Tungsten composite X-ray target assembly for radioactive treatment

A ray and component technology, applied in the directions of X-ray tube parts, X-ray tube target materials, X-ray tube targets and converters, etc., can solve problems such as water leakage cracks, reduce cracks and reduce the risk of cooling fluid leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

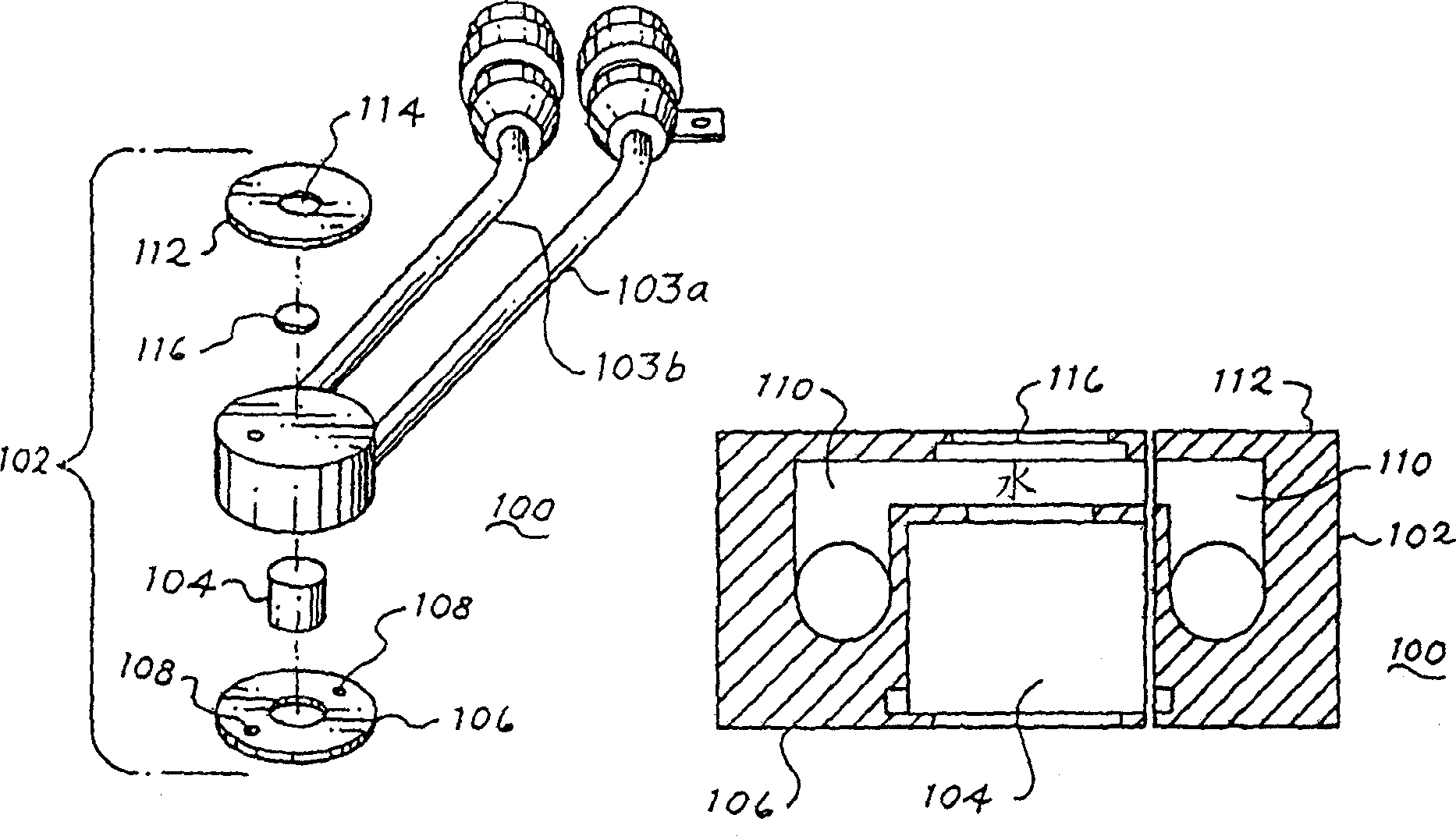

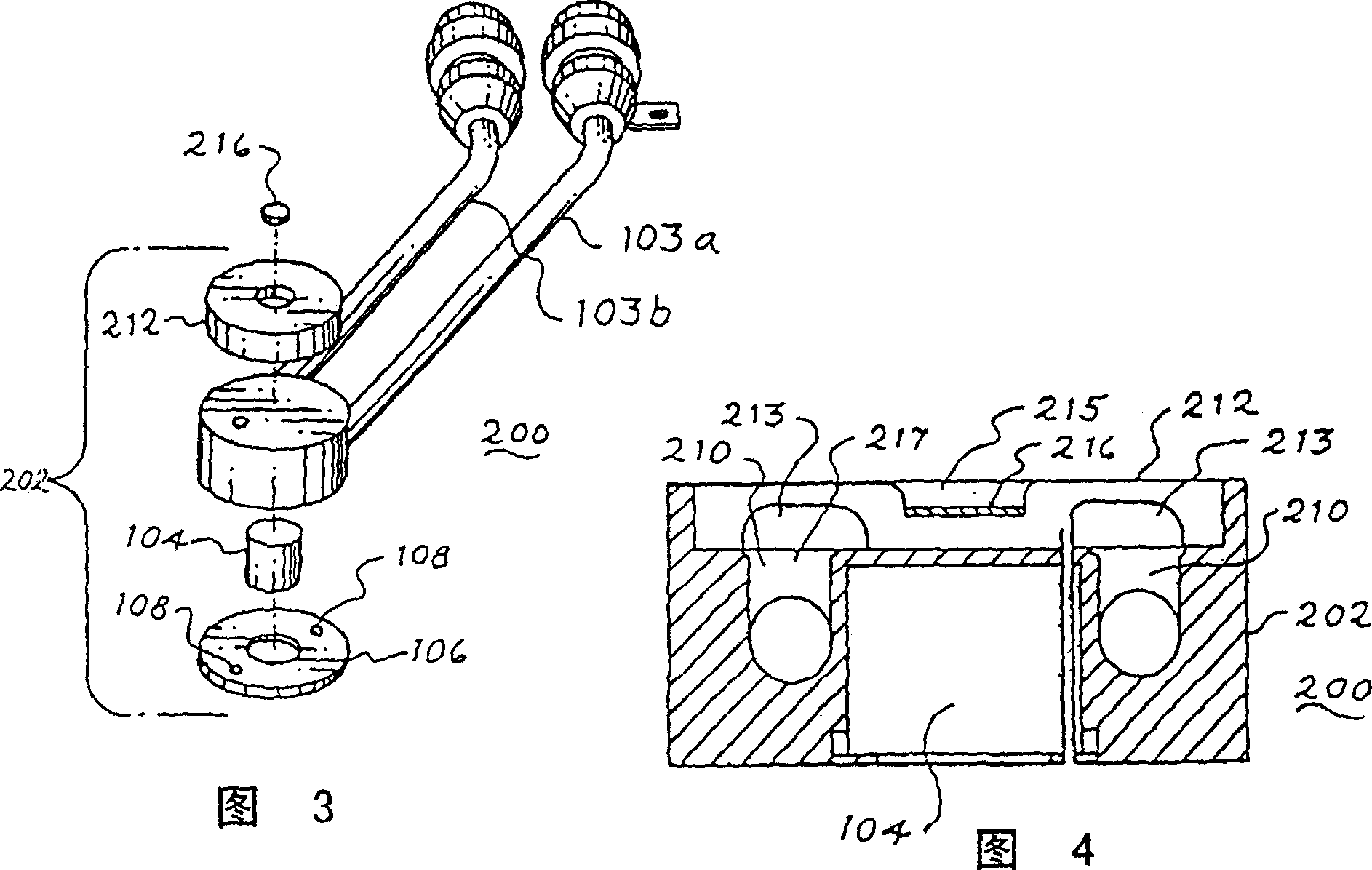

[0022] An X-ray target assembly for various applications including medical radiation therapy according to an embodiment of the present invention will be described below with reference to FIGS. 3 and 4 . X-ray target assembly 200 is similar in some respects to x-ray target assembly 100 and, accordingly, like numbers are used to refer to like parts.

[0023] X-ray target assembly 200 includes a stainless steel cylindrical housing 202 supported by a pair of tubes 103 . Inside the housing 202 , a graphite cylindrical electron absorber 104 is mounted in the center of the housing 202 and supported on an annular bottom part 106 of the housing 202 . The ring-shaped bottom part 106 is connected to the housing 202 by mechanical fixing means, such as screws in the opening 108 of the insertion part 106 and the opening of the housing 202 .

[0024] As shown in FIG. 4 , an annular groove 210 is formed in the housing 202 . On top of recess 210, a copper heat dissipating top lid 212 of hous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com