Method for mfg. vortex compressor and its cross ring

A technology for scroll compressors and Oldham rings, applied in the direction of rotary piston machinery, rotary piston/swing piston pump components, mechanical equipment, etc., can solve the problem of sticking, easy wear of sliding parts, and reduce the support structure Lifespan and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

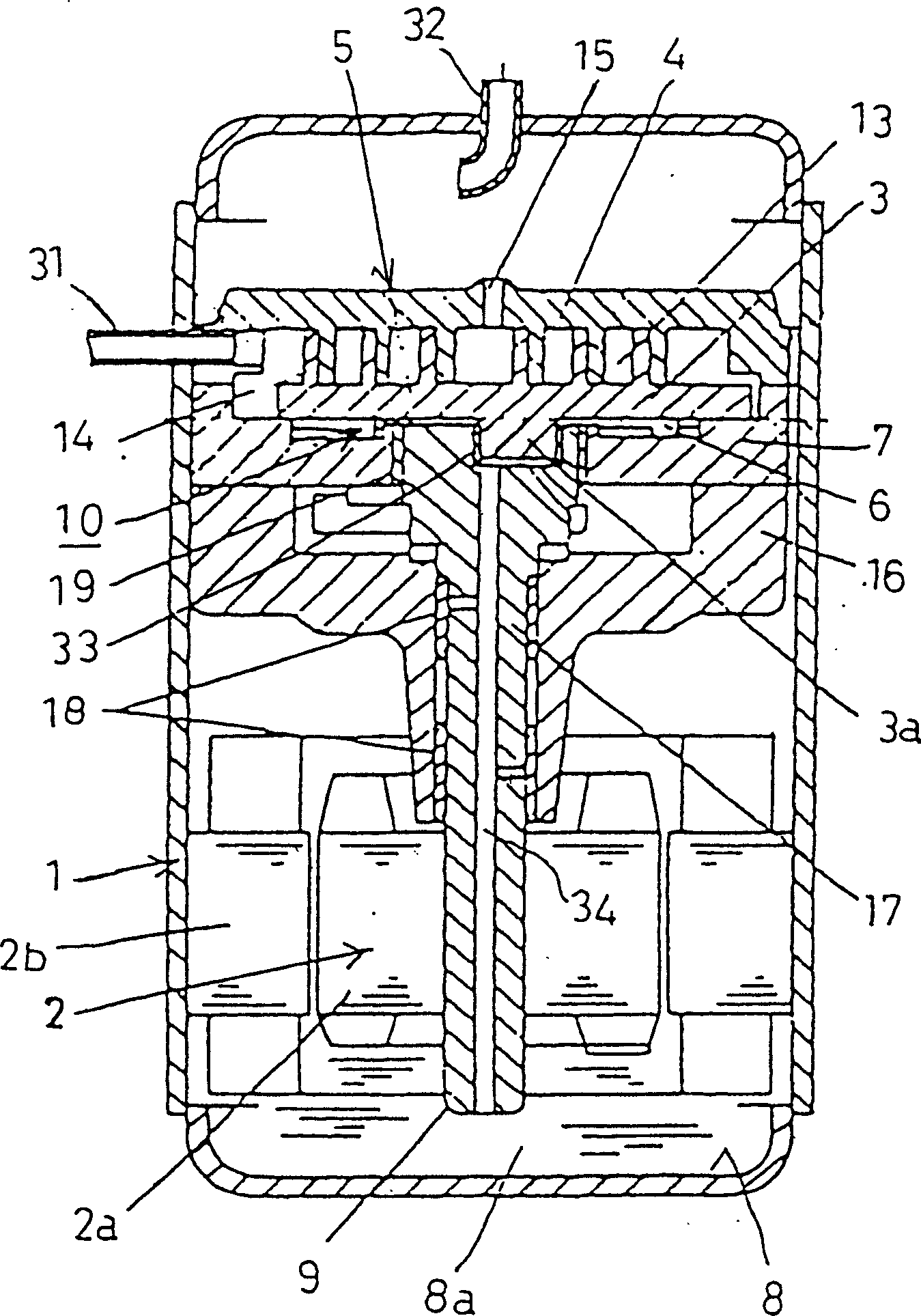

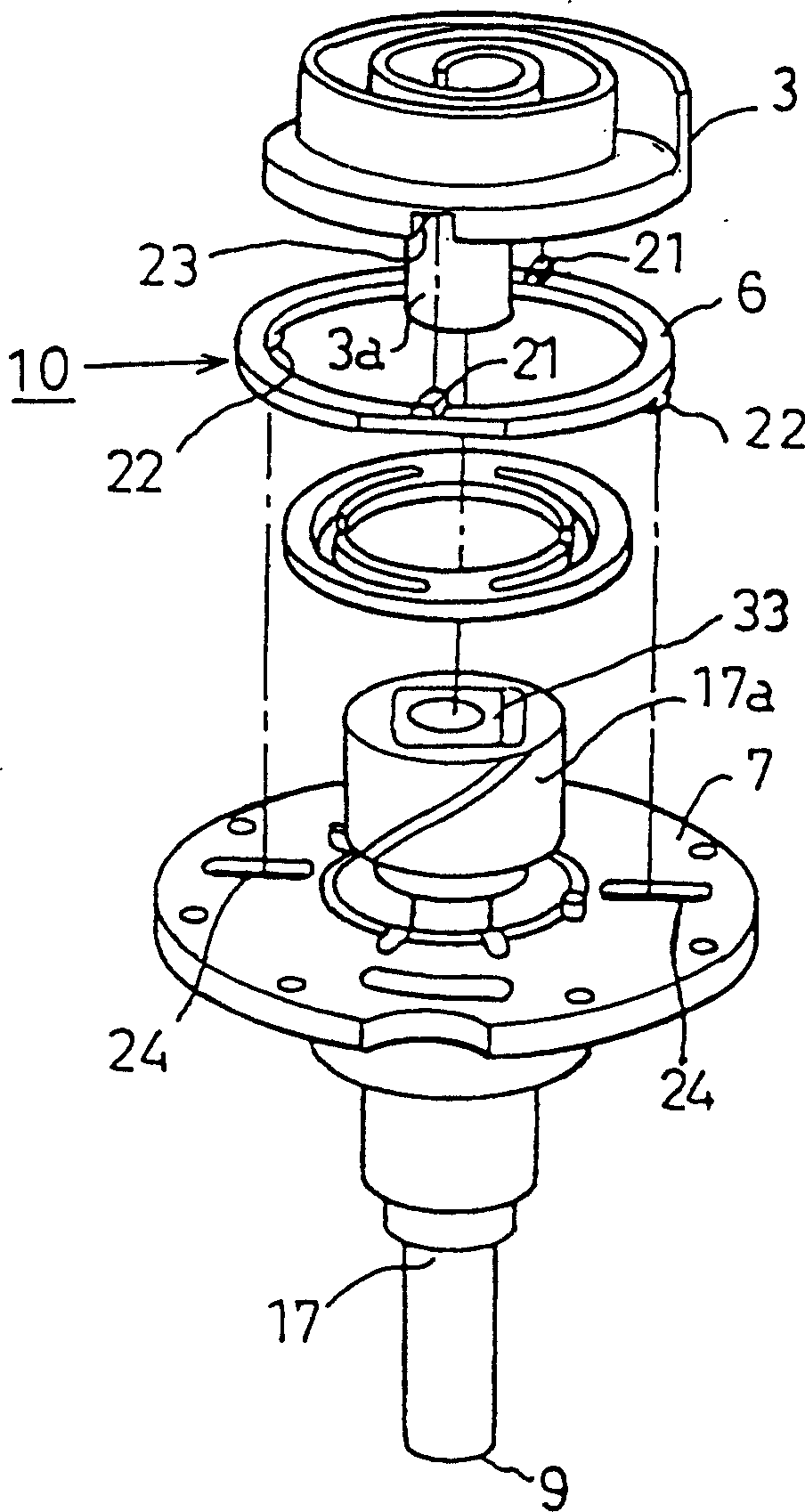

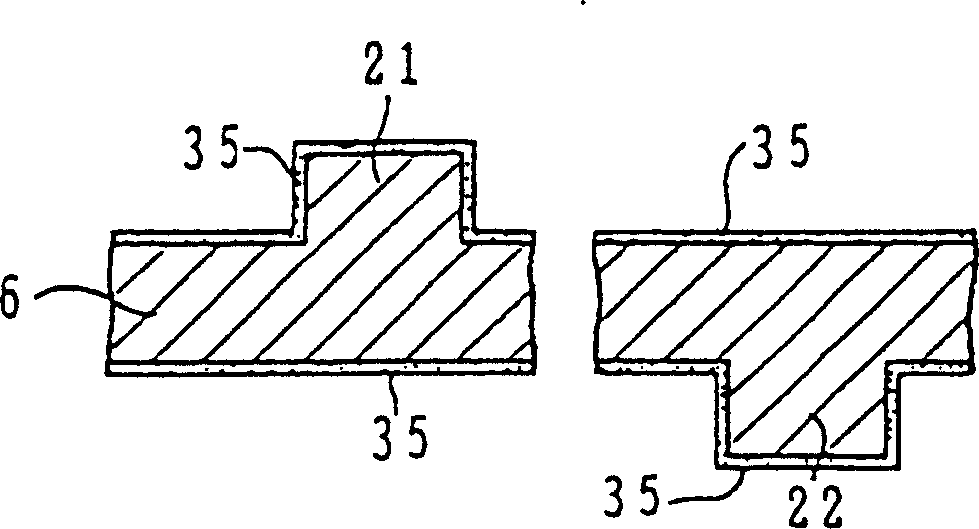

[0031] The first embodiment of the scroll compressor of the present invention is such as Figure 1-Figure 3 shown. This embodiment is a vertical scroll compressor for refrigeration and air conditioning, figure 1 is a longitudinal sectional view of a scroll compressor, figure 2 Yes figure 1 An exploded perspective view of the main parts of the compressor shown, figure 2 Yes figure 2 A cross-sectional view of the main part of the cross ring in . figure 1 represent the overall structure.

