Apparatus for stacking and delivering non-woven fabric fiber-net

A technology of non-woven fabrics and fiber webs, applied in the directions of non-woven fabrics, fabrics, fiber processing, etc., can solve the problems of poor quality, damage, oversize, etc., and achieve the effect of easy cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

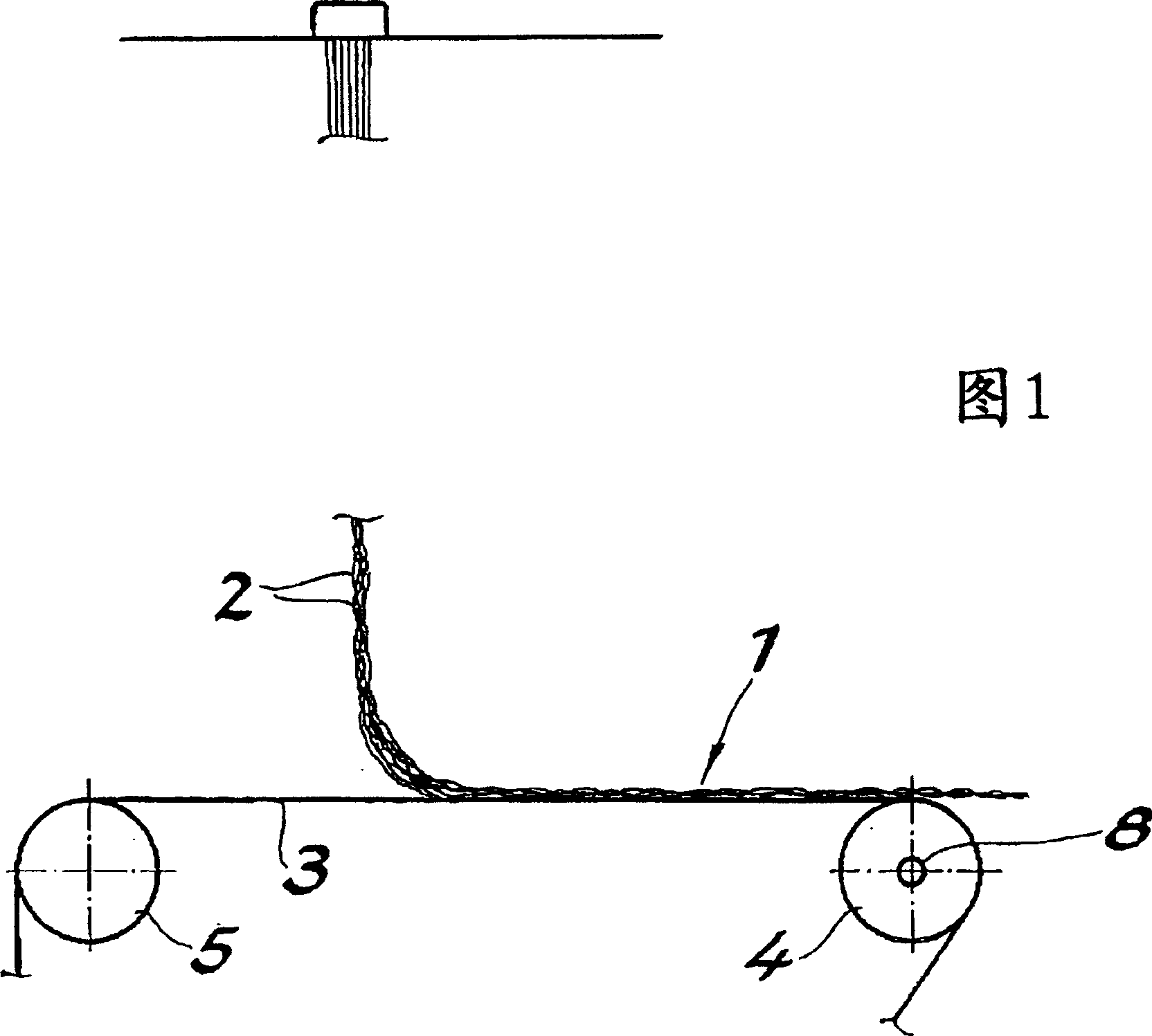

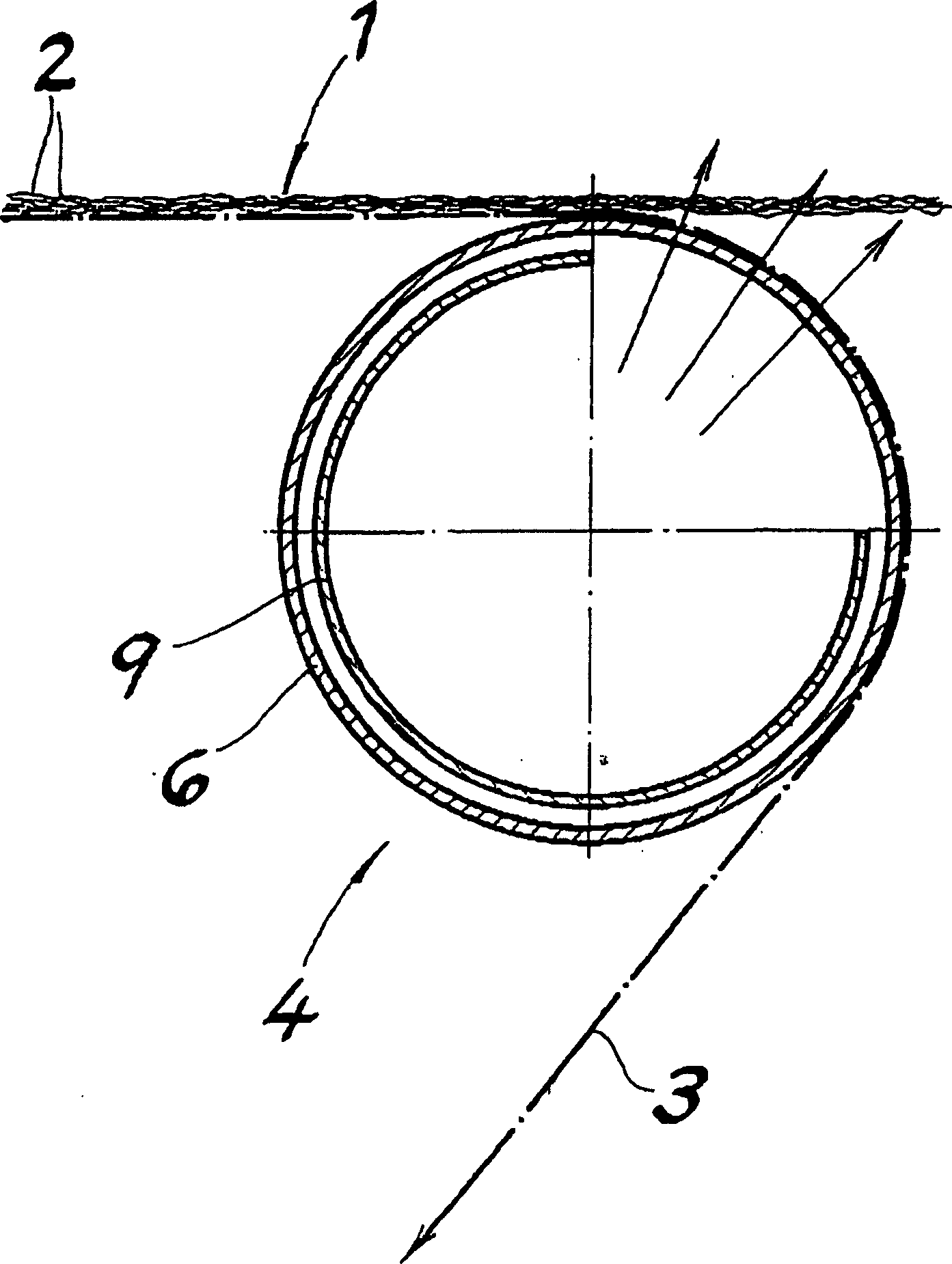

[0018] FIG. 1 shows a device for stacking and transporting a nonwoven web 1 consisting of plastic threads 2 . The plastic filaments 2 emerge in a molten state from suitable spinneret holes not shown and are finally deposited on the surface of the laying belt 3 for the nonwoven web 1 . The overlapping web belt 3 is in this embodiment a continuously circulating overlapping web belt 3 guided by rollers 4 , 5 . In FIG. 1 , on the right-hand side of the horizontal part of the superimposed belt 3 which receives the nonwoven web 1 , there is a first roller 4 which is designed as a deflection guide roller in this exemplary embodiment. Here, the continuously circulating superimposed web belt 3 is diverted downwards around the first roller 4 from its horizontal transport position for the nonwoven web 1 .

