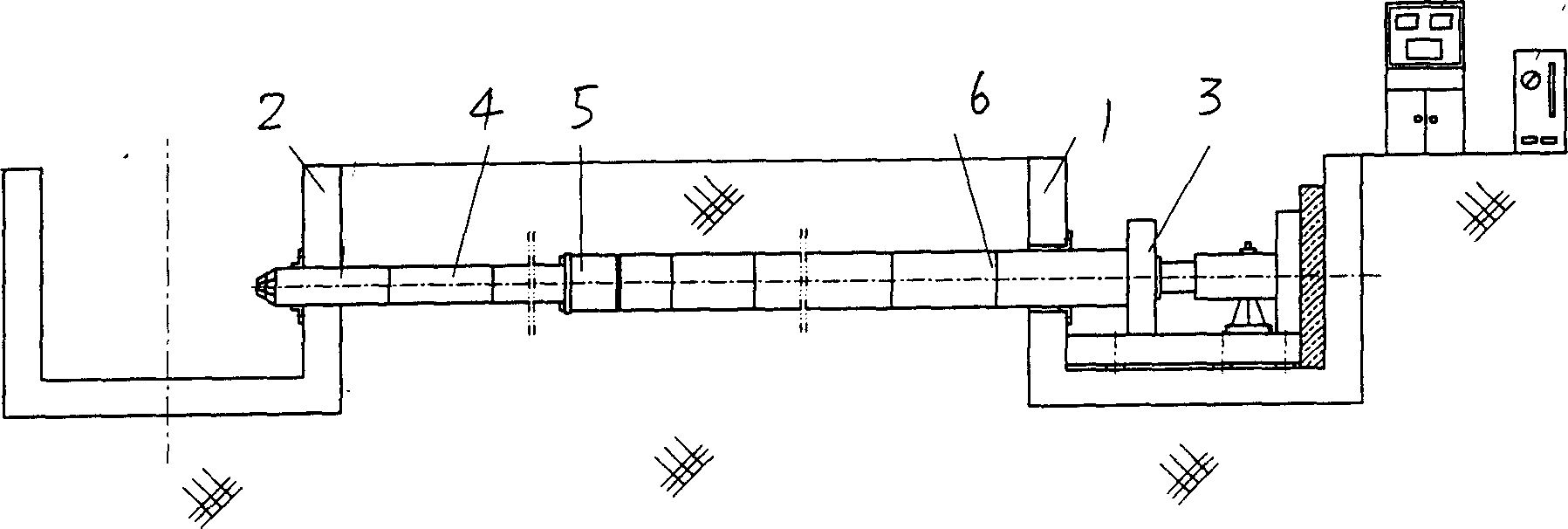

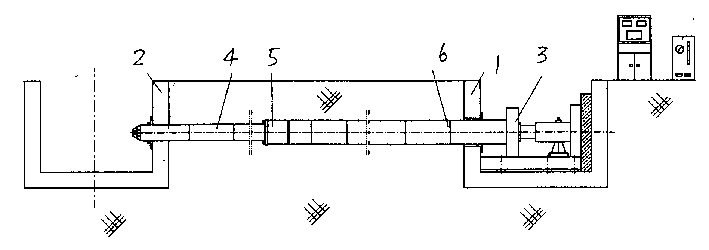

[0005] The figure includes a working well 1 and a receiving well 2 for pipe jacking construction between the two ends of the scheduled laying. A guide steel pipe 4 is jacked between the working well 1 and the receiving well 2, and then the guide steel pipe 4 is used as the guide, and the cutter head reamer 5 or extrusion reamer 5 is pushed by the propulsion device 7 to carry out reaming and forming. The laid pipes 6 are pushed in joint by joint with the reamer 5 , and the guide steel pipe 4 is pushed out by the cutter head reamer 5 or extrusion reamer 5 and recovered by the receiving well 2 . When encountering the cutter head reamer 5 and carrying out the reaming and forming under the propulsion device 7, the soil broken in the cutter head reamer 5 is rushed to the guide steel pipe 4 by the high-pressure water in the cutter head reamer 5, and then Received from receiving well 2 outflow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com