[0032] As the main configuration, an electric motor 2 and a rotary motor driven by the electric motor 2 are arranged inside a closed container 1 using at least one or two or more mixed refrigerants in the mixed fluorinated hydrocarbon-based refrigerant group. Between the scroll 3 and the fixed scroll 4 is a scroll compression mechanism 5 that compresses the aforementioned refrigerant. The Oldham ring 6 is disposed so as to support the orbiting scroll 3 so that the orbiting scroll 3 ca...

Embodiment 2

[0048] The second embodiment of the scroll compressor of the present invention is for Figure 4 to illustrate. The scroll compressor structure of the present embodiment and figure 1 and figure 2 The shown scroll compressors are substantially the same, but the structure of the Oldham ring 6 is different. The sectional view of the main part of the Oldham ring 6 constituting the present embodiment is as follows: Figure 4 shown.

[0049] like Figure 4 As shown, on the surface of the Oldham ring 6, a nitriding treatment such as gas nitriding is performed on the steam treatment layer 35 formed in the same manner as in the first embodiment to form a nitriding treatment layer 36.

[0050] With this structure, the surface of the Oldham ring 6 having the steam-treated layer 35 is formed of a different material surface with higher wear resistance by the nitriding-treated layer 36, so that a long life can be obtained as a matter of course.

[0051] In addition, when the Oldham ri...

Embodiment 3

[0055] The third embodiment of the scroll compressor of the present invention is for Figure 5 to illustrate. The structure of the scroll compressor of the present embodiment and figure 1 and figure 2 The shown scroll compressors are substantially the same, but the structure of the Oldham ring 6 is different. The sectional view of the main part of the Oldham ring 6 constituting the present embodiment is as follows: Figure 5 shown.

[0056] like Figure 5 As shown, on the same steam-treated layer 35 as in the first embodiment formed on the surface of the Oldham ring 6, a reformed reforming layer 37 is formed by manganese phosphate reforming treatment.

[0057] With this structure, the surface of the Oldham ring 6 having the vapor treatment layer 35 is formed with a solid lubricating material and a smoothed surface by the modification treatment layer 37 of manganese phosphate. Therefore, since a different material surface with higher sliding properties is formed, a longe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com