Method and equipment for producing plastic cup food can, and can food thereof

The technology of processing equipment and processing method is applied to the processing, processing equipment and food canning fields of plastic cup food cans, which can solve the problems of inconvenience in eating, affecting the appearance and reducing productivity, etc., and achieves convenient and hygienic consumption, and uniform processing and disinfection. , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

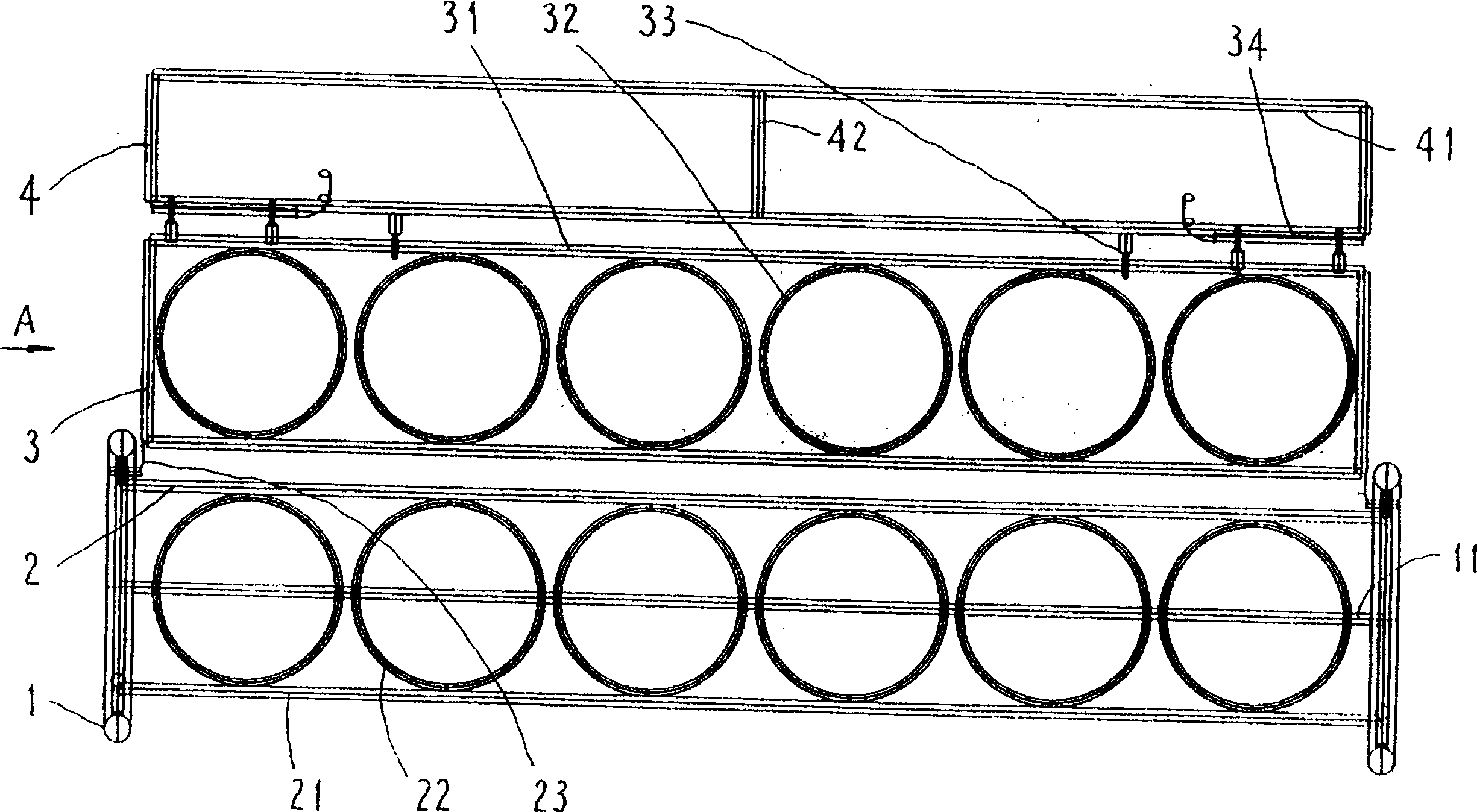

