Roll conveyer

A conveyor and roller technology, applied in the direction of conveyors, conveyor objects, rollers, etc., can solve problems such as scratches, low substrate strength, and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] An embodiment of the present invention will be described below with reference to the drawings.

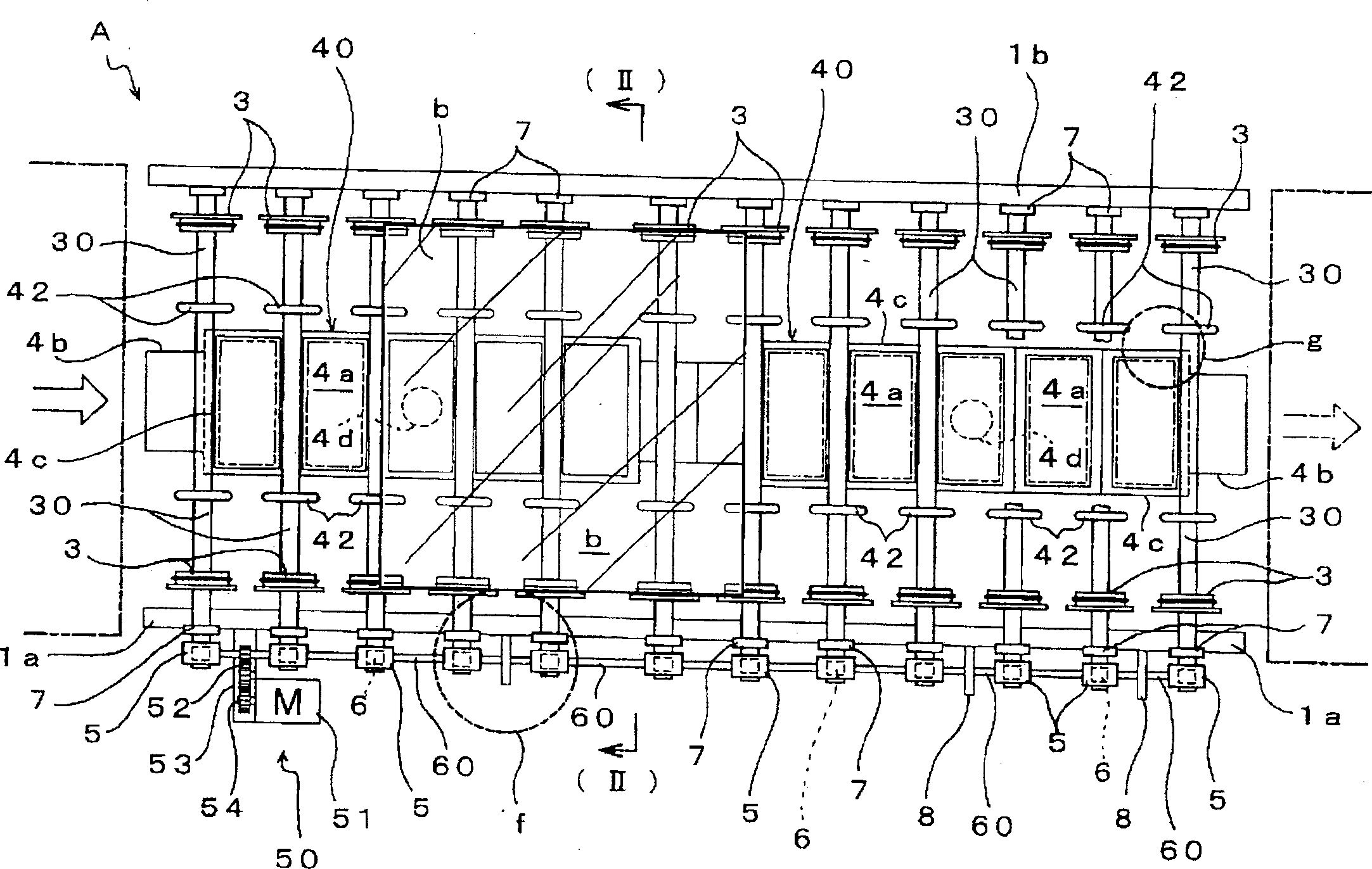

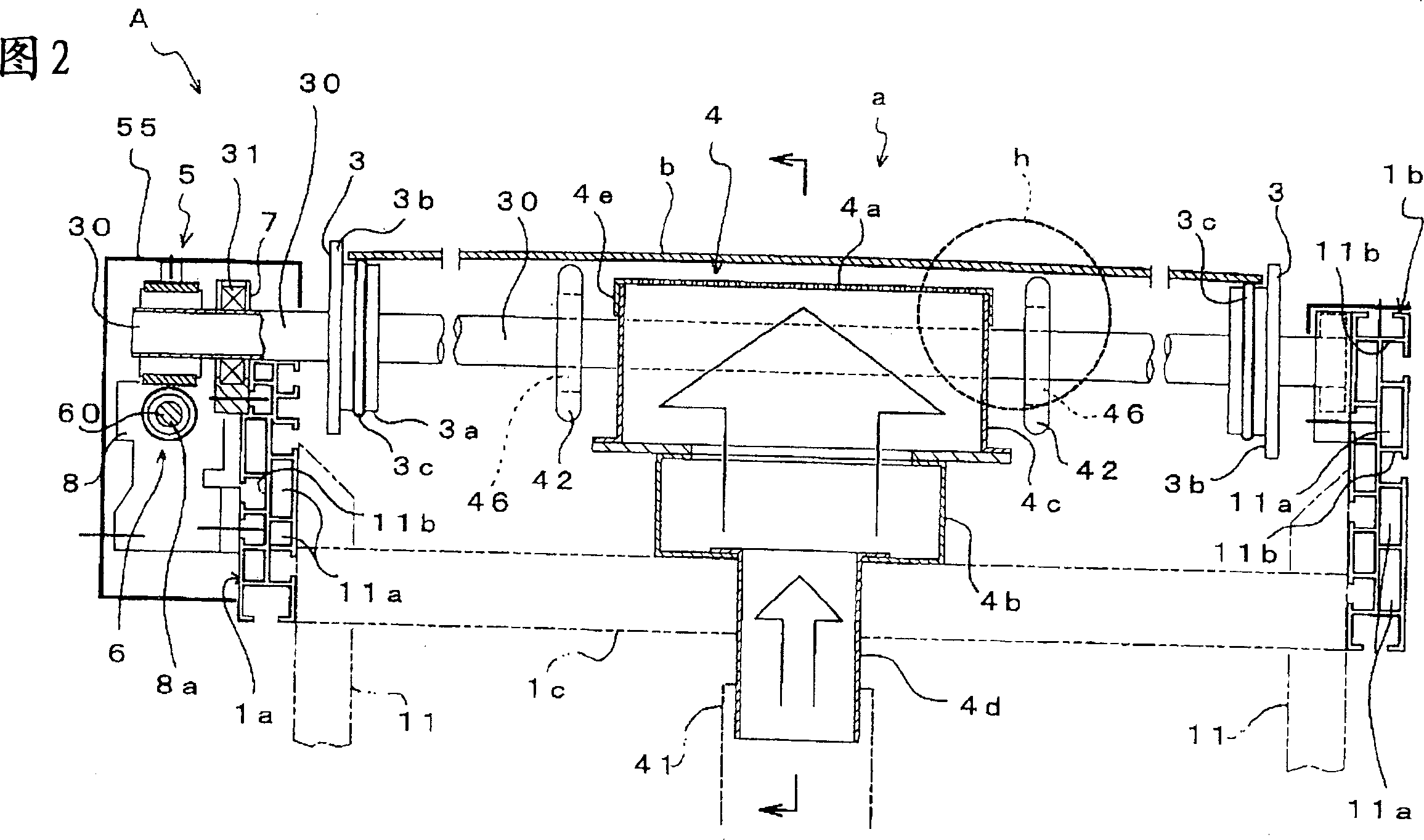

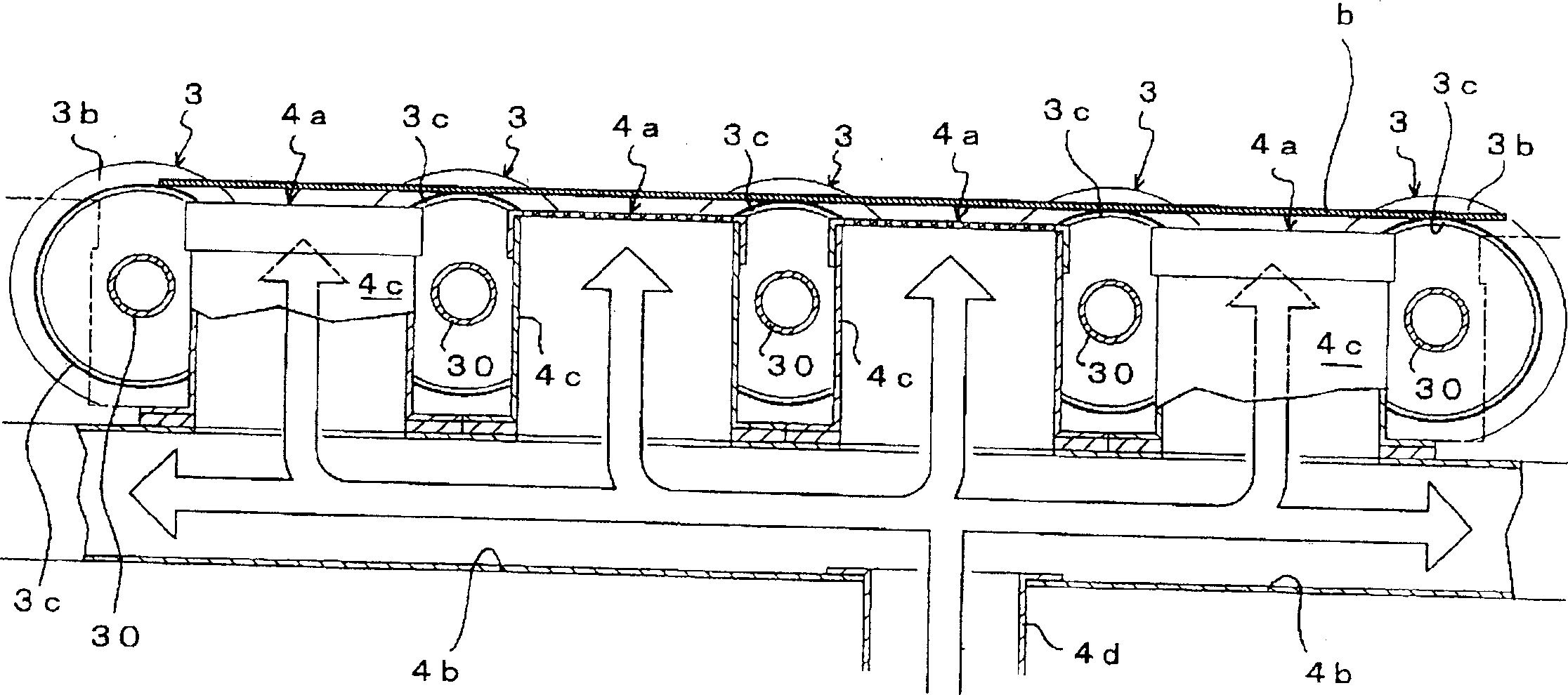

[0031] Figure 1 to Figure 3 Roller conveyor A embodying the invention is shown. This roller conveyor A has two left and right frames 1a, 1b supported by legs 11, and a support shaft 30 on which the rolling rollers 3 are mounted is provided between the frames 1a, 1b.

[0032] The left and right frames 1a, 1b are elongated plate-shaped bodies formed by extruding aluminum, as shown in the cross-sectional view of Figure 2, hollowed out to form a hollow part 11a and gaps for inserting bolts, nuts, fixing parts, etc. Groove 11b etc. Between the lower parts of these frames 1a, 1b, a connecting rod 1c is horizontally provided to connect the left and right frames 1a, 1b.

[0033] The roller conveyor A of this embodiment is a mechanism for conveying panels with a width of approximately 700mm to 800mm and 1200mm to 1500mm, and it conveys substrates such as liquid crystal display pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com