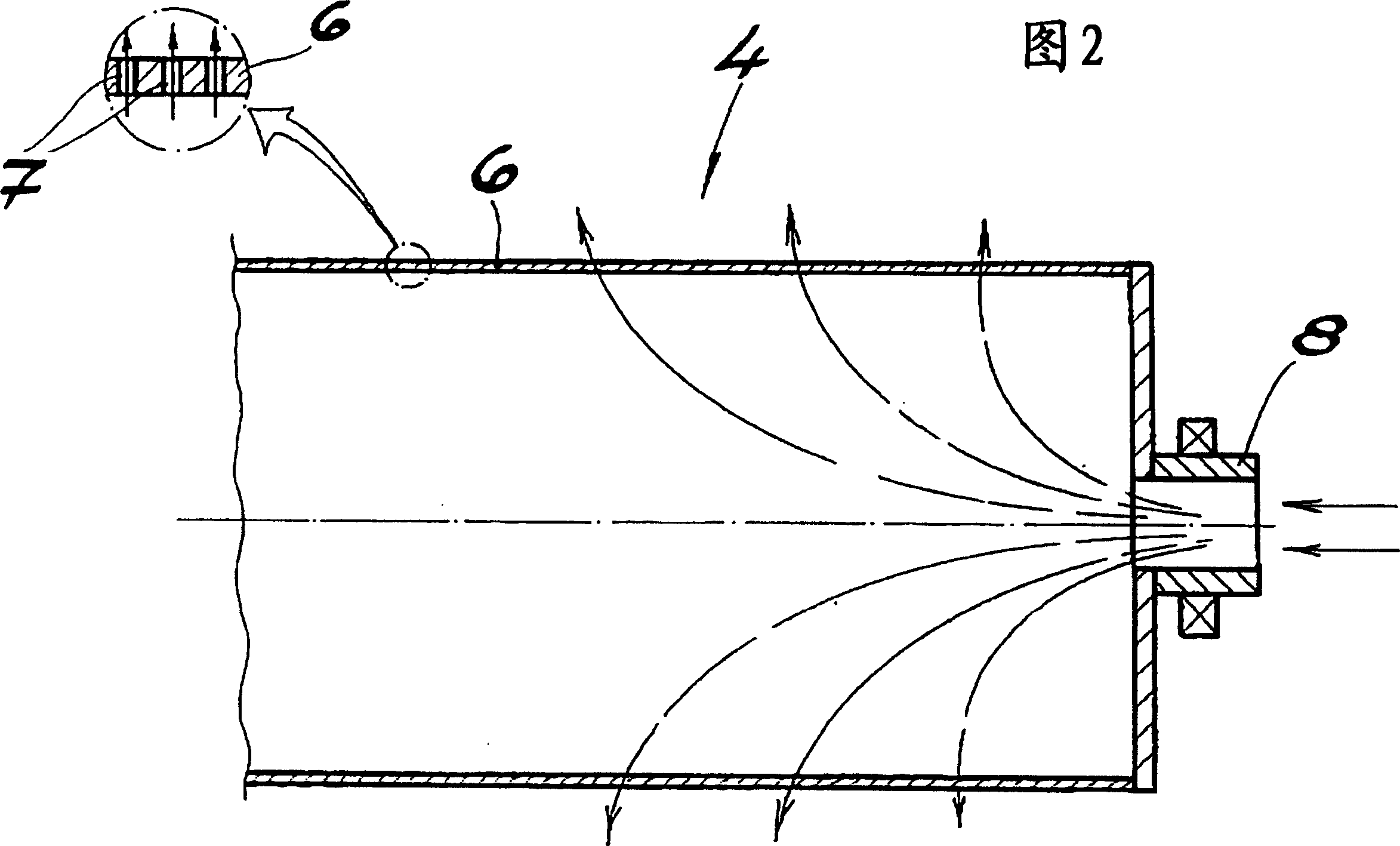

[0019] According to the invention, the first roller 4 has outlet openings 7 distributed along its roller jacket 6 . The discharge holes 7 are provided for the discharge of a fluid m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com