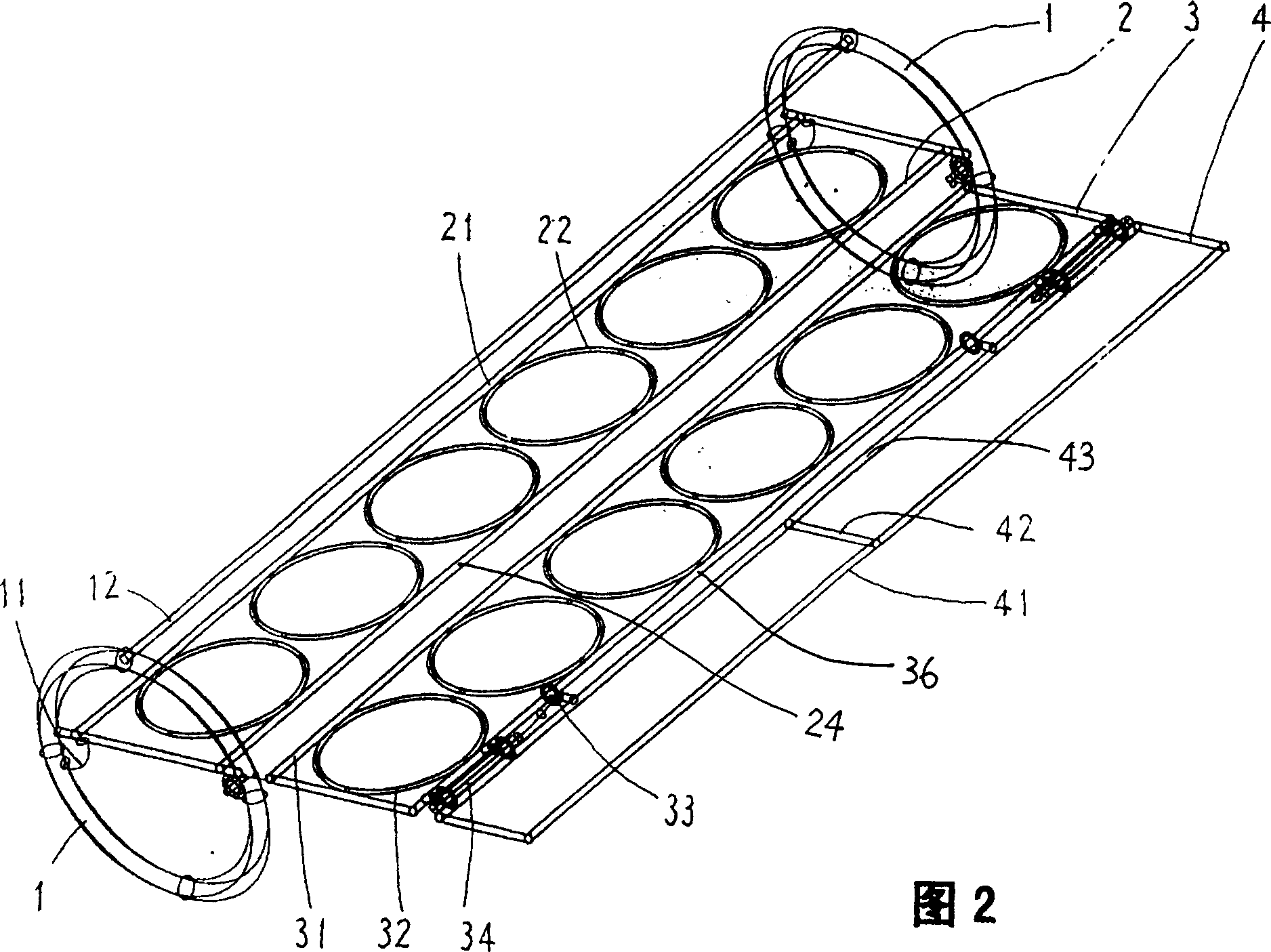

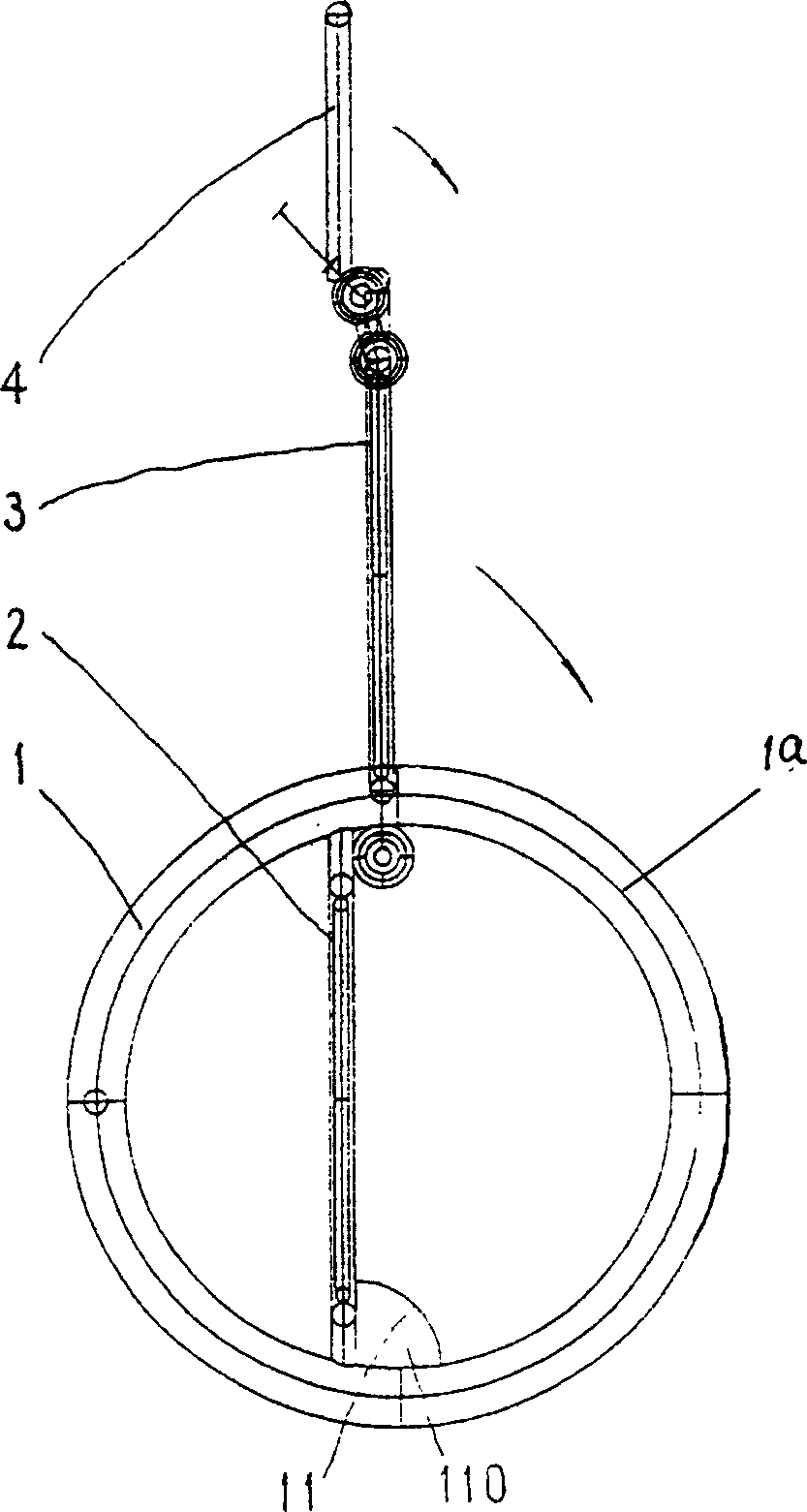

[0028] see figure 1 , 2 and 3, the rotary sterilization clamp of an embodiment of the present invention comprises: two rolling rings 1 that the torus faces are arranged oppositely, and the torus here is defined as the central axis 1a of the rolling ring 1 ring itself (see image 3 ) plane; the first frame body 2 fixedly connected to the two rolling rings 1 between the torus surfaces of the two rolling rings 1; the second frame body rotatably connected to the first frame body 2 between the two rolling rings 1 torus surfaces 3.

[0029] The positions where the two rolling rings 1 are fixedly connected to the first frame body 2 are slightly lower than the centerline of the rolling rings 1, the plane formed by the first frame body 2 is perpendicular to the ring surface of the rolling ring 1, and the plane of the second frame body 2 Slightly lower than the center position of the torus of rolling ring 1.

[0030] After the second frame body 3 is rotated to overlap with the